Method for preparing mono-methyl succinate

A technology of monomethyl succinate and succinic anhydride, which is applied in the field of preparation of monomethyl succinate, can solve the problems of unfavorable large-scale production, complicated separation process, and low product purity, and shorten the reaction time of esterification , Reasonable preparation process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

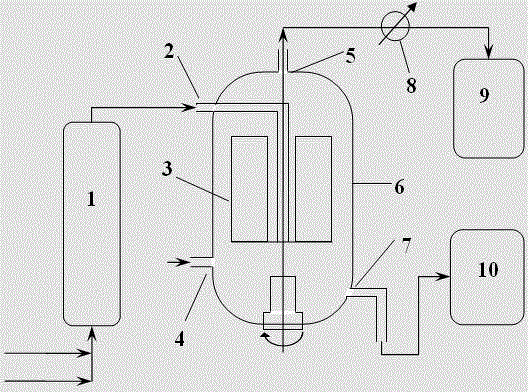

Image

Examples

Embodiment 1

[0023] The molar ratio of succinic anhydride to methanol is 1:2, and the monoesterification reaction conditions are as follows: the reaction temperature is 100°C, the reaction pressure is 0.5MPa, and the reaction residence time is 1h. The speed of the supergravity reactor is 400rpm, and the liquid-gas ratio is 2L / Nm 3 , the cooling temperature of the liquid phase material is 10°C.

Embodiment 2-4

[0025] Same as Example 1, the difference is that the molar ratio of succinic anhydride and methanol varies between 1:1-4.

Embodiment 5-7

[0027] Same as Example 1, except that the temperature of the monoesterification reaction between succinic anhydride and methanol is changed between 70°C and 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com