Patents

Literature

202results about How to "Facilitate the realization of large-scale industrial production" patented technology

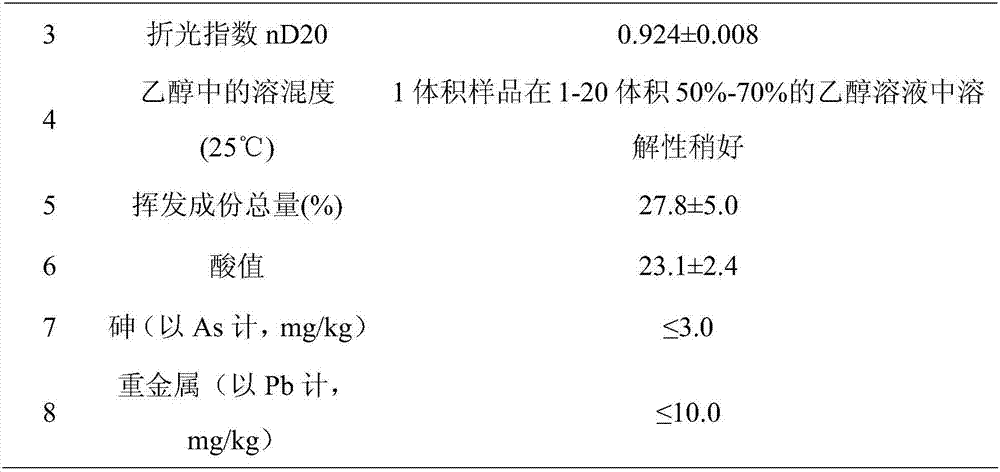

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refining method of carbon 11-18 long chain diacid

InactiveCN1410408AShort process routeLow costCarboxylic compound separation/purificationOrganic solventPetroleum

A process for refining (or purifying) C11-18 long-chain dibasic acid includes such steps as dissolving the said long-chain dibasic acid prepared by fermenting petroleum in organic solvent, filtering,cooling the filtrate, crystallizing and drying. Its advantages are high purity and output rate, and low cost.

Owner:ZIBO GUANGTONG CHEM

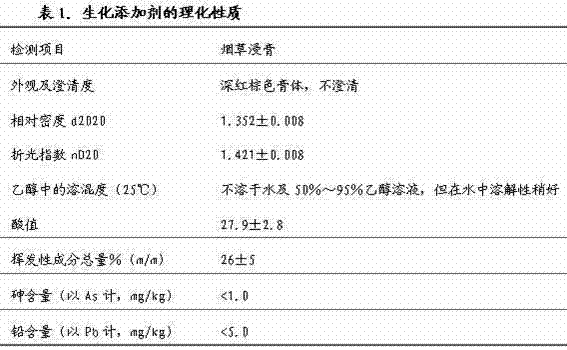

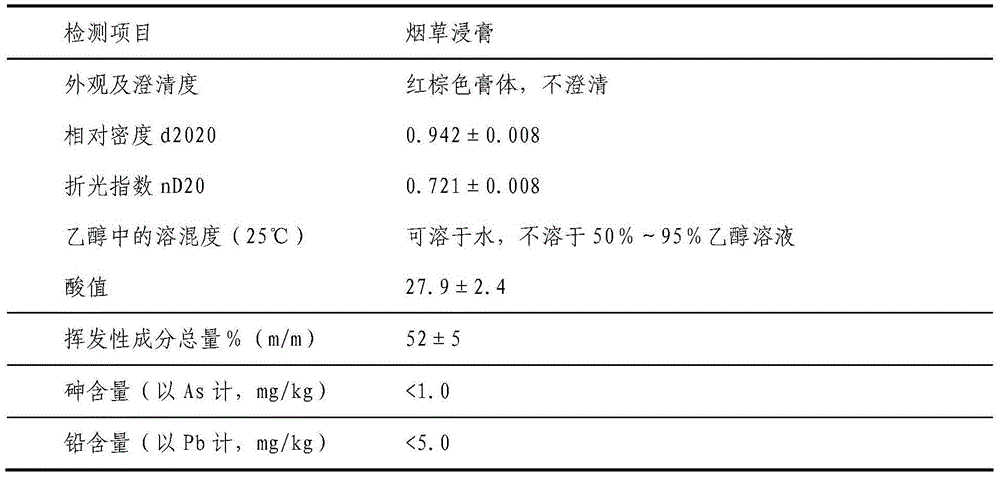

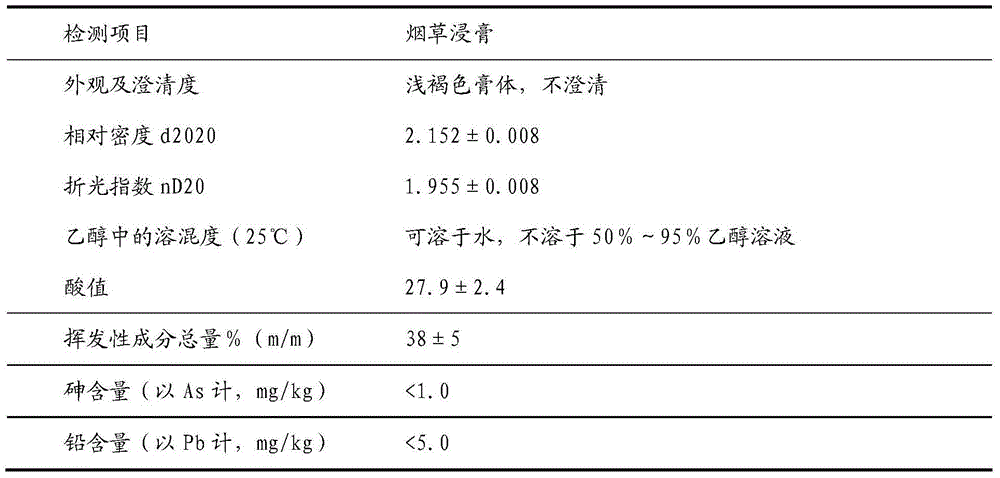

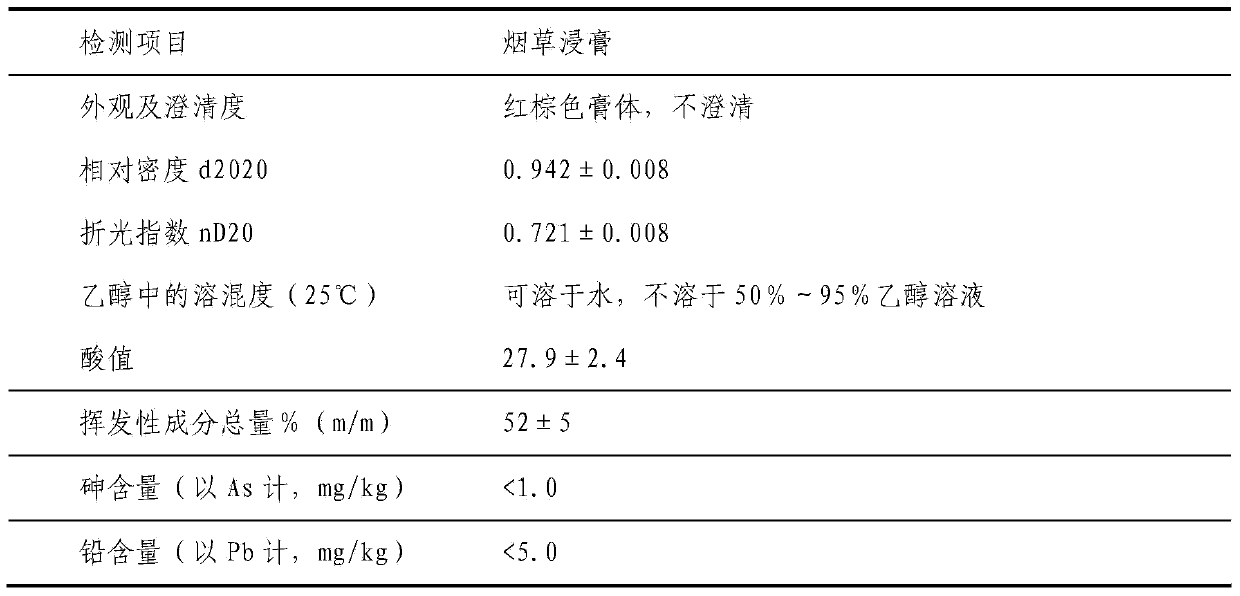

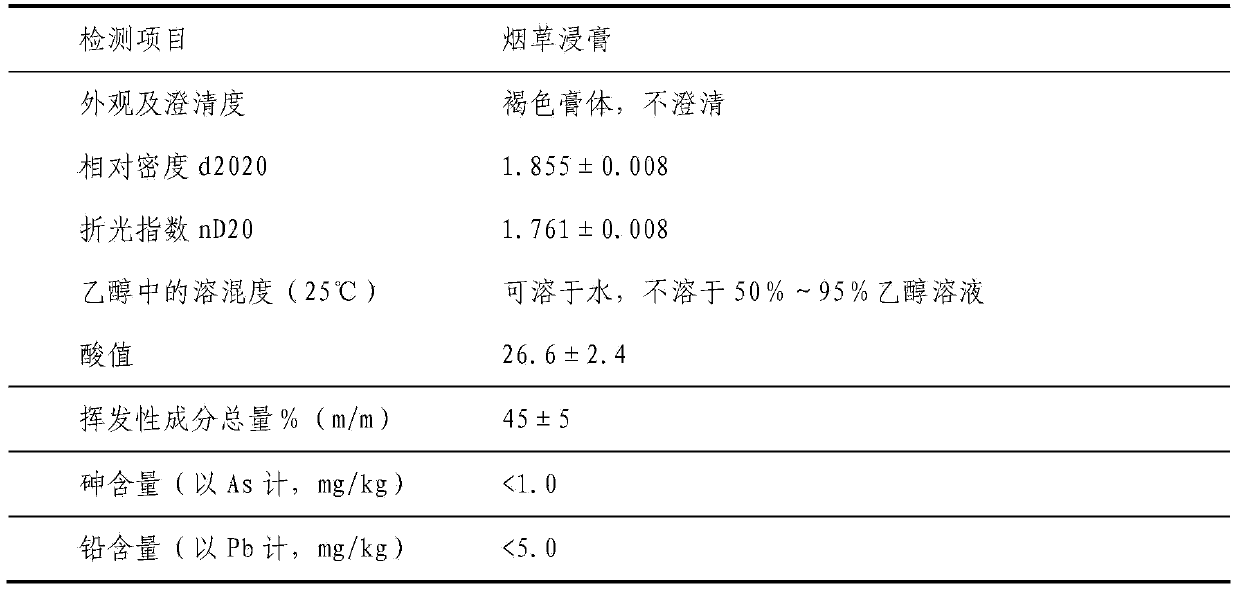

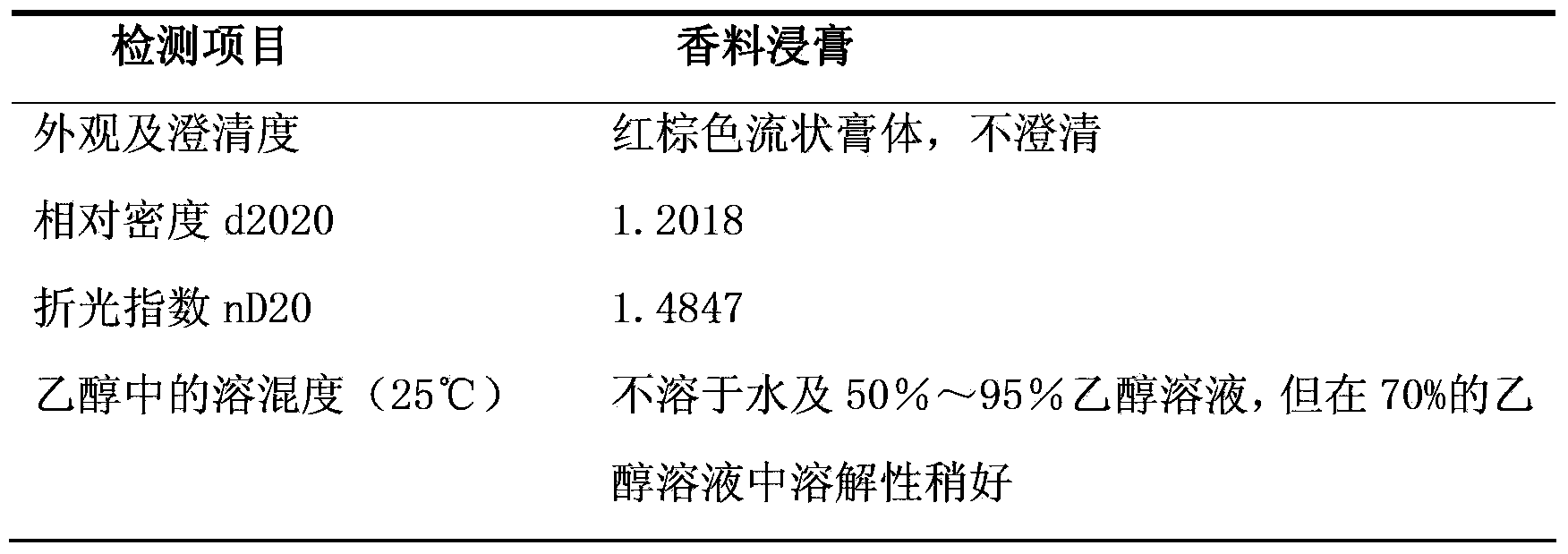

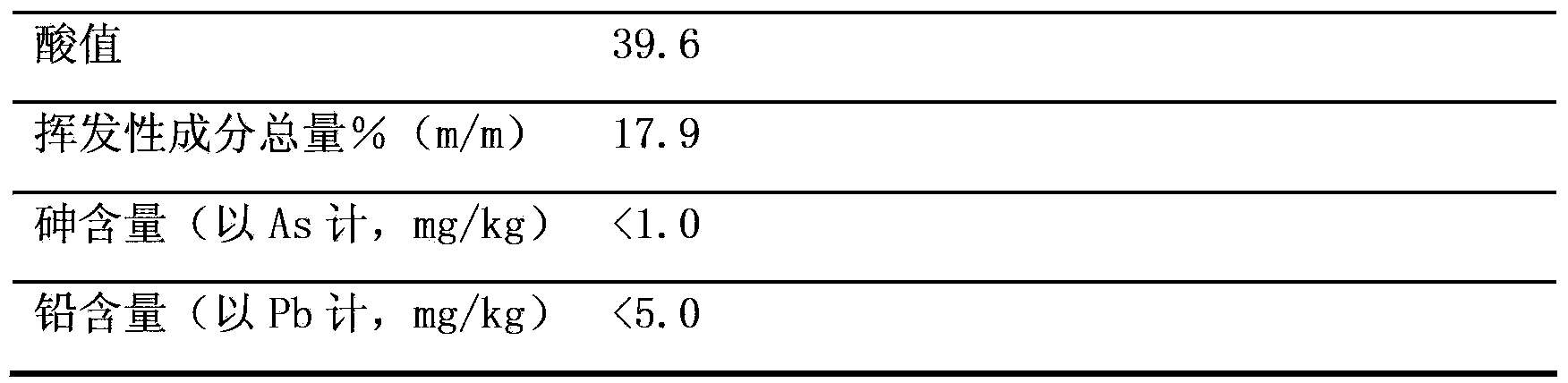

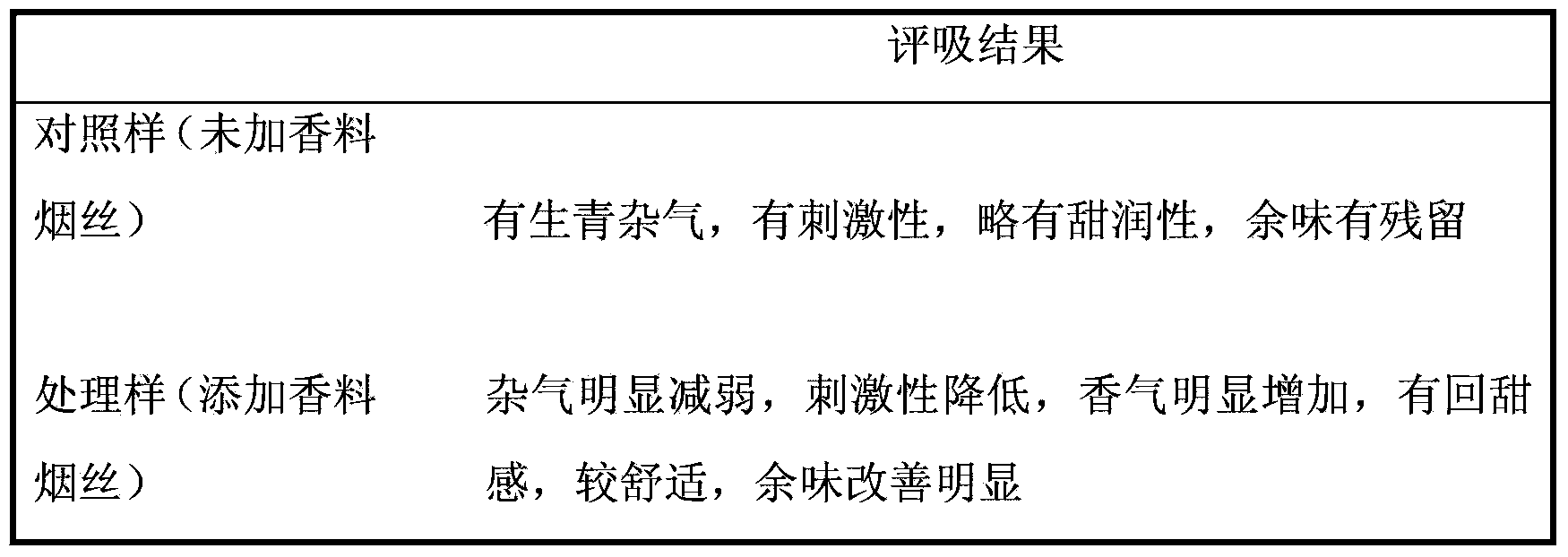

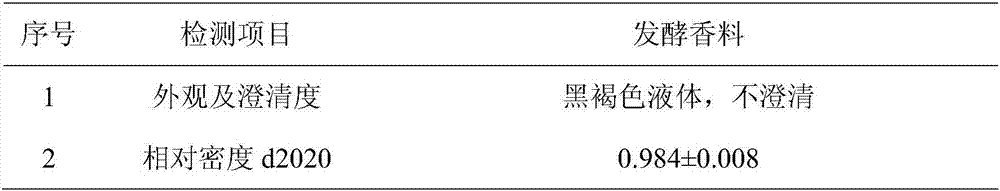

Spice extractum prepared by waste tobacco leaf, preparation method thereof and application thereof

ActiveCN102119784AAvoid wasting resourcesReduce pollutionTobacco preparationBacteriaBenzyl alcoholDamascenone

The invention discloses a spice extractum prepared by waste tobacco leaf, a preparation method thereof and application thereof. The preparation method comprises the steps of: taking the waste tobacco leaf as a raw material; sequentially fermenting acinetobacter, bacillus pumilus and bacillus subtilis to reduce nicotine in the waste tobacco leaf; transforming ferulic acid in the tobacco leaf to generate flavor ingredients such as the 4-guaethol, the vanillin and the like; and extracting the flavor ingredients in the waste tobacco leaf after fermenting to prepare the spice extractum. The spice extractum comprises higher-content flavor ingredients which are mainly to be benzyl alcohol, solanone, vanillin, BETA-damascenone, dihydro kiwifruit lactone, megastigmatrienone, duvatriene diol and neophytadiene. The result of the aromaticflvouring smoke panel test shows that the spice extractum has the effects of obviously dispatching the tobacco aroma, fining and smoothing the alcohol and the smoke, reducing the pungency, covering up the impure smell, and improving the absorbed smell of a cigarette.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Disposable controlled completely-degradable plastic packing bag and preparation method thereof

The invention discloses a disposable controlled completely-degradable plastic packing bag, which is formed through melting, blending, extruding and film-blowing of components comprising in parts by weight: 20 to 45 parts of polyvinyl alcohol, 72 to 87 parts of starch, 10 to 20 parts of micromolecule plasticizer, 0.2 to 2 parts of modified inorganic nanometer additive, 0.1 to 1.5 parts of antioxidant, 0.5 to 3 parts of compatibilizer, 8 to 15 parts of inorganic filler, 0.1 to 1 part of ultraviolet absorber, and 0.1 to 1 part of pigment. The invention further discloses a preparation method of the plastic packing bag. The nanometer composite modifier in the packing bag adopts a micromolecule plasticizer easy to form a hydrogen bond with the starch, a certain amount of inorganic nanometer additives subject to surface treatment are added in the packing bag, so that after PVA (polyvinyl acetate) is modified by the nanometer composite modifier, the use amount of the molecule plasticizers is reduced greatly, the cost is lowed, the reduction of the mechanical property of a film is avoided, and the controlled completely-degradable film with excellent mechanical property and the use performance can be obtained.

Owner:NINGXIA GREEN BIODEGRADABLE PROD +1

Method for manufacturing low-carbon TWIP steel through AOD (argon oxygen decarburization) furnace

ActiveCN103468874AEase of mass productionRaw materials are easy to getProcess efficiency improvementManufacturing technologySlag

The invention belongs to the field of metal smelting, and mainly relates to smelting manufacturing technology of low-carbon TWIP steel through an AOD (argon oxygen decarburization) furnace. The smelted TWIP steel comprises the following components in percentage by weight: 0%-0.06% of C, 20%-30% of Mn, 2.0%-3.0% of Si, 2.5%-3.5% of Al, and the balance of Fe. The particular technology procedures comprises the following steps: 1), the AOD furnace is adopted for oxygen decarburization process, once the carbon in the liquid steel is lower than 0.03%, the liquid steel is subject to alloying; 2), after the TWIP steel is subject to manganese alloying, ferrosilicon or / and metal aluminium is adopted to perform reduction reaction on manganese oxide, so that the yield of metal manganese is increased; the oxidation heat of silicon or / and aluminium is adopted to regulate the temperature of the liquid steel and compensate temperature drop of the liquid steel generated by the manganese alloying of the TWIP steel. The method is high in manufacturing efficiency, low in cost, stable in operation and easily-mastered in technology; the main raw material is easily accessible, and no specific requirement is needed; the realization of large-scaled industrialized production is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

Concrete flavouring for tobacco and preparation method and application thereof

ActiveCN102217780AAchieve recyclingAvoid wastingTobacco preparationEssential-oils/perfumesDihydroactinidiolideAdditive ingredient

The invention discloses concrete flavouring for tobacco and a preparation method and application thereof, belonging to the technical field of additive for tobacco. In the invention, waste tobacco used as raw material is sequentially fermented with rhodococcus, bacillus pumilus and bacillus subtilis to reduce nicotine in the waste tobacco and convert ferulic acid in the tobacco into incense ingredients such as 4-guaethol and vanillin; after fermentation is finished, the conventional biochemical technology is utilized to extract the incense ingredients from the waste tobacco for preparing concrete flavouring. The concrete flavouring obtained by invention contains the following main incense ingredients with higher contents: benzyl alcohol, solanone, vanillin, BETA-damascenone, dihydroactinidiolide, megastigmatrienone, duvatriene diglycol and neophytadiene. Results of an aromatic flavouring smoke panel test show that the concrete flavouring has obvious effects of increasing tobacco aroma,smoothing alcohol and smoke, reducing irritation, covering impurity gas and improving smoking taste of cigarettes.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Novel starch-polyvinyl alcohol blend fully-degradable plastic film and preparation method thereof

InactiveCN104927093AScientific and reasonable particle sizeSmall particle sizeEnvironmental resistanceTert butyl

The invention discloses a novel starch-polyvinyl alcohol blend fully-degradable plastic film. The novel starch-polyvinyl alcohol blend fully-degradable plastic film is characterized by being prepared from the following raw materials in parts by weight: 60-65 parts of corn starch, 7-9 parts of nano montmorillonite, 0.6-0.7 part of peanut oil, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 30-35 parts of polyvinyl alcohol, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 4-6 parts of nano titanium dioxide, and 1-1.5 parts of 2,6-di-tert-butyl-4- methyl phenol. The product disclosed by the invention is produced by a safe formula, and can be used for manufacturing a food packaging bag and the like; in use, the product is high in strength, waterproof, oil-resistant and durable in use, beneficial to realizing large-scale industrial production, easy to grasp, and convenient to popularize; and under the action of oxygen enrichment and microorganisms, the wasted product is automatically degraded and finally generates carbon dioxide and water, so that the novel starch-polyvinyl alcohol blend fully-degradable plastic film is ecological and environmentally-friendly.

Owner:TONGLING FOUNDER PLASTICS TECH

A kind of Bacillus subtilis preparation for shredded tobacco treatment

InactiveCN102286404AIncrease the amount of aromaIncrease pleasureBacteriaTobacco treatmentIrritationMicrobiology

The invention discloses a microbial preparation for tobacco, a preparation method and application thereof, and belongs to the technical field of tobacco additives. The present invention obtains corresponding microbial preparations after liquid fermentation and culture of production strains. The production strain is Bacillus subtilis.Van3, which has been preserved in the General Microorganism Center of China Committee for the Collection of Microbial Cultures on August 16, 2010, and the preservation number is CGMCC No.4091. The microbial preparation of the present invention can significantly improve the aroma and pleasantness of shredded tobacco, reduce miscellaneous gas and irritation, reduce smoke concentration and strength, and make the aftertaste more comfortable, thereby achieving the purpose of improving the smoking quality of shredded tobacco.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Fermentation production method of tobacco

ActiveCN101322580AFast agingSave proteinTobacco preparationTobacco treatmentControllabilityFermentation

The invention discloses a fermentation production method of tobacco leaves. The tobacco leaves after threshing and redrying or the tobacco leaves after primary drying and arranging are carried out the resurgence till the water content reaches 16 percent to 22 percent, the fermentation is carried out for 3 days under the conditions of the temperature of 25 DEG C to 40 DEG C and the humidity of 70 percent to 90 percent, the tobacco leaves are further dried till the water content reaches 11 percent to 13 percent, and the process is repeated for 180 to 700 days. The method inspires the activity of biological enzymes in the tobacco leaves which are not passivated, the fermentation is simultaneously carried out along with the non-enzymatic oxidation and the microbial effect, and the rapid alcoholization of the tobacco leaves is carried out through the control of the temperature and the humidity. Compared with the naturally alcoholized and the alcoholized tobacco leaves by adding the biological enzymes, the contents of the protein, the nicotine and tar of the obtained tobacco leaves are lower, and the contents of the fragrant substances and the reducing sugar are higher. The types of the fragrant substances are more, the aroma is natural and delicate, and the smoke is alcoholized. The fermentation production method is characterized by simple operation, low cost and strong operationality, regulation and controllability, thereby facilitating the realization of the large-scale industrial production.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

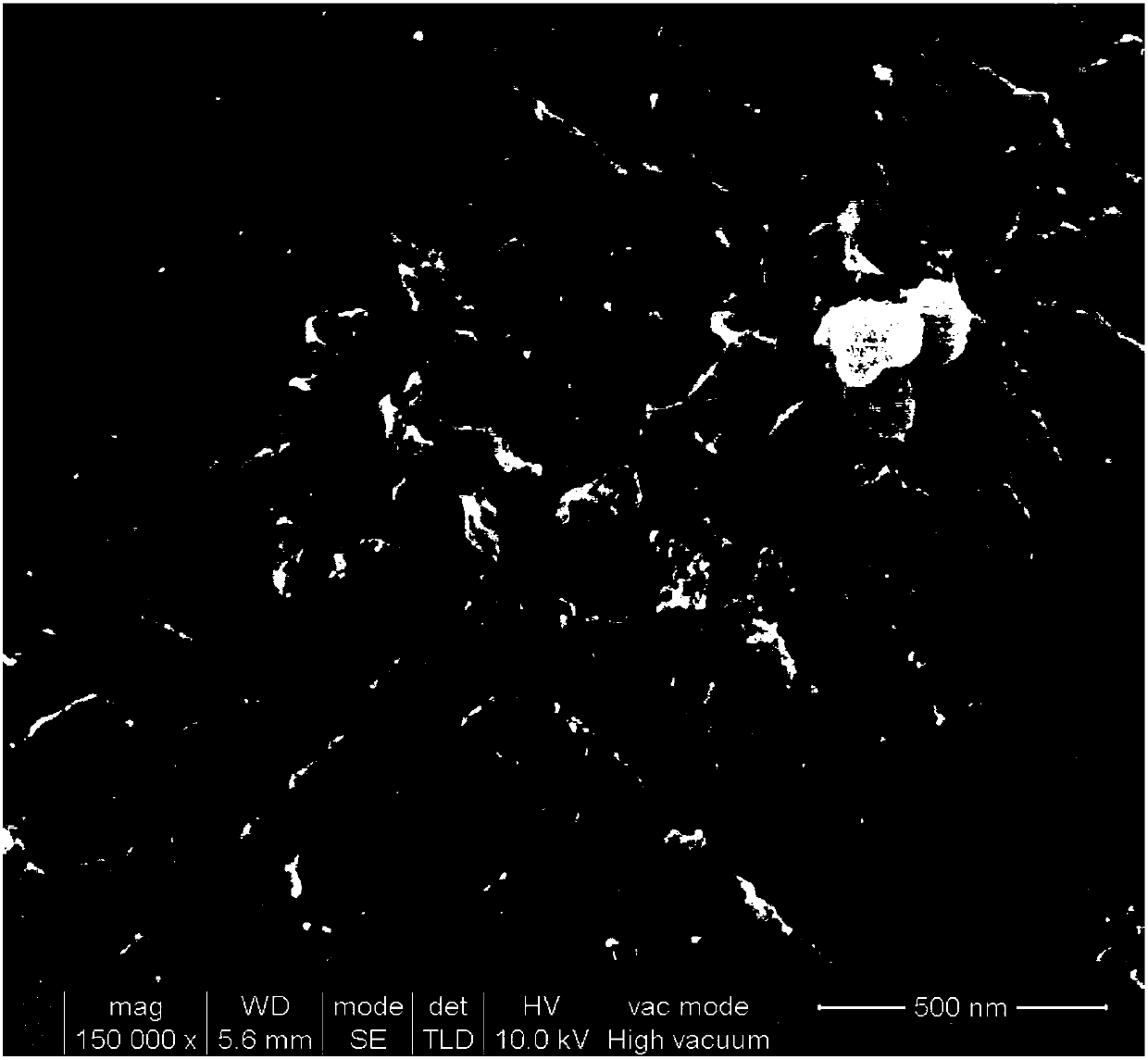

Activated carbon supported nanometer iron oxide adsorbent and preparation method thereof

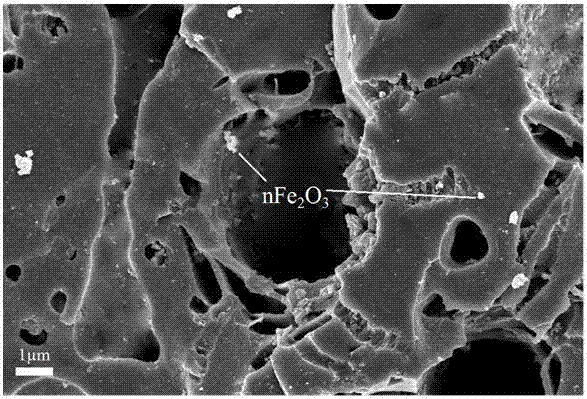

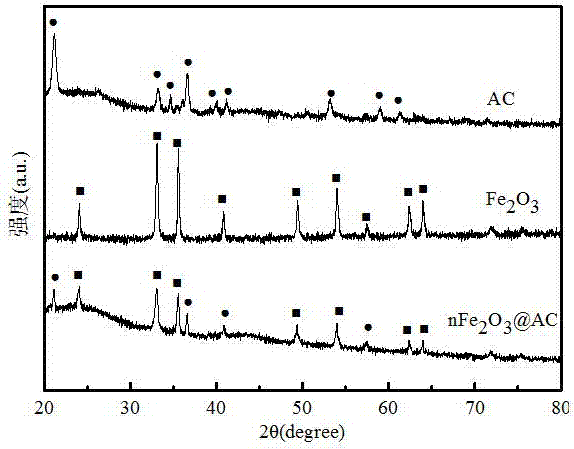

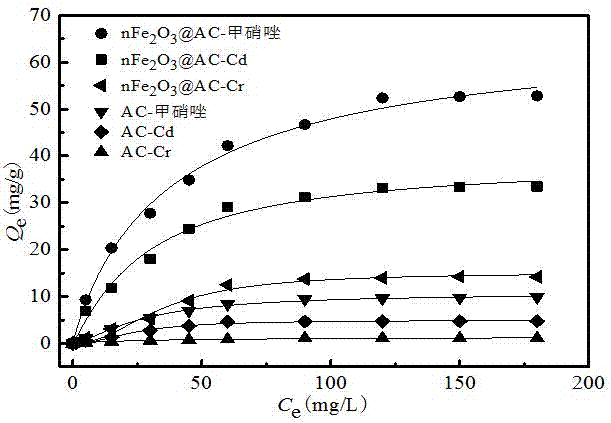

InactiveCN107983306AGood adsorption performanceImprove performanceOther chemical processesWater contaminantsActivated carbonBrown iron oxide

The invention discloses an activated carbon supported nanometer iron oxide adsorbent as well as a preparation method and application thereof. The preparation method comprises the following steps: by taking activated carbon as a carrier, performing simple dipping, alkali blending and calcining, and successfully supporting nanometer iron oxide onto the activated carbon surface and pore channels, thereby obtaining the activated carbon supported nanometer iron oxide adsorbent. The activated carbon supported nanometer iron oxide adsorbent disclosed by the invention is capable of synchronously and effectively removing heavy metal anions, heavy metal cations and antibiotics in drinking water, and has excellent adsorption performance for synchronously remvoving Cr(VI), Cd(II) and antibiotics, so that the efficiency of the activated carbon in the drinking water treatment field is improved, the drinking water adsorption and treatment process is simplified, and the safety of the drinking water isensured.

Owner:SOUTH CHINA UNIV OF TECH

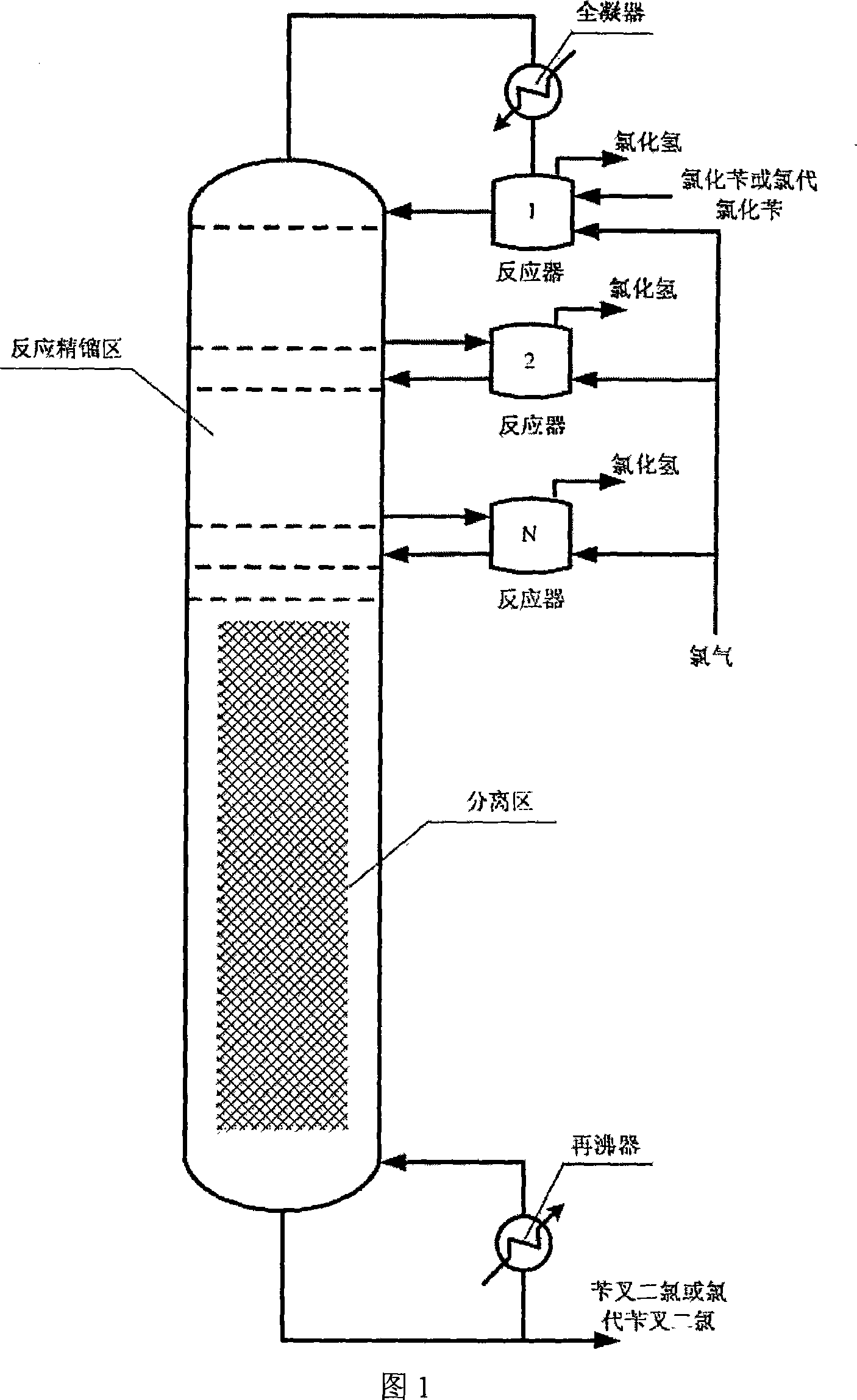

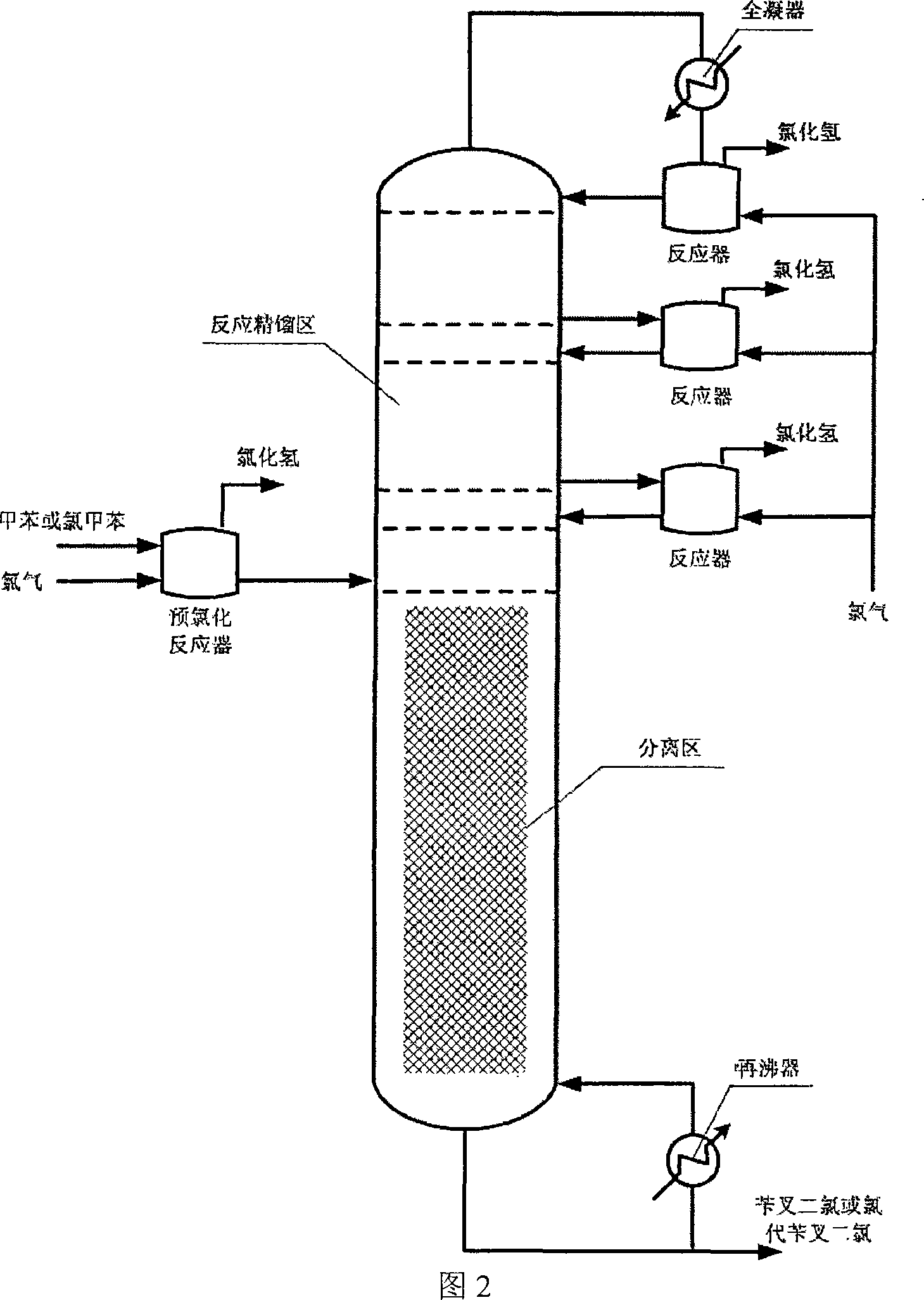

Process for producing benzal chloride or chloro benzal chloride

ActiveCN101070267AVolume can be adjusted freelyAdjust the volume arbitrarilyHalogenated hydrocarbon preparationNuclear chemistryBlue light

This invention relates to a preparation method of benzal dichloro or chlor-benzal dichloro. The invention process: inlet toluene or chlorotoluene, benzyl chloride or chlor- benzyl chloride and chlorine gas according to certain mol ratio to reactor that coupled with fractionating tower or prechlorination reactor, under series stable operation condition, control the operating pressure of fractionating tower at 0.002 to 0.05MPa. The chlorination is stimulated by sunlight or blue light, temperature of reactor is controlled at 80 to 120 deg.

Owner:NANTONG TIANSHI CHEM

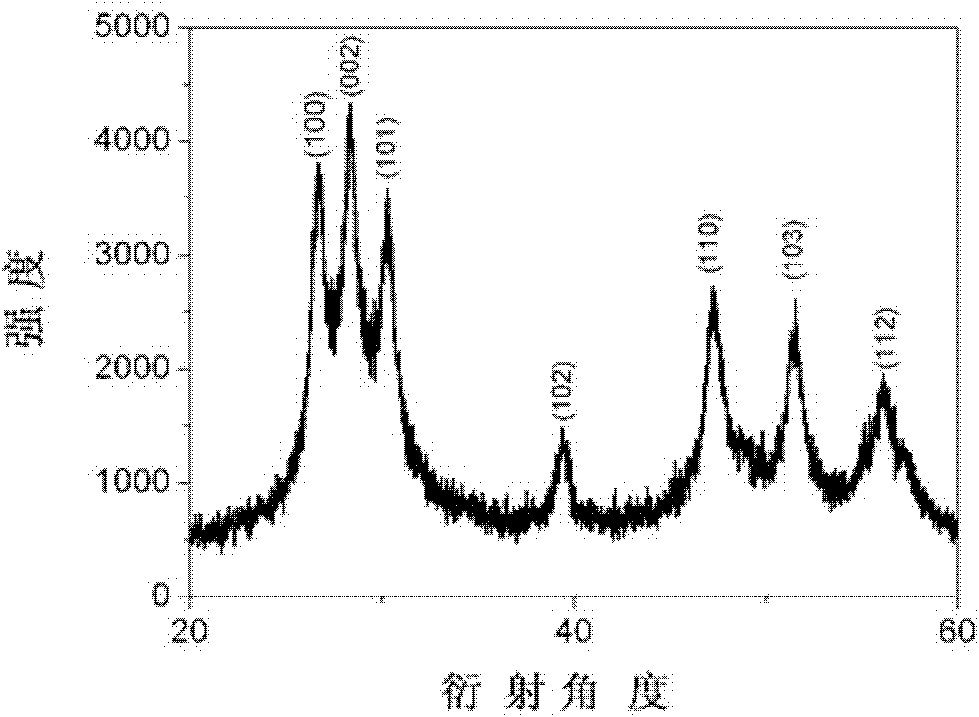

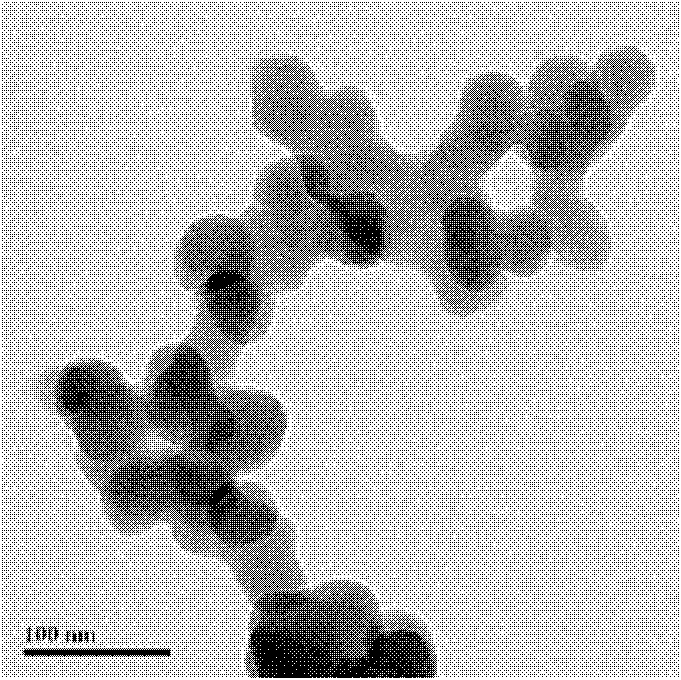

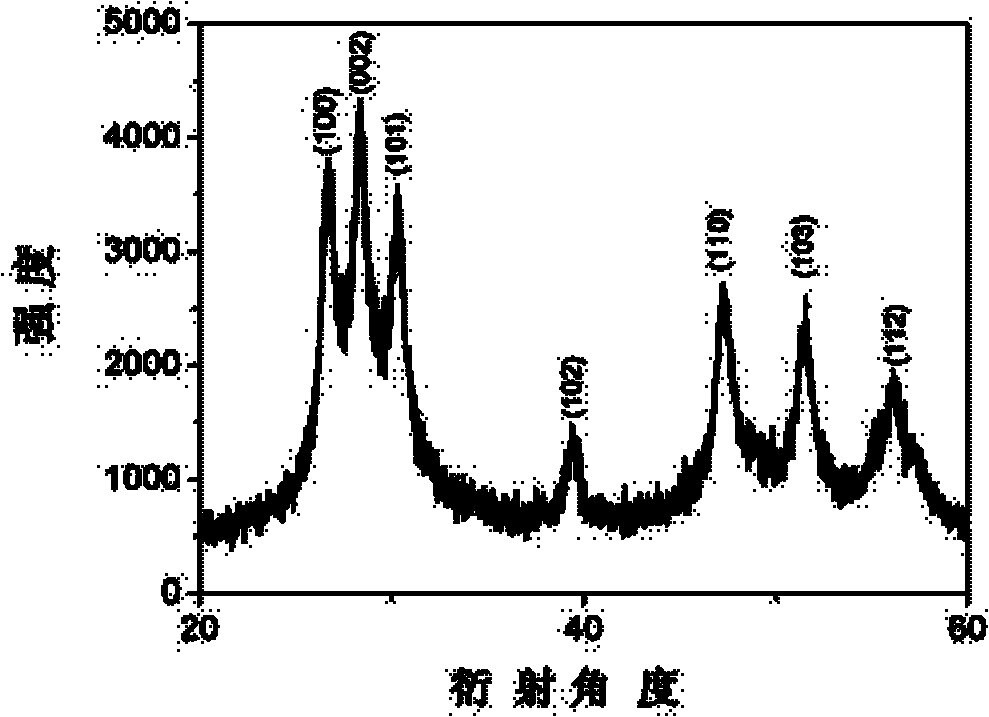

Method for preparing doping type hexagonal system nano ZnS at low temperature

InactiveCN102079541ALow costFacilitate the realization of large-scale industrial productionZinc sulfidesNanotechnologySemiconductor materialsActive agent

The invention provides a method for preparing doping type hexagonal system nano ZnS at a low temperature, belonging to the field of semiconductor materials. The method is characterized in that transition metal and rare earth-doped hexagonal system nano ZnS is synthesized by a reversed micelle method at the temperature of less than 100 DEG C, wherein an oil phase is an organic solvent, a water phase is a zinc salt aqueous solution, N,N-dimethylformamide is used as the solvent, a zinc salt is used as an zinc ion source, thiourea serves as a sulphur ion source, and mercaptoacetic acid serves as a surface active agent; and the heating temperature is controlled by an oil bath, and the whole reaction is carried out in the air, and any air isolating measure is not needed. The method is simple tooperate, the required reactions are carried out in a liquid phase, subsequent high-temperature annealing treatment is not needed, and reaction conditions are mild; and the method is energy-saving andenvironment-friendly, and an economically feasible way is provided for producing the hexagonal system nano ZnS with high stability and good water solubility on large scale.

Owner:UNIV OF SCI & TECH BEIJING

Chrysanthemum fermentation broth extract as well as preparation method and application thereof

InactiveCN104164456AEasy to storeEasy to activate and fermentTobacco preparationMicroorganism based processesLaboratory cultureChemistry

The invention discloses a chrysanthemum fermentation broth extract as well as a preparation method and application thereof. The extract is prepared by fermenting a raw material chrysanthemum with lodderomyces elongisporus and then extracting aroma components from fermentation broth. Lodderomyces elongisporus is collected in the China General Microbiological Culture Collection Center (CGMCC), with collection number of CGMCC No.6645 and collection date of October 08, 2012. The chrysanthemum fermentation broth extract contains various aroma components, such as phenethyl alcohol, 1,8-cineole, camphor, borneol, linalool, megastigmatrienone and the like. Flavoring smoke panel test results show that the extract can harmonize with cigarette aromas and can obviously improve and regulate cigarette aromas, refine alcohols and smoke, reduce the irritation, hide offensive odors, improve the smoking flavors of cigarettes and produce fresh special aroma.

Owner:CHINA TOBACCO YUNNAN IND

Tobacco flavor prepared from liquorice fermentation and application of tobacco flavor

ActiveCN104223352AImprove comfortIncrease aromaTobacco treatmentMicroorganism based processesPhenethyl alcoholFood flavor

The invention discloses a tobacco flavor prepared from liquorice fermentation and application of the tobacco flavor. A dominant microorganism is separated from fresh tobacco leaves of flue-cured tobacco, and the classification name of the dominant microorganism is Lodderomyces elongisporus. CGMCC 6645; the Lodderomyces elongisporus is inoculated into a culture medium, taking liquorice as a raw material, for fermentation cultivation; a fermentation product after culture has a natural fragrance, and contains various aroma components, such as 2,4-resacetophenone, 2,4,5-methylphenol, 3,4-dimethyl benzyl alcohol and phenethyl alcohol. The tobacco flavor is added to tobacco shreds, and thus, the aroma and the moistening effect of a cigarette can be enhanced, and the cigarette quality is improved; the sweetness of smoke is rich, local offensive odor and wood odor are reduced, the throat comfort is enhanced, the remaining taste is comparatively comfortable, and the mouth astringency is strong; the whole production process for the tobacco flavor is simple and practical, and the tobacco flavor has a good application prospect.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method of high-anticorrosion self-cleaning super-hydrophobic phosphating composite film on surface of zinc coating

InactiveCN107893223ALow costImprove performanceMetallic material coating processesComposite filmPhosphate

The invention discloses a preparation method of a high-anticorrosion self-cleaning super-hydrophobic phosphating composite film on the surface of a zinc coating. Through the preparation method, a filmis formed on the surface of the zinc coating through phosphate and is constructed with the roughness, and the nanometer / micrometer phosphating film with the anticorrosion performance and of the roughstructure is formed; and then, the nanometer / micrometer phosphating film is subjected to hydrophobic modification through an environment-friendly low-surface-energy modifying agent, and the high-anticorrosion self-cleaning super-hydrophobic phosphating composite film is prepared on the surface of the zinc coating. The preparation method is simple in technological process and low in material costand equipment requirement; the process is free of toxicity and friendly to environment. The preparation method is beneficial to achievement of large-scale industrial production, is adopted to replacethe traditional high-toxicity and cancer-causing chromating process and has better comprehensive use performance.

Owner:SOUTH CHINA UNIV OF TECH

Bacillus pumilus preparation for processing tobacco stems

InactiveCN102250813AIncrease the amount of aromaIncrease pleasureBacteriaTobacco treatmentBacillus pumilusIrritation

The invention discloses a microorganism preparation for tobaccos as well as a preparation method and application thereof, belonging to the technical field of tobacco additives. A production bacterial strain liquid is fermented and cultured to obtain the corresponding microorganism preparation. The production bacterial strain is bacillus pumilus.Van35, the bacterial strain is collected in the Center for General Microorganism of China Committee for Culture Collection of Microorganisms and the collection number is CGMCC No.3411. The microorganism preparation provided by the invention can obviously improve the qualities of stems, such as fragrance amount, joviality and the like; impure gas, irritation and the like are reduced; smoke concentration and strength are reduced and remaining taste becomes more comfortable so that the doping amount of the stems in a cigarette is further increased so that aims of reducing harm, decreasing coke content and reducing the production cost of the cigarette are achieved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Solanum lycopersicum fermentation broth extract as well as preparation method and application thereof

InactiveCN104164452AEasy to storeHigh activityTobacco preparationMicroorganism based processesAdditive ingredientIrritation

The invention discloses a solanum lycopersicum fermentation broth extract as well as a preparation method and application thereof. The extract is prepared by fermenting a raw material solanum lycopersicum with lodderomyces elongisporus and then extracting aroma components from fermentation broth. Lodderomyces elongisporus is collected in the China General Microbiological Culture Collection Center (CGMCC), with collection number of CGMCC No.6645 and collection date of October 08, 2012. The solanum lycopersicum fermentation broth extract contains various aroma components, such as phenethyl alcohol, furfural, 5-hydroxymethylfurfural, germacrone, cis-3-hexenol, megastigmatrienone and the like. Flavoring smoke panel test results show that the extract can harmonize with cigarette aromas and can obviously improve and regulate cigarette aromas, refine alcohols and smoke, reduce the irritation, hide offensive odors, improve the smoking flavors of cigarettes and produce fresh special aroma.

Owner:CHINA TOBACCO YUNNAN IND

Evernia furfuracea fermented extract and preparation method and application thereof

ActiveCN104178522AEasy to storeHigh activityTobacco preparationMicroorganism based processesIrritationPhenethyl alcohol

The invention discloses an Evernia furfuracea fermented extract and a preparation method and application thereof. The Evernia furfuracea fermented extract is prepared from Evernia furfuracea, which serves as a raw material, through fermenting with Lodderomyces elongisporus and extracting aroma components from a fermented solution. The Lodderomyces elongisporus is collected in the China General Microbiological Culture Collection Center (CGMCC); the collection number is CGMCC No. 6645; the collection date is October 08, 2012. The product contains a variety of aroma substances, such as phenethyl alcohol, orcinol monomethyl ether, Alan phenol, beta-orcinol methyl ester, methyl haematommate, ethyl haematommate, ethyl everninate, methyl divaicate and the like. Shown by results of flavored smoking assessment tests, the product can be harmonized with cigarette flavors, can obviously promote the cigarette flavors, make smoke gas delicate and mellow, lower irritation, conceal impurity gases and improve the smoking flavor of cigarettes, and can generate a fresh and special aroma.

Owner:CHINA TOBACCO YUNNAN IND

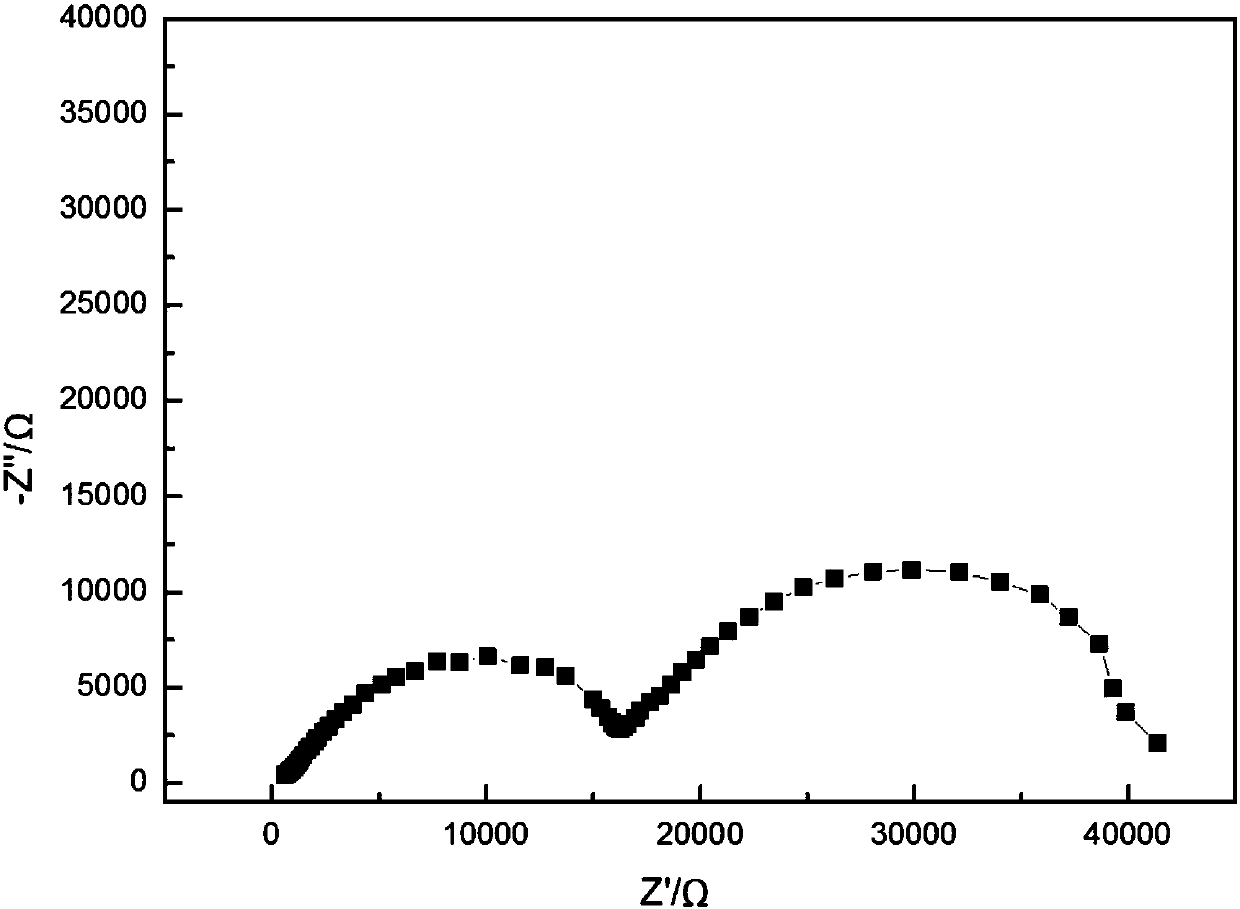

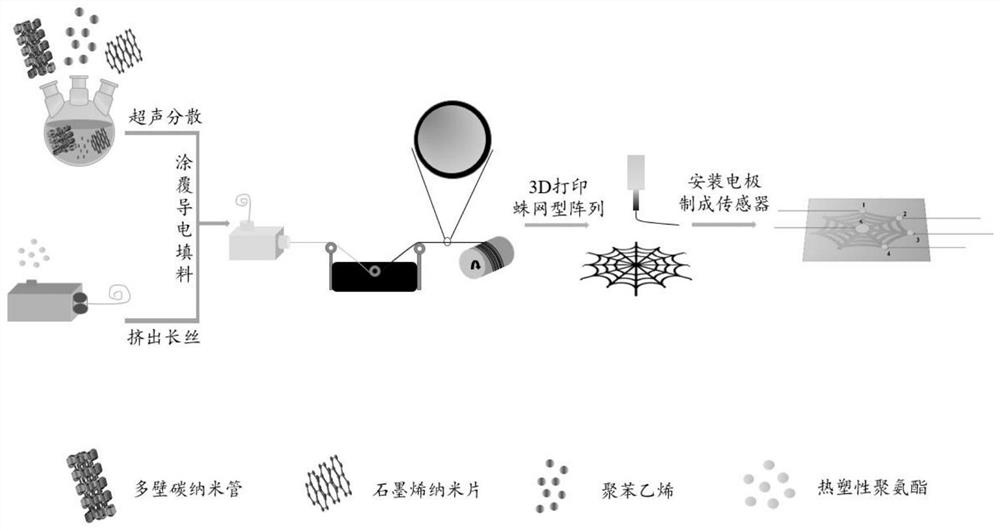

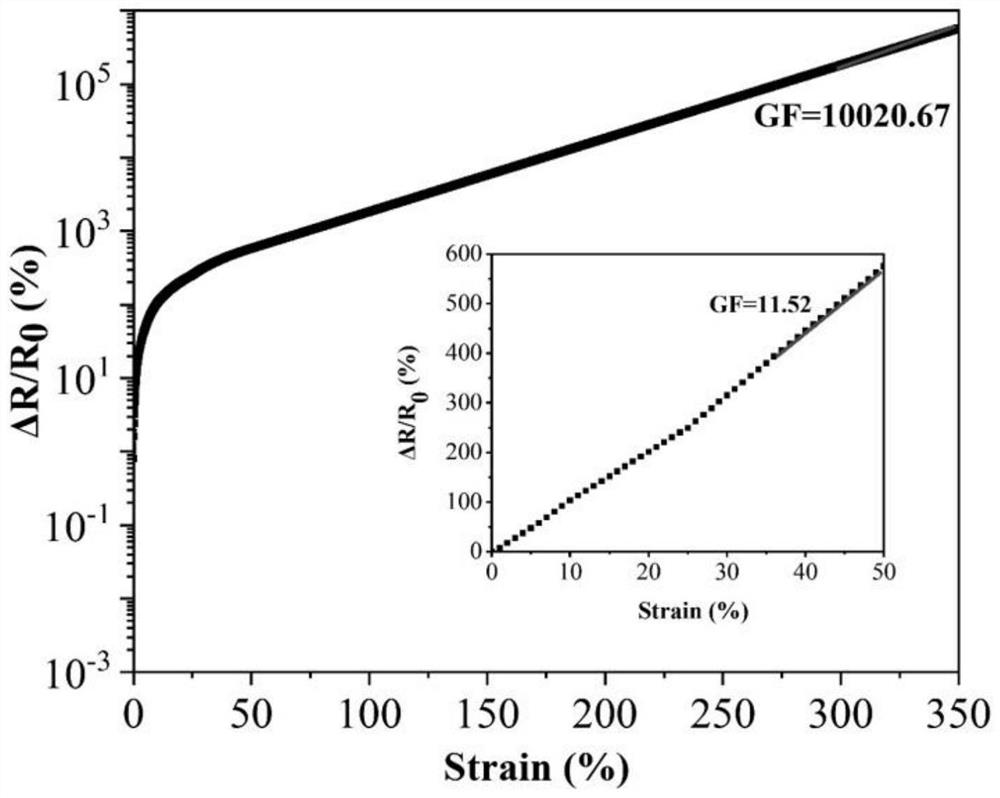

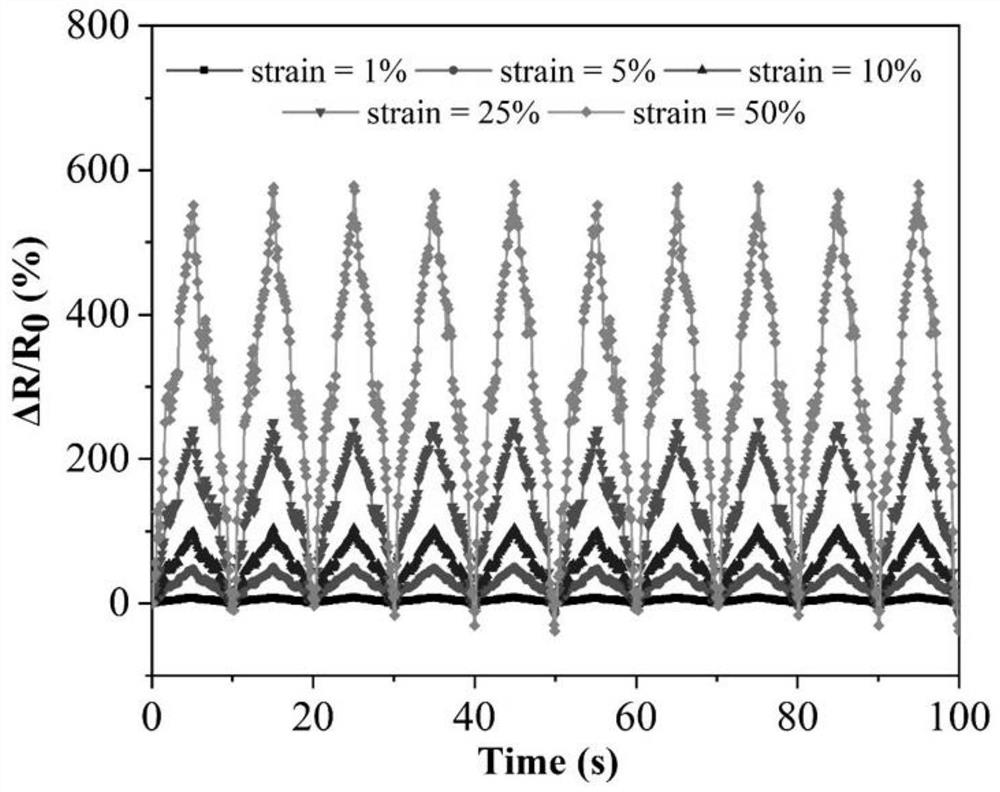

Cobweb-shaped flexible strain sensor capable of identifying strain direction and preparation method thereof

ActiveCN111649665AImprove conductivitySmall hysteresisFibre typesElectrical/magnetic solid deformation measurementPolymer scienceAdhesive

The invention discloses a cobweb-shaped flexible strain sensor capable of identifying a strain direction and a preparation method. The method comprises the following steps of mixing a conductive filler, a hot-melt adhesive and an N, N-dimethylformamide solvent, and carrying out ultrasonic dispersion to obtain a dispersion liquid, putting the granular thermoplastic polymer into a screw extruder, and extruding a pure thermoplastic polymer wire, drawing the wire material to pass through the dispersion liquid at a constant speed by utilizing a wire winding roller traction device, forming a uniformand thin conductive layer on the surface of the wire material, and printing the wire material into a cobweb-shaped array by utilizing a 3D printer after the wire material is completely dried, and fixing the wire at the center of the cobweb and the tail end of the longitudinal wire by using conductive silver adhesive to prepare the cobweb-shaped flexible strain sensor. The cobweb-shaped customizedstructure is rapidly prepared, and the sensor also has the function of identifying the strain direction, has the advantages of high linearity, high sensitivity, wide strain range, rapid response, lowhysteresis, good stability and the like, and has great potential in the application of wearable equipment.

Owner:SOUTHWEST PETROLEUM UNIV

Armeniaca vulgaris fermented extract and preparation method and application thereof

InactiveCN104178520AEasy to storeHigh activityTobacco preparationMicroorganism based processesBenzaldehydeEthyl acetate

The invention discloses an Armeniaca vulgaris fermented extract and a preparation method and application thereof. The Armeniaca vulgaris fermented extract is prepared from Armeniaca vulgaris, which serves as a raw material, through fermenting with Lodderomyces elongisporus and extracting aroma components from a fermented solution. The Lodderomyces elongisporus is collected in the China General Microbiological Culture Collection Center (CGMCC); the collection number is CGMCC No. 6645; the collection date is October 08, 2012. The Armeniaca vulgaris fermented extract contains a variety of aroma substances, such as phenylethyl alcohol, capronaldehyde, benzaldehyde, ethyl acetate, 1-butanol and the like. Shown by results of flavored smoking assessment tests, the product can be harmonized with cigarette flavors, can obviously promote the cigarette flavors, make smoke gas delicate and mellow, lower irritation, conceal impurity gases and improve the smoking flavor of cigarettes, and can generate a fresh and special aroma.

Owner:CHINA TOBACCO YUNNAN IND

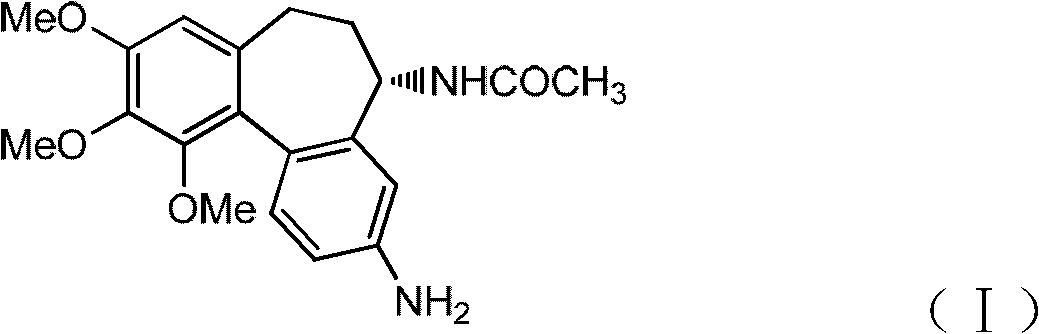

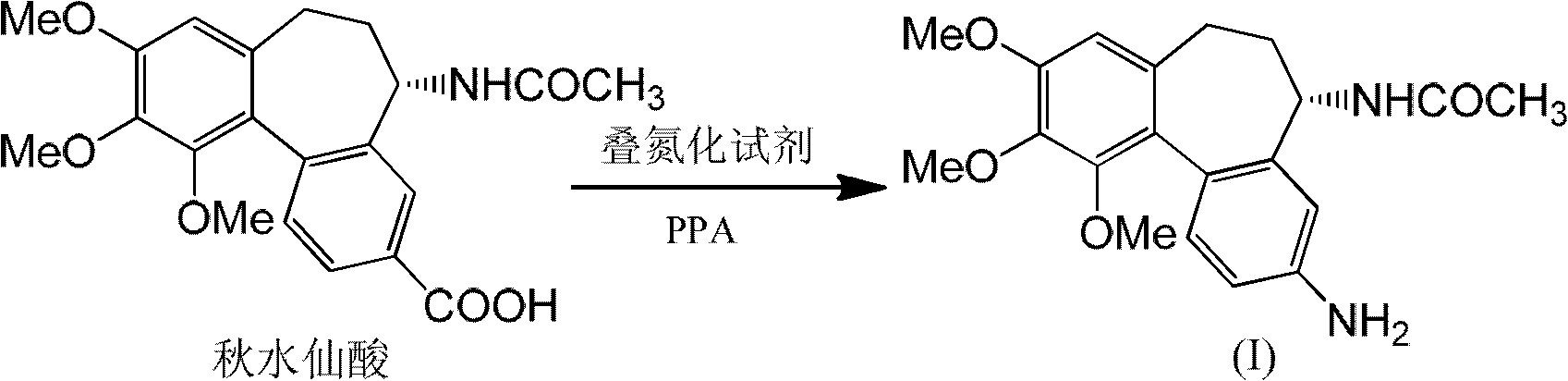

Method for preparing intermediate of colchicine derivatives

ActiveCN102603556AMild reaction conditionsSimple processOrganic compound preparationCarboxylic acid amides preparationBenzeneColchicine derivatives

The invention discloses a method for preparing an intermediate of colchicine derivatives, namely (5S)-N-(3-amino-9,10,11-trimethoxy-6,7-dihydro-5H-dibenzo [a, c] cycloheptene-5-yl) acetamide. The method comprises the steps of rearranging colchicine under the action of sodium methylate to generate allo-colchicine, hydrolyzing the allo-colchicine under alkaline conditions to obtain colchicinic acid and carrying out Schmidt rearrangement on the colchicinic acid and an azide reagent under the catalysis of polyphosphoric acid to obtain the intermediate of the colchicine derivatives, namely the (5S)-N-(3-amino-9,10,11-trimethoxy-6,7-dihydro-5H-dibenzo[a,c]cycloheptene-5-yl)acetamide. The method has the advantages that the polyphosphoric acid is adopted to catalyze the Schmidt rearrangement; the reaction condition is mild; the process is simple; the product purification is easy; the yield is high; and large-scale industrial production is easy to realize.

Owner:ZHEJIANG UNIV

Tobacco casing method

The invention discloses a tobacco casing method. The method is characterized by comprising the following steps: uniformly spraying tobacco bottom materials on the inner wall of a wooden case made of natural wood during casing, then filling the conditioned leaves into the wooden case and controlling the storage temperature, humidity and time of the tobaccos to ensure the tobaccos to fully absorb the tobacco bottom materials, wherein the natural wood is preferably thuja occidentalis, juniperus pingii, juniper, sabina vulgaris var. jarkendensis, cupressus gigantea or cupressus duclouxiana. The tobacco casing method has the following advantages: the tobacco bottom materials can be promoted to permeate into the internal tissues of the cut tobaccos by controlling the temperature and humidity while the tobaccos are stored and aged to give full play to the effect of the added tobacco bottom materials on improving the quality of the tobacco products, thus effectively reducing the usage and cost of the tobacco bottom materials in the tobacco processing process; the flavor components of the tobaccos are fully coordinated to ensure the aroma of the tobaccos to be more natural, exquisite and stronger, have rich layers and ensure the smoke to be mellow; and the tobacco casing method has the characteristics of simplicity and convenience in operation, low cost and strong controllability, and is convenient for realization of large-scale industrial production.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Aureobasidium pullulans OF-01 strain and method for preparing tobacco endogenous derived spice by using strain

The invention discloses an aureobasidium pullulans OF-01 strain (CGMCC No.7609) (China General Microbiological Culture Collection Center Number 7609), a method for preparing a tobacco endogenous derived spice by using the strain, and an application of the strain in a tobacco additive. A tobacco leaf fragment is used as a raw material, the aureobasidium pullulans OF-01 strain is used for fermentation, a plurality of products, such as extracellular polysaccharides (pullulan), enzymes, antibiotics, single-cell protein, volatile aroma components and the like, are generated, and the fermented tobacco leaf fragment is extracted and condensed to prepare the tobacco endogenous derived spice, therefore, the application of the spice and flavor products which are not derived from the tobacco in cigarette is reduced to achieve the re-utilization of the tobacco leaf fragment. The analysis on the aroma components proves that the spice comprises a plurality of types of tobacco aroma components and other derived aroma components. The result of a flavoring smoke panel test proves that the spice can be used for obviously increasing cigarette flavor, causing the smoke pure and mild, reducing the irritation, covering the offensive odor, and improving the cigarette smell. The spice has the characteristics of low cost, rich aroma components, safety to people and livestock and the like, therefore, the spice can be used in the production of the cigarette.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

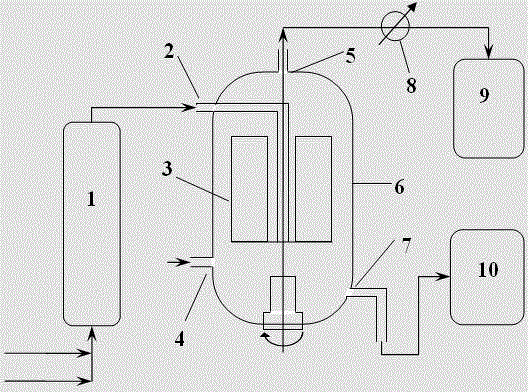

Method for preparing tobacco perfume by pile-fermenting tobacco stems by utilizing resting cells

The invention provides a method for preparing tobacco perfume by pile-fermenting tobacco stems by utilizing resting cells. Aroma-producing strains separated from the surfaces of tobacco leaves are amplified and cultured in a luria-bertani (LB) liquid culture medium and then centrifugally collected for standby application; a phosphate buffer solution is compounded, and the concentration of the buffer solution is controlled within a range that the osmotic pressure of the buffer solution can satisfy the requirement for cell growth; all the aroma-producing strains are grafted to the phosphate buffer solution and cultured for 20 to 72 hours at a temperature of 20 to 37 DEG C, and then the resting cells are manufactured for standby application; 2 to 5 times of water is added to the tobacco stems to sterilize the tobacco stems, and the resting cells are inoculated with pathogens at a proportion of 0.5 to 10 percent of the total weight of the sterilized tobacco stems; the tobacco stems and the resting cells are evenly mixed, and pile-fermented and cultured at a temperature of 20 to 37 DEG C for 24 to 120 hours after the resting cells are inoculated with the pathogens, and then a fermentation product is obtained; and finally, water is added to the fermentation product, the fermentation product is heated, extracted and concentrated, and then the tobacco perfume is manufactured. By adopting the method, wood gas in tobacco stem extracts can be effectively reduced and sweet aroma can be supplemented, so that the smoking quality of the tobacco stem extracts can be improved, the originalaroma of tobacco can be effectively promoted, stimulation can be reduced and the richness of the tobacco stem extracts can be increased.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

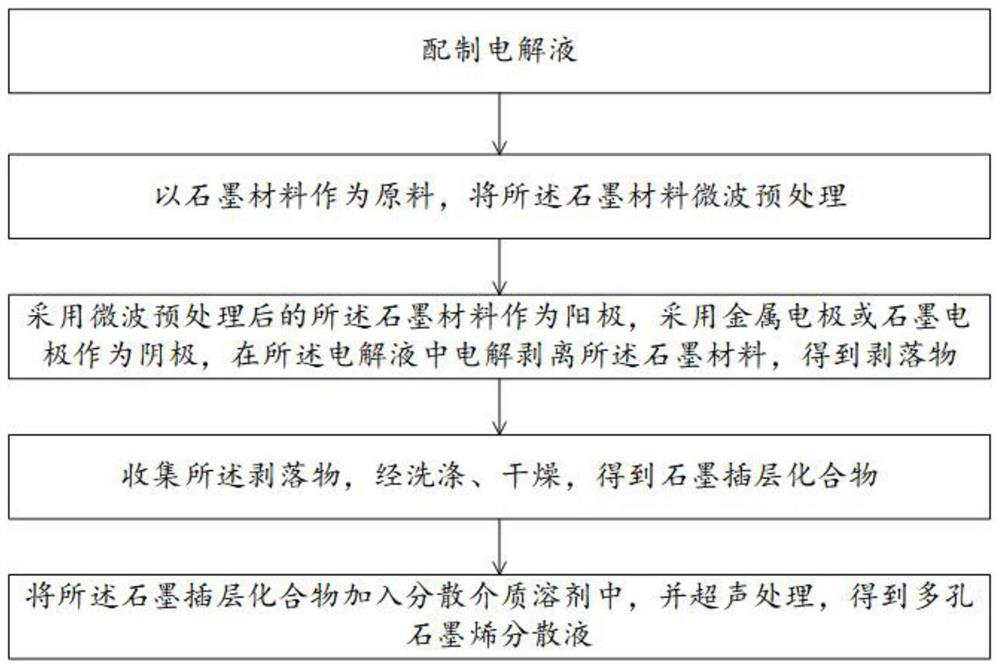

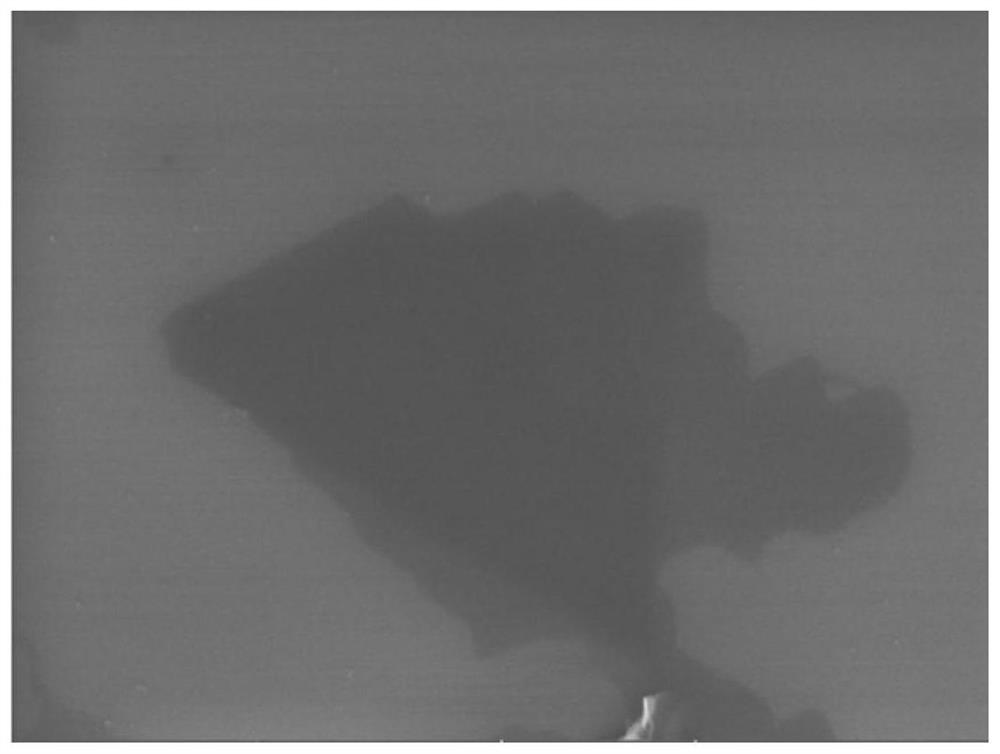

Electrochemical preparation method of porous graphene dispersion liquid

ActiveCN112239203APromotes electrochemical strippingSimple manufacturing methodGraphenePorous grapheneElectrochemical response

The invention discloses an electrochemical preparation method of a porous graphene dispersion liquid. The electrochemical preparation method comprises the following steps: preparing an electrolyte; performing microwave pretreatment on a graphite material serving as a raw material; taking the graphite material subjected to microwave pretreatment as an anode, taking a metal electrode or a graphite electrode as a cathode, and electrolytically stripping the graphite material in the electrolyte to obtain a stripped material; collecting the stripped material, and washing and drying the stripped material to obtain a graphite intercalation compound; and adding the graphite intercalation compound into a dispersion medium solvent, and carrying out ultrasonic treatment to obtain the porous graphene dispersion liquid. Compared with the prior art, the porous graphene can be prepared through one-step electrochemical reaction, and the preparation method is simple, efficient, mild in condition, low inequipment requirement, free of environmental pollution, low in cost and beneficial to industrial production.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Starch-novolac epoxy resin blended fully-degradable zip lock bag and preparation method thereof

InactiveCN106243636AHigh strengthFacilitate the realization of large-scale industrial productionEpoxyMagnesium stearate

The invention discloses a starch-novolac epoxy resin blended fully-degradable zip lock bag and a preparation method thereof. The starch-novolac epoxy resin blended fully-degradable zip lock bag is prepared from, by weight, 50-60 parts of novolac epoxy resin, 8-15 parts of calcium carbonate, 1-4 parts of nanometer titania, 10-20 parts of benzoin ethyl ether, 7-9 parts of nano-montmorillonite, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 60-65 parts of corn starch, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 1-1.5 parts of 2,6-ditert-butyl-4-methylphenol, 4-6 parts of 3-hydroxybenzoic acid, 1-2 parts of laurinol sulfate and 4-6 parts of plant saponin. The product is produced according to a safe formula, and can be used for manufacturing food packaging bags and the like; during use, the product is high in strength, resistant to water and oil and durable, large-scale industrial production can be achieved, grasping is easy, popularization is convenient, the waste product can be automatically degraded under the effects of rich oxygen and microorganisms, carbon dioxide and water are finally generated, and the starch-novolac epoxy resin blended fully-degradable zip lock bag is ecological and environmentally friendly.

Owner:ANHUI MEIXIANG PLASTIC

Stable high-strength conducting fibroin gel in natural environment and preparation method of gel

InactiveCN108034057AConducive to environmental protection and operator healthEasy to recycleSolventIon

The invention discloses a stable high-strength conducting fibroin gel in a natural environment and a preparation method of the gel. Fibroin denaturation solvents mutually soluble with ionic liquid areadded into fibroin ionic liquid solution, so that fibroin is subjected to conformation transformation in the mixed solvents, and a physical crosslinking network is further formed, namely, the stablehigh-strength conducting fibroin gel in the natural environment is prepared. The preparation method is simple, green, mild, high in efficiency and low in cost, energy is saved, and the mechanical property of the final gel can be regulated by changing solid content or types and the content of the denaturation solvents (or changing the proportion of the denaturation solvents to the ionic liquid). The prepared fibroin gel is high in strength, good in toughness and stable in performance, has conductivity, cannot run dry in long-time placement in the natural environment, can serve as a gel electrolyte material without sealing, and has application values in a plurality of fields.

Owner:FUDAN UNIV

Tobacco charging method for promoting using effect of tobacco spice

The invention discloses a tobacco charging method for promoting the using effect of a tobacco spice. The method comprises the following steps of: preparing clean water into alkaline water with the pH value of between 8 and 9 in an electrolysis mode, fully dissolving a tobacco concentrated base material into the alkaline water, uniformly applying the solution into tobacco leaves, and simultaneously controlling the temperature and the humidity during charging and after charging. By using the characteristics of small water molecule clusters and high permeability of the alkaline electrolyzed water, the spice is effectively permeated to the internal tissue structure of tobacco shreds, the components of the spice are fully reacted with the chemical components of the tobacco leaves, and the effect of the spice on adjustment of the quality of the tobacco is fully exerted. Free nicotine and volatile alkali substances in the tobacco can be released in the industrial links of charged tobacco leaf alcoholization, shred drying and the like, so that the strength of cigarettes is reduced, the comfortableness of the cigarettes is improved, and the addiction of a tobacco product is reduced. The method is easy to operate and low in cost, has the characteristics of strong operability, normalization and controllability, and is convenient to realize large-scale industrialized production.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Method for preparing mono-methyl succinate

ActiveCN104557536ALow costEasy to operateOrganic compound preparationCarboxylic acid esters preparationChemistryHigh Gravity

The invention provides a method for preparing mono-methyl succinate. The method comprises the following steps: carrying out a mono-esterification reaction on succinic anhydride and methanol in a static mixer, conveying the reaction effluent into a high gravity reactor, and meanwhile filling water vapor into the high gravity reactor; cooling and separating the liquid material after the reaction to obtain mono-methyl succinate. The method for preparing mono-methyl succinate provided by the invention is reasonable in craft process, simple in separation method, high in product purity, good in quality and high in yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

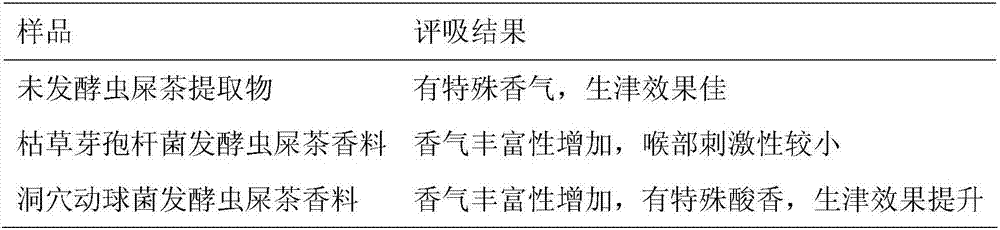

Tobacco flavor prepared from microbial fermented insect droppings tea and application of tobacco flavor

InactiveCN107034239AIncrease aroma richnessThe effect of promoting body fluid is remarkableTobacco preparationMicroorganismsSecretionSaliva

The invention discloses tobacco flavor prepared from microbial fermented insect droppings tea and application of the tobacco flavor. The insect droppings tea is used as a raw material, after cave planococcus SYSUZL-1 is subjected to enlarge cultivation, the insect droppings tea is fermented, after the insect droppings tea is subjected to shake culture at the temperature of 30 DEG C for 24-48 hours, and then procedures of refluxing extraction, filtering and slag removal and concentration of supernate under reduced pressure are implemented to obtain the tobacco flavor. The storage number of the strain is CCTCC M2016738. Microbiology characteristic analysis and 16S rRNA gene sequence analysis show that the cave planococcus is a new species of microorganisms. After combined fermentation of the strain and the insect droppings tea, compared with untreated tobacco flavor, the tobacco flavor has the characteristics that while the original characteristic aroma of the insect droppings tea is maintained, special acid aroma is added, aroma richness is improved, and the effect of promoting the secretion of saliva or body fluid is remarkable.

Owner:CHINA TOBACCO YUNNAN IND

Fully-synthetic glass cutting fluid and preparation method thereof

PendingCN110846117AFully synthetic water-based formula with low CODReduce CODLubricant compositionDefoaming AgentsMaterials science

The invention discloses a fully-synthetic glass cutting fluid. The fully-synthetic glass cutting fluid comprises the following components in percentage by weight: 0.1-5% of triethanolamine, 0.1-5% oftriethanolamine borate, 1-20% of hyperbranched quaternary ammonium salt, 1-10% of a penetrating agent, and 0.01-3% of a defoaming agent, with the balance being deionized water. The fully-synthetic glass cutting fluid is endowed with certain lubricating property by triethanolamine borate, and due to good lubricating property and low addition amount of triethanolamine borate, the glass cutting fluidis favorable for environmental protection; and due to high lubricating property, cutting precision is improved, surface precision is good, the lubricating property is improved, the service life of adiamond wire can be prolonged, and cost is saved.

Owner:广西珀源新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com