Bio-based epoxy resin containing silicon phenylene structure, composition and preparation method thereof

A technology based on epoxy resin and biotechnology, applied in the direction of silicon organic compounds, compounds of group 4/14 elements of the periodic table, chemical instruments and methods, etc., can solve the problem of low yield of closed-loop products and difficult to meet high-quality application requirements , High content of hydrolyzable chlorine, etc., to achieve excellent intrinsic flame retardant properties, excellent catalytic performance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

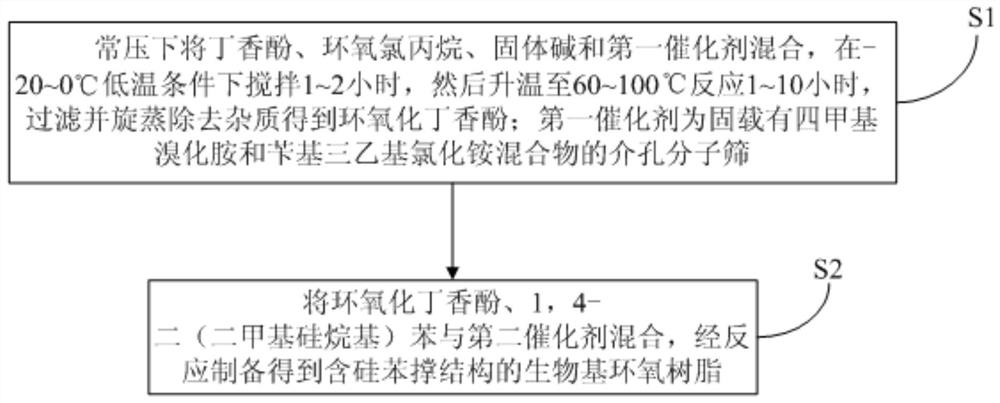

[0048] figure 1 It is a schematic flow diagram of a preparation method of a bio-based epoxy resin containing a silicon phenylene structure provided by the embodiment of the present invention, as figure 1 As shown, according to the first aspect of the embodiments of the present invention, the preparation method of the bio-based epoxy resin containing silicon phenylene structure, the preparation method comprises the following steps:

[0049] S1. Mix eugenol, epichlorohydrin, solid base and the first catalyst under normal pressure, stir at -20-0°C for 1-2 hours, then raise the temperature to 60-100°C for 1-10 hours, Filtration and rotary evaporation to remove impurities to obtain epoxidized eugenol; wherein, the first catalyst is a mesoporous molecular sieve solidly loaded with a mixture of tetramethylammonium bromide and benzyltriethylammonium chloride.

[0050] In this step, the content of tetramethylammonium bromide and benzyltriethylammonium chloride in the first catalyst is...

Embodiment approach

[0076] As a preferred embodiment, the preparation method includes the following steps:

[0077] In step (1), the molar ratio of eugenol, epichlorohydrin and solid base is 1: (5-10): (1-5), preferably, 1: (5-8): (2-5 ).

[0078] The content of tetramethylammonium chloride and tetramethylethylenediamine in the first catalyst is 1%-10% of the total mass of eugenol, epichlorohydrin and solid base, preferably 1%-9%.

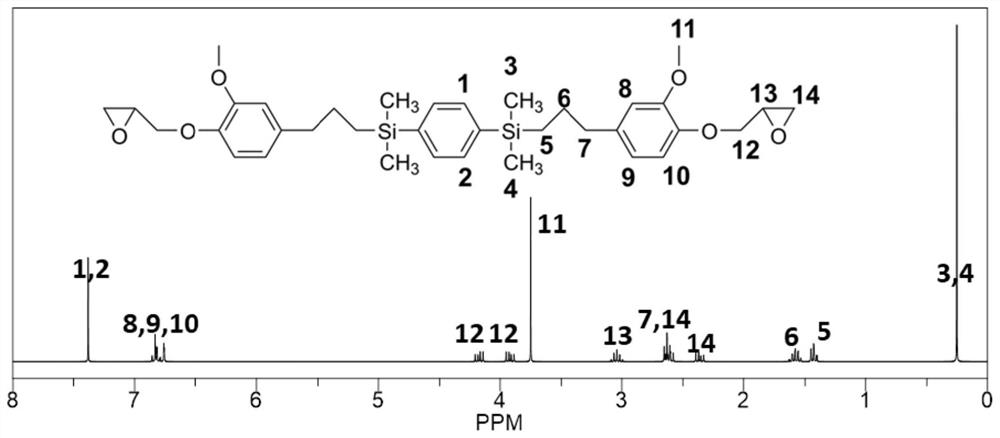

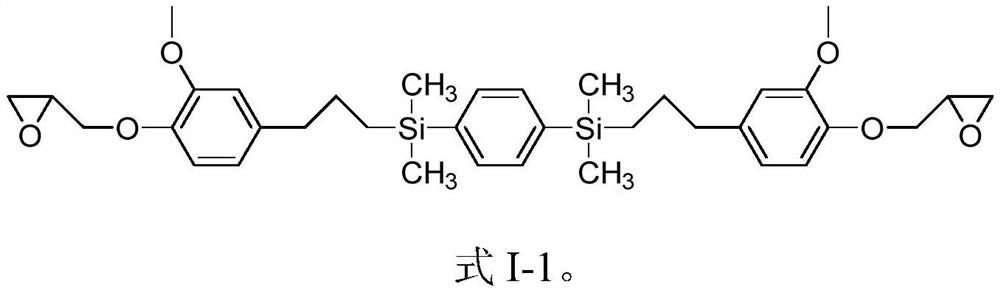

[0079] figure 2 It is a schematic diagram of the hydrogen nuclear magnetic resonance spectrum of a bio-based epoxy resin with a silicon-phenylene structure having a structural formula I-1 provided by the embodiment of the present invention, such as figure 2 As shown, according to the second aspect of the embodiments of the present invention, there is provided a bio-based epoxy resin containing silicon phenylene structure prepared according to the above process, and the structural formula is as shown in (I-1):

[0080]

[0081] The above-mentioned bio-based epo...

Embodiment 1

[0092] (1) Add 2g of SBA-15 mesoporous molecular sieve and 2g of (N-(β-aminoethyl))-γ-aminopropyltrimethoxysilane into 150ml of absolute ethanol. Use a high-speed disperser to process the mixed suspension at a speed of 5000r / min for 0.5 hour; then use an ultrasonic oscillator to continue processing the suspension with an oscillation power of 600W, an oscillation frequency of 22kHz, and an oscillation time of 1 hour. The uniformly mixed suspension is evaporated in a water bath under electromagnetic stirring, and when the solvent is evaporated to dryness, the vacuum-dried particles are ground with a mortar to obtain a modified mesoporous molecular sieve.

[0093] (2) Mix tetramethylammonium bromide and benzyltriethylammonium chloride aqueous solution (concentration is 10g / L, 100ml) with the treated SBA-15 mesoporous molecular sieve (2g), and remove the water by evaporation , the remaining material was placed in an ultrasonic oscillator, and treated at 100° C. for 0.3 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com