Patents

Literature

52results about How to "No need to change the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

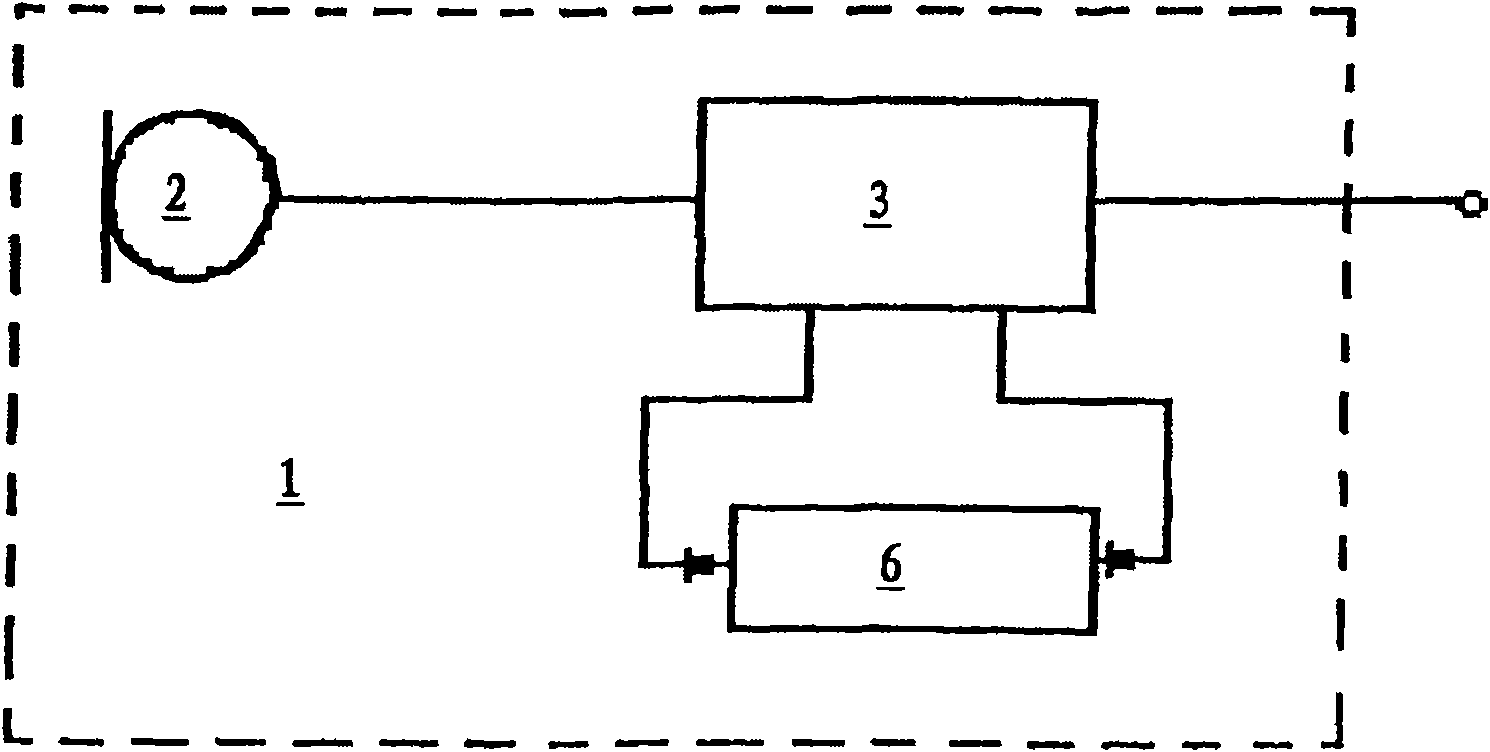

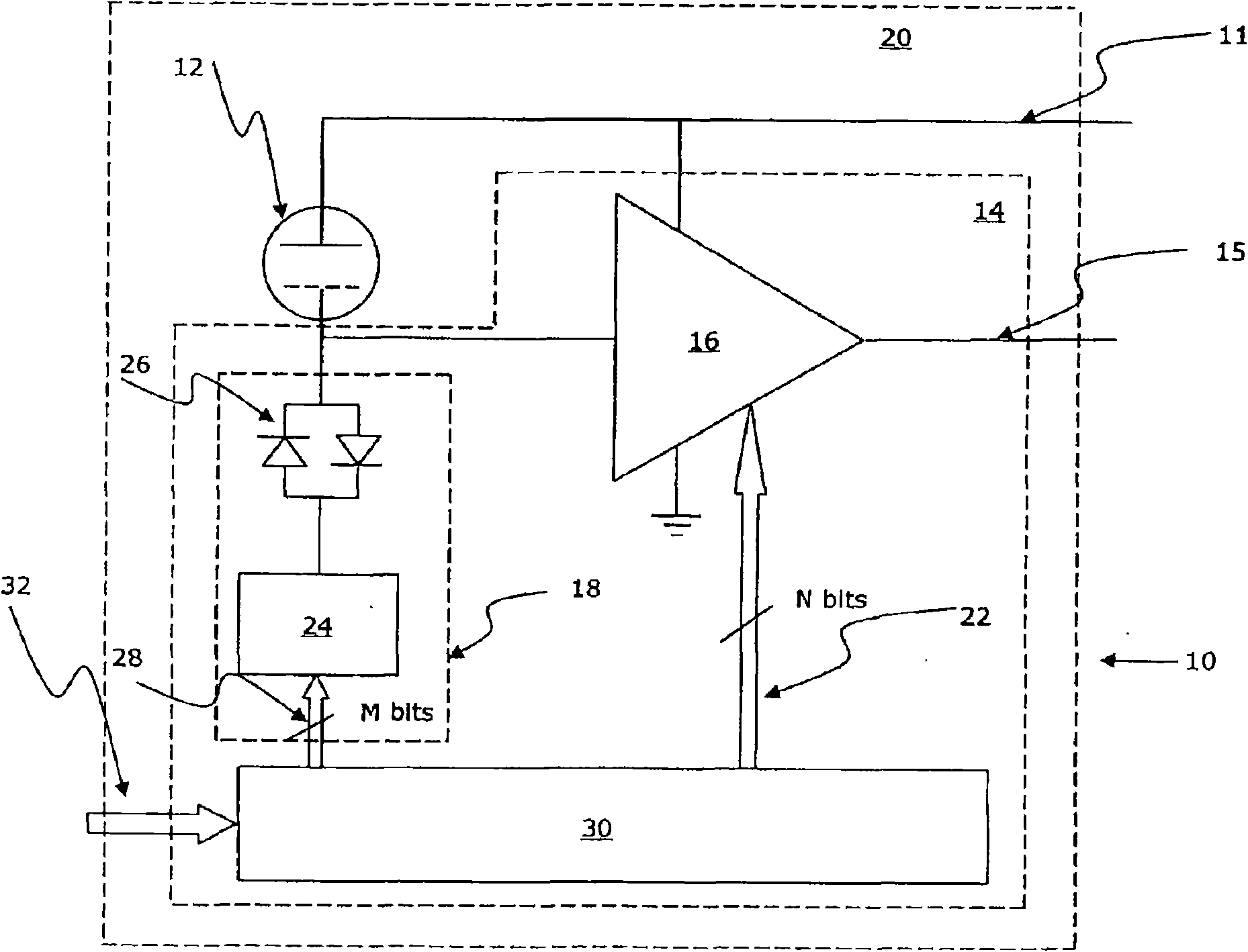

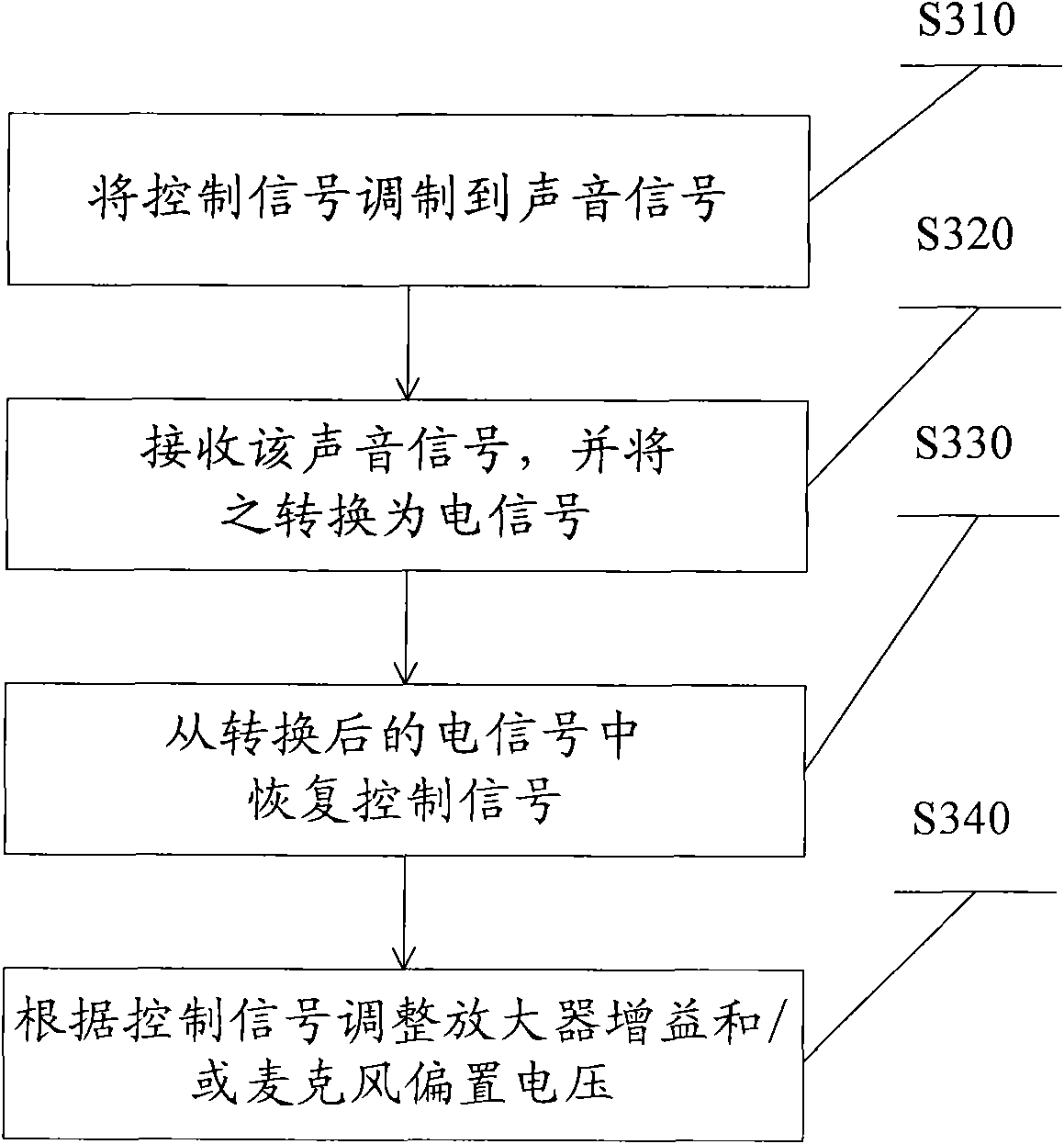

Method and device for calibrating sensitivity of microphone

ActiveCN101621728AFree pin connectionQuick calibrationElectrical apparatusElectricityAudio power amplifier

The invention relates to a method for calibrating sensitivity of a microphone, comprising the following steps: receiving a power supply voltage signal and a sound input signal; judging whether the power supply voltage signal meets a preset condition or not, if so, entering a calibrating mode to continue, and otherwise, stopping; restoring a clock signal from a sound signal; restoring a data signal from the power supply voltage signal; and regulating the amplifier gain and / or microphone bias voltage according to the clock signal and the data signal. A microphone calibrating circuit applying the method comprises a clock restoring module, a data signal restoring module, a gain regulating and controlling and register interface module and a storage, wherein the clock restoring module is used for restoring the clock signal from an output signal of a sound / electricity switching assembly; the data signal restoring module is used for restoring the data signal from the power supply voltage signal, the gain regulating and controlling and register interface module is used for writing amplifier gain regulating data into the storage according to the output of the clock restoring module and the data signal restoring module, and the storage is used for receiving the amplifier gain regulating data from the gain regulating and controlling and register interface module and is used as the grain arrangement when an amplifier normally operates.

Owner:SHANDONG GETTOP ACOUSTIC

Method for producing aerated concrete with refuse incinerator slag

InactiveCN103387411AReduce processing costsReduce manufacturing costCeramicwareAluminiumResource utilization

The invention provides a method for producing aerated concrete with refuse incinerator slag. The method is characterized in that the following raw materials are added by mass percent: 30-60% of fly ash, quartz sand and / or granulated blast furnace slag, 5-15% of Portland cement, 15-25% quicklime, 3-5% of dihydrate gypsum and 10-40% (preferably 9.5-39%) of refuse incinerator slag. Compared with the prior art, the method has the following advantages: (1) the refuse incinerator slag is greatly utilized to produce aerated concrete, so that the method belongs to the resource utilization technology and can substantially reduce the high treatment costs; and (2) the metallic aluminium is fully utilized.

Owner:YANTAI UNIV

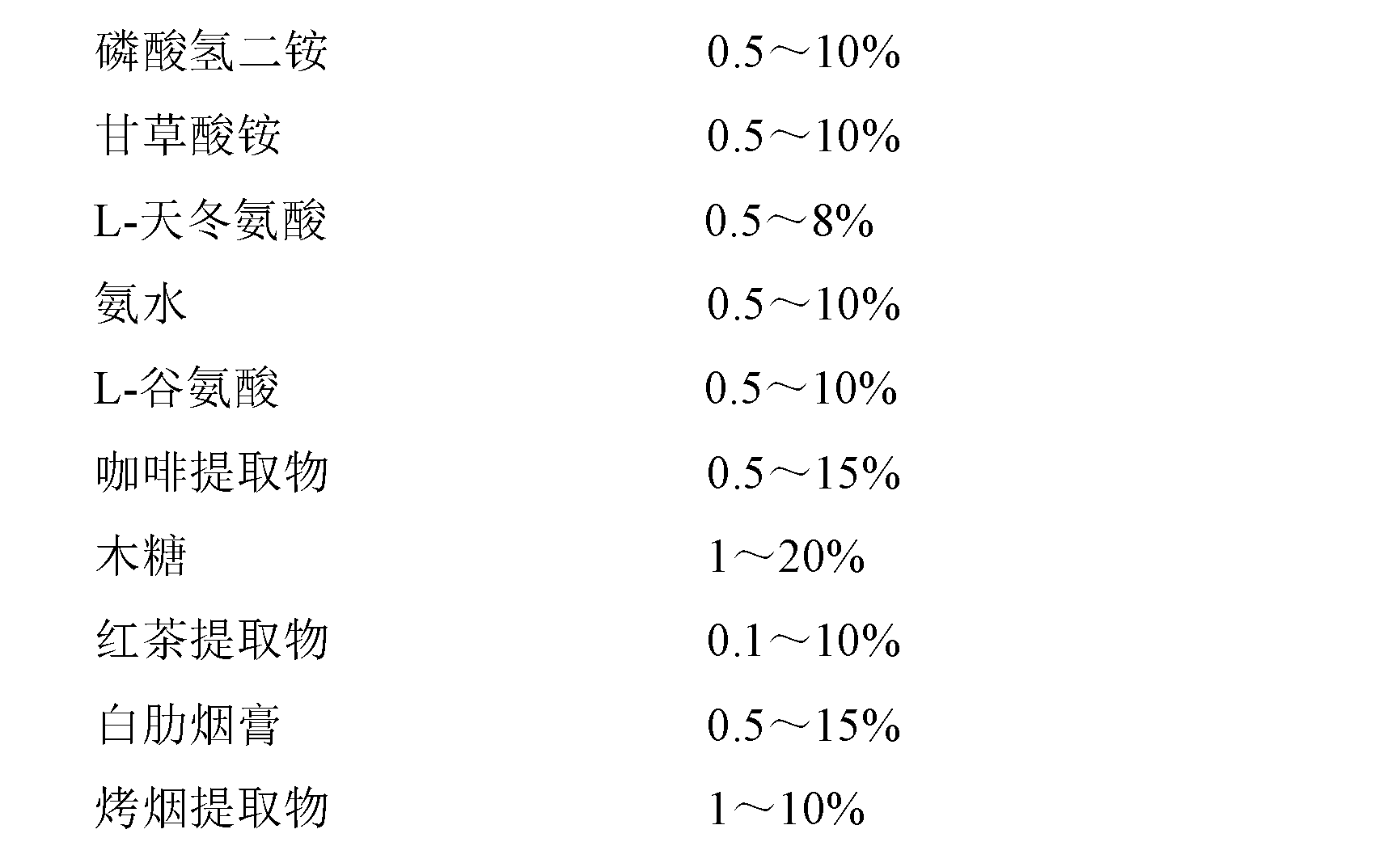

Additive for boosting maillard reaction of recombined tobacco leaves and method for preparing tobacco leaves by using additive

ActiveCN102697168AIncrease aromaRaw materials are easy to getTobacco preparationTobacco treatmentMaillard reactionNicotiana tabacum

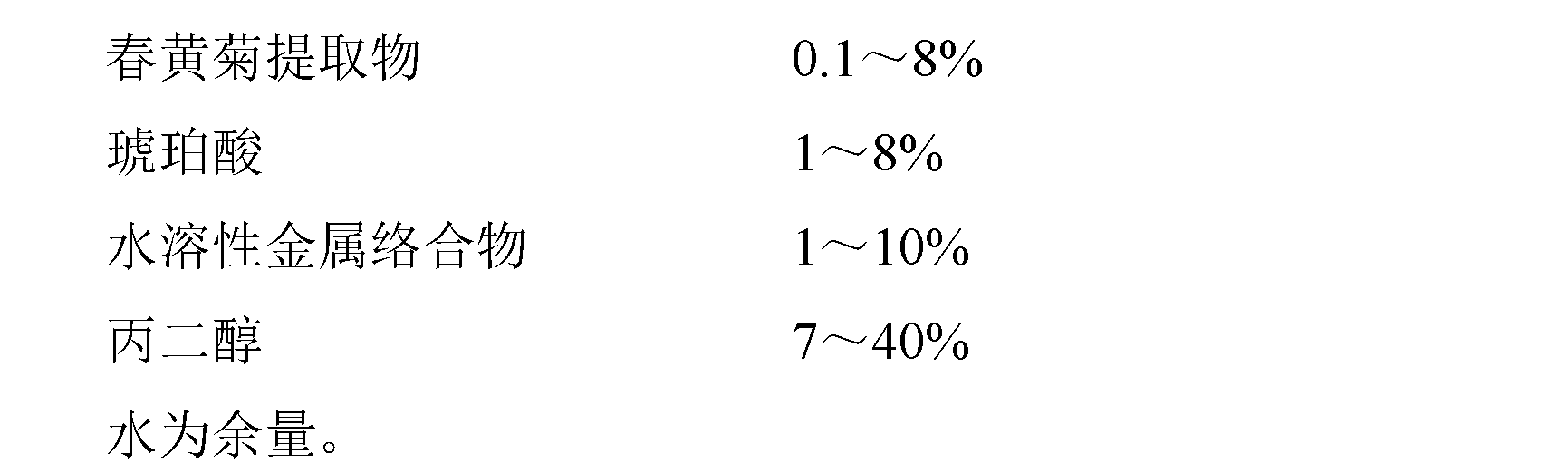

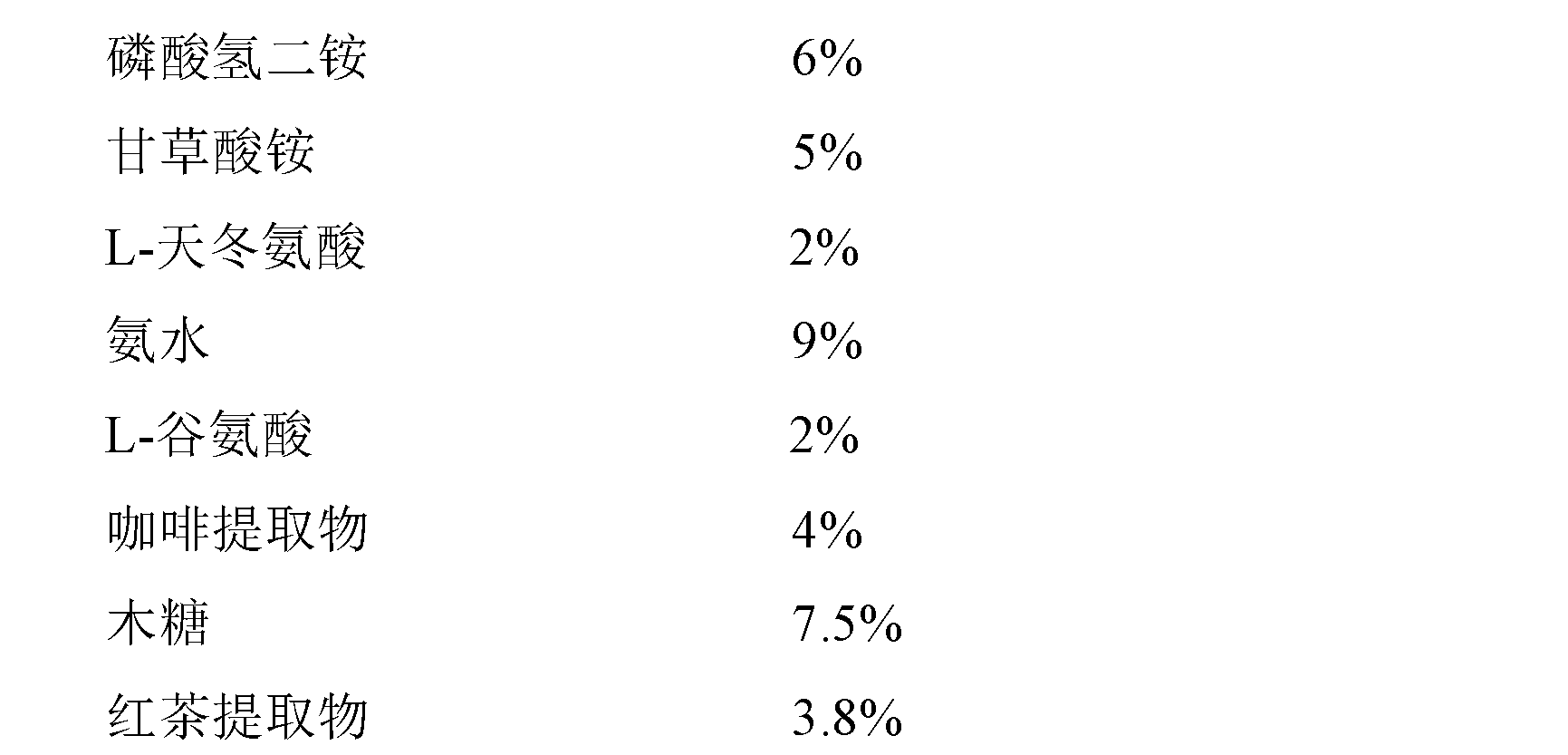

The invention discloses an additive for boosting maillard reaction of recombined tobacco leaves and a method for preparing the tobacco leaves by using the additive. The additive comprises 0.5-10% of diammonium hydrogen phosphate, 0.5-10% of ammonium glycyrrhetate, 0.5-8% of L-Aspartic acid, 0.5-10% of ammonia water, 0.5-10% of L-glutamic acid, 0.5-15% of coffee extractives, 1-20% of xylose, 0.1-10% of black tea extractives, 0.5-15% of burley tobacco paste, 1-10% of cured tobacco extractives, 0.1-8% of chamomile extractives, 1-8% of succinic acid, 1-10% of water-soluble metal complex, 7-40% of propylene glycol and the balance of water. The speed of the maillard reaction in the stages of extracting and concentrating tobacco materials is accelerated by the additive, so as to increase the fragrance of the tobacco leaves, reduce the wood flavor and relieve irritation. When the additive is used for preparing the tobacco leaves, the production technology is not changed and equipment is not added; the usage method is simple; the raw materials of the additive are easily obtained; and the cost is low.

Owner:HUBEI CHINA TOBACCO IND

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU high solid resin combination for synthetic leather

The invention discloses a water-based PU high solid resin combination for synthetic leather, which comprises the following materials by weight percent: 25 to 35 percent of water-based polyurethane resin, 45 to 55 percent of water, 10 to 20 percent of modified organic silicon polymer, 0.5 to 1.5 percent of organic silicon flatting agent, 1 to 3 percent of organic silicon foam killer and 1.5 to 4.5 percent of water-based polyurethane thickening agent. The water-based PU ironing finishing agent has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the high solid resin combination has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the high solid resin combination, has the advantages that the original effect of the leather surface is not affected, raised patterns on the leather surface are sufficient in contrast to the leather sole after the leather surface is treated and modified, and the leather surface has unique high solid effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

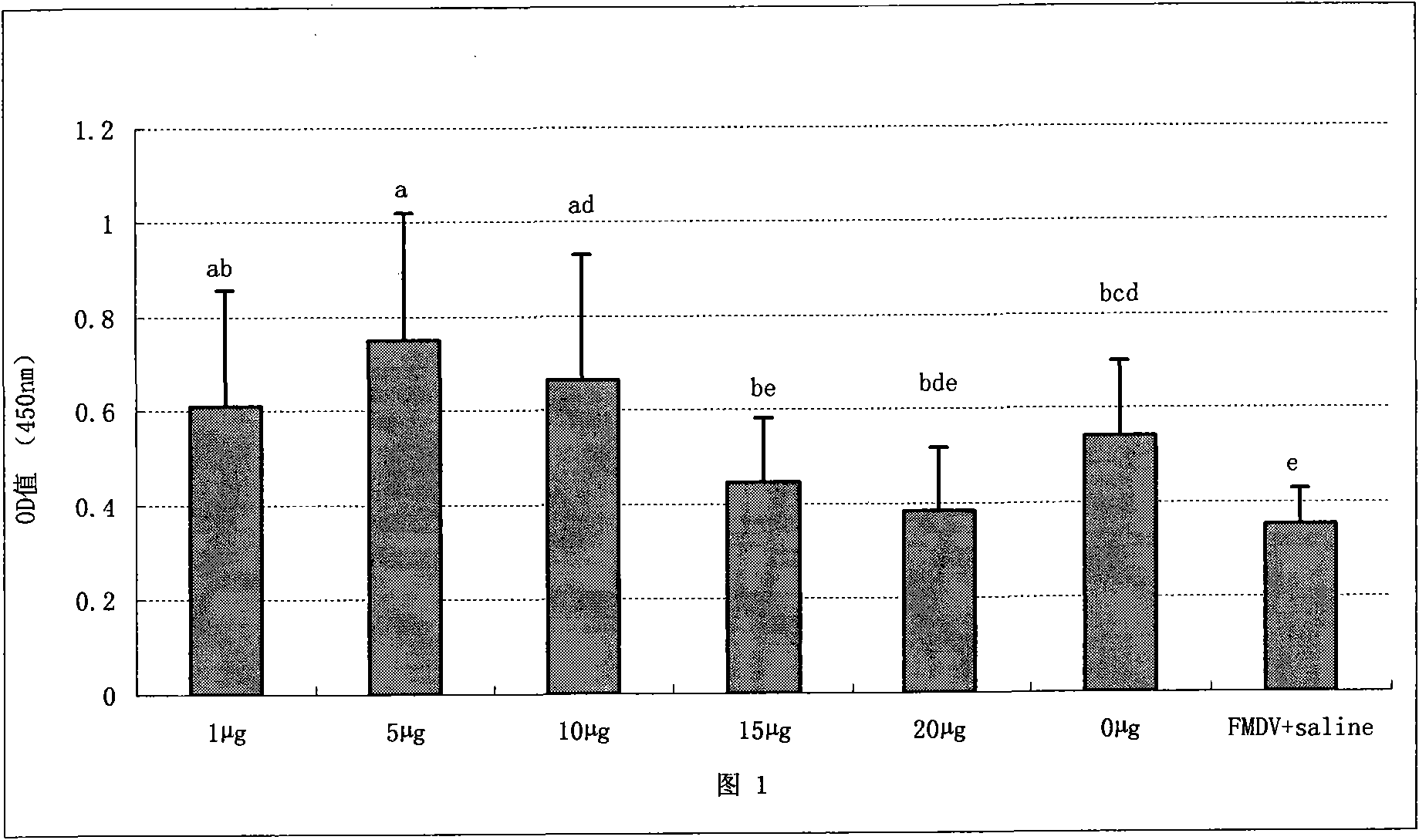

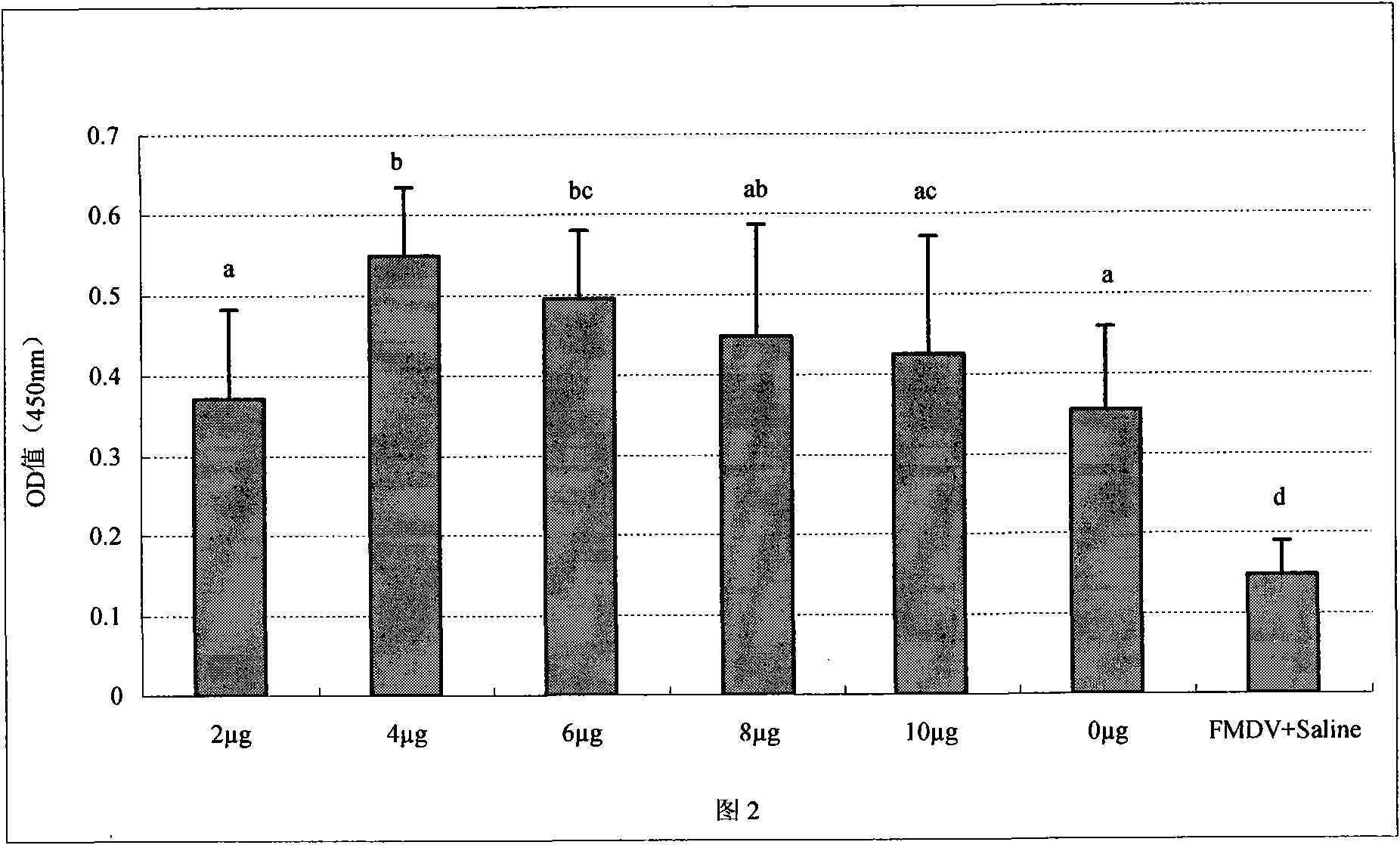

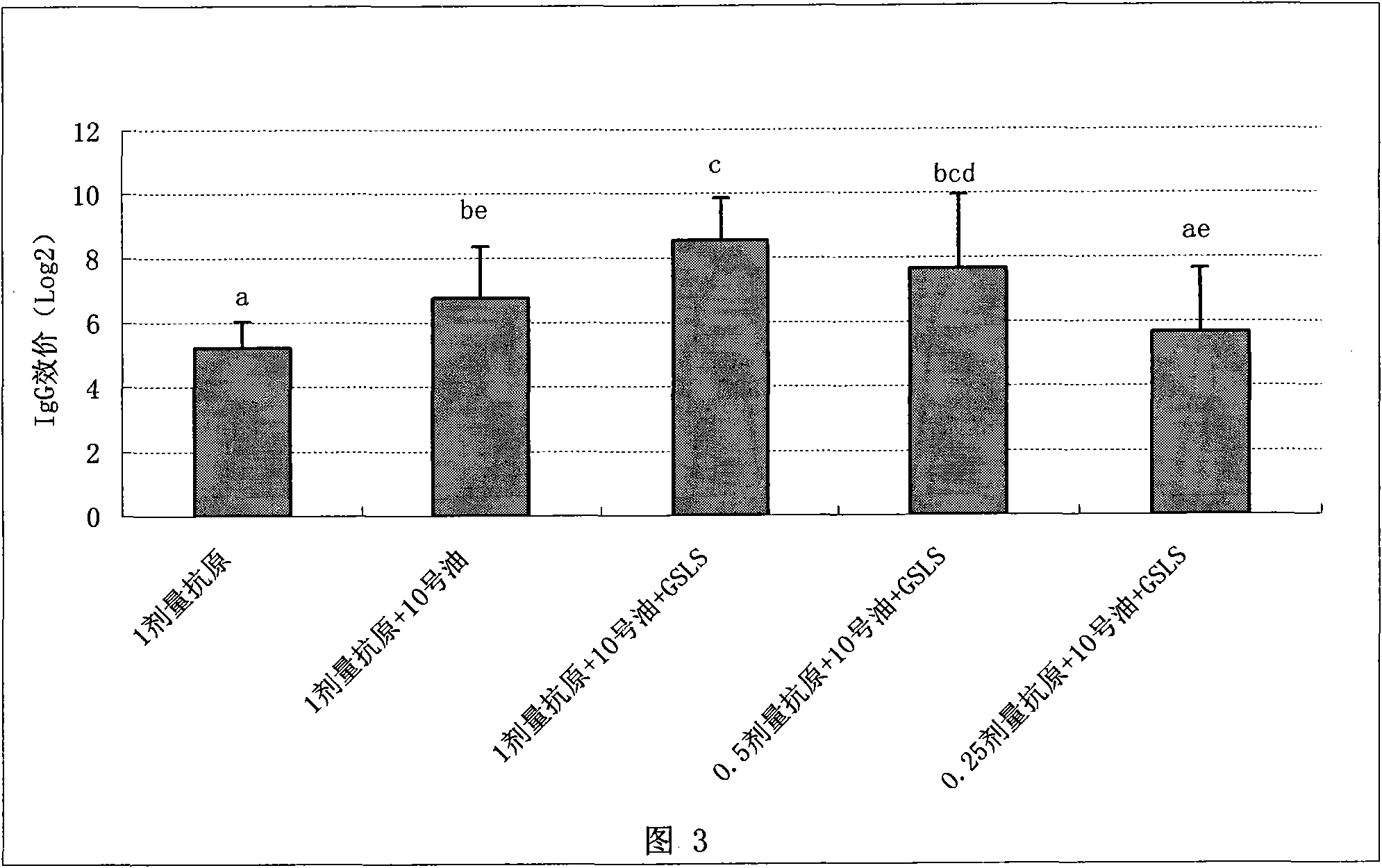

Oil adjuvant containing panaxoside and preparation method thereof

InactiveCN101670104AThe method is simpleIncrease the strength of the immune responseAntibody medical ingredientsSolventSORBITOL MONOOLEATE

The invention provides an oil adjuvant containing panaxoside and a preparation method thereof. The oil adjuvant is a mixture consisting of panaxoside, adjuvant oil, aluminium stearate and sorbitol mono-oleic acid ester, wherein per milliliter of the oil adjuvant contains 10-100Mug of panaxoside. The preparation method comprises the following steps: heating the oil for preparing the adjuvant to thetemperature of 60-150 DEG C, adding 10-20milligram of aluminium stearate into per milliliter of oil, and mixing evenly; after the temperature of the oil reduces to 50-20 DEG C, adding 5-7% of dehydro-sorbitol mono-oleic acid ester according to volume ratio, stirring evenly, and filtering for standby; and using dimethyl sulfoxide or tween solvent to dissolve the panaxoside into solution; adding 10-100Mug of panaxoside solution into the per milliliter of the prepared standby matter, mixing evenly, and sterilizing for 30min at the temperature of 110 DEG C. Vaccines for immune animals, which is prepared by using oil containing panaxoside as the adjuvant, greatly improve the strength of specificity cells induced by the vaccines and humoral immune response, and reduce local stimulation reactionof injection sites.

Owner:ZHEJIANG UNIV

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

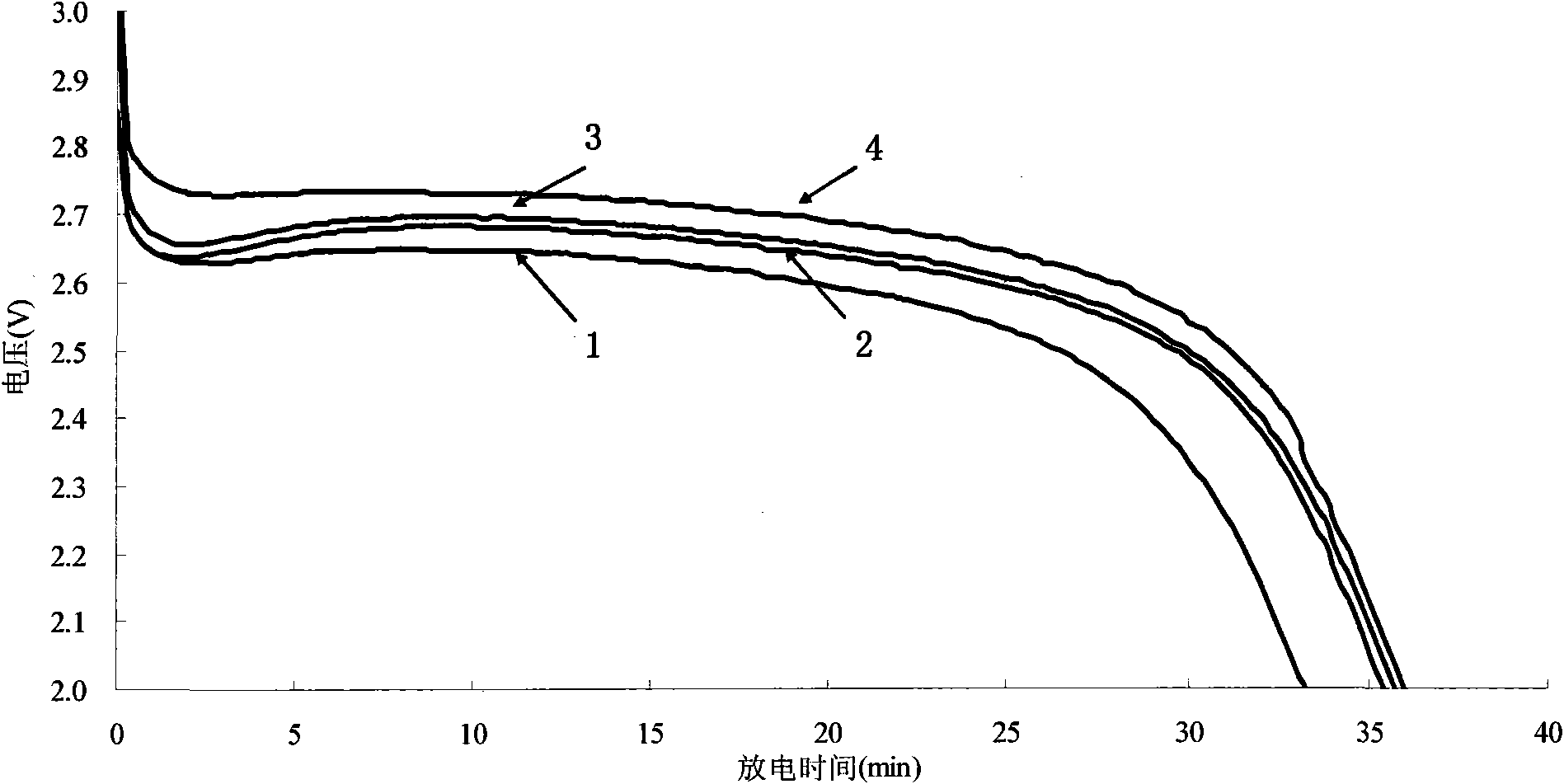

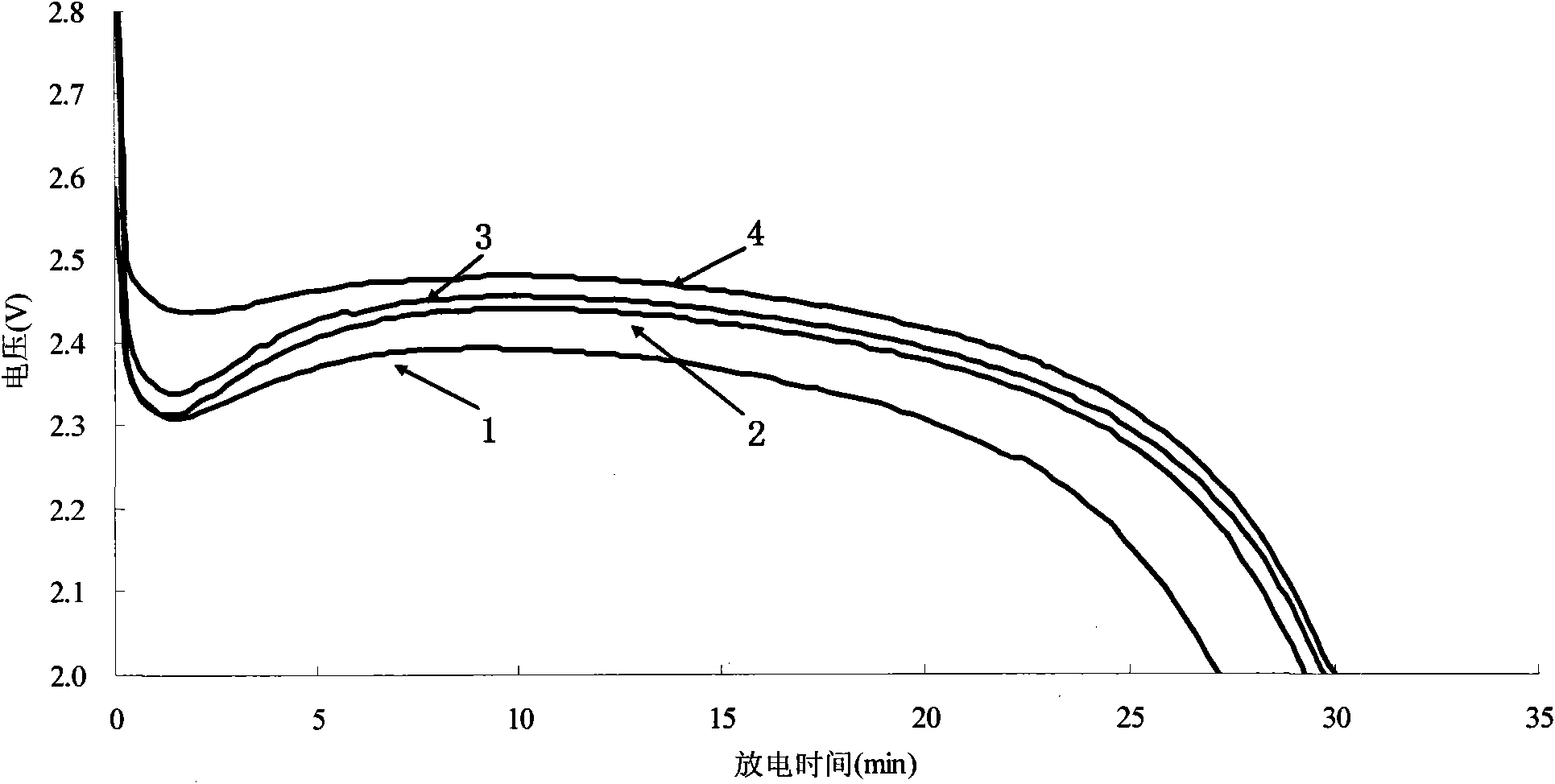

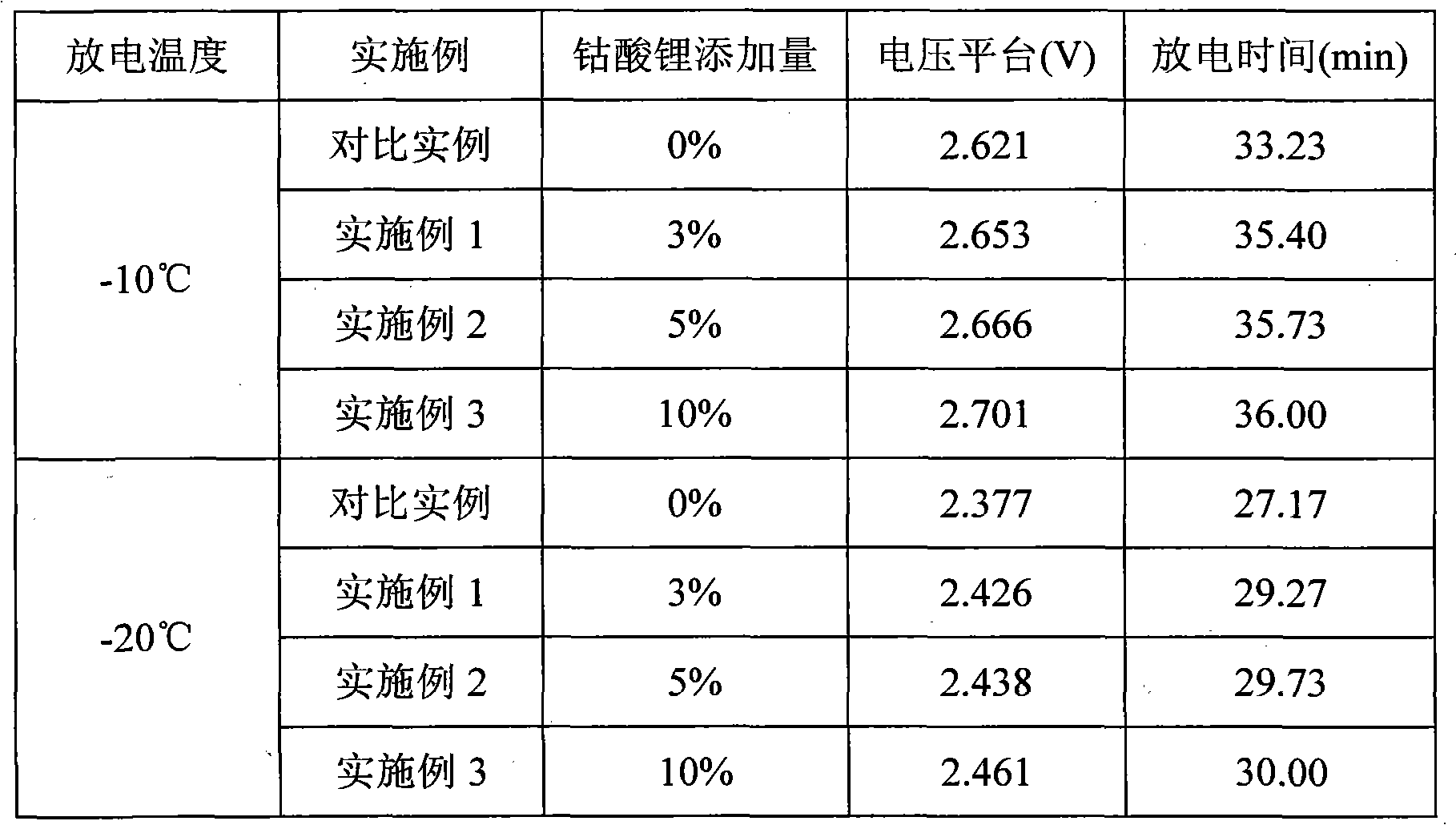

Method for improving low-temperature performance of lithium iron phosphate anodic material for lithium batteries and lithium batteries

InactiveCN101958416AImprove poor low temperature performanceLow temperature discharge capacity retention rate increasesSecondary cellsNon-aqueous electrolyte accumulator electrodesLithium vanadium phosphate batteryLithium-ion battery

The invention discloses method for improving the low-temperature performance of a lithium iron phosphate anodic material for lithium batteries and lithium batteries. The method is to add lithium cobaltate into the formula of the lithium iron phosphate anodic material for lithium batteries. In the invention, based on the characteristic that the low-temperature discharging performance of the lithium cobaltate is high, the problem of low-temperature performance of the conventional lithium iron phosphate batteries is solved, the conventional production process is not changed, and the lithium iron phosphate batteries with high low-temperature performance are manufactured. In the invention, by optimizing and screening the added amount of lithium cobaltate, the low-temperature discharging volume retention rate is increased, the discharging time is prolonged, and better effect is obtained.

Owner:FULLYMAX BATTERY CO LTD

Conductive binding agent and lithium ion battery

InactiveCN104861897AHigh specific capacityReduce dosageNon-macromolecular adhesive additivesCell electrodesDopantOrganic solvent

The invention provides a conductive binding agent and a lithium ion battery. The conductive binding agent comprise, by weight, 0.5-5% of a conventional binding agent, 0.5-5% of a conductive conjugated polymer, 0.001-2% of a dopant and 89-98% of an organic solvent. According to the invention, the conductive binding agent for lithium ion batteries is prepared with a mature conductive polymer system. The conductive binding agent has adhesiveness and also electronic conductivity. With the redox properties of the conductive binding agent, the binding function can be performed, and the conducting function can be performed between the positive and negative electrodes of the lithium ion battery. Therefore, the dose of a traditional conductive additive can be reduced, and lithium ion battery specific capacity can be improved.

Owner:DONGGUAN CHUANGMING BATTERY TECH

Water-based PU matte surface finishing agent for synthetic leather

The invention discloses a water-based PU matte surface finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 45 to 55 parts of water, 4 to 10 parts of modified organic silicon polymer, 0.5 to 1.5 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 3 to 5 parts of modified organic silicon matting agent. For the water-based PU matte surface finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Cement reinforcing agent

InactiveCN101104552AIncrease the dosageImprove the compressive strength of cementUreaRe introduction

The present invention discloses a cement reinforcer. 0.5-1.5 part per thousand of cement intensifier and modest plaster are added to cement clinker to be ball-milled to crank out the cement. The cement reinforcer is composed of triethanolamine, ethylene glycol, acetic acid sodium or anhydrous sodium acetate, urea, calcium chloride and calcium lignosulfonate, wherein, the mass percentage of the components is: triethanolamine: 5-25 percent; ethylene glycol: 5-25 percent, acetic acid sodium or anhydrous sodium acetate 1-10percent; urea: 10-30 percent; calcium chloride: 5-30 percent; calcium lignosulfonate: 3-20 percent. Under the condition of equivalent clinker, the application of the cement reinforcer provided by the invention can help improve 3-10 MPa of the cement compressive strength and reduce 10-15 percent of the clinker amount (namely, the dosage of the re-introduction of cheap mixed materials) in the original cement formula, so as to save 6-15 yuan on the cement cost per ton. Moreover, the invention can make full use of industrial mixed waste materials so as to save the mineral resources, reduce the cement costs and improve the ecological environment. The cement intensifier is easy to use and simple to be operated, and need not change the existing cement production process.

Owner:谭永中

Water PU cracking resin for synthesizing leather

The invention discloses water PU cracking resin for synthesizing leather, which comprises following materials in percentage by weight: 60-70 percent of water polyurethane resin, 20-35 percent of water, 0.3-2 percent of organic silicon flatting agent and 0.5-4 percent of water polyurethane thickener. The water PU cracking resin for synthesizing leather uses water as solvent to replace dimethyl formamide and butanone and other toxic solvents, thereby achieving the non-inflammable, safe, environmental-protection and cost-saving performance. In addition, the cracking resin has the advantages of good film forming, firm bonding, solvent-resist, cold resist, hydrolysis-resist and heat aging-resist performances, and the like. Finished products made by using the cracking resin have the advantages of excellent cracking effect, better real leather quality, fine and smooth texture, good air permeability, and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Cigarette tissue with variable permeating degree and method for producing the same

ActiveCN101195977ALarge poresUniform distribution of poresNon-fibrous pulp additionFiltration separationTarCoal tar

The invention provides cigarette paper with changeable air permeability, wherein, the adding particle is a foaming agent particle with the particle diameter of 0.1 micron to 10 micron, the air permeability of the cigarette paper with about 1 to 10 mm behind the carbonization line of the cigarette paper can be improved during the burning process of the cigarette, and thus the quantity of the air intake from the cone-shaped burning part is increased during the cigarette smoking process to achieve the effects that the burning condition is improved, the content of CO in the fume is reduced, and the tar intake quantity of the human body is decreased. The processing and preparing process of the cigarette paper with changeable air permeability of the invention are simple, the prior production process is not required to be changed, and the invention is suitable for popularizing in application.

Owner:CHINA TOBACCO HUNAN INDAL CORP

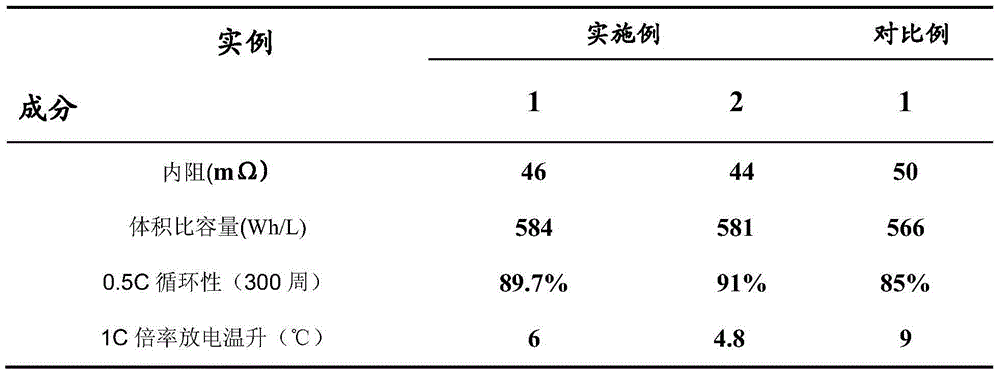

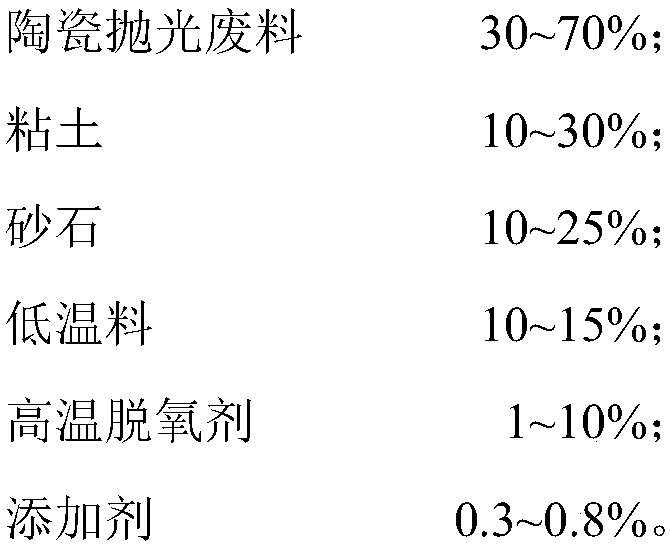

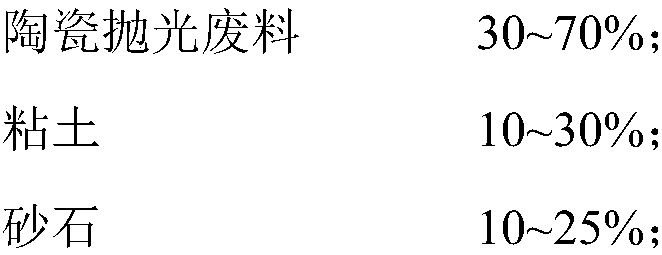

Porcelain tile with high polishing waste content and preparation method thereof

InactiveCN107651940AIncrease profitEnabling densified applicationsCeramic materials productionClaywaresBrickResource utilization

The invention discloses a porcelain tile with high polishing waste content. The porcelain tile comprises the following components by mass percentage: 30-70% of polished ceramic waste, 10-30% of clay,10-25% of sandstone, 10-15% of a low temperature material, 1-10% of a high temperature deoxidizing agent, and 0.3-0.8% of an additive. According to the invention, the high temperature deoxidizing agent is introduced into the formula, the high temperature deoxidizing agent consumes the oxygen around silicon carbide particles in the polished waste to inhibit oxidation of silicon carbide in the polished waste, thus realizing densification application of the polished waste. The prepared porcelain tile has a water absorption rate controlled at 0.5% or below and a shrinkage rate controllable in therange of 5%-15%. The porcelain tile provided by the invention achieves efficient resource utilization of polished ceramic waste, reduces the raw material cost of porcelain tile production, and has high polished waste utilization rate and wide applicability. The preparation method provided by the invention has no need to change the porcelain tile production process and add new equipment, the technology is simple and is easy for industrialization.

Owner:FOSHAN OCEANO CERAMICS

Waterborne matte velour-wetting treatment agent for synthetic leather and preparation method thereof

InactiveCN103103782ANon-combustibleEnvironmentally friendlyFibre treatmentTherapeutic effectSilicon dioxide

The invention relates to a waterborne matte velour-wetting treatment agent for synthetic leather. The waterborne matte velour-wetting treatment agent is composed of the following components: waterborne polyurethane resin varnish, water, penetrant, silica extinction powder, an organosilicone levelling agent, an organosilicone defoamer and a waterborne polyurethane thickener. The invention further relates to a preparation method of the waterborne matte velour-wetting treatment agent for the synthetic leather. The waterborne matte velour-wetting treatment agent for the synthetic leather has a good hand feel and a good comprehensive treatment effect and is environment-friendly; and the preparation method of the waterborne matte velour-wetting treatment agent is simple in process and dispenses with the change of production equipment and the increase of cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU matte surface color fixing finishing agent for synthetic leather

The invention discloses a water-based PU matte surface color fixing finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 50 to 60 parts of water, 3 to 6 parts of modified organic silicon polymer, 1 to 2 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 2 to 3 parts of modified organic silicon matting agent. For the water-based PU matte surface color fixing finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface color fixing finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface color fixing effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Environment-friendly type polyurethane adhesive agent and preparation method thereof

The invention discloses an environment-friendly polyurethane adhesive. The invention is characterized in that the adhesive is made from polyester polyol, isocyanate, monobasic alcohol, catalyst, and chain extender. The invention has a following formula: 20.5 percent to 27.5 percent of polyester polyol, 2.7 percent to 3.3 percent of isocyanate, 64.4 percent to 76.4 percent of monobasic alcohol, 0.09 percent to 0.11 percent of catalyst, and 0.3 percent to 0.55 percent of chain extender. The isocyanate can be HDI, MDI, IPDI, HMDI, TDI, and so on. At the same time, the invention discloses a preparation method of the adhesive: first the polyester polyol and the isocyanate react; then the chain extender is added; and the proportion of '- NCO-' group is kept excessive; when the reaction solution reaches a certain viscosity, the monobasic alcohol is added to dilute; after being mixed at a high speed, molecules are uniformly dispersed and the stable viscose liquid can be got. The invention has the advantages of environmental protection, effective use, and good stability, low cost and so on.

Owner:GOOD CHEM SCI & TECH

Trace element premix

InactiveCN102239964AAvoid chemical reactionsImprove stabilityAnimal feeding stuffAccessory food factorsAnimal scienceCalcium biphosphate

The invention discloses a trace element premix. Each 1000g of trace element premix contains 50-983g of stabilizer, such as calcium hydrophosphate and / or monocalcium phosphate. The trace element premix provided by the invention has stable color and quality, can be used as a trace element premix for cultivating animals, and has important significance for the growth and health of the cultivated animals.

Owner:广州市诚一水产科技有限公司

Calcinion method for calcining coal gangue to produce cement additive

InactiveCN102173607ALow costA large amount of cement is addedCement productionCoal waterFree cooling

The invention relates to a calcinion method for calcining coal gangue to produce a cement additive. The method comprises the following steps of: selecting a convenient-to-transport flat area in a place with stacked coal gangue; laying a ventilation pipe, a combustion layer and a coal layer with the thickness of 9 to 11 cm in sequence; igniting the combustion layer and stacking coal gangue; and continuously blowing air through the pipe to support the combustion of coal gangue for 6 to 7 days, and naturally cooling to obtain a sintered material which can be used as a cement additive. The invention has the benefits that: the coal gangue is fully utilized and 1.9 tons of cement additive is produced per 2 tons of coal gangue; the addition amount of the cement additive is 3 to 4 times that of the basalt, so that the cement cost is greatly reduced; the cement grade of the additive is about 250#, the addition amount in cement is increased and reaches 25% for ordinary cement and 30% to 40% for pozzolanic cement; owing to the natural cooling process, the sintered material is fragile and easy to mill; and the blower has a high blowing capacity, the coal gangue has a large combustion value, and the coal gangue on the surface of the coal gangue stack combusts completely.

Owner:CHIBI CITY MOYU CEMENT

Waterborne matte polishing treatment agent for synthetic leather and preparation method thereof

InactiveCN103103786ANon-combustibleEnvironmentally friendlyFibre treatmentEmulsionTherapeutic effect

The invention relates to a waterborne matte polishing treatment agent for synthetic leather. The waterborne matte polishing treatment agent is composed of the following components: waterborne polyurethane resin varnish, modified polyurethane emulsion, water, silica extinction powder, methoxy silicone oil, penetrant, an organosilicone levelling agent, an organosilicone defoamer and a waterborne polyurethane thickener. The invention further relates to a preparation method of the waterborne matte polishing treatment agent for the synthetic leather. The waterborne matte polishing treatment agent for the synthetic leather has a good hand feel and a good comprehensive treatment effect and is environment-friendly; and the preparation method of the waterborne matte polishing treatment agent is simple in process and dispenses with the change of production equipment and the increase of cost.

Owner:JIANGSU BAOZE POLYMER MATERIAL

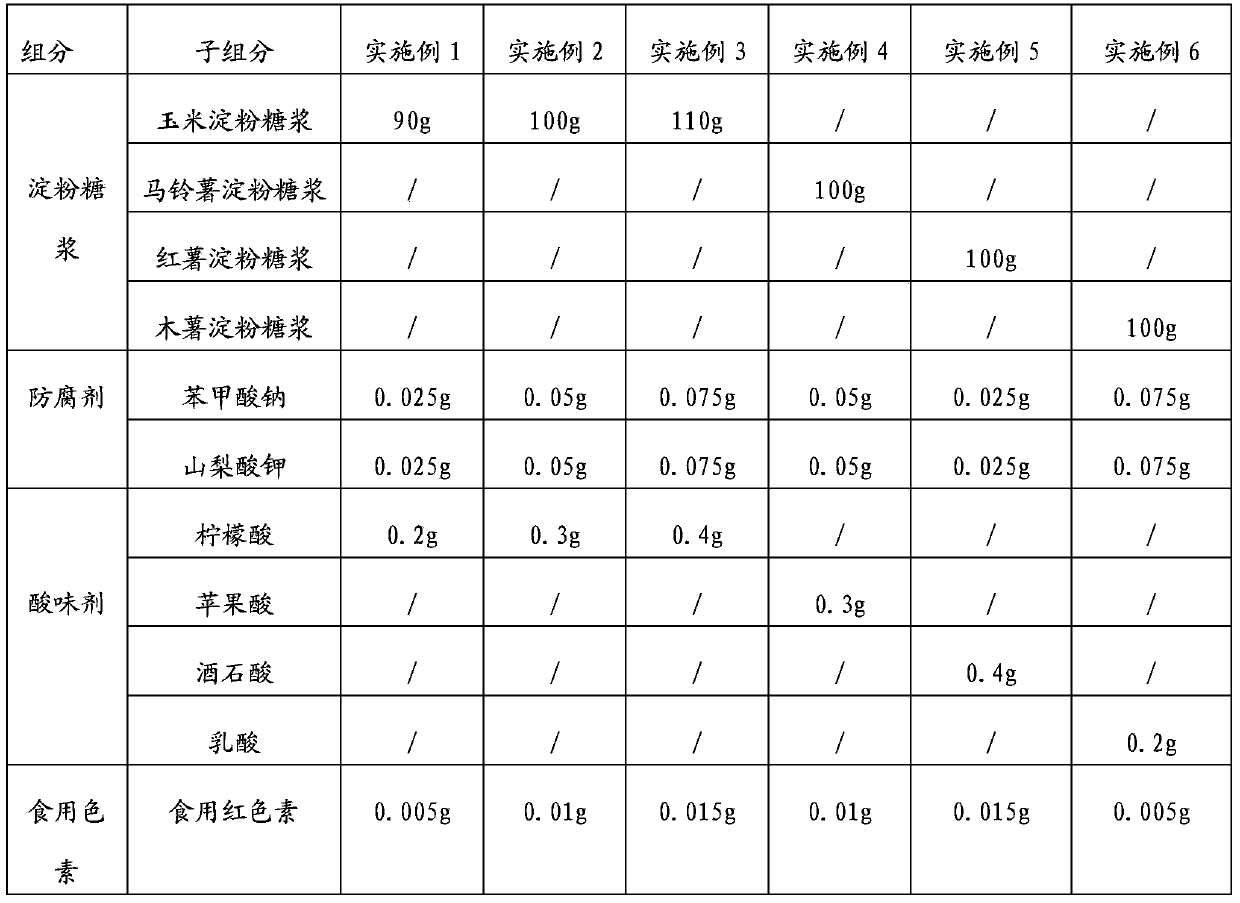

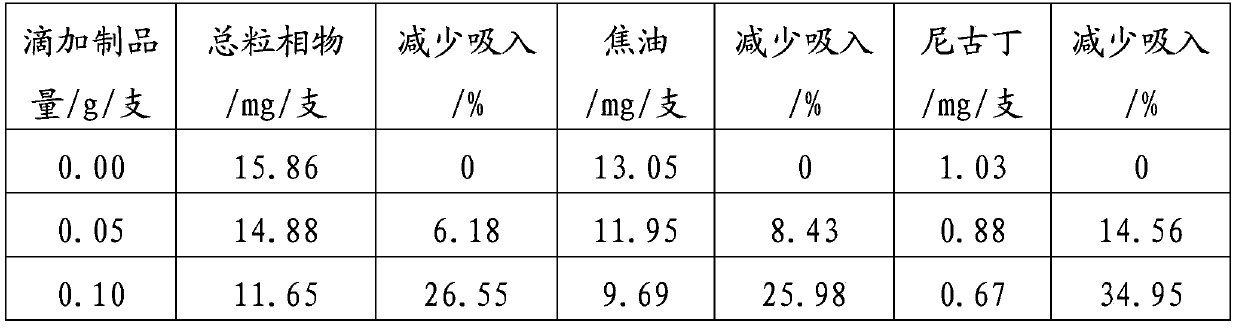

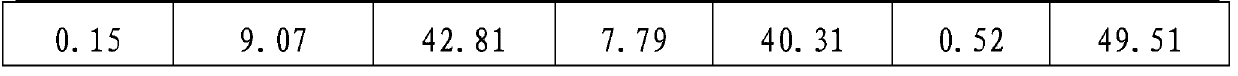

Composition for reducing intake of total particulate matter, tar and nicotine and method for preparing composition

The invention discloses a composition for reducing the intake of total particulate matter, tar and nicotine and a method for preparing the composition. The composition comprises the following raw materials, by weight, 90-110 parts of starch syrup, 5-15 parts of antiseptic, 20-40 parts of acidulant and 0.5-1.5 parts of food coloring. The composition is safe, non-toxic, and simple and feasible in the application method. The intake of total particulate matter, tar and nicotine of a smoker in the smoking process can be remarkably reduced. The method is simple in process, an existing process for processing tobacco is not affected, and the method is conveniently massively popularized and applied.

Owner:天津贝罗尼生物科技有限公司

Chemical corrosive used for manufacturing micropore aluminum foil

InactiveCN107740100AHigh resistivityHigh tensile strengthElectrode carriers/collectorsMolar concentrationMetallurgy

The invention discloses a chemical corrosive used for manufacturing a micropore aluminum foil, belonging to the technical field of manufacturing of lithium battery anode materials. The invention aimsto solve the technical problem of providing the chemical corrosive for manufacturing the high-performance micropore aluminum foil. The scheme adopted by the invention is characterized in that the corrosive comprises the following solution of molar concentrations: 0.1-3 mol / L of Cl<-> and 0.1-3 mol / L of Fe<3+> and Cu<2+>; the corrosive further comprises the following solution of molar concentrations: 0.01-0.1 mol / L of H<+>; and the corrosive further comprises the following solution of molar concentrations: 0.01-0.1 mol / L of OH<->. The chemical corrosive can be widely applied to the technical field of micropore aluminum foil manufacturing.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Refreshing method of fresh chicken conditioning product

InactiveCN103300125AExtended shelf lifeImprove color qualityMeat/fish preservation using chemicalsL&D processNisin

The invention relates to a refreshing method of a fresh chicken conditioning product, belongs to the field for refreshing meat products, and aims to provide a simple effective fresh chicken conditioning product refreshing method. The method provided by the invention comprises the following steps of: directly adding a composite antistaling agent which is composed of 70% sodium lactate, pure glacial acetic acid and 1100IU / mg Nisin when a rolling kneading pickling solution is prepared according to a preparation technical process of a fresh chicken conditioning product, wherein the component dosages are respectively 4% (v / w),0.4%(v / w) and 0.1g / kg of the raw meat; and statically pickling 12 hours after rolling and kneading, and packing the product through an oxygen tray so as to be stored under 0-4 DEG C. By using the technology, the marketable life of the fresh chicken conditioning product packed by the tray is prolonged from four days to more than 20 days, and the color quality is obviously improved; the technology does not need to change a production process, the operation is simple and convenient, the production efficiency is improved, and the effective refreshing technology is provided for the development of the fresh chicken conditioning product.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

PVC edge sealing strip gravure printing water-based ink with good stability

The invention relates to PVC edge sealing strip gravure printing water-based ink with good stability. The ink comprises the following components, by mass: 30-40 parts of a binder, 30-40 parts of water, 10-20 parts of pigments, and 5-10 parts of auxiliary agents. The binder is modified polyurethane acrylic emulsion. The modified polyurethane acrylic emulsion is modified by introducing a hexafluoropropene dimer, a hexafluoropropene trimer and dialkyl maleate into a branch of an acrylic acid molecular chain. The PVC edge sealing strip gravure printing water-based ink with good stability has the characteristics of high stability, strong adhesion and simple process.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Electrochemical corrosion preparation method for microporous battery aluminum foil

InactiveCN107658470AReduce pollutionThe reaction speed is easy to controlElectrode manufacturing processesElectrode carriers/collectorsSurface cleaningElectrochemical corrosion

Belonging to the technical field of preparation of battery aluminum foils, the invention provides an electrochemical corrosion preparation method for a microporous battery aluminum foil. The inventionovercomes the defects of the existing technology, and aims to provide an electrochemical corrosion preparation method for a high-performance lithium battery microporous aluminum foil. The technical scheme is carried out according to the steps of: conducting surface cleaning on a rolled battery aluminum foil to remove a lubricant; immersing the cleaned battery aluminum foil totally in a chemical corrosive liquid, which is a salt solution and contains Cl<-> anions with a molar concentration of 0.1-3mol / L, and Fe<3+> and Cu<2+> cations with a molar concentration of 0.1-3mol / L, adopting a corrosion groove as the negative electrode, using the battery aluminum foil as the positive electrode, applying 24V direct current for corrosion, retaining the battery aluminum foil in the corrosive liquid for 20-120s; and cleaning the surface residual liquid on the corroded battery aluminum foil, and performing drying. The preparation method provided by the invention can be widely applied to the manufacturing field of lithium battery microporous aluminum foils.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

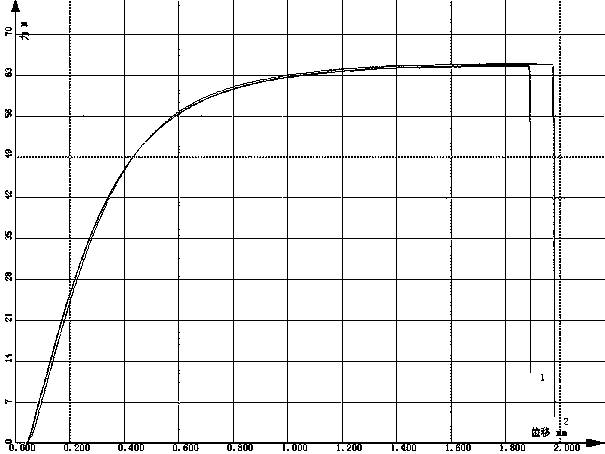

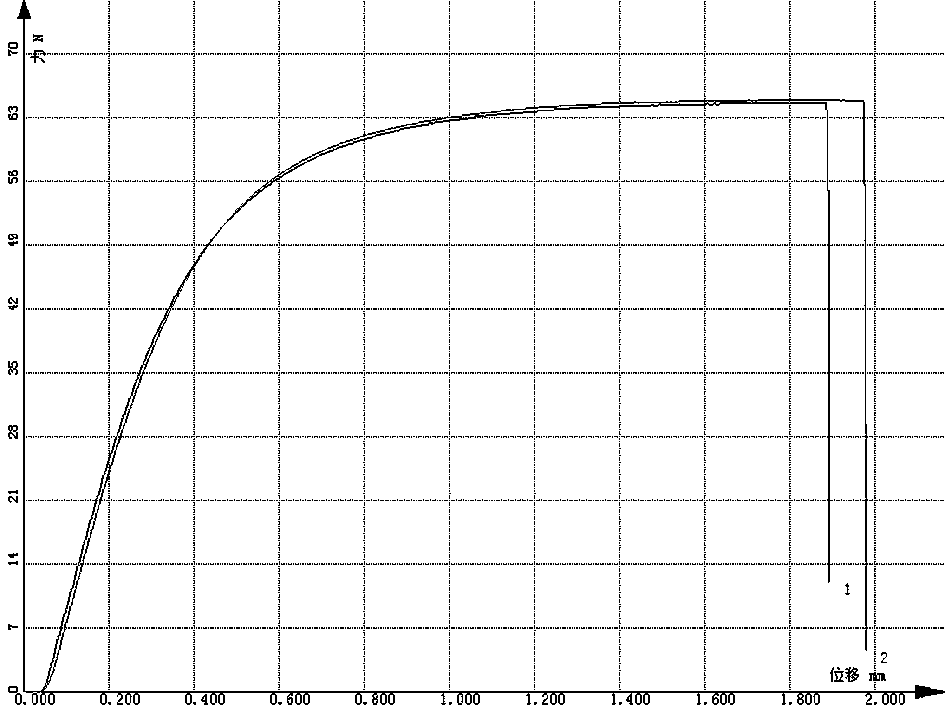

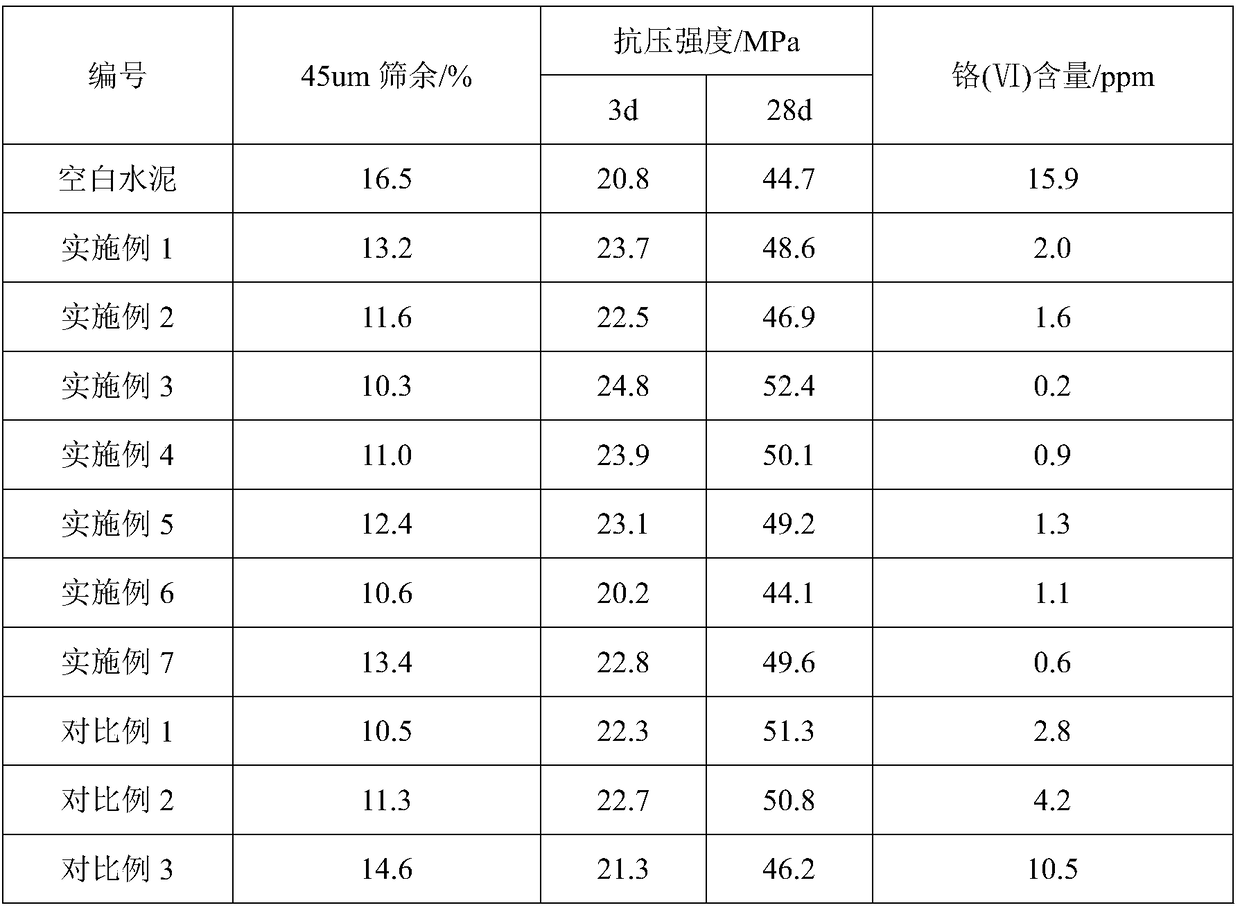

Cement grinding aid

The invention belongs to the technical field of cement production, and discloses a cement grinding aid. The cement grinding aid is prepared from the following raw materials in parts by weight: 8%-12%of a phosphite anhydride-ethylene glycol reactant, 1%-3% of a polycarboxy compound, 3%-5% of a grinding aid, 1%-5% of potassium metabisulfite, 0.1%-1% of a defoamer and the balance of water. The cement grinding aid can improve grinding efficiency of cement and also has a good function of reducing water-soluble hexavalent chromium in cement.

Owner:鸡西市恒昌新材料科技有限公司

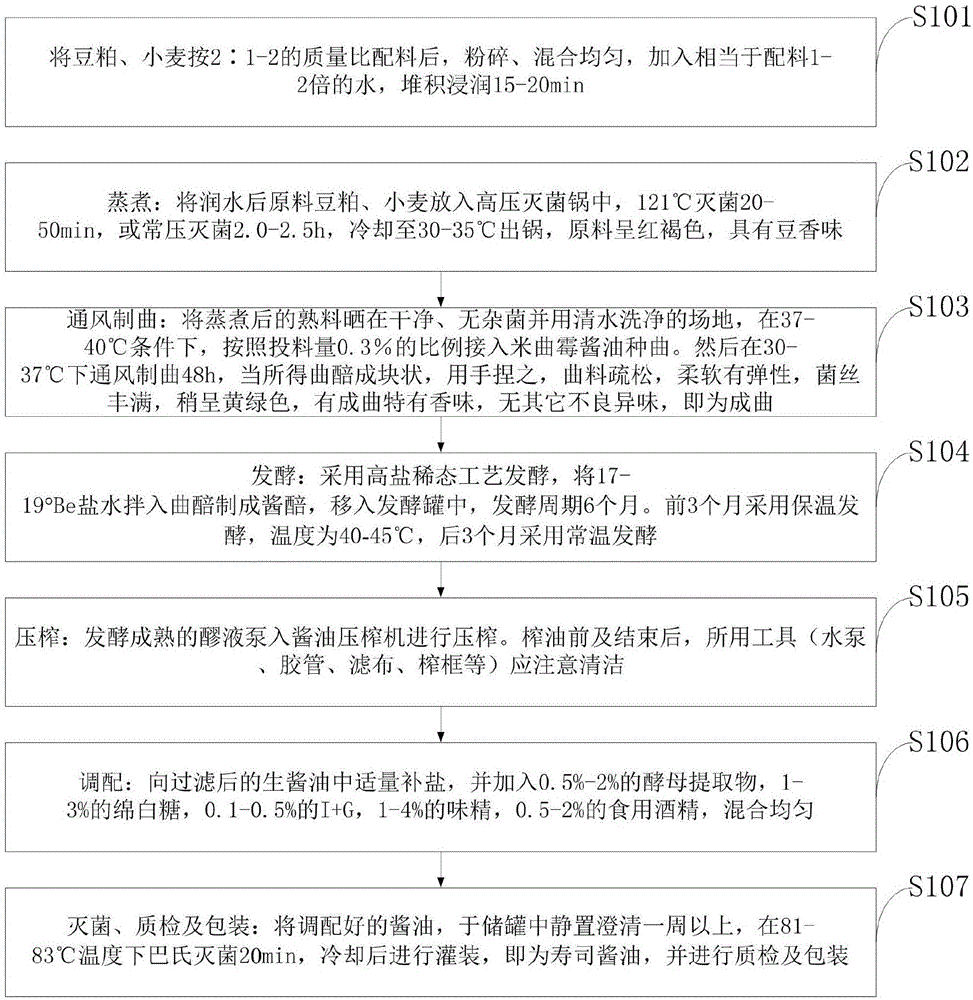

Preparation method of sushi soybean sauce

InactiveCN106262684ASatisfy the needs of fresh fragranceNo need to change the production processFood scienceFlavorAdditive ingredient

The invention discloses a preparation method of sushi soybean sauce. The method comprises the steps that high-quality bean pulp and wheat are selected, and a proper amount of water is added for soaking the bean pulp and the wheat which are mixed and crashed; after cooking, cooling, inoculation, fermentation and squeezing are carried out, obtained highly-diluted soybean sauce is subjected to salt supplementing and blending, and the sushi soybean sauce with clear luster, red brown color and a palatable flavor is obtained after pasteurization treatment. Sushi soybean sauce production comprises the specific steps of screening of bean pulp and wheat, soaking, cooking, cooling, fermentation, squeezing, salt supplementing, blending, sterilization, canning, quality inspection and packaging. The sushi soybean sauce produced through the method contains nutritional ingredients in traditional soybean sauce, product ingredients are reasonable in proportion, the taste and flavor are unique, and the demands of people for deliciousness and fragrance of seasoning soybean sauce for sushi products can be met; the product is low in production cost and simple in manufacturing process, the original production process of soybean sauce does not need to be changed, and technical popularization is promoted.

Owner:HENGSHUN WANTONG FOOD MAKING XUZHOU

Cigarette paper for reducing harmful substance contents of carbon monoxide, oxynitride and phenols in cigarette smoke gas and preparation thereof

ActiveCN101435176BNo need to change the production processEasy to operateSpecial paperPaper/cardboardHazardous substanceCerium

The invention relates to double-layer cigarette paper formed by an inner layer of cigarette paper wrapped outside tobacco shred, and an outer layer of cigarette paper wrapped outside the inner layer of cigarette paper. The inner layer of cigarette paper can be loaded with a catalyst which comprises a metallic oxide, a metallic compound oxide, a metallic hydroxide or a metallic oxide hydroxide, concretely relates to one or a plurality of the oxides, the compound oxides, the hydroxide or the oxide hydroxide of iron, manganese, copper, zinc, titanium, aluminum, calcium, cobalt, palladium, platinum, lanthanum, strontium or cerium and the like; the mass content of the catalyst accounts for 1 to 30 percent of the mass of the inner layer of cigarette paper, preferably 3 to 10 percent of the massof the inner layer of cigarette paper. The technique can effectively reduce the content of hazardous substances such as carbon monoxide, oxynitride and phenols and the like in the smoke of the cigarette.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Environment-friendly water-based ink for PVC surface printing

The invention relates to environment-friendly water-based ink for PVC surface printing. The ink is prepared from, by mass, 30-40 parts of connecting materials, 30-40 parts of water, 10-20 parts of pigment and 5-10 parts of auxiliaries. The connecting materials are a modified polyurethane acrylic acid emulsion, the modified polyurethane acrylic acid emulsion is obtained by introducing the (1,4)-2-amino-2-deoxy-beta-D-glucan structure of deacetylation to branch chains of acrylic acid molecular chains. The environment-friendly water-based ink for PVC surface printing has the advantages of being good in environment-friendliness, high in adhesive force and simple in technology.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Chlorine salt corrosive agent for preparing microporous aluminum foil

InactiveCN107740099AReduce pollutionThe reaction speed is easy to controlElectrode carriers/collectorsSecondary cellsChlorideAluminum foil

The invention relates to a chlorine salt corrosive agent for preparing microporous aluminum foil, and particularly relates to the corrosive agent for a high-performance lithium battery positive electrode material. The chlorine salt corrosive agent overcomes the defects of an existing technology. The purpose is to provide the corrosive agent for a high-performance lithium battery positive electrodecurrent collector material. According to the technical scheme, the chlorine salt corrosive agent used for preparing the microporous aluminum foil is a salt solution, wherein the chlorine salt corrosive agent is the salt solution with negative ions only containing chloride ions, the molar concentration of Cl<-> is 0.1-3mol / L, and positive ions contain Fe<3+> and Cu<2+> with the molar concentrationof 0.1-3mol / L. The chlorine salt corrosive agent can be widely applied to the field of battery aluminum foil manufacturing.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com