Disposable controlled completely-degradable plastic packing bag and preparation method thereof

A completely degradable and packaging bag technology, applied in the field of disposable controllable and completely degradable plastic packaging bags and their preparation, can solve the problems of film mechanical properties, physical and mechanical properties, material mechanical properties, etc., and achieve later use performance. Good uniformity, avoiding the decline of mechanical properties, and the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

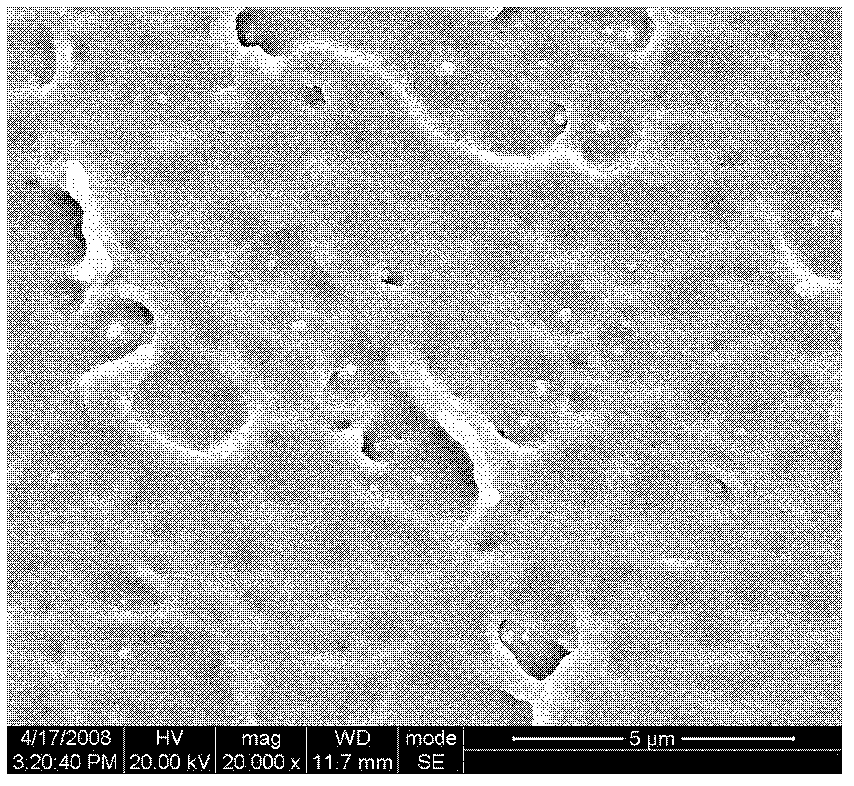

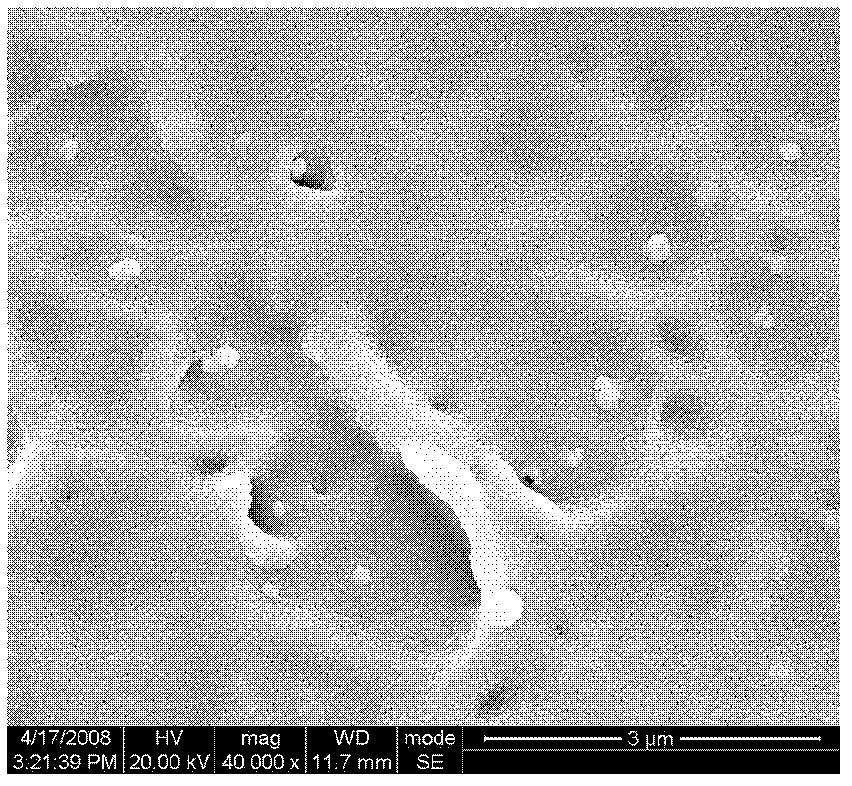

[0051] First put 50 parts of nano-cerium oxide with a particle size of 30-50nm into an ultra-high-speed mixer, and stir for 20 minutes at 4000 rpm, during which 1 part of γ-aminopropylmethyldiethoxysilane and no The mixed solution of 80 parts of water and ethanol was added in 3 times. After the addition, continue to stir and mix at a high speed for 1.5 hours, then filter with suction, dry the powder at 120°C, and put it into a ball mill for grinding for at least 1 hour.

[0052] 0.2 parts of the obtained surface-modified nano additives and 5 parts of polyoxyethylene polyoxypropylene ether block copolymers with a relative molecular weight of 1000 g / mol, 5 parts of triethyl citrate and acetyl tri-n-butyl citrate 10 parts of ester, 5 parts of water, 10 parts of glycerin, 5 parts of polyethylene glycol with a relative molecular weight of 400g / mol were dispersed for 2 hours by a colloid mill, and then mixed with 75 parts of cornstarch, 15 parts of polyvinyl alcohol of 1799, bis( Pu...

Embodiment 2

[0055] First put 30 parts of anatase-type nano-titanium dioxide with a particle size of 30-50nm into an ultra-high-speed mixer, and stir for 30 minutes at 3000 rpm, during which 0.5 parts of γ-aminopropylmethyldiethoxy Add the mixture of 50 parts of silane and absolute ethanol in 3 times. After the addition, continue to stir and mix at ultra-high speed for 2 hours, then filter with suction, dry the powder at 110°C, and put it into a ball mill for grinding for at least 1 hour.

[0056] 1 part of the obtained surface-modified nano-auxiliary and 15 parts of acetyl tri-n-butyl citrate were dispersed through a colloid mill for 1 hour, and then mixed with 40 parts of rice starch, 40 parts of mung bean starch, and 10 parts of polyvinyl alcohol of 1799 , 1 part of 2,6-tertiary butyl-4-methylphenol antioxidant is put into a high-speed mixer, stirred at a temperature of 70°C and a speed of 120 rpm for 20 minutes, discharged, and then added to twin-screw extrusion It can be melt extruded...

Embodiment 3

[0059] First put 40 parts of anatase-type nano-titanium dioxide with a particle size of 30-50nm and 10 parts of nano-cerium oxide with a particle size of 30-50nm into an ultra-high-speed mixer, and stir at 5000 rpm for 10 minutes, during which 1.5 parts of γ - The mixture of aminopropylmethyldiethoxysilane and 100 parts of absolute ethanol was added in 3 times. After the addition, continue to stir and mix at a high speed for 1.5 hours, then filter with suction, dry the powder at 110°C, and then Put into a ball mill and grind for at least 1 hour.

[0060] 1.5 parts of nano additives after the surface modification obtained and 5 parts of polyoxyethylene polyoxypropylene ether block copolymers and 10 parts of acetyl tri-n-butyl citrate with a relative molecular weight of 1500 g / mol were dispersed by a colloid mill for 2 hour, then with 30 parts of lotus root starch, 42 parts of potato starch, 20 parts of polyvinyl alcohol of 1799, 5 parts of polyvinyl alcohol of 2499, 1 part of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com