Additive for boosting maillard reaction of recombined tobacco leaves and method for preparing tobacco leaves by using additive

A technology of Maillard reaction and recombination of tobacco leaves, which is applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of weak tobacco aroma, sharp mouth, miscellaneous gas, woody gas, etc., to reduce woody gas and reduce irritation , the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Further describe with producing 100g of this additive below:

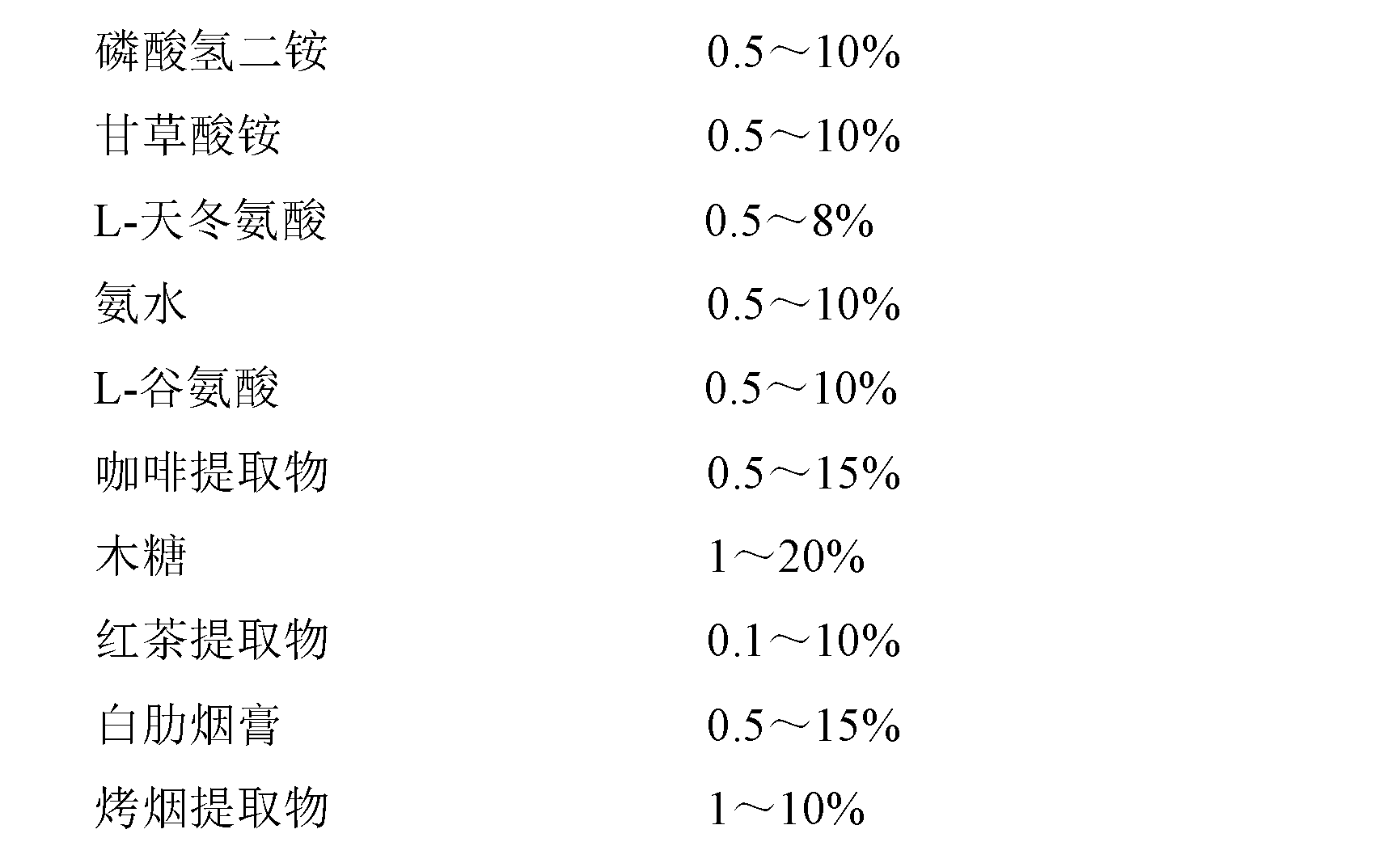

[0023] The recipe ratio is:

[0024]

[0025]

[0026] Weigh each material according to the proportion of the formula, put it into a container, stir and mix evenly, and then obtain the additive 1 for promoting Maillard reaction for recombined tobacco leaves.

[0027] Accurately weigh a certain amount of tobacco stems and tobacco powder to form a tobacco material, add 3 times the mass of tobacco material in water and 4.5% of the mass of tobacco material in reconstituted tobacco leaves with additive 1 for promoting Maillard reaction, soak and extract at 60 ° C for 2 hours , after solid-liquid separation, add 3 times of water and repeat the extraction once, the conditions are the same as the first extraction, after the extraction is completed, the two extracts are combined, concentrated to make a coating solution, and the remaining insoluble matter is made into fibers by papermaking The film base, and th...

Embodiment 2

[0029] Further describe with producing 100g of this additive below:

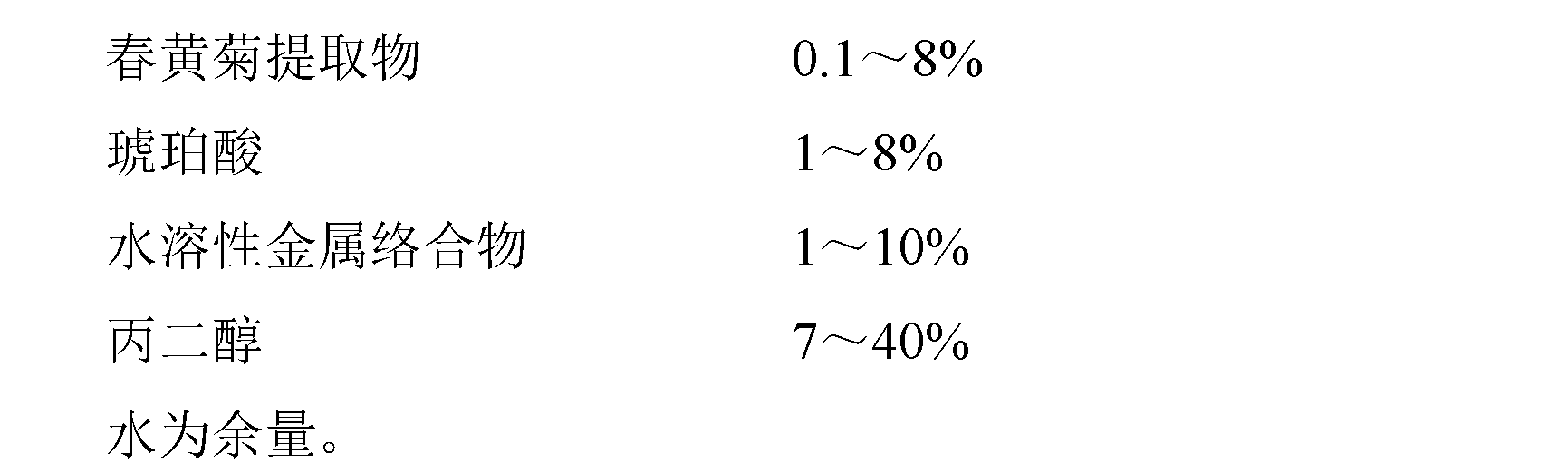

[0030] The recipe ratio is:

[0031]

[0032]

[0033] Each material is weighed according to the proportion of the formula, put into a container, stirred and mixed evenly, and the additive 2 for promoting the Maillard reaction for recombined tobacco leaves is obtained.

[0034] Accurately weigh a certain amount of tobacco stems and tobacco powder to form a tobacco material, add water 3 times the mass of the tobacco material, soak and extract at 60°C for 2 hours, add 3 times water to repeat the extraction once after solid-liquid separation, and the conditions are the same as those in the first The first extraction is the same, after the extraction is completed, the two extractions are combined, and 2.5% of the quality of the tobacco material is added to the restructured tobacco leaf to promote the Maillard reaction. Additive 2 is concentrated to make a coating solution, and the remaining insoluble matte...

Embodiment 3

[0036] Further describe with producing 100g of this additive below:

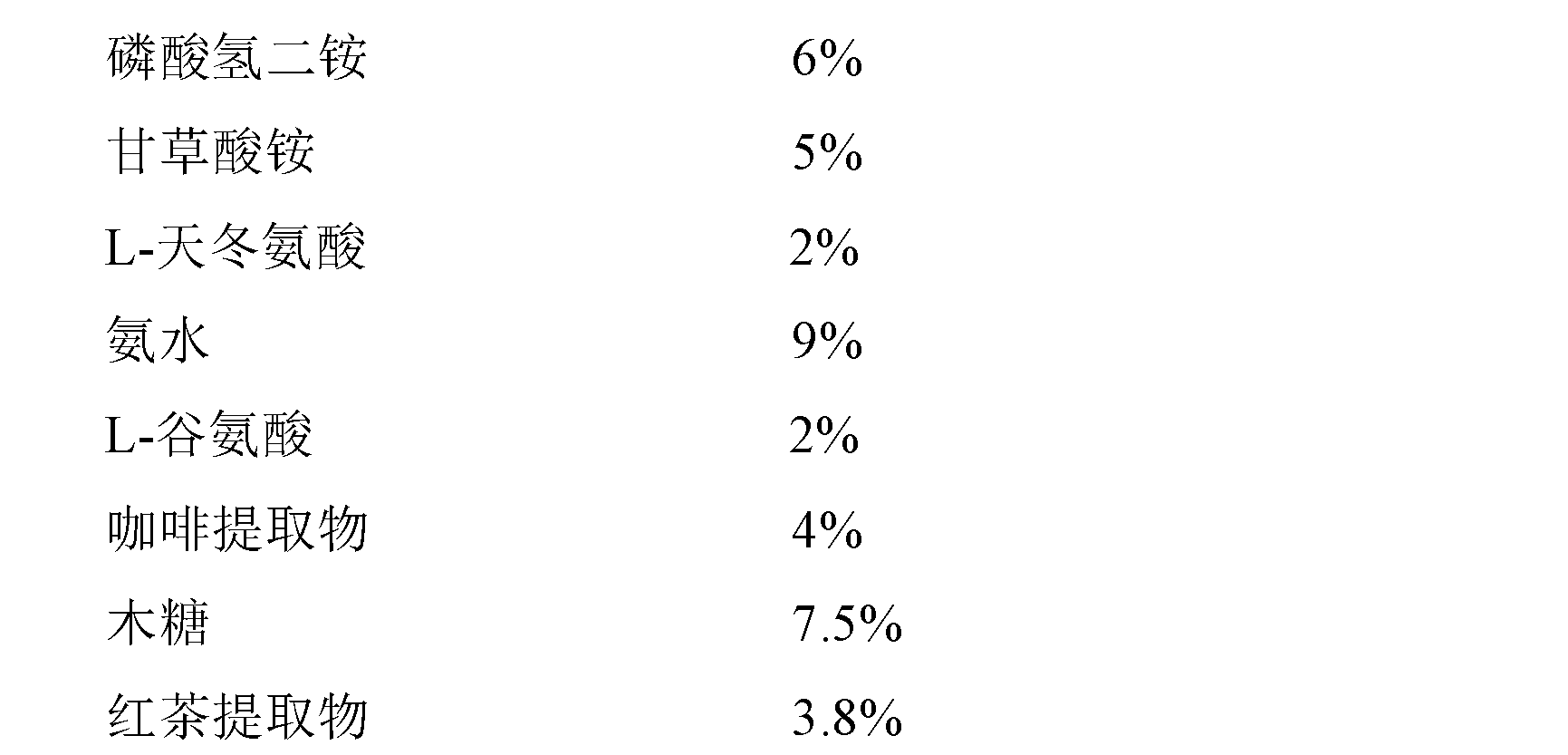

[0037] The recipe ratio is:

[0038]

[0039]

[0040] Each material is weighed according to the proportion of the formula, put into a container, stirred and mixed evenly, and the additive 3 for promoting Maillard reaction for recombined tobacco leaves is obtained.

[0041] Accurately weigh a certain amount of tobacco stems and tobacco dust to form a tobacco material, add 3 times the mass of tobacco material in water and 3.5% of the mass of tobacco material in reconstituted tobacco leaves with an additive 3 for promoting Maillard reaction, soak and extract at 60°C for 2 hours , after solid-liquid separation, re-add 3 times of water and repeat the extraction once. The conditions are the same as the first extraction. After the extraction is completed, the two extracts are combined, and 1% of the mass of tobacco material is added to recombine tobacco leaves to promote Maillard reaction. , concentrated to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com