Tea flower fragrance combination and lined paper coated with same

A technology of tea tree flower extract and composition, applied in the direction of coating, papermaking, paper coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

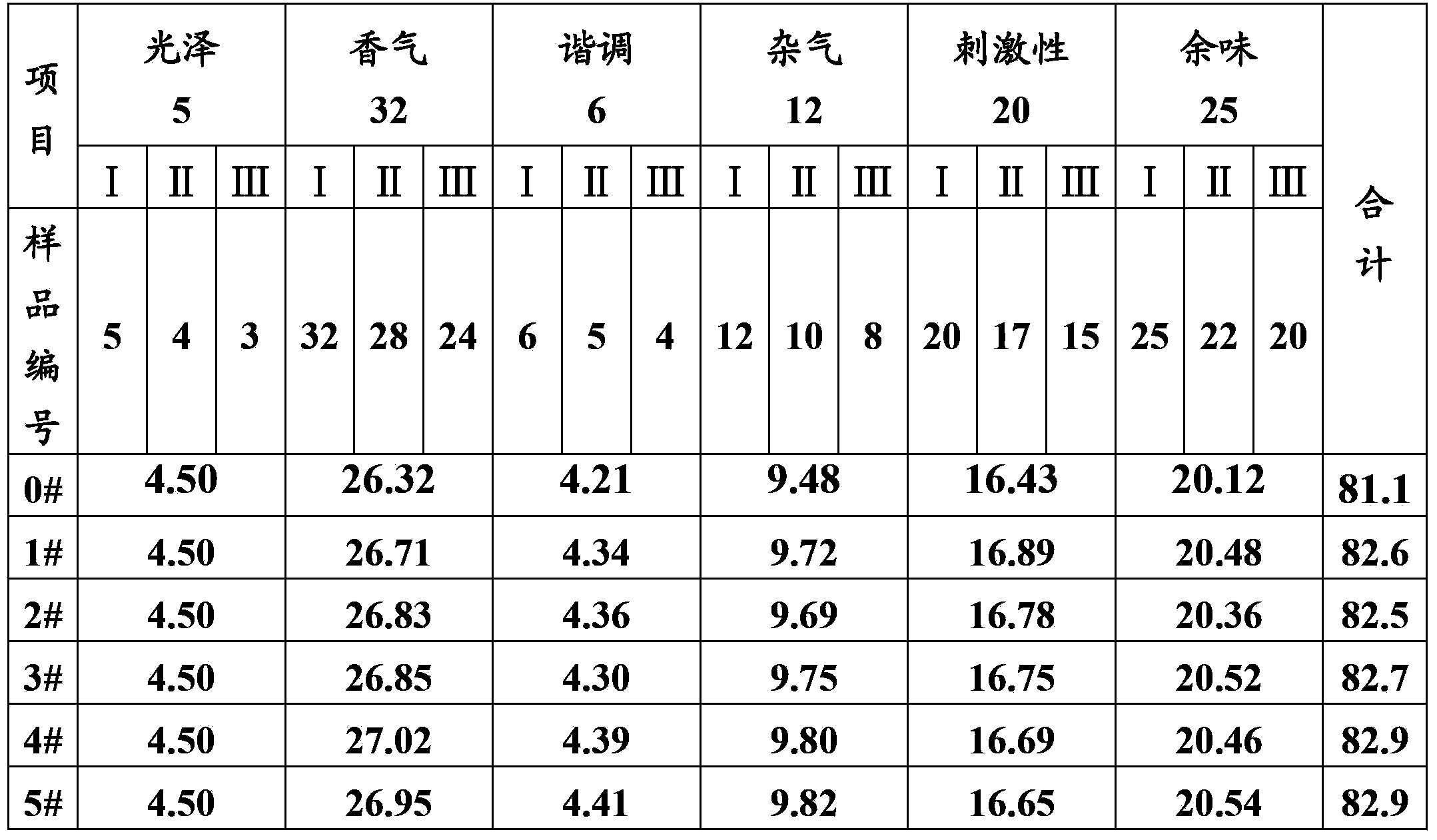

Image

Examples

Embodiment 1

[0067] The tea tree flowers collected from the Tieguanyin tea tree in Anxi, Fujian Province were prepared according to the following steps:

[0068] (1) Ultra-high pressure extraction: Weigh a certain amount of fresh tea tree flowers and put them into an ultra-high pressure extraction tank, add 20% edible alcohol at a concentration 7 times the weight of tea tree flowers, and release the pressure immediately after ultra-high pressure extraction; the ultra-high pressure The pressure is: 150MPa, holding time: 30min;

[0069] (2) Concentrate the extract in step (1) to 1 / 5-1 / 10 of the original volume to obtain the tea tree flower tincture.

[0070] Weigh the above-mentioned tea tree flower tincture 5%, ethanol 10%, water 84.83%, guar gum 0.1g%, malic acid potassium salt 0.02%, vitamin E 0.05%, stir evenly, and make it into lining paper coating Liquid, according to 1% of the weight of the inner liner paper, is added to the inner liner paper base by coating, and then dried and surfa...

Embodiment 2

[0072] The tea tree flower of Wuyi rock tea tree collected from Wuyi Mountain, Fujian Province was prepared according to the following steps:

[0073] (1) Ultra-high pressure extraction: Weigh a certain amount of fresh tea tree flowers and put them into an ultra-high pressure extraction tank, the concentration of which is 5 times the weight of tea tree flowers is 70% edible alcohol, and immediately release the pressure after ultra-high pressure extraction; the pressure of the ultra-high pressure For: 300MPa, holding time: 20min;

[0074] (2) Concentrate the extract in step (1) to 1 / 5-1 / 10 of the original volume to obtain tea tree flower tincture;

[0075] (3) Preparation of tea tree flower extract: continue to concentrate the tea tree flower tincture obtained in step (2) to obtain tea tree flower extract;

[0076] (4) Preparation of tea tree flower absolute oil: redissolve tea tree flower extract with a certain amount of 95% ethanol, freeze (for example -10°C to -20°C) for 24...

Embodiment 3

[0079] The tea tree flower collected from Yunnan Pu'er tea tree was used to prepare the tea tree flower essential oil according to the following steps:

[0080]Take a certain amount of dried tea tree flowers and place them in a 1000mL round bottom flask, add 500mL of distilled water containing 0.5mL of defoamer, and heat to a slight boil with an electric heating mantle. Another 30 mL of redistilled diethyl ether was placed in a 250 mL round bottom flask, placed at the other end of the device, and heated in a water bath at 47°C. Start timing when the sample side boils, and keep a slight boiling state on both sides for continuous distillation and extraction for a period of time. After distillation, extract and cool for 15 minutes. The ether extract was dehydrated with anhydrous sodium sulfate and placed in a refrigerator at 17°C overnight. Concentrate to 0.5mL by nitrogen blowing to obtain tea tree flower essential oil.

[0081] Take by weight percentage 15% of the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com