Patents

Literature

108results about How to "Reduce woodiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for preparing thin slice of tobacco and prepared thin slice of tobacco

InactiveCN101438852ARich aromaImprove combustion qualityTobacco preparationTobacco treatmentPectinaseChemistry

The invention provides a technique for preparing tobacco sheets and the tobacco sheets. The technique comprises the following steps: soaking tobacco materials in water to obtain extract liquid and a water-insoluble solid; carry out enzymatic hydrolysis on the extract liquid by pectinase and / or protease so as to obtain a first water-soluble extract; degrading the protein in the water-insoluble solid by the protease so as to obtain an enzyme-hydrolyzed water-insoluble solid and a second water-soluble extract; placing the enzyme-hydrolyzed water-insoluble solid in acidic alcohol solution so as to acid-degrade lignose, then preparing the separated solid into tobacco sheet bases; and carrying out vacuum concentration on the first and the second water-soluble extracts and applying the first and the second water-soluble extracts to the tobacco sheet bases to prepare the tobacco sheets. The technique can effectively reduce the content of water-soluble pectin and water-insoluble protease, and reduce the unique lignin flavor in the tobacco sheets by the chemical degradation of the lignose.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD +1

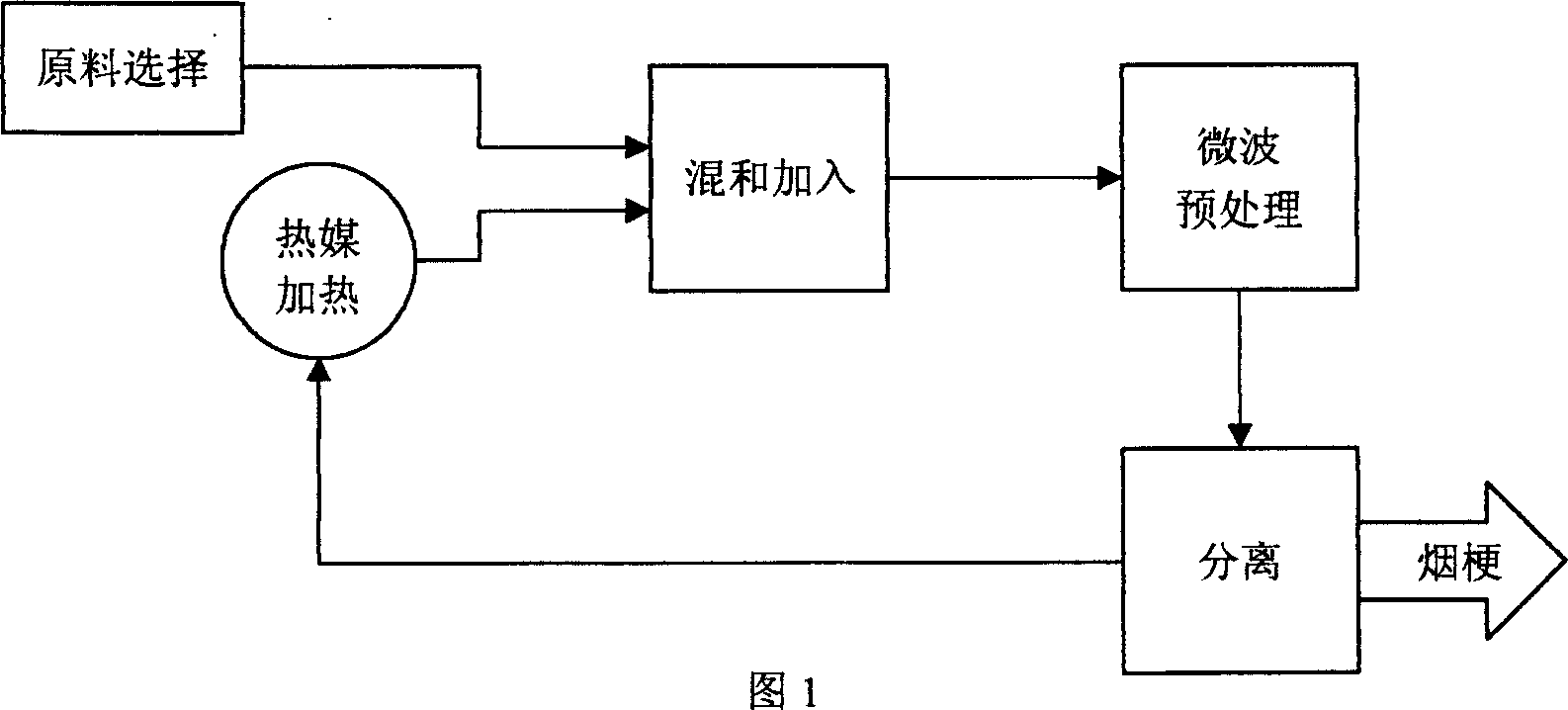

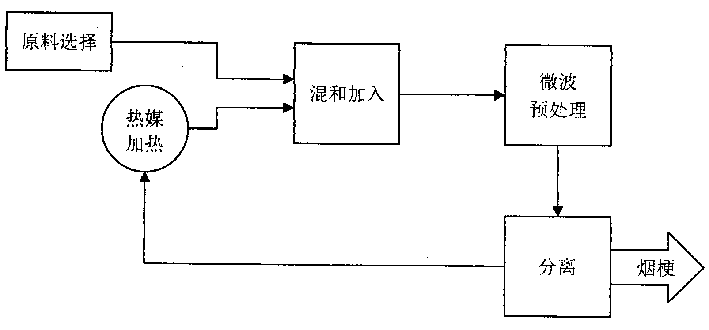

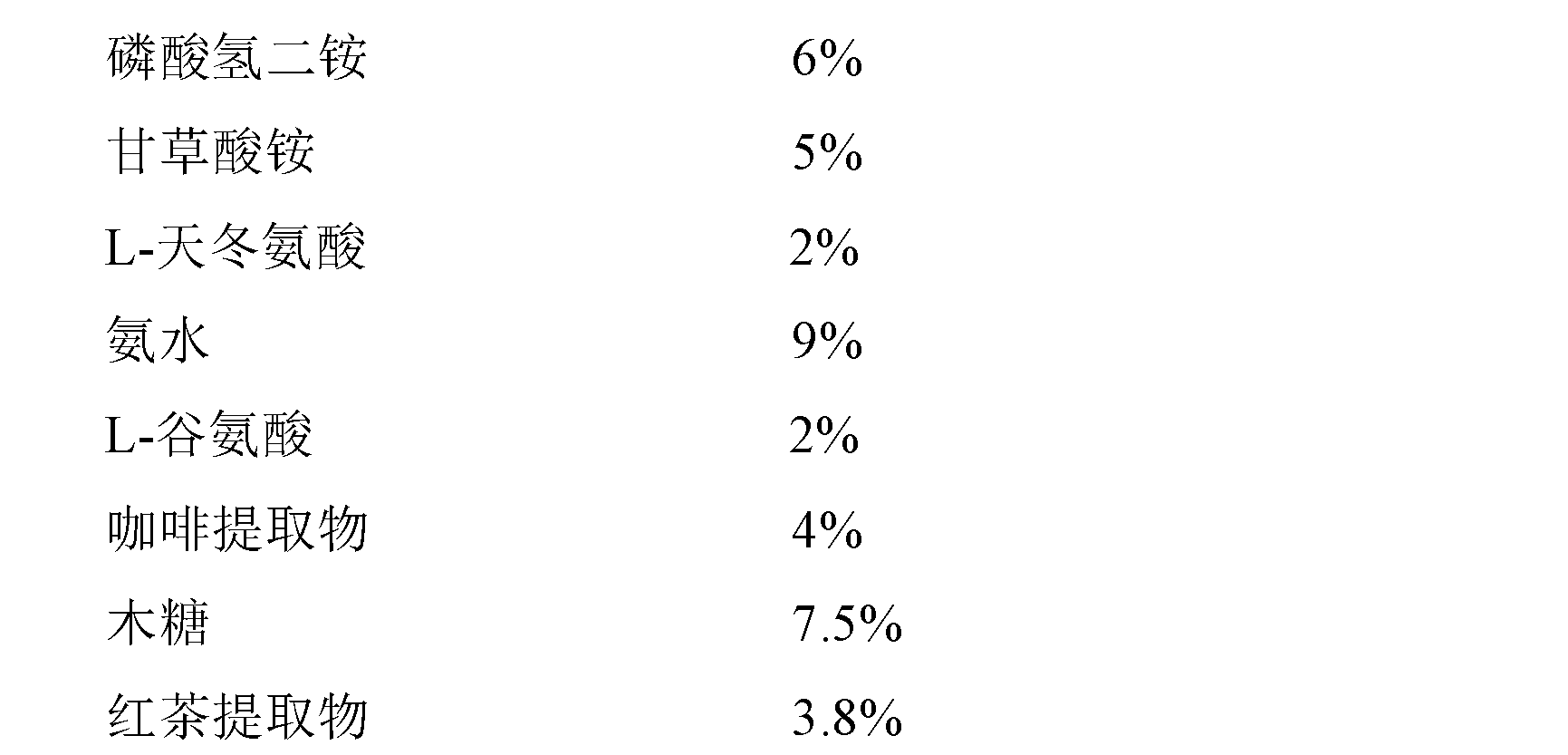

Technique for pretreating cabo

InactiveCN1518906AReduce energy consumptionGood smokeTobacco preparationPretreatment methodMicrowave

A technology for pre-processing the stems of tobacco leaves includes heating the low-loss granular solid microwave medium as thermal medium to 100-200 deg.c, mixing said stems with said thermal medium, heating in microwaven over for puffing the stems, and separating the tobacco stems from thermal medium. The pre-processed stems feature high loseness and elasticity, and good smell.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

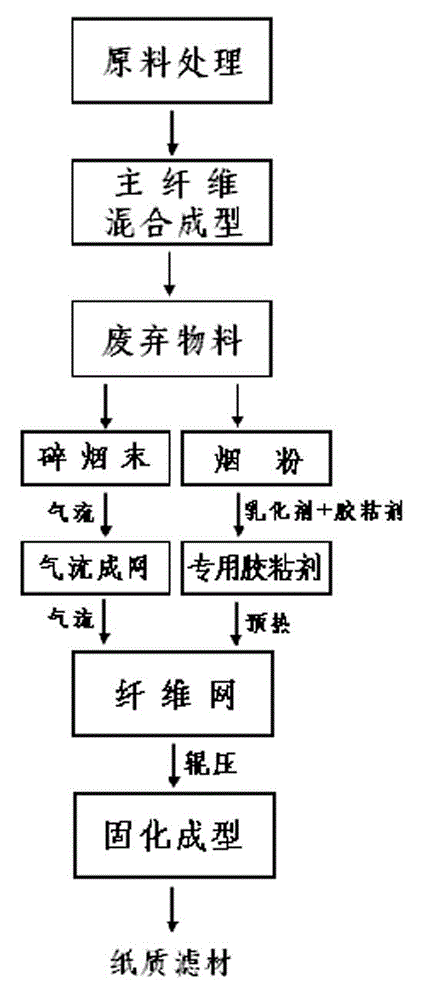

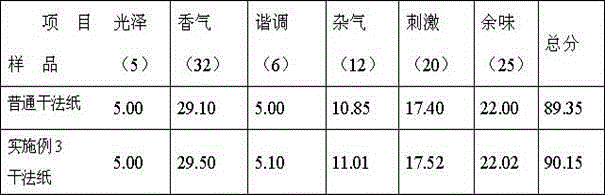

Paper cigarette filter rod filter media and processing method thereof

ActiveCN102747647AImprove sensory qualityEvenly distributedTobacco smoke filtersTextiles and paperFiberFilter media

The present invention discloses a paper cigarette filter rod filter media and a processing method thereof, wherein the paper filter media is obtained through performing a dry process on the following components: 40-74% of natural cigarette fiber, 4-40% of bast fiber, 1-12% of natural tobacco waste raw material, and 4-20% of adhesive. The method comprises the following steps: raw material processing, main fiber mixing shaping, waste material adding and prepared paper shaping process. After the natural tobacco fiber is mixed with the bast fiber, discongestion is performed. After sufficient dispersion, the mixed material is conveyed to a shaping section through a blower for being laid on a net and shaped. A fluffy and uniform fiber net is formed on a shaping net belt. The cigarette filter media paper is obtained through adhesive applying, preheating, roller pressing, solidifying and shaping. As the cigarette fiber is used as the main fiber raw material, the paper cigarette filter rod filter media according to the invention has reduced foreign gas of wood and settles a problem that the fragrance quality is reduced by the foreign gas of wood in the prior-art paper filter rod. The natural tobacco waste raw material is added in the paper shaping process. Not only is whole aesthetic quality of the cigarette improved, but also the tobacco raw material is uniformly distributed in the dry process paper and does not easily drop off. The quality of the filter rod is more stable.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

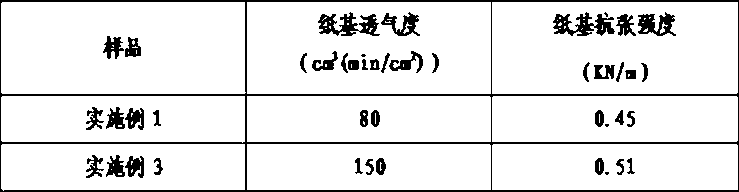

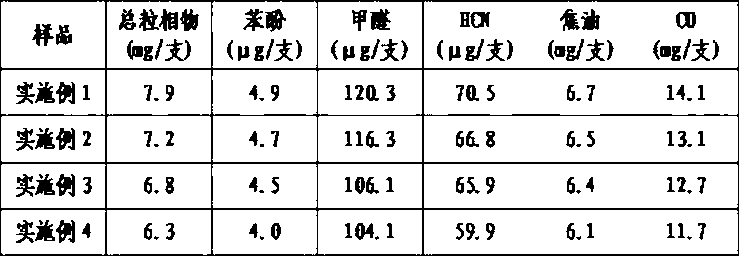

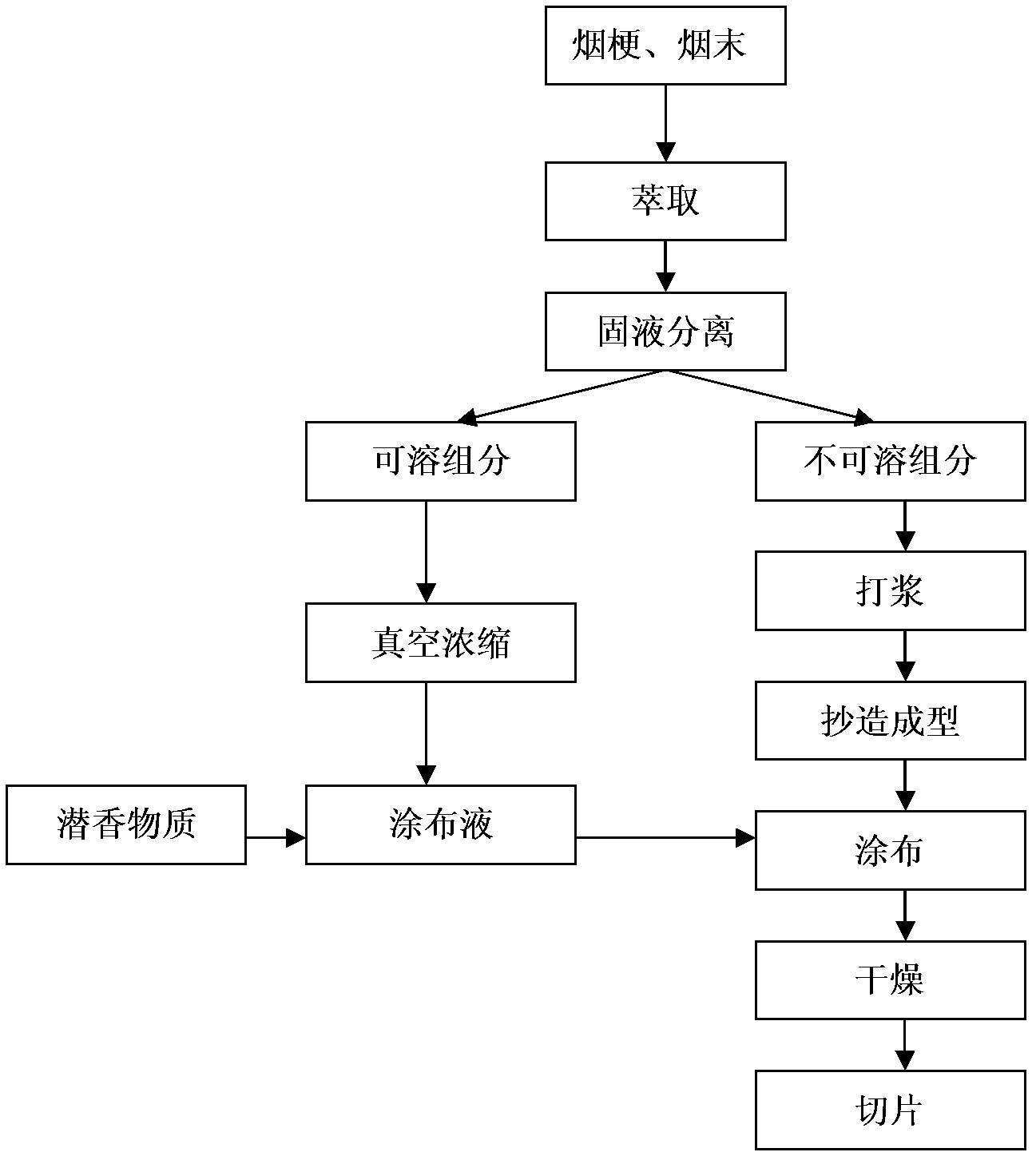

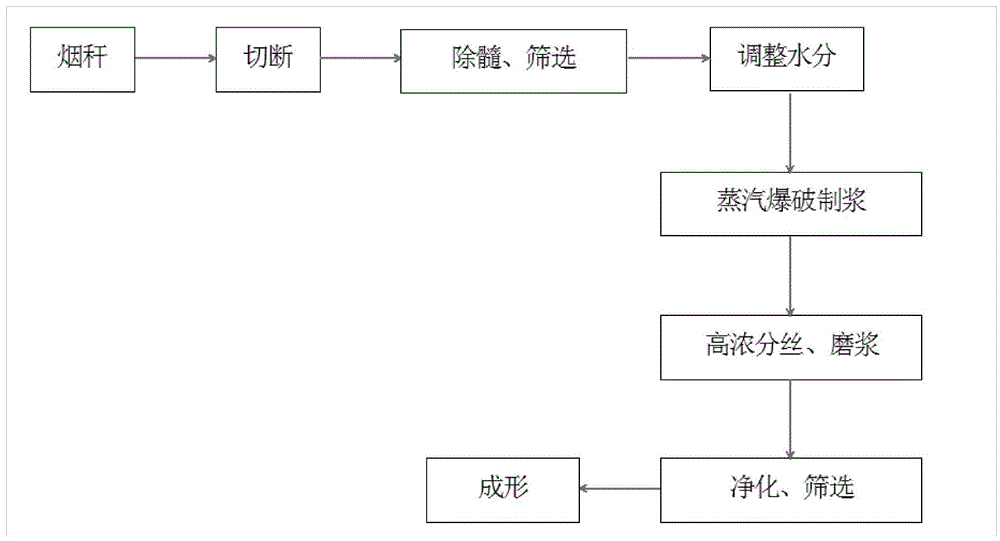

A kind of production method of tobacco sheet cigarette paper

ActiveCN102277780AImprove taste qualityReduce woodinessNon-fibrous pulp additionCoated paper substrateFiberIrritation

The invention relates to a production method of tobacco sheet cigarette paper. The method comprises the following steps of: (1) adding tobacco leaf pieces or tobacco stems into hot water, and extracting at 40-70 DEG C for 20-40 minutes, wherein the adding amount of the hot water is 3-5 times of the weight of the tobacco pieces; (2) primarily extruding the extracted tobacco leaf pieces or tobacco stems with a pulp extrusion machine, then adding hot water of which the amount is 1-3 times of the total weight of the tobacco leaf pieces or tobacco stems, extracting at 45+ / -5 DEG C for 20 minutes, extruding again, and then pulping with a pulping machine until the SR (Schopper-Riegler) degree reaches 25-40; (3) pulping applied fibers with the pulping machine until the SR degree reaches 40-75, mixing with the tobacco pulp, and making cigarette paper, wherein the adding amount of the applied fibers is 0.25-0.5 time of the total weight of the tobacco leaf pieces or tobacco stems; and (4) mixingthe two extraction liquids, then concentrating until the relative density reaches 1.02-1.2 g / cm<3>, adding potassium salts, food pigments and spices, mixing to obtain a coating liquid, and spreading the coating liquid on the cigarette paper. The method provided by the invention can improve the cigarette quality, can reduce the woody smoke of cigarettes and reduce the irritation, and makes naturalsweet taste of tobaccos more predominant.

Owner:HUBEI CHINA TOBACCO IND +1

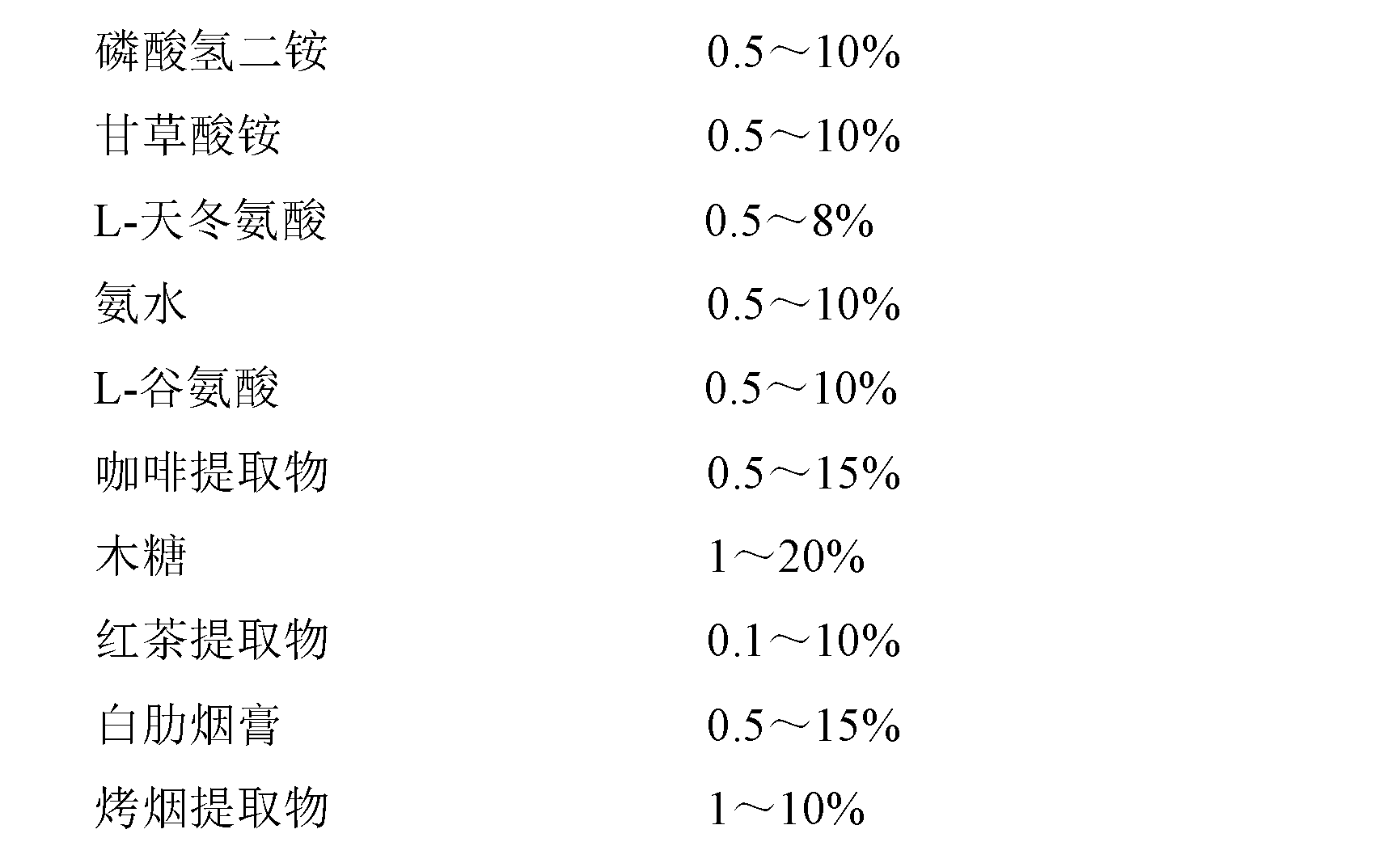

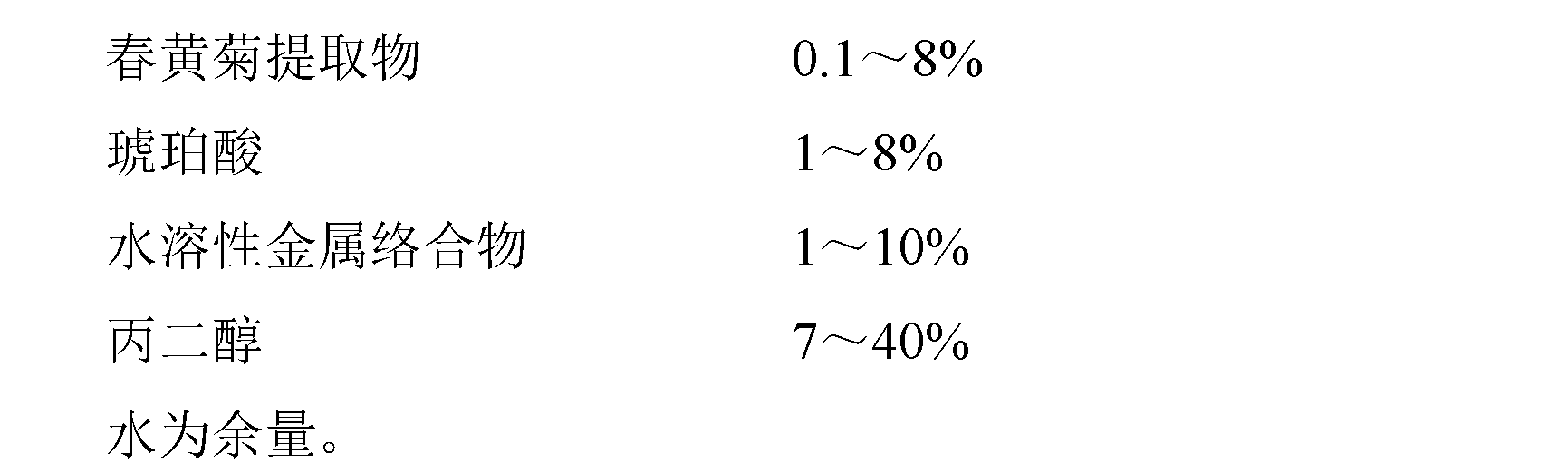

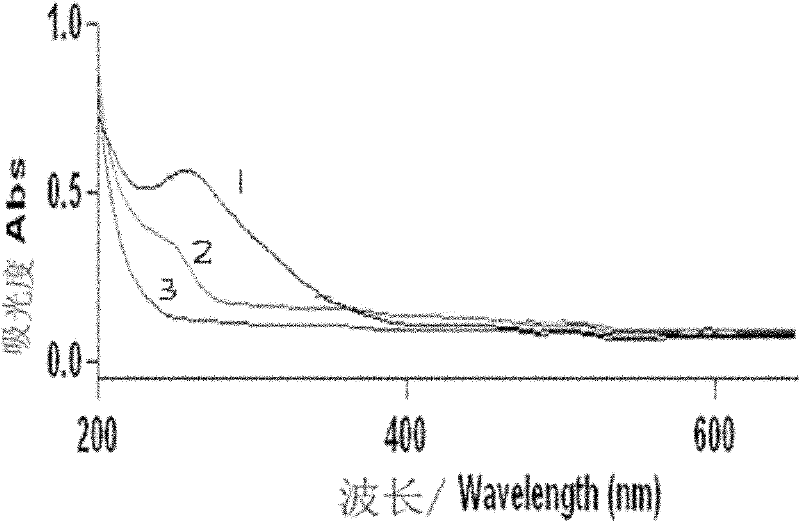

Additive for boosting maillard reaction of recombined tobacco leaves and method for preparing tobacco leaves by using additive

ActiveCN102697168AIncrease aromaRaw materials are easy to getTobacco preparationTobacco treatmentMaillard reactionNicotiana tabacum

The invention discloses an additive for boosting maillard reaction of recombined tobacco leaves and a method for preparing the tobacco leaves by using the additive. The additive comprises 0.5-10% of diammonium hydrogen phosphate, 0.5-10% of ammonium glycyrrhetate, 0.5-8% of L-Aspartic acid, 0.5-10% of ammonia water, 0.5-10% of L-glutamic acid, 0.5-15% of coffee extractives, 1-20% of xylose, 0.1-10% of black tea extractives, 0.5-15% of burley tobacco paste, 1-10% of cured tobacco extractives, 0.1-8% of chamomile extractives, 1-8% of succinic acid, 1-10% of water-soluble metal complex, 7-40% of propylene glycol and the balance of water. The speed of the maillard reaction in the stages of extracting and concentrating tobacco materials is accelerated by the additive, so as to increase the fragrance of the tobacco leaves, reduce the wood flavor and relieve irritation. When the additive is used for preparing the tobacco leaves, the production technology is not changed and equipment is not added; the usage method is simple; the raw materials of the additive are easily obtained; and the cost is low.

Owner:HUBEI CHINA TOBACCO IND

Preparation method of cigarette expansion cabo granule filling material

The invention discloses a preparation method of cigarette expansion cabo granule filling material, which comprises subjecting expanded cabo containing 5-9% of water to moisture regaining and balanced water treatment, loading into wind separation cabo beating machine, conveying bulked cabo particles into drying equipment for quick-speed drying till the moisture content is 7-14%, resulting cabo particles reexpansion, finally balancing water content of the cabo particles to 13+-0.5%.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

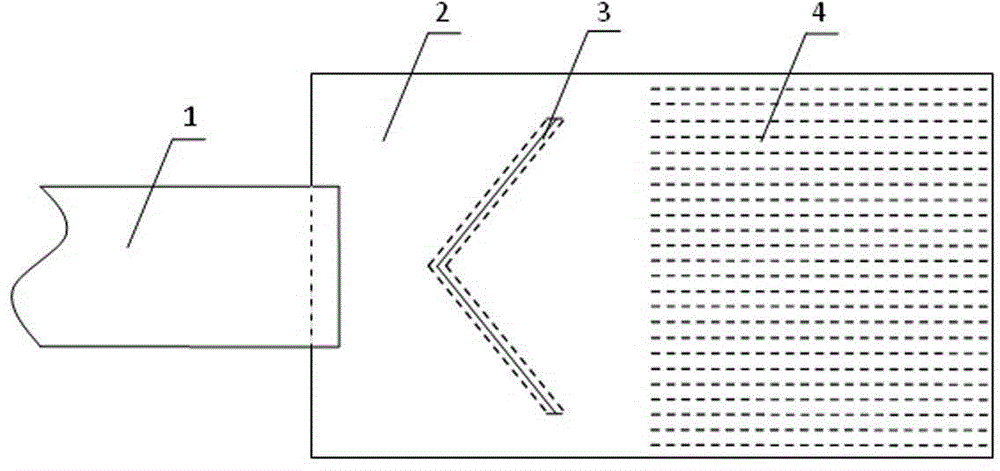

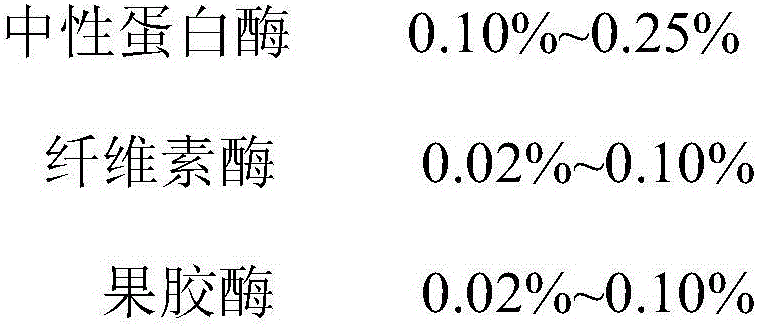

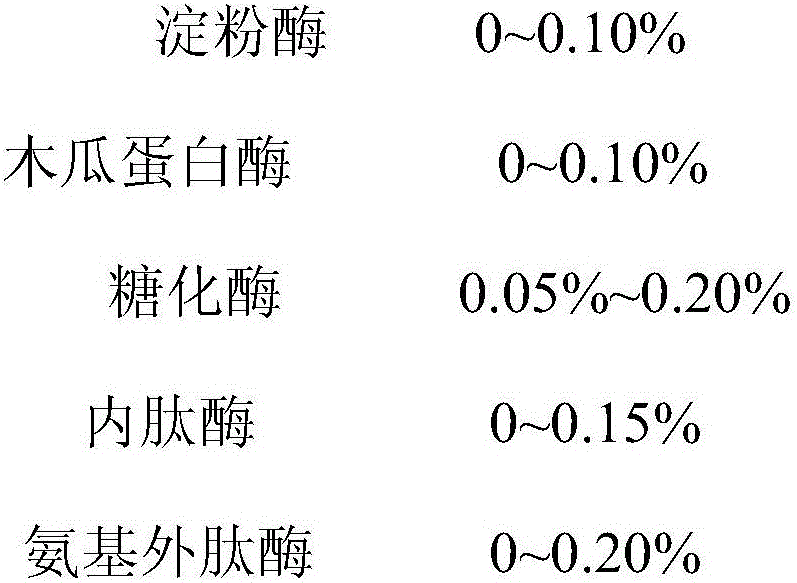

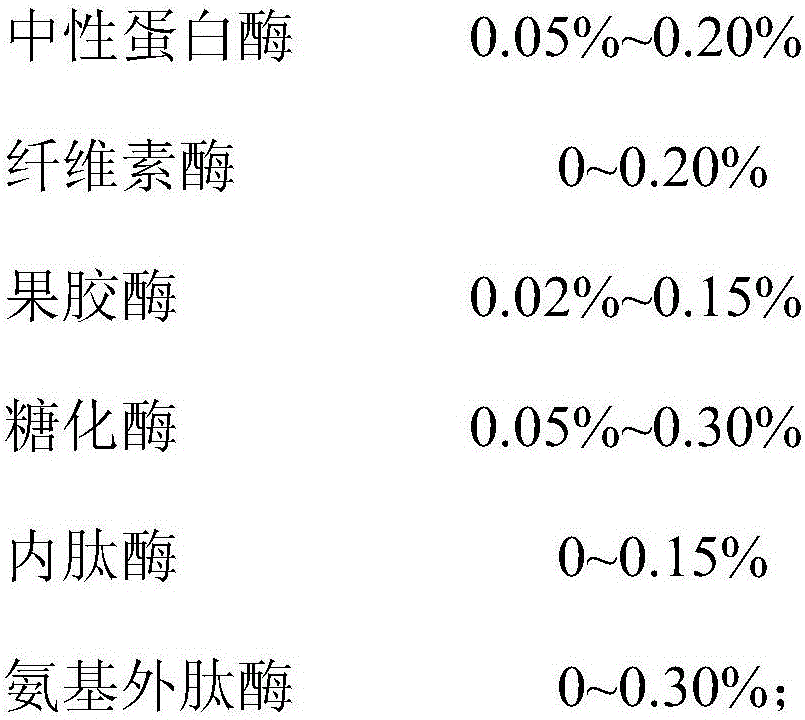

Method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco

The invention provides a method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco. The method for manufacturing reconstituted tobacco suited to flue-cured tobacco flavor from sun-cured tobacco comprises the steps as follows: a water extracting solution of a sun-cured tobacco material and a water extracting solution of flue-cured tobacco stems are mixed and concentrated to form a coating solution, and slices are prepared from water extraction filter residues of the sun-cured tobacco material and water extraction filter residues of the flue-cured tobacco stems through mixing with a papermaking method, and are then coated with the coating solution; a special complex enzyme preparation and aids are added during water extraction, concentration and pulping respectively. Excessive macromolecular substances such as protein, pectin, starch and the like in the sun-cured tobacco material are degraded through a special enzyme group, and a large number of small-molecule substances and precursors of flavoring substances are produced; meanwhile, the extraction efficiency is improved, and offensive odor and irritation produced by the reconstituted tobacco after combustion are reduced; various aroma producing and aroma increasing reactions are performed in the concentration process, and accordingly, the aroma quality of the reconstituted tobacco is improved, and the satisfaction and the coordination of smoke are increased.

Owner:HUBEI CHINA TOBACCO IND

Novel production process for cut tobacco stems

InactiveCN102972856AIncrease softnessIncrease fill valueTobacco preparationTobacco treatmentAgricultural engineeringDrum drying

The invention discloses a novel production process for cut tobacco stems. The novel production process comprises the steps as follows: carrying out vacuum moisture regaining and evaporating the stems; storing the stems; heating and humidifying; straightening the stems; pressing the stems; arranging the stems; cutting the stems; feeding; expanding and drying; and perfuming. According to the novel production process, the vacuum moisture regaining and stem evaporating mode is adopted for moisture regaining of the tobacco stems, so that the impurity gases in the tobacco stems can be removed and the smoke softness is improved. The thinly pressing and cutting mode is adopted, so that the physical forms of the formed cut stems are threadlike and are closer to cut tobaccos. The flash evaporation, expansion and drum drying mode is adopted for drying of the cut stems, so that the cut stems are better in crimpiness and are closer to the form of the cut tobaccos and the filling capability of the cut stems can be improved. The cut steams produced by the production process has the advantages that the filling value is high, the impurity gases in the tobacco stems are reduced, the fragrance is increased, cigarettes can be endowed with a certain burned sweet fragrance, the physical forms of the cut stems are closer to the cut tobaccos, and the suitability is better in the cigarettes.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

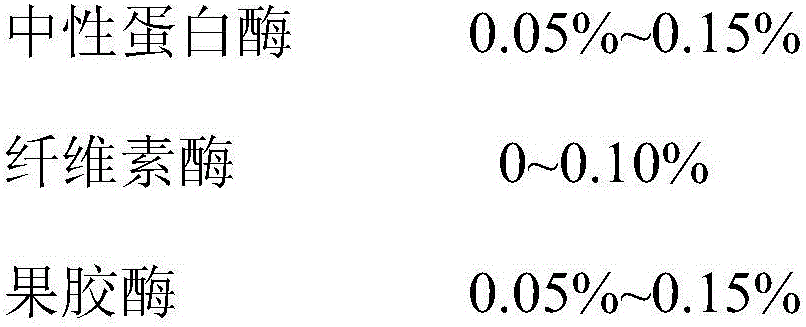

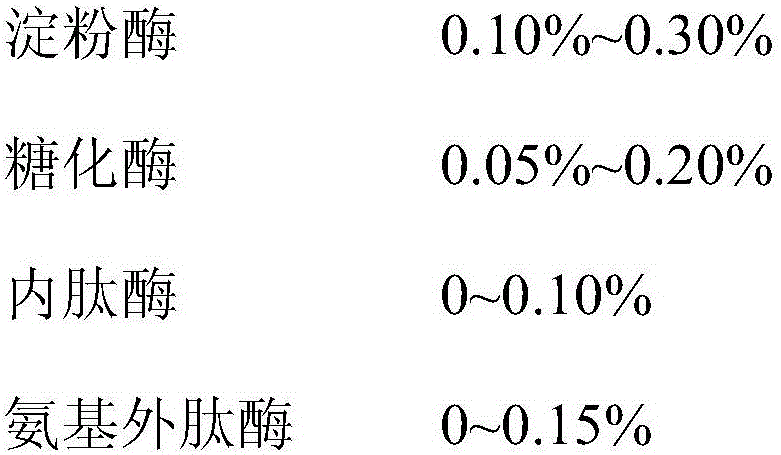

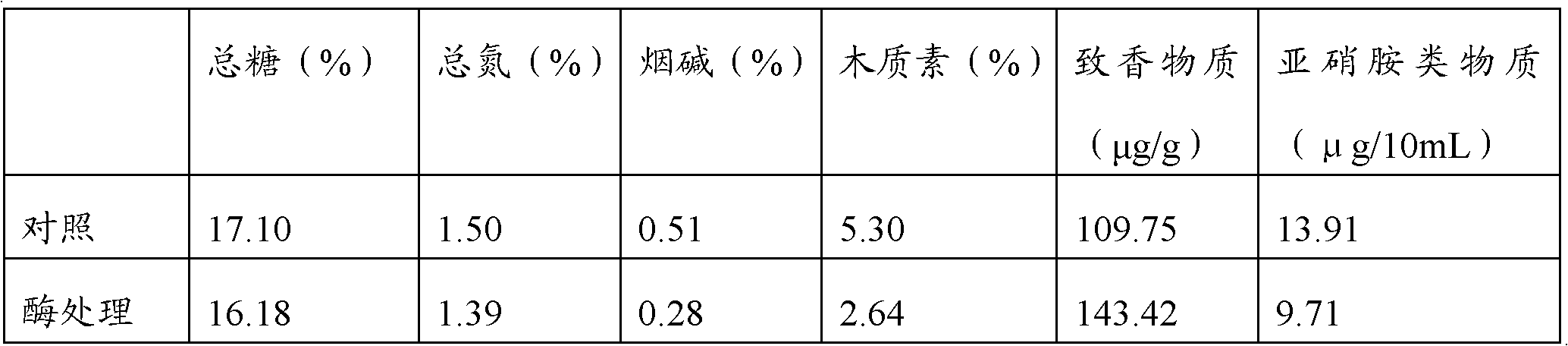

Complex enzyme preparation for tobacco stalk treatment and tobacco stalk treatment method

The invention relates to a complex enzyme preparation for tobacco stalk treatment and a tobacco stalk treatment method. The complex enzyme preparation for the tobacco stalk treatment comprises the following raw materials in percentage by weight: 1-4% of neutral protease, 1-4% of cellulose, 1-4% of pectinase, 3-8% of laccase, 1-2% of nicotine dehydrogenase and the balance of water. The complex enzyme preparation can be used for treating tobacco stalks by virtue of synergistic effects of complex enzyme systems, so that stalk wax, grease, pectic substance, starch, protein, cellulose and xylogen in the tobacco stalks are partially degraded. Since the structure and components of the tobacco stalk are varied, the physicochemical properties are varied. Therefore, the purposes of reducing woodiness gas and pungent smell of cigarettes, improving smoking taste, and increasing internal and external qualities can be achieved.

Owner:南宁雄晋生物科技有限公司

Application of astragalus extract in stem strings or reproduced tobaccos

The invention discloses application of an astragalus extract in stem strings or reproduced tobaccos. The application is characterized in that the astragalus extract is added into the stem strings or the reproduced tobaccos, so that the wood gas and the irritation of the stem strings or the reproduced tobaccos can be obviously reduced, the doping rate of the stem strings or the reproduced tobaccos in a medium-grade and high-grade cigarette formula is increased, and the smoke quality of cigarettes is not influenced; and the astragalus extract is prepared from astragalus by the process of solvent soaking, extraction and concentration. The application has the outstanding characteristics that new astragalus application is developed by the conventional solvent and the common extraction method; and a new natural stem flavoring agent is provided.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

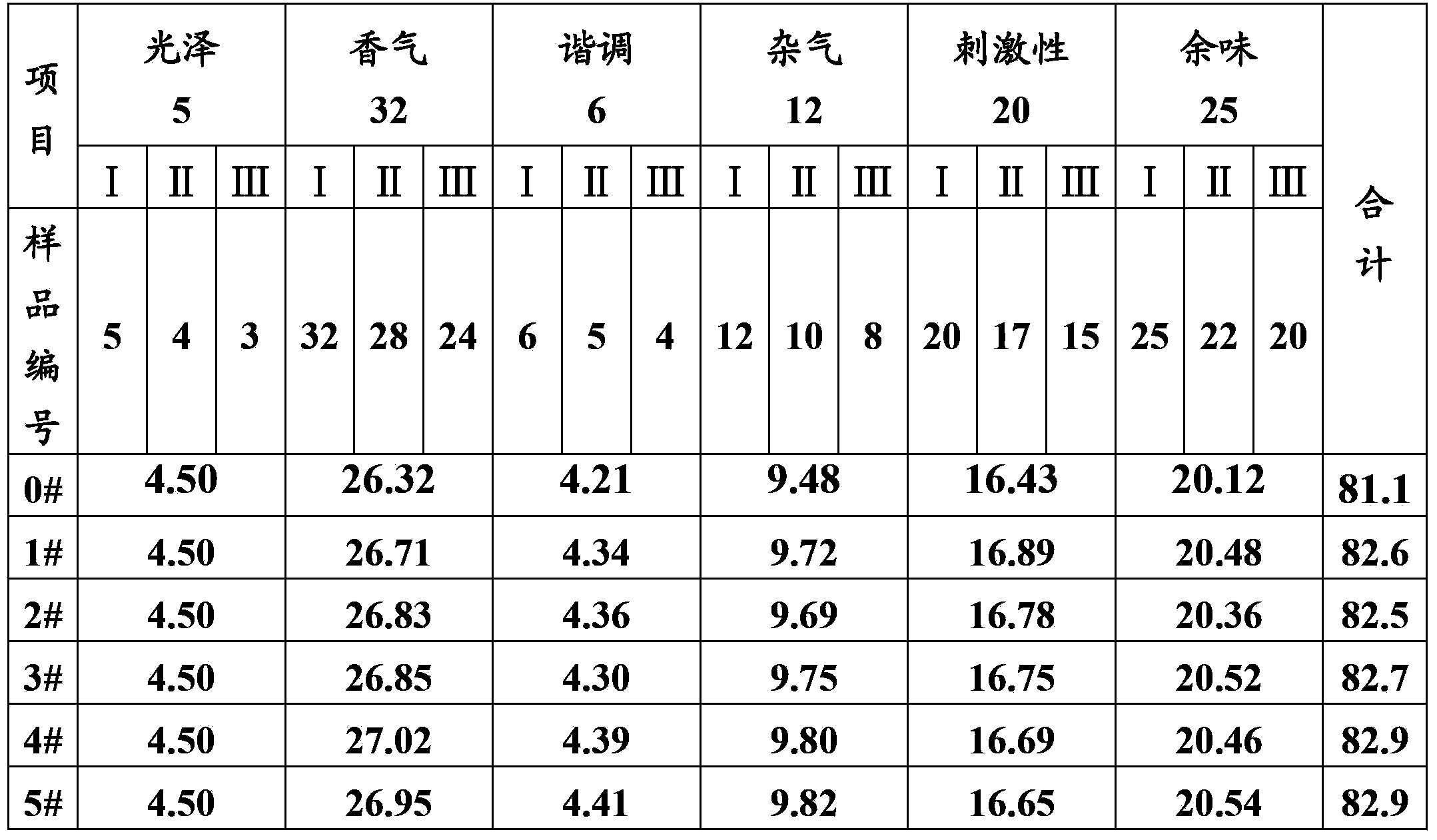

Method for preparing tobacco sheet through enzymolysis extraction-Maillard reaction composite technology

InactiveCN105077571AQuality improvementImprove extraction efficiencyTobacco treatmentMaillard reactionChemical composition

The invention discloses a method for preparing a tobacco sheet through an enzymolysis extraction-Maillard reaction composite technology. The method comprises the following specific steps: carrying out enzymolysis extraction simultaneously on tobacco powder in water, carrying out solid-liquid separation, concentrating the enzymolysis liquid, adding with reducing sugar and amino acid and carrying out Maillard reaction at 70 DEG C, uniformly coating paper base with the reaction liquid, drying, and shredding, and thus obtaining the tobacco sheet. With the adoption of the enzymolysis extraction-Maillard reaction composite technology, the advantages of the preparing process of the tobacco sheet through the paper-making process are exerted, meanwhile, the two technological means of the enzymolysis and the Maillard reaction are comprehensively utilized, so that the extraction efficiency of the tobacco aroma materials is improved, and moreover, the chemical components of tobacco are selectively changed, so that the purposes of aroma enhancement and harm reduction are achieved, and therefore, the method has the incomparable advantages.

Owner:CHINA TOBACCO GUANGXI IND +1

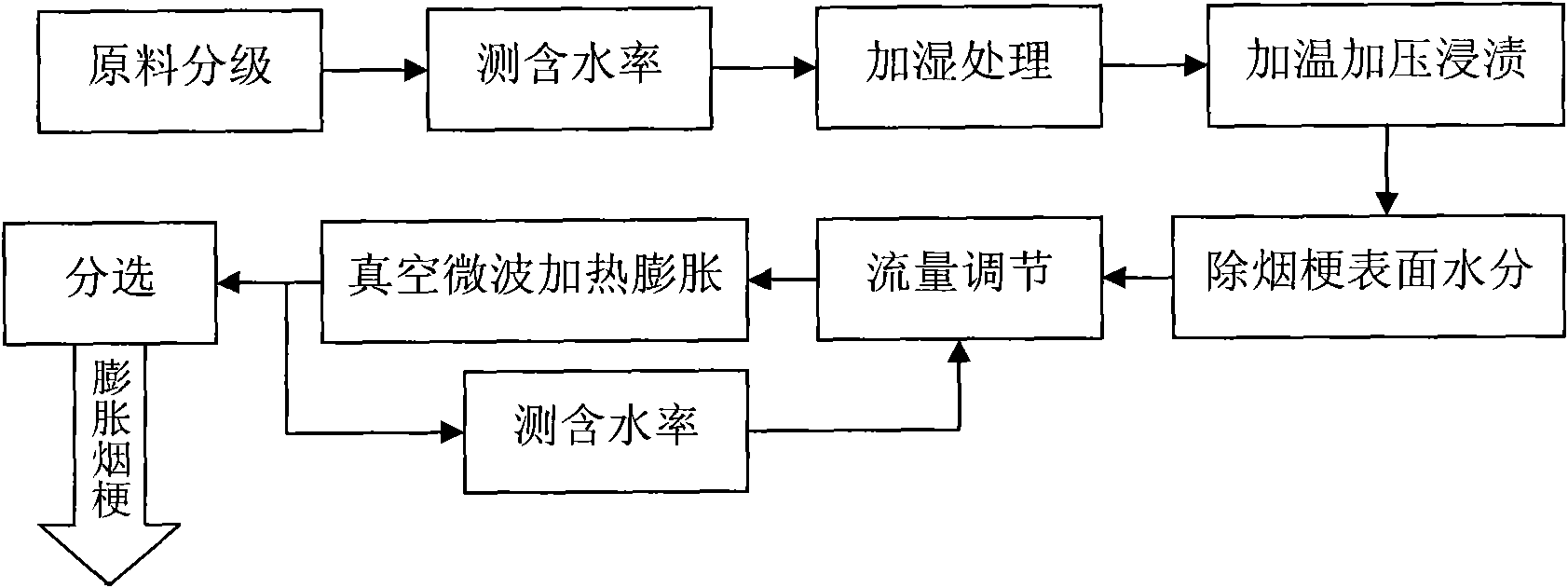

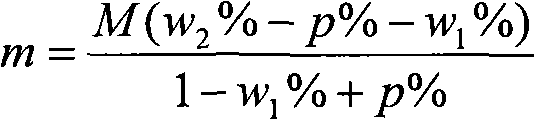

Tobacco stalk expansion method

InactiveCN101862023AUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Tea flower fragrance combination and lined paper coated with same

ActiveCN103510425AElegant Tea Tree Flower ScentRich aromaNon-fibrous pulp additionPaper coatingAlcoholAntioxidant

The invention relates to tea flower fragrance combination and lined paper coated with the same. The combination comprises the constituents in percentage by weight: 5 to 25 percent of a tea flower extractive, 10 to 25 percent of ethyl alcohol, 0.05 to 2 percent of a thickener, 0.01 to 0.3 percent of a pH conditioning agent, 0.01 to 0.2 percent of an antioxidant, and the balance of water. The tobacco wrapping paper can be coated with the combination, and the lined paper coated with the combination has elegant tea flower fragrance, changes the micro ageing environment of cigarettes, so that a cigarette case is full of fragrance, the fragrance of cigarettes is improved, and the elegant tobacco case unpacking fragrance is provided for consumers.

Owner:CHINA TOBACCO FUJIAN IND +1

Reproduced tobacco by adding tea

A regenerated tobacco product containing tea for cigarette is composed of the basic material prepared proportionally from the leaf and stem of tobacco and tea and the tea extract chosen from tea extract, tea tincture, tea oil and tea essence. It can decrease the tar in cigarette.

Owner:李荣 +1

Method for preparing flue-cured flavor reconstituted burley tobacco leaves

ActiveCN106333383AReduce mistLess irritatingTobacco preparationTobacco treatmentChemical reactionIrritation

The invention provides a method for preparing flue-cured flavor reconstituted burley tobacco leaves. The reconstituted burley tobacco leaves are prepared according to the following steps of mixing an extracting solution obtained by means of performing water extraction on a burley tobacco material with an extracting solution obtained by means of performing water extraction on flue-cured tobacco stems, and concentrating the mixed solution into a coating solution; mixing filter residues obtained after the water extraction on the burley tobacco material with filter residues obtained after the water extraction on the flue-cured tobacco stems, making the mixture into a thin sheet by utilization of a papermaking method, and then coating the coating solution on the thin sheet; respectively adding a special compound enzyme preparation and an auxiliary during a water extraction process, a concentration process and a pulp making process. The method provided by the invention has the advantages that excessive macromolecular substances, such as proteins, pectin and the like, in burley tobacco raw materials (such as tobacco leaves, tobacco waste, fragments and the like) are pointedly reduced by utilization of the compound enzyme preparation, and a biochemical reaction is combined, so that the aroma is enhanced, the quality is promoted, numerous disadvantageous odor on flue-cured cigarettes from burley flue gas can be radically eliminated, meanwhile the extraction efficiency is improved, and offensive odor and irritation generated after the combustion of the reconstituted tobacco leaves are reduced.

Owner:HUBEI CHINA TOBACCO IND

Tobacco flavor prepared from liquorice fermentation and application of tobacco flavor

ActiveCN104223352AImprove comfortIncrease aromaTobacco treatmentMicroorganism based processesPhenethyl alcoholFood flavor

The invention discloses a tobacco flavor prepared from liquorice fermentation and application of the tobacco flavor. A dominant microorganism is separated from fresh tobacco leaves of flue-cured tobacco, and the classification name of the dominant microorganism is Lodderomyces elongisporus. CGMCC 6645; the Lodderomyces elongisporus is inoculated into a culture medium, taking liquorice as a raw material, for fermentation cultivation; a fermentation product after culture has a natural fragrance, and contains various aroma components, such as 2,4-resacetophenone, 2,4,5-methylphenol, 3,4-dimethyl benzyl alcohol and phenethyl alcohol. The tobacco flavor is added to tobacco shreds, and thus, the aroma and the moistening effect of a cigarette can be enhanced, and the cigarette quality is improved; the sweetness of smoke is rich, local offensive odor and wood odor are reduced, the throat comfort is enhanced, the remaining taste is comparatively comfortable, and the mouth astringency is strong; the whole production process for the tobacco flavor is simple and practical, and the tobacco flavor has a good application prospect.

Owner:CHINA TOBACCO YUNNAN IND

Sheeting method for suncuring tobacco

InactiveCN1631275AImprove endoplasmReduce woodinessTobacco treatmentEngineeringPreparation procedures

Disclosed in a sheeting method for suncuring tobacco which comprises a stock preparation procedure, which employs time delayed collection to increase the defoliation maturity, a tendon pulling out procedure to extract the main tendon after fresh tobacco picking up, a sun curing procedure which employs two-stage solarizing process in the yellow-turning phase and the dry plate color deciding phase.

Owner:WUHAN TOBACCO GROUP

Method for increasing smoking quality of papermaking-reconstituted slices

InactiveCN102423117AIncrease the amount of aromaReduce volatilityTobacco preparationIrritationChemistry

The invention relates to a method for increasing the smoking quality of papermaking-reconstituted slices by utilizing tobacco flavor precursors, which belongs to the field of tobacco slice processing. Specifically, the flavor precursors can give certain style characteristics to slices, remarkably increase the aroma of slices, reduce wood gas, decrease irritation and improve the smoking quality. The method is characterized in that the method is implemented by adding one or more types of tobacco flavor precursors into slice coating. The method of adding the tobacco flavor precursors effectively increases the aroma of slices, reduces wood gas, decreases irritation, improves aftertaste, increases comfort, and provides an effective approach for the improvement of the smoking quality of slices.

Owner:HONGTA TOBACCO GRP

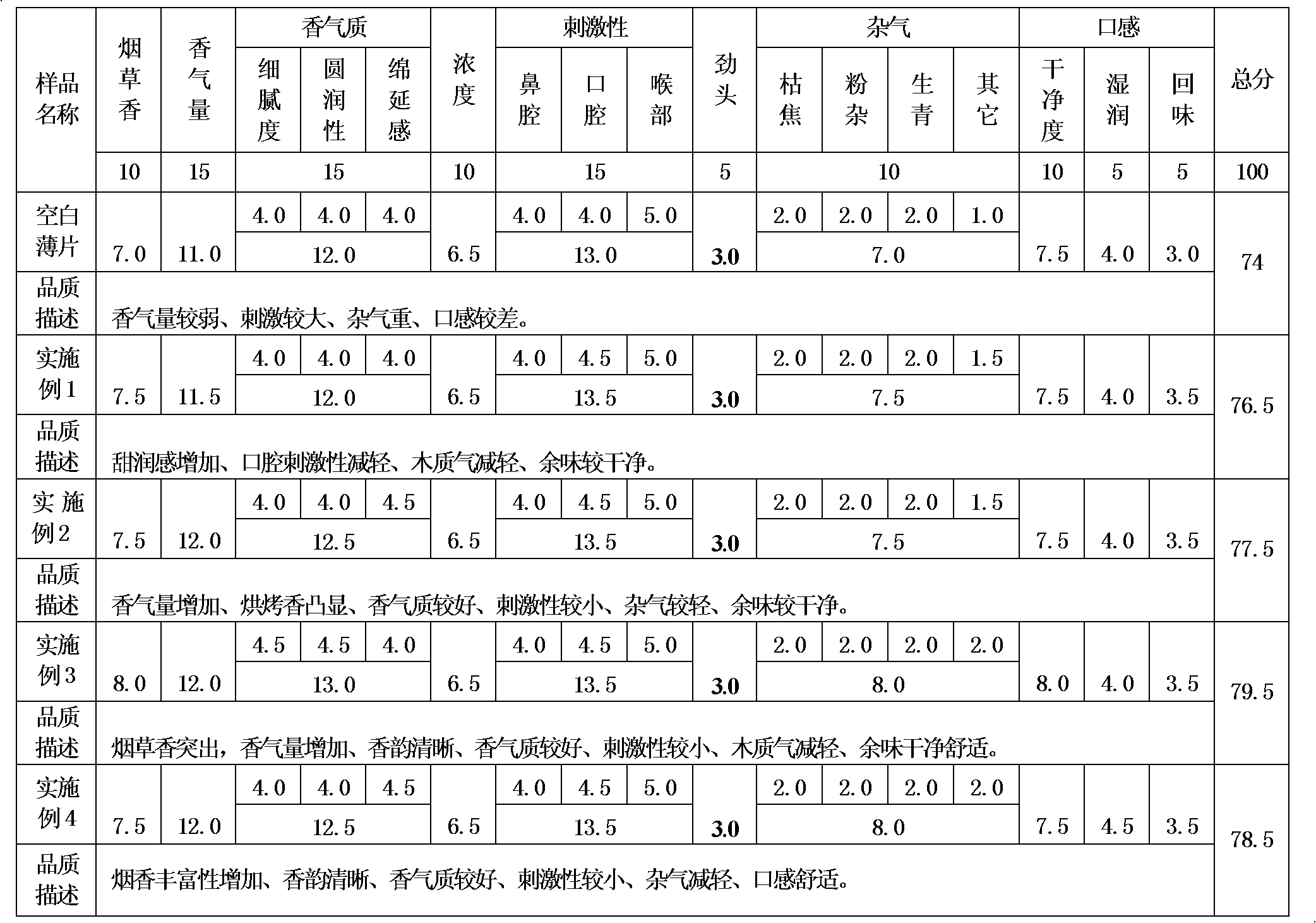

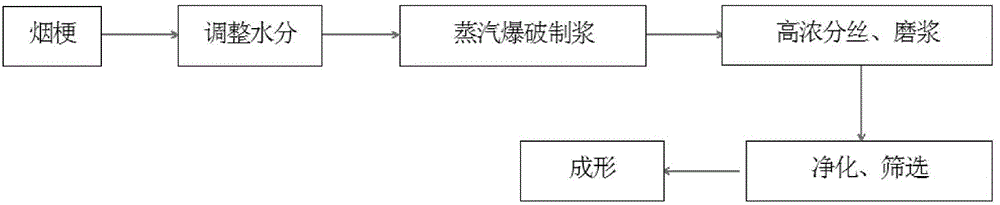

Preparation method of tobacco fiber for cigarette paper

InactiveCN104687236AReduce woodinessIncrease the content of aroma substancesTobacco preparationHigh concentrationFiber

The invention provides a preparation method of tobacco fiber for cigarette paper. Tobacco stems tobacco stalks containing 6%-60% of water are subjected to steam explosion pulping through saturated steam or coupling steam formed by mixing the saturated steam and high-pressure air under the pressure smaller than or equal to 3MPa for 5s-20min, and then are subjected to high-concentration shred division, defibrination, screening and purification to be prepared into tobacco fiber pulp, the tobacco fiber pulp accounting for less than 60% of cigarette paper pulp in mass percentage is added to the cigarette paper pulp, papermaking is performed, and then the cigarette paper containing the tobacco fiber is prepared. According to the preparation method, the proportion of wood pulp in the cigarette paper can be reduced, offensive wood odor generated during combustion of the cigarette paper can be reduced, the cigarette paper contains the fiber in tobacco color, and the matching attribute of the cigarette paper and a cigarette style is improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

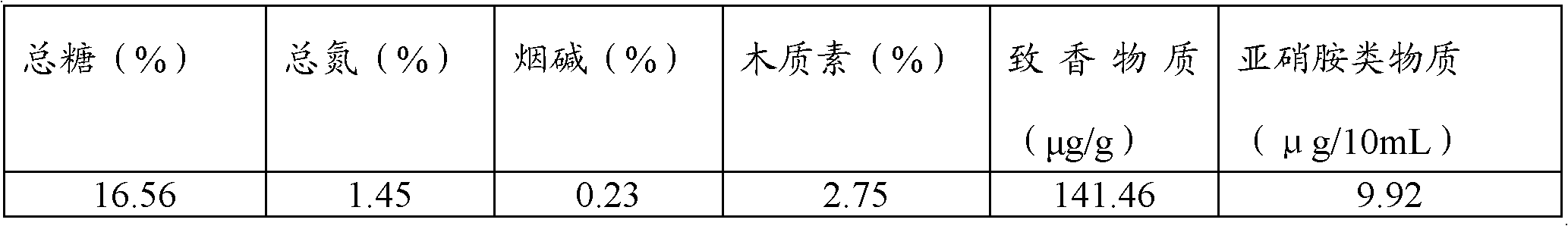

Method for improving softness and sensory quality of reconstituted tobacco by white rot fungus enzyme solution

The invention discloses a method for improving softness and sensory quality of reconstituted tobacco by white rot fungus enzyme solution. Steps before and after a pulping phase of raw tobacco stem can be finished according to the existing technological process. The white rot fungus T42 enzyme solution accounting for 1.0-10.0% of dry weight of the raw tobacco stem is proportionally added during the pulping phase of the raw tobacco stem in production of the reconstituted tobacco. Lignin in the tobacco stem pulp is degraded at the stem pulp temperature of 30-80 DEG C under the pH value of 2.0-6.0 for 20-90 minutes. A strain of the white rot fungus T42 is named as coriolus versicolor T42 under the preservation number of CCTCC (china center for type culture collection) NO. M2012252. The method is reasonable, convenient to operate, evidently effective and capable of evidently improving softness of the reconstituted tobacco, sensory quality of the reconstituted tobacco is improved, wood gas is reduced, and irritation is reduced.

Owner:HUBEI CHINA TOBACCO IND +1

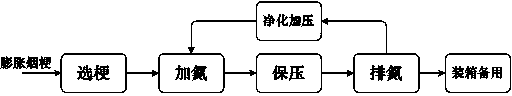

Treatment process for expanded tobacco stems

The invention relates to a treatment process for expanded tobacco stems, and belongs to the technical field of main material and auxiliary material processing in the tobacco industry. The microwave expanded tobacco stems are classified according to the thickness and / or the length, the expanded tobacco stems are placed into a pressure vessel, nitrogen with the purity being larger than 78% is connected into the pressure vessel, the tobacco stems and the nitrogen are evenly mixed, the pressure in the vessel is normal pressure to 8 MPa, the pressure is kept for 10 seconds to 40 minutes, the nitrogen in the pressure vessel is exhausted, the nitrogen can be recycled after purification and compressing treatment, the expanded tobacco stems after treatment are taken out, and the expanded tobacco stems are boxed or bagged in a classified mode for standby application; or moisture regain is conducted directly, so that products such as stem shreds, stem strip shreds and stem particles are manufactured. The microwave expanded tobacco stems treated through the process do not need to be stored any more, wooden odors and offensive odors in the tobacco stems are reduced, the tobacco stems cannot retract after moisture regain, and good elasticity and processing resistance are achieved. By means of the treatment process for the expanded tobacco stems, the requirement for the conditions such as warehouse space, manpower and logistics in the storage link is met, and therefore enterprise cost is greatly lowered.

Owner:姚波

Method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology

InactiveCN101933655AFluffy structureImprove the smoke effectTobacco preparationTobacco treatmentProcess engineeringAnaerobic microorganisms

The invention discloses a method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology. The method comprises the following steps of: performing steam explosion on tobacco stalks by using a steam exploder; placing the exploded tobacco stalks in a sealed container, adding anaerobic microorganisms into the container and forming an anaerobic environment in the container to perform anaerobic treatment by vacuuming or filling the container with an inert gas; taking the tobacco stalks out of an anaerobic treatment container and quickly dehydrating at the low temperature to control water content to be about 20 to 30 percent; and finally slicing the dehydrated tobacco stalks for the production of cigarette. The method can improve the amount of the tobacco stalk added during the production of the cigarette on the premise of not influencing the aesthetic quality of the cigarette, so that the cigarette cost is effectively reduced.

Owner:CHINA TOBACCO CHUANYU IND

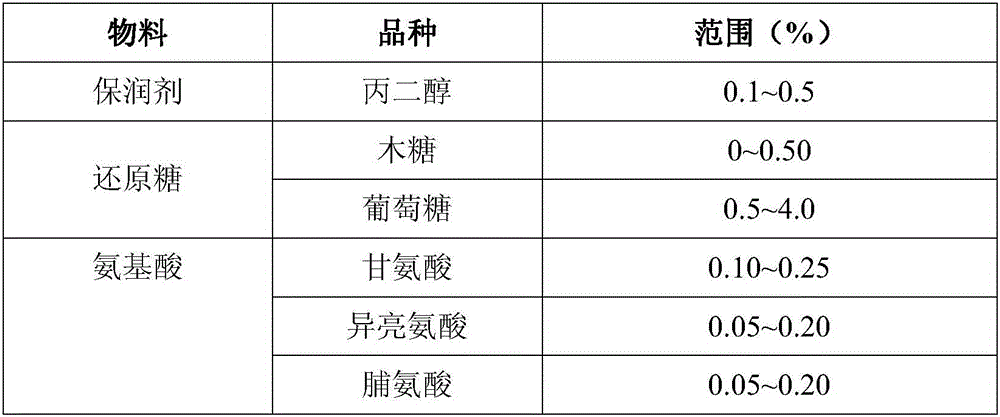

Coating liquid for tobacco sheet cigarette paper

ActiveCN105040518AIncrease contentProduct quality, safety and stabilityNon-fibrous pulp additionPaper/cardboardMaillard reactionIrritation

The invention discloses a coating liquid for tobacco sheet cigarette paper. The coating liquid is prepared from a toner, a combustion improver and a spice, wherein the toner is prepared by the following steps: (1) adding water to tobacco leaf waste, decocting, extracting, adding saccharomycetes and protease to an extracted liquid for fermentation, concentrating the fermented liquid, adding ethanol, standing, taking a supernatant liquid, recovering the ethanol and carrying out vacuum concentration to form clear paste; and (2) adding hot water, revertose and amino acid to the clear paste, carrying out maillard reaction, ending the reaction, and concentrating a reaction liquid, so as to obtain the coating liquid. According to the coating liquid disclosed by the invention, the wood gas, the offensive odor and the oral irritation of the tobacco sheet cigarette paper can be reduced; the fragrance of the tobacco sheet cigarette paper can be increased; the smoke panel test result is improved; and meanwhile, the cigarette paper can also be dyed by the coating liquid instead of a natural pigment.

Owner:HUBEI CHINA TOBACCO IND

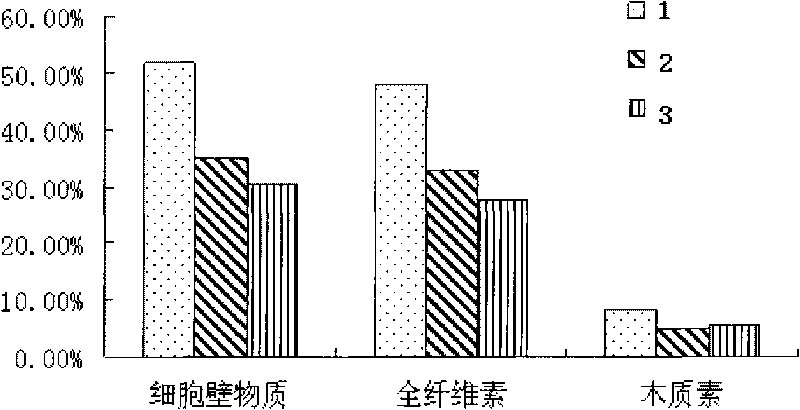

Method for treating tobacco stem

The invention relates to the field of tobacco, and more particularly relates to a method for treating tobacco stem, comprising the steps of: soaking the tobacco stem into the mixed solution of NH3.H2O and H2O2; filtering and washing filter residue; and roasting the washed filter residue. The invention also provides the best technical condition for the treatment of the tobacco stem: the tobacco stem is soaked into the mixed solution of 1.5% of NH3.H2O and 1.0% of H2O2 for 1h at 60 DEG C; and the ratio between liquid and material is 1:10. Compared with the untreated tobacco stem, the treated tobacco stem respectively reduces the content of cell wall material, lignin and total nitrogen by 12.71%, 2.14% and 1.24%; the filling quantity is increased, and impurity gas is reduced by sensory smoking; therefore, the method not only can increase the filling quantity of the tobacco stem, but also obviously reduces the content of lingo-cellulose the smell of lignin of the tobacco stem and improves the using value thereof, thus having industrial application prospect.

Owner:CHINA TOBACCO GUANGDONG IND

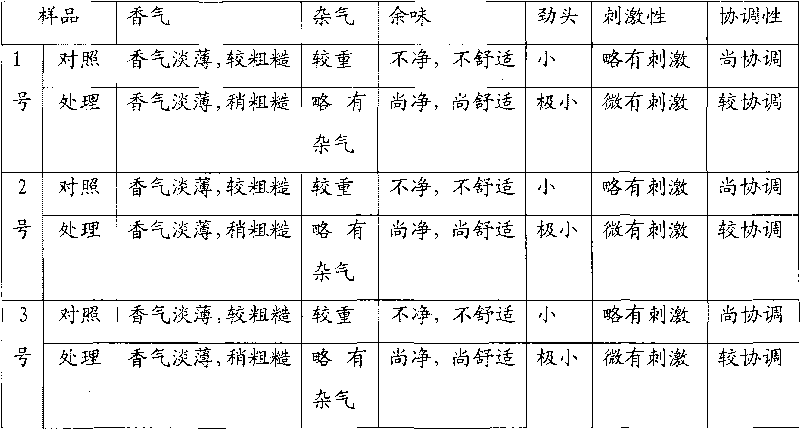

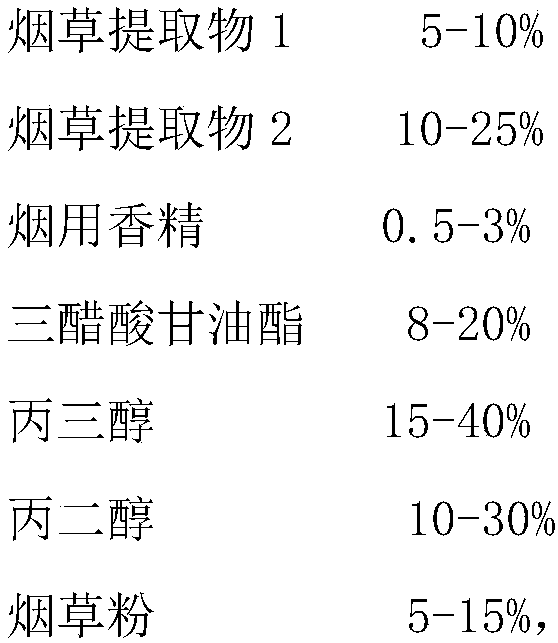

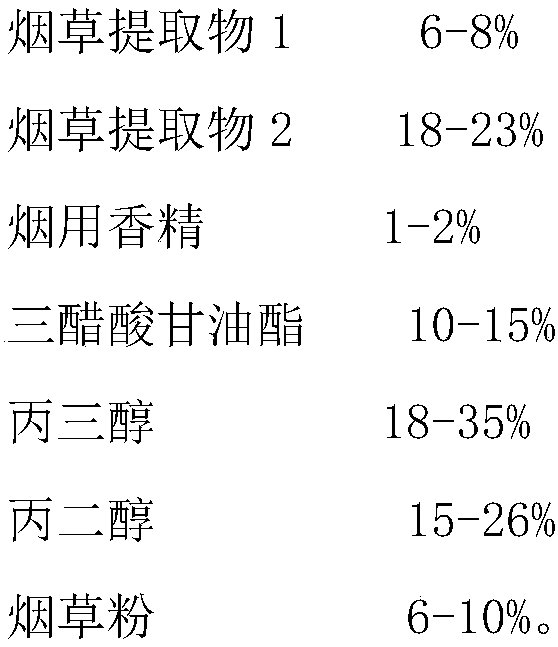

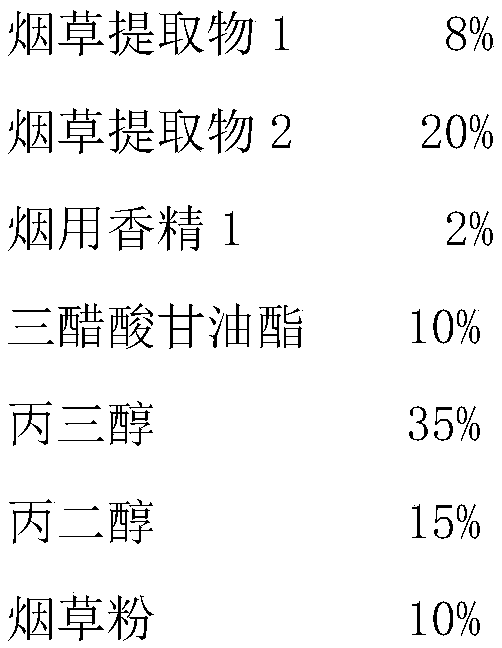

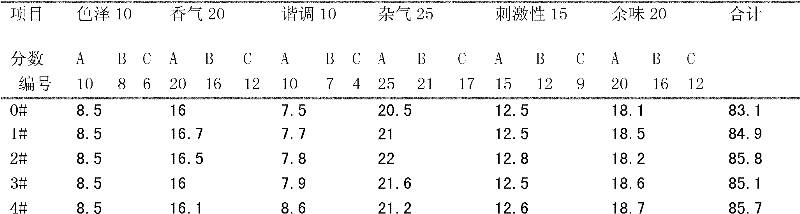

Formula of essence for heat-not-burn cigarette

InactiveCN108893195AReduce woodinessLess irritatingTobacco preparationEssential-oils/perfumesAlcoholDistilled water

The invention provides a formula of an essence for a heat-not-burn cigarette. The essence is prepared from the following components in percentage by mass: 5-10 percent of tobacco extract 1, 10-25 percent of tobacco extract 2, 0.5-3 percent of tobacco essence, 8-20 percent of glycerol triacetate, 15-40 percent of glycerol, 10-30 percent of propylene glycol and 5-15 percent of tobacco powder, wherein the tobacco extract 1 is prepared by grinding tobacco threads or stem threads, screening and selecting particles having 25-100 meshes, adding a water and alcohol mixed solvent for ultrasonic extraction, filtering and concentrating supernatant liquid; the tobacco extract 2 is prepared by adding distilled water into the tobacco extract 1 in a solid-liquid ratio being 1:1-1:1.2, adding ethanol alcohol in a volume ratio of 50-80 percent, sufficiently mixing, refrigerating, filtering and concentrating. The essence prepared from the formula can be used for improving the sensing quality of the heat-not-burn cigarette, weakening the wooden smell and enhancing the tobacco fragrance, so that the smoking experience of users can be further promoted.

Owner:NANTONG JIN YUAN NEW MATERIALS CO LTD

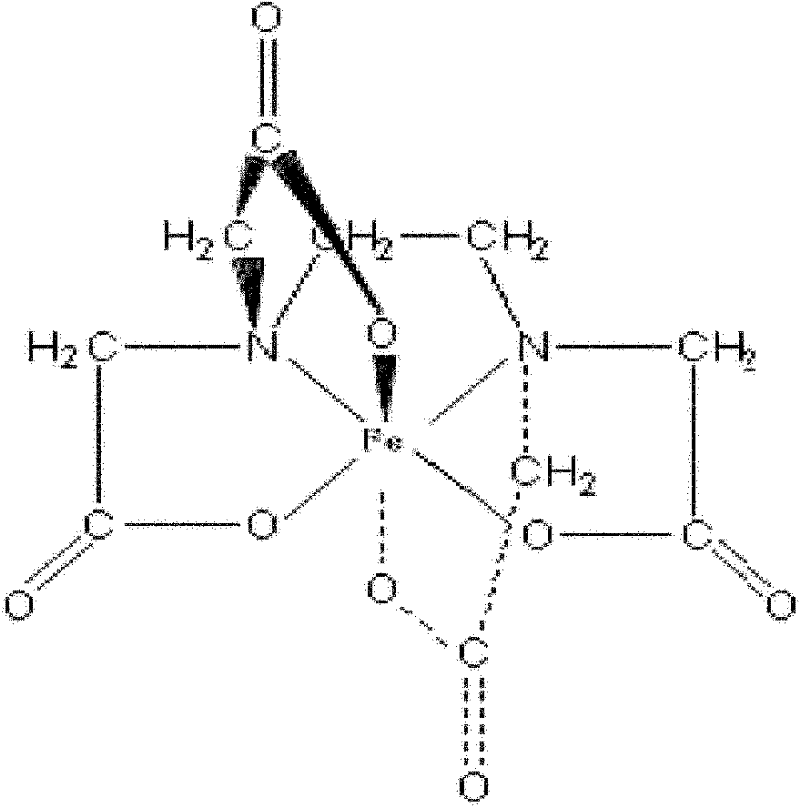

Method for reducing content of lignin in papermaking tobacco sheets

InactiveCN102631023ALow lignin contentImproved taste qualityTobacco treatmentIron organic compoundsDry weightCitric acid

The invention discloses a method for reducing the content of lignin in papermaking tobacco sheets, belonging to the technical field of cigarette tobacco sheets. The method comprises the following step: at the tobacco raw material pulping state of the papermaking tobacco sheet production process, adding mimic enzyme according to a proportion of 1-6.5% of the dry weight of tobacco pulp material, wherein the temperature of the tobacco pulp material during the addition of the mimic enzyme is 25-40 DEG C, and after the addition, the temperature is kept for 20-40 minutes. The mimic enzyme formula comprises the following components by weight percent: 10-35% of FeSO4.7H2O, 5-20% of citric acid, 2-15% of oxalic acid and 20-60% of water. The mimic enzyme is obtained by the following steps: firstly adding the FeSO4.7H2O in the water at the temperature of 25-45 DEG C; then adding citric acid and oxalic acid; and mixing uniformly. The method provided by the invention is simple to operate and marked in effect, and is capable of decreasing the content of the lignin in the papermaking tobacco sheets and enhancing the smoking quality.

Owner:HUBEI XINYE TOBACCO SLICE DEV

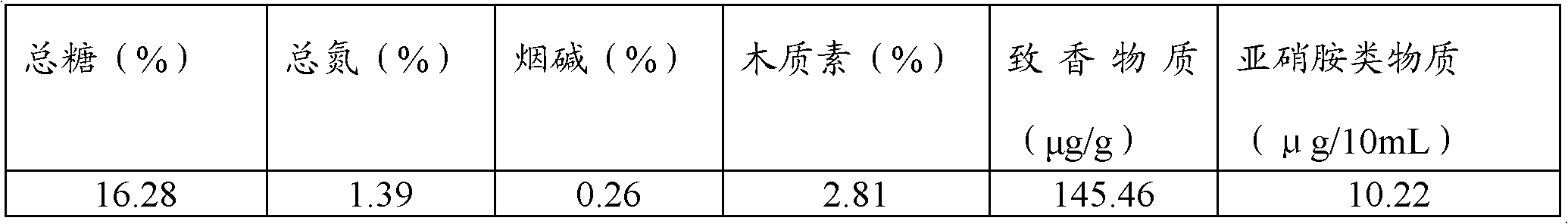

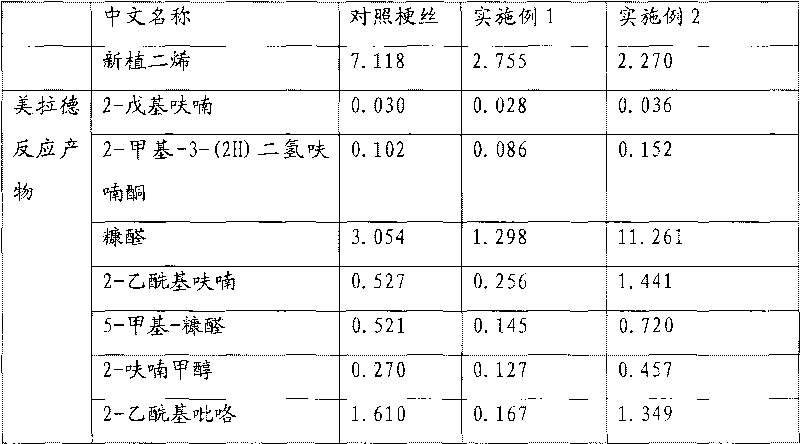

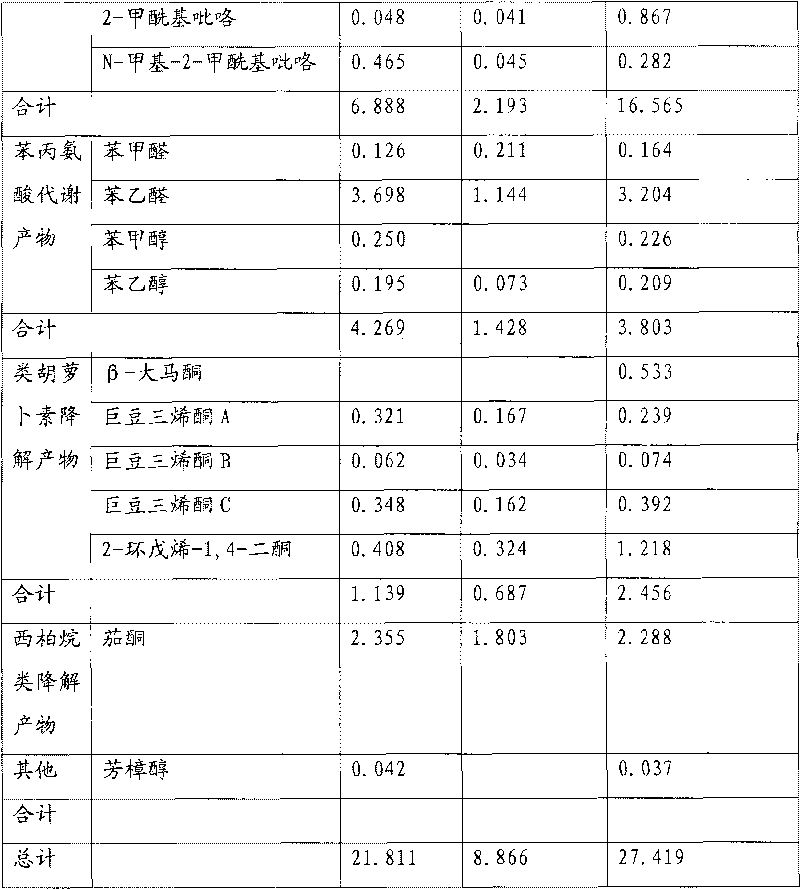

Process for treating cut stems of tobacco leaves

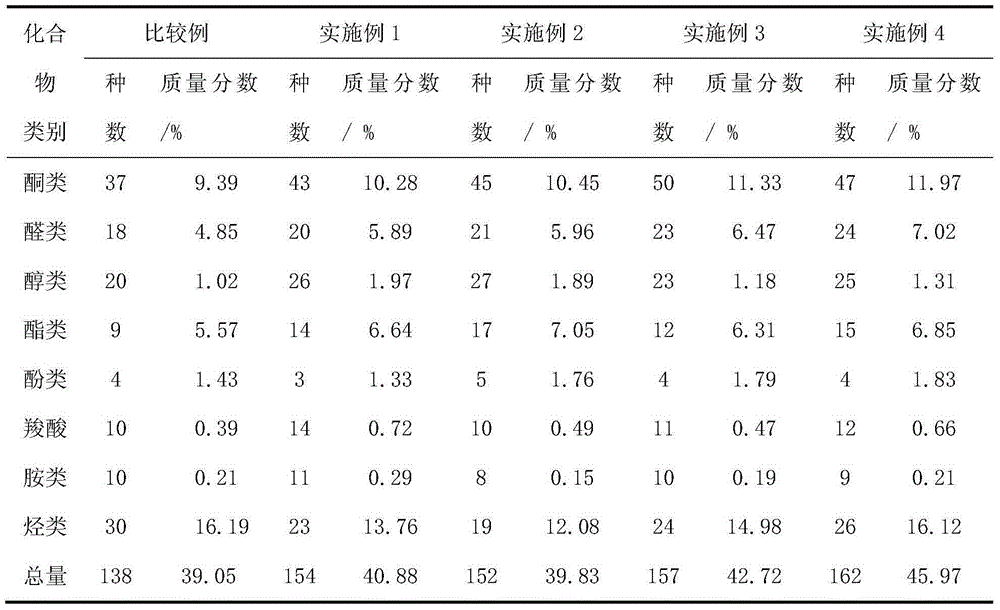

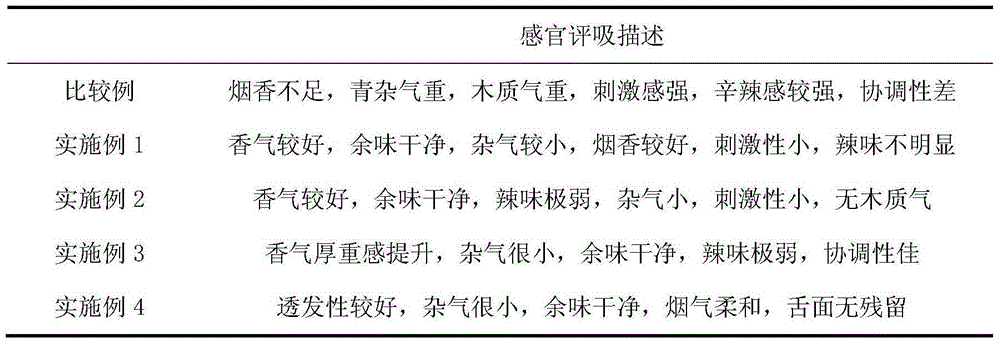

The invention relates to the field of tobacco, in particular to a method for treating cut stems of tobacco leaves. The method comprises the steps of reducing the content of cell wall substances through H2O2 and ammonia, improving the reactivity of the cut stems with an enzyme, further utilizing the compound enzyme for catalytic degradation of proteins, starch, cellulose and other macromolecules, generating an aroma precursor, sugar and amino acids and further generating aroma substances by further decomposition. The adoption of the method for treating the cut stems can improve the filling value by 27.6%, improve the sugar / nicotine ratio by 49.5% and reduce the content of the cell wall substances by 42.3%, and the analysis of main aroma components shows that the total content of the aroma components is improved by 25.7%, wherein the content of Maillard reaction products is improved by 140.5%, and the content of carotenoid degradation products is improved by 115.6%. The sensory evaluation shows that the effects of reducing wood flavor, reducing irritation, increasing aroma quantity and leading the smoke to be coordinated and thicker can be realized after the treatment of the cut stems of the tobacco leaves by using the method, indicating that the method has good application prospect in the tobacco industry.

Owner:CHINA TOBACCO GUANGDONG IND

Method for preparing cigarette blast by further performing Maillard reaction on internal flavor after forming

InactiveCN109536280ACompact structurePenetrability canTobacco preparationTobacco treatmentMaillard reactionCross-link

The invention provides a method for preparing cigarette blast by further performing a Maillard reaction on an internal flavor after forming. The method for preparing the blast comprises the followingsteps: weighing purified water, adding reducing sugar and amino acids, adding CaCO3 or CaCl2 or Ca(NO3)2, then adding an emulsifier, performing uniform mixing, and emulsifying the obtained mixture andblast flavor essential oil under a high-speed homogenization condition; preparing an aqueous solution of sodium alginate, adding polysaccharides or low-acyl gellan gum or glycerin, and adding a surfactant to prepare a blast forming solution; and rotating or circularly flowing the blast forming solution under a magnetic stirring condition, dropwise adding the prepared flavor emulsion into the blast forming solution by using a peristaltic pump or an injection pump, allowing the flavor emulsion to grow for 3-10 min, taking out and washing the grown flavor emulsion, cross-linking the grown flavoremulsion in a cross-linking solution, and drying the cross-linked flavor emulsion in a microwave oven when gel skins are in a wet state in order to obtain the finished blast. The tobacco blast prepared in the invention has the advantages of good forming effect, no loss of the fragrance, realization of harmony with the smoke fragrance after being broken, effective improvement of the quality of low-grade tobacco, reduction of the woody gas, and enhancement of the smoke fragrance.

Owner:HUBEI CHINA TOBACCO IND +1

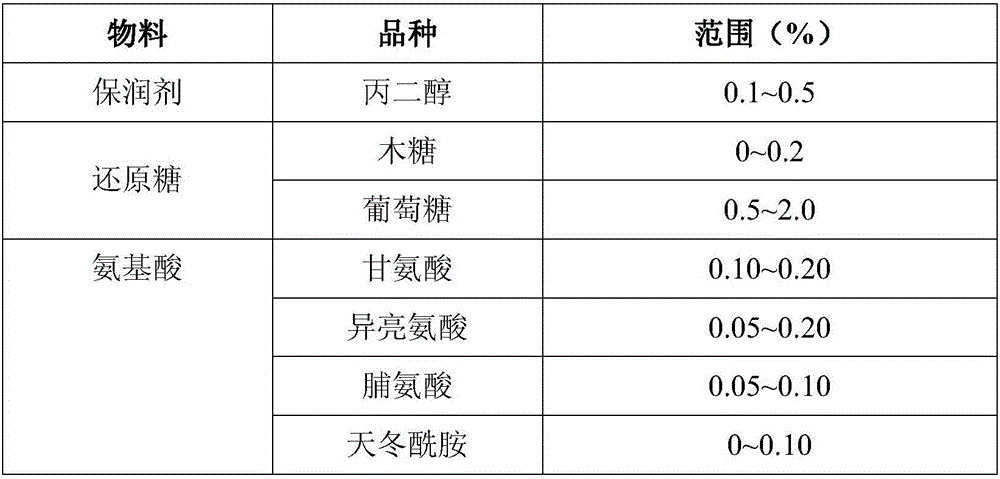

Method for manufacturing low-nicotine reconstituted tobacco leaves by taking Maryland tobaccos as raw materials

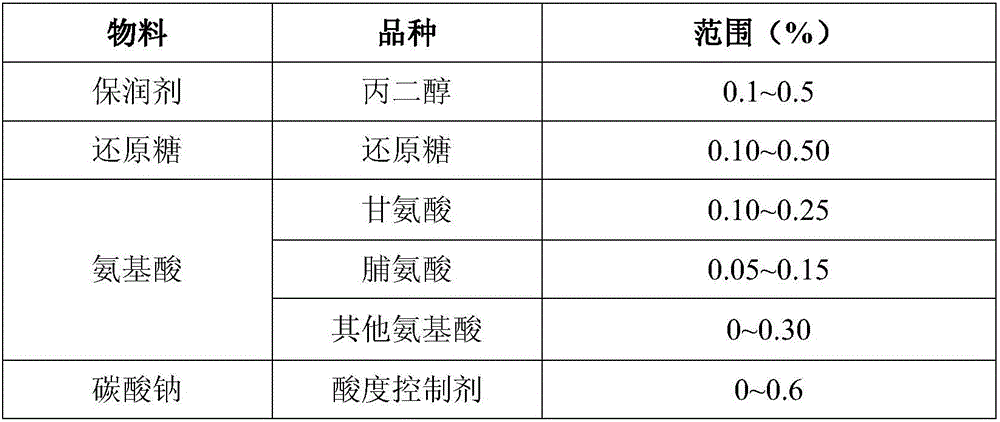

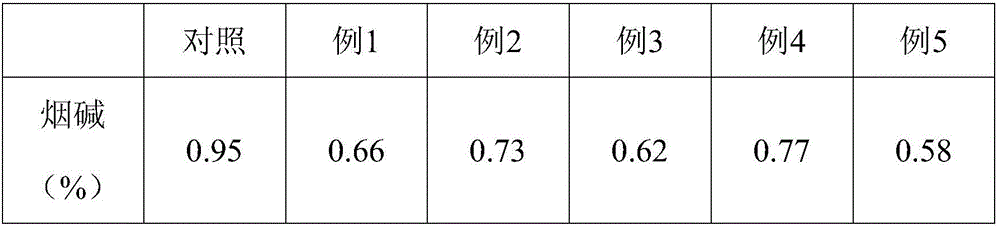

The invention provides a method for manufacturing low-nicotine reconstituted tobacco leaves by taking Maryland tobaccos as raw materials. The low-nicotine reconstituted tobacco leaves are manufactured by the following steps: mixing tobacco leaf fragments or powder of the Maryland tobaccos with water, and adding a mixture into a raw material extracting tank; controlling the temperature to be 25 DEG C to 50 DEG C; then adding a compound enzyme preparation for extracting; adding tobacco stems of the Maryland tobaccos and water into another raw material extracting tank; controlling the temperature to be 65 DEG C to 75 DEG C and carrying out water extraction; after combining a tobacco leaf extracting solution and a tobacco stem extracting solution, putting a mixed solution into a concentration tank; adding propylene glycol, reducing sugar, amino acids and sodium carbonate and decompressing and concentrating at the temperature of 70 DEG C to 90 DEG C to prepare a coating solution; after mixing and pulping a tobacco leaf extracting solid substance and a tobacco stem extracting solid substance, papermaking to obtain a reconstituted tobacco leaf substrate; coating the coating solution on the reconstituted tobacco leaf substrate and drying to prepare the low-nicotine reconstituted tobacco leaves. According to the method provided by the invention, macromolecular substances including proteins, pectin and the like in the Maryland tobaccos are reduced; a biochemical reaction is combined and aroma and quality are improved; the high-tobacco-aroma and low-nicotine reconstituted tobacco leaves are prepared.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com