Concrete flavouring for tobacco and preparation method and application thereof

A technology for tobacco spices and extracts, which is applied in the field of tobacco additives, can solve the problems of few comprehensive utilization channels, occupy a large storage space, and low comprehensive utilization degree, achieve strong standardization and controllability, improve utilization rate, The effect that is conducive to the benign development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

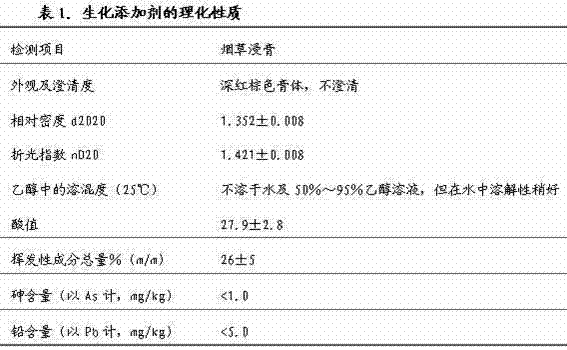

Image

Examples

Embodiment 1

[0027] ——Preparation of Tobacco Flavor Extract 1

[0028] 1. Medium and Culture Conditions

[0029] The strains used in the experiment were inoculated into 50 mL of LB liquid medium, and cultured at 37 °C for 12 h to obtain liquid strains. The liquid strains were transferred to 1 L of LB liquid medium according to the inoculum amount of 5%, and cultured with shaking at 37°C and 150 r / min for 12 h. Centrifuge the culture solution at 3500 rpm / min for 10 min, wash the precipitate with sterile water, centrifuge, and finally shake it evenly with 20 mL of sterile water, and dilute it 10 times before use to obtain the bacterial agent.

[0030] 2. Fermentation treatment of waste tobacco leaves

[0031] 1) Fermentation by nicotine-degrading bacteria

[0032] For every 200 g of low-grade tobacco leaves, 40 mL of nicotine-degrading bacteria (Rhodococcus Y22) bacterial agent was sprayed (the control sample was sprayed with an equal volume of sterile water). The treated tobacco leaf sa...

Embodiment 2

[0052] ——Preparation of Tobacco Flavor Extract 2

[0053] 1. Culture medium and culture conditions: the same as in Example 1.

[0054] Fermentation treatment of waste tobacco leaves

[0055] 1) Fermentation by nicotine-degrading bacteria

[0056] For every 200 g of low-grade tobacco leaves, 40 mL of nicotine-degrading bacteria (Rhodococcus Y22) bacterial agent was sprayed (the control sample was sprayed with an equal volume of sterile water). The treated tobacco leaf samples were fermented in a 22°C, 60% constant temperature and humidity box for 10 days for the next experiment.

[0057] 2) Mixed fermentation treatment of esterase-producing bacteria and aroma-producing bacteria

[0058] The samples fermented by nicotine-degrading bacteria were sprayed with 20 mL of ferulic esterase-producing bacteria (Bacillus pumilus Van35) and aroma-producing bacteria (Bacillus subtilis) (the control sample was sprayed with an equal volume of sterile water). The treated tobacco leaf samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com