Bio-based reactive flame retardant, flame-retardant waterborne polyurethane emulsion and preparation methods of bio-based reactive flame retardant and flame-retardant waterborne polyurethane emulsion

A reactive flame retardant, water-based polyurethane technology, applied in the field of flame retardant materials, can solve the problems of complex preparation process, poor compatibility between bio-based flame retardants and substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

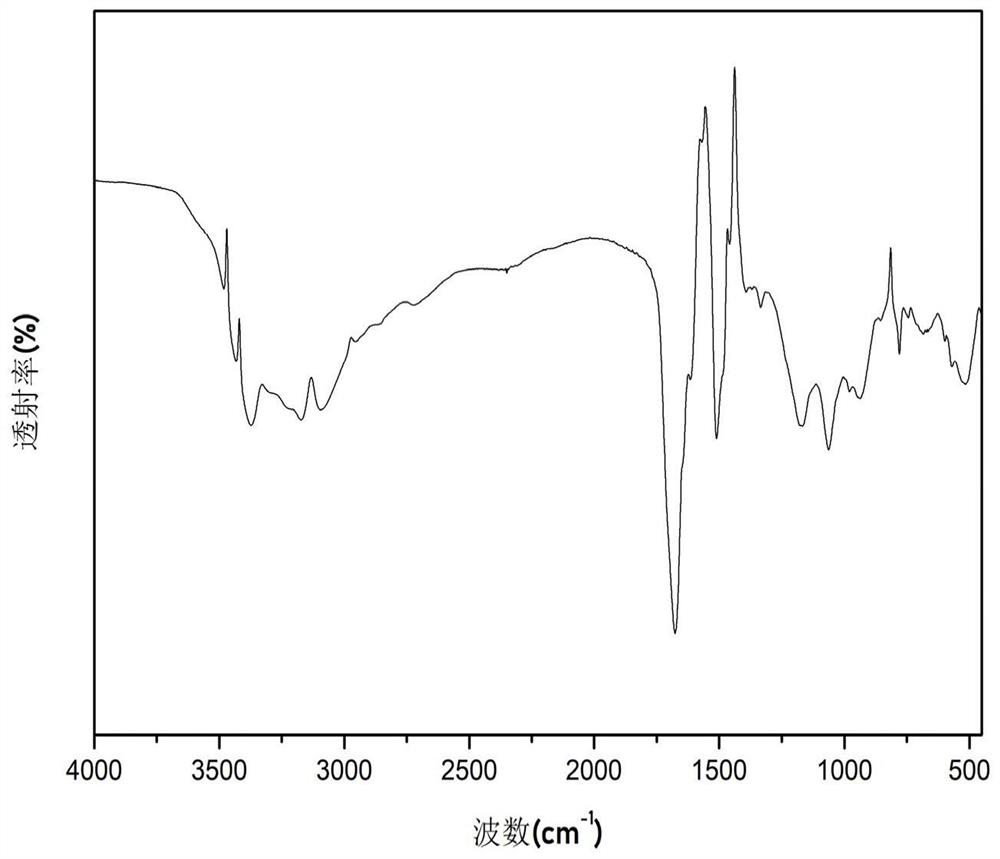

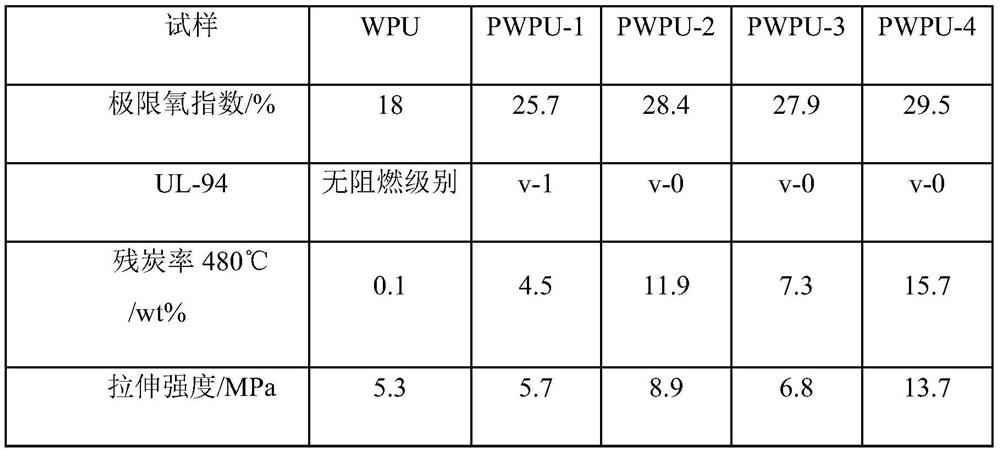

[0045] 1. Preparation of bio-based reactive flame retardant (PAMAD-1):

[0046] Add 0.55g of dimethylolpropionic acid (DMPA), 7.95g of phytic acid (PA) and 3.1g of melamine (MA) into 60mL of deionized water respectively to obtain 2,2-dimethylolpropionic acid dispersion, phytic acid Dispersions and dispersions of nitrogenous compounds;

[0047] At a stirring speed of 100r / min and 75°C, add the 2,2-dimethylolpropionic acid dispersion liquid dropwise to the melamine dispersion liquid, react for 4 hours, and then slowly add the phytic acid dispersion liquid dropwise into the reaction system , after all the dropwise addition, continue to react for 5h, filter with suction, wash, dry with a blast oven to remove most of the water, and then dry with a vacuum oven to obtain a bio-based reactive flame retardant PAMAD-1 with a yield of 74.7% , The char formation rate is 12.37% (at a temperature of 480°C).

[0048] Yield / %=m 产物 / (m DMPA +m PA +m MA )*100

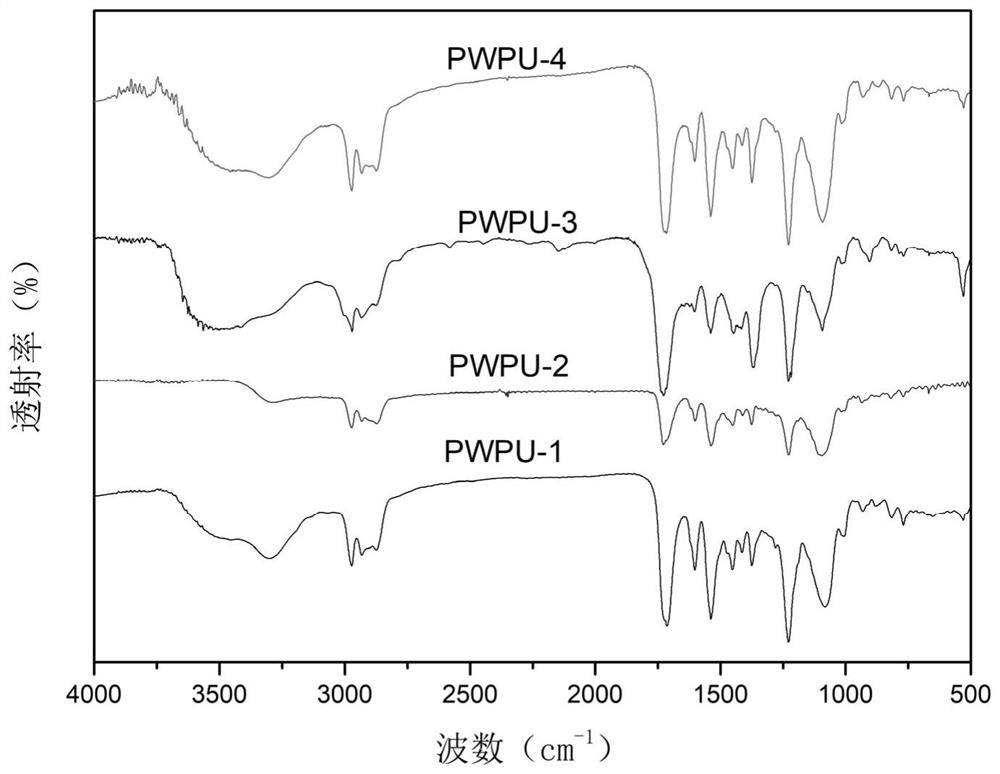

[0049] 2. Preparation of f...

Embodiment 2

[0052] 1. Preparation of bio-based reactive flame retardant (PAMAD-2):

[0053] Add 1.6g dimethylolpropionic acid (DMPA), 7.54g phytic acid (PA) and 10.1g melamine (MA) into 60mL deionized water respectively to obtain 2,2-dimethylolpropionic acid dispersion, phytic acid Dispersions and dispersions of nitrogenous compounds;

[0054] At a stirring speed of 100r / min and 85°C, add the 2,2-dimethylolpropionic acid dispersion liquid dropwise to the melamine dispersion liquid, react for 2 hours, and then slowly add the phytic acid dispersion liquid dropwise into the reaction system , after all the dropwise addition, continue to react for 3h, filter with suction, wash, remove most of the water by drying in a blast oven, and then dry in a vacuum oven to obtain a bio-based reactive flame retardant PAMAD-2, with a yield of 81.27% , The char formation rate is 17.11% (at a temperature of 480°C).

[0055] 2. Preparation of flame retardant water-based polyurethane emulsion PWPU-2:

[0056...

Embodiment 3

[0058] 1. Preparation of bio-based reactive flame retardant (PAMAD-3):

[0059] Add 2.6g dimethylolpropionic acid (DMPA), 7.54g phytic acid (PA) and 7.06g melamine (MA) into 60mL deionized water respectively to obtain 2,2-dimethylolpropionic acid dispersion, phytic acid Dispersions and dispersions of nitrogenous compounds;

[0060] At a stirring speed of 100r / min and at 80°C, add the 2,2-dimethylol propionic acid dispersion liquid dropwise to the melamine dispersion liquid, react for 3 hours, and then slowly add the phytic acid dispersion liquid dropwise into the reaction system , after all the dropwise addition, continue to react for 4h, filter with suction, wash, remove most of the water by drying in a blast oven, and then dry in a vacuum oven to obtain a bio-based reactive flame retardant PAMAD-3 with a yield of 80.7% , The char formation rate is 16.77%.

[0061] 2. Preparation of flame retardant water-based polyurethane emulsion PWPU-3:

[0062] Weigh 56.2g of polypropy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com