Patents

Literature

130 results about "SORBITOL MONOOLEATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

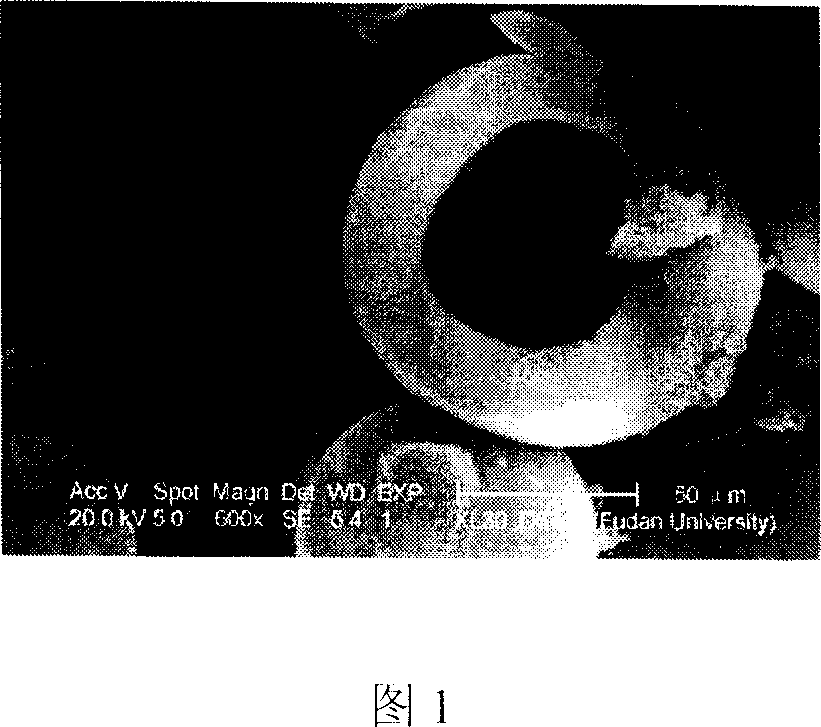

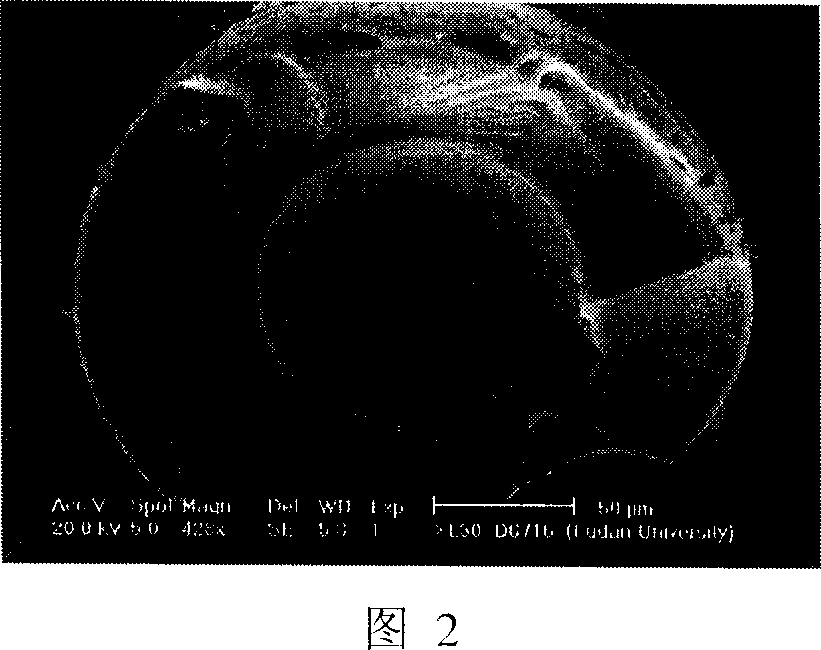

Synthetic method for porous silicon dioxide hollow micro ball

The present invention relates to synthesis process of hollow porous silicon dioxide micro ball. By means of combining O / W / O emulsion and sol-gel technology, using TEOS as silicon source and HNO3 as TEOS hydrolyzing catalyst, and through catalytic hydrolysis reaction at relatively high temperature, the present invention synthesizes hollow porous silicon dioxide micro ball with kerosene as oil phase and Span-80 as emulsifier. The present invention has simple process and cheap material, and the obtained hollow porous silicon dioxide micro ball has wide application foreground in catalysis, selective separation, dielectric material and other field.

Owner:FUDAN UNIV

Additive composition for producing emulsified oil, preparation method of additive composition and application of additive composition

The invention relates to an additive composition for producing emulsified oil, a preparation method of the additive composition and an application of the additive composition. The additive composition is prepared by the following components in parts by weight: 0-15 parts of base oil, 0-10 parts of grease, 5-10 parts of higher aliphatic acid, 5-15 parts of alkylol amine, 15-35 parts of sodium alkane sulfoate, 10-25 parts of dehydration sorbitol single oleate, 2-15 parts of fatty alcohol-polyoxyethylene ether, 1-10 parts of coconut oil fatty acid diethanolamide, 1-10 parts of polyoxyethylene dehydration sorbitol single oleate, 0-0.6 parts of copper alloy corrosion inhibitor, 1-7 parts of antiseptic bacteriacide and 1-8 parts of water. The additive composition is good in stability, easy to keep and transport, strong in emulsifying capacity and high in emulsifying efficiency. Prepared emulsified oil is good in hard water resistance and good in foam restraining performance.

Owner:JINAN COOLANT TECH CO LTD

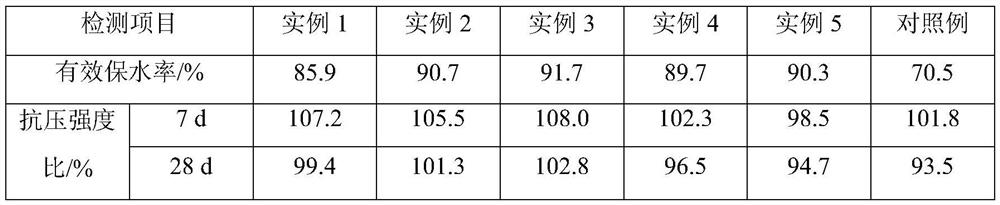

Reinforced organic-inorganic composite concrete external curing agent and preparation method thereof

The invention discloses a reinforced organic-inorganic composite concrete external curing agent and a preparation method thereof. The external curing agent is prepared from the following raw materials: 15-20 parts of paraffin, 10-15 parts of micro-crystalline wax, 5-10 parts of stearic acid, 10-20 parts of polymer emulsion, 5-10 parts of a reinforcing component, 5-10 parts of a composite emulsifier, 0.2-2 part of an anti-foaming agent, 0-3 parts of a leveling agent and 50-100 parts of deionized water. The polymer emulsion is a styrene-acrylic emulsion, a pure acrylic emulsion, a silicone acrylic emulsion or an ethylene-propylene emulsion; the reinforcing component is a polyether-hydrated calcium silicate organic inorganic composite material, triethanolamine, calcium nitrate, calcium formate, urea, sodium silicate, potassium silicate and sodium meta-silicate pentahydrate; and the composite emulsifier is polyoxyethylene sorbitan mono-oleate, polyoxyethylene sorbitan mono-stearate, sorbitan mono-stearate, sorbitan fatty acid ester, nonyl phenol polyoxyethylene ether and the like. The invention also provides a preparation method of the external curing agent. The effective water retention rate and the compressive strength ratio of concrete can be improved by the external curing agent.

Owner:刘翠芬

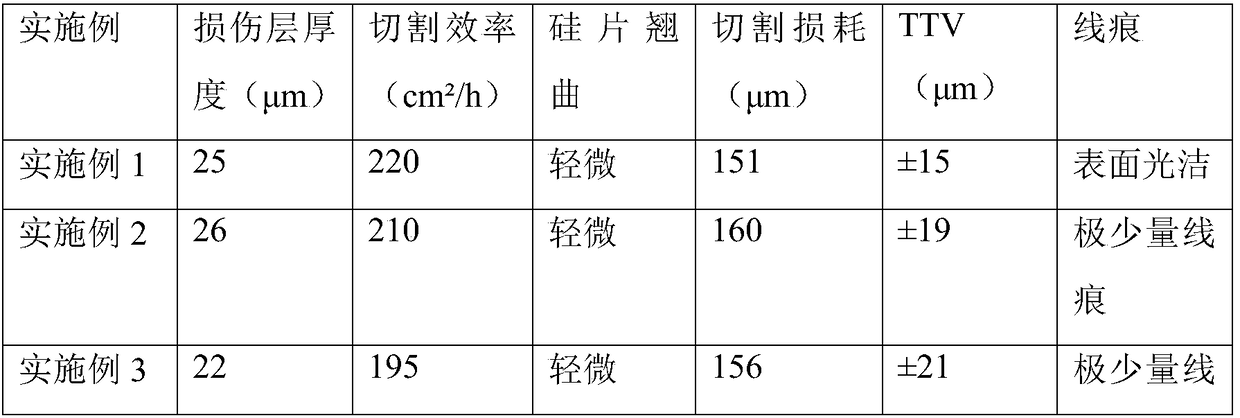

Water-based diamond wire silicon wafer cutting fluid

ActiveCN108559602AImprove the lubrication effectFast cutting speedFine working devicesLubricant compositionWater basedPhotovoltaic industry

The invention belongs to the technical field of cutting of silicon crystals of a photovoltaic industry, and particularly relates to water-based diamond wire silicon wafer cutting fluid. The water-based diamond wire silicon wafer cutting fluid is prepared from the following components: fatty acid methyl ester, polyethylene glycol 400 monolaurate, sodium di-sec-octylmal-eacesulfonate, polyoxyethylene dehydrated sorbitol monooleate, sodium xylene sulfonate, decyne-diol-polyoxyethylene ether and deionized water. The water-based diamond wire silicon wafer cutting fluid is excellent in lubricating performance and cooling performance, high in silicon powder precipitation speed, small in diamond wire abrasion, simple in preparation method, easy in controlling conditions, low in cost, low in requirement for equipment and suitable for industrialized production.

Owner:CHINA THREE GORGES UNIV

Microemulsion and its preparation process and use in treating industrial phenolic waste water

InactiveCN1837081AHigh phenol removal rateLess investmentTransportation and packagingMixingHigh concentrationIndustrial waste water

This invention refers to a microemulsion and Process for preparing as well as the use in dealing with industrial sewage contains hydroxybenzene. The invention is consisted of oil phase and internal water, thereinto the oil phase is consisted of two-(2-ethyl group hexyl) phosphate ester, dehydration sorbitol monooleate and coal oil according to mass ratio 1:0.5- 1.5:4-6, internal water phase is alkaline solution, the volumetric ratio of oil phase and internal water phase is 5:2- 3. The industrial waste water dealed by this invention has the virtues of good liquid film stability, quick mass transfer velocity, high separating efficiency, simple technics, recoverable solute, needing no strong agitation, high pressure static electricity demulsifying setting and so on. The operation cost is low, the stability of motion is good, especially adapts to the dealing, reclamation and utilization of waste water of high concentration hydroxybenzene contain, conquering the biological method's disadvantages of large initial investment, high operation cost, large accommodation area and not suit to the disposal of high concentrated wastewater.

Owner:JIANGHAN UNIVERSITY

Semi-synthetic metal cutting liquid and preparation method thereof

ActiveCN103695144AImprove the lubrication effectEasy to cleanLubricant compositionSebacic acidDimethyl siloxane

The invention relates to a semi-synthetic metal cutting liquid. The semi-synthetic metal cutting liquid is prepared by the following raw materials in parts by weight: 2-3 parts of sodium dodecyl sulfate, 4-5 parts of sebacic acid, 3-5 parts of sorbitol monooleate, 1-2 parts of monoethanolamine, 10-12 parts of mineral oil, 10-12 parts of isopropyl myristate, 3-4 parts of polydimethylsiloxane, 2-3 parts of sodium sulfate, 2-3 parts of citric acid, 10-12 parts of poly alkylene glycol, 6-8 parts of additive, and 200 parts of water. The metal cutting liquid has the advantages of good lubricity and cleaning performance, overcomes the defect that emulsified cutting liquid is easy to go bad and stink and has short service life and the defect that synthetic cutting liquid has poor oily lubricating property, has good cooling performance, and is environment-friendly.

Owner:广州市蓝化润滑科技有限公司

Compound emulsifier for emulsion explosive

The invention discloses a compound emulsifier for an emulsion explosive. The compound emulsifier comprises the following components as follows in parts by weight: 5-70 parts of oil-soluble surfactant OSP, 1-30 parts of calcium sulfonate, 3-60 parts of sorbitol monooleate and 3-15 parts of oleic acid. The compound emulsifier disclosed by the invention is applicable to the preparation of the emulsion explosive of level 1 emulsion process; consequently, the prepared emulsion explosive is stable in storage and excellent in explosion performance.

Owner:广东灵捷制造化工有限公司

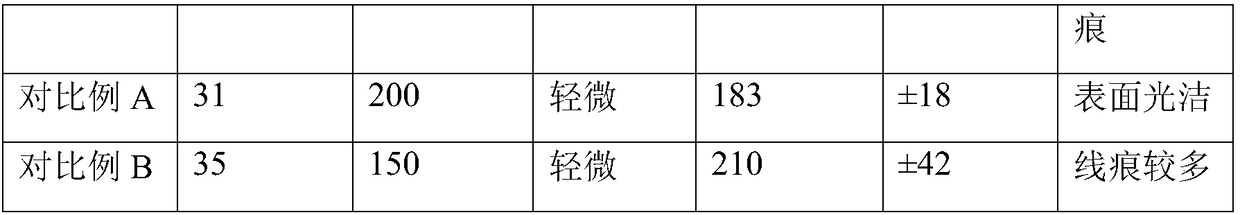

Lubricating oil for mechanical equipment and preparation method thereof

InactiveCN108822934AHigh viscosityImprove the lubrication effectLubricant compositionAntioxidantMechanical equipment

The invention discloses lubricating oil for mechanical equipment and a preparation method thereof, and relates to the field of lubricating oil. The lubricating oil for the mechanical equipment comprises the following raw materials in parts by weight: 30-40 parts of polyalphaolefin, 15-20 parts of fluorosilicone oil, 1.5-4 parts of pentaerythritol ester, 2-5 parts of modified nanodiamond, 1-3 partsof castor oil, 3-6 parts of grapheme, 1-3 parts of molybdenum disulfide, 0.4-0.8 part of Tween, 0.5-1.2 parts of sorbitol monooleate, 0.2-0.6 part of an antioxidant, 0.4-0.8 part of a demulsifying agent and 0.7-1.5 parts of a viscosity index improver. Through cooperation of the raw materials, the lubricating oil has good viscosity, lubricity and antioxidation; the lubricating oil forms a curing protection layer on the surface of the mechanical equipment; meanwhile, the lubricating oil has good wear resistance and durability.

Owner:合肥博创机械制造有限公司

Health care craem for oral taking and external use and its preparation

InactiveCN1583030ASignificant curative effect on angina pectorisSignificant effectDigestive systemUnknown materialsVegetable oilEmulsion

A health-care cream able to be applied both internally and externally is prepared from 10 raw materials including vegetable oil, puerarin, tea polyphenol, sodium alginate, propanetriol, etc through preparing solution, emulsion, homogenizing and packing.

Owner:冯成铨

Metal antirust emulsion and preparation method thereof

InactiveCN103450754AComply with the requirements of impregnated paintWax coatingsAnti-corrosive paintsPolyvinyl alcoholLacquer

The invention discloses a metal antirust emulsion and a preparation method thereof. The metal antirust emulsion comprises the following components in parts by weight: 20-30 parts of oleic acid, 1-5 parts of alkylphenol polyoxyethylene, 3-8 parts of triethanolamine, 5-10 parts of polyvinyl alcohol, 3-8 parts of paraffin, 6-12 parts of barium petroleum sulfonate, 0.5-3 parts of dehydrated sorbitol monooleate and 50-60 parts of pure water. The preparation method comprises the following steps: adding polyvinyl alcohol into pure water, dissolving by stirring at 80-90 DEG C until the solution becomes clear, cooling to 40-50 DEG C to obtain a solution 1, dissolving the rest of components by stirring at 70-85 DEG C, and finally, mixing with the solution 1. The metal antirust emulsion disclosed by the invention is free of toxicity and smell, and adopts an oily corrosion inhibitor with antirust action, so that the metal workpiece immersed in the emulsion can be quickly dried due to the evaporation of water without oil stain seepage, and thus, the immersed workpiece can satisfy the requirements for dipping lacquer.

Owner:WUJIANG LONGXU METAL PROD

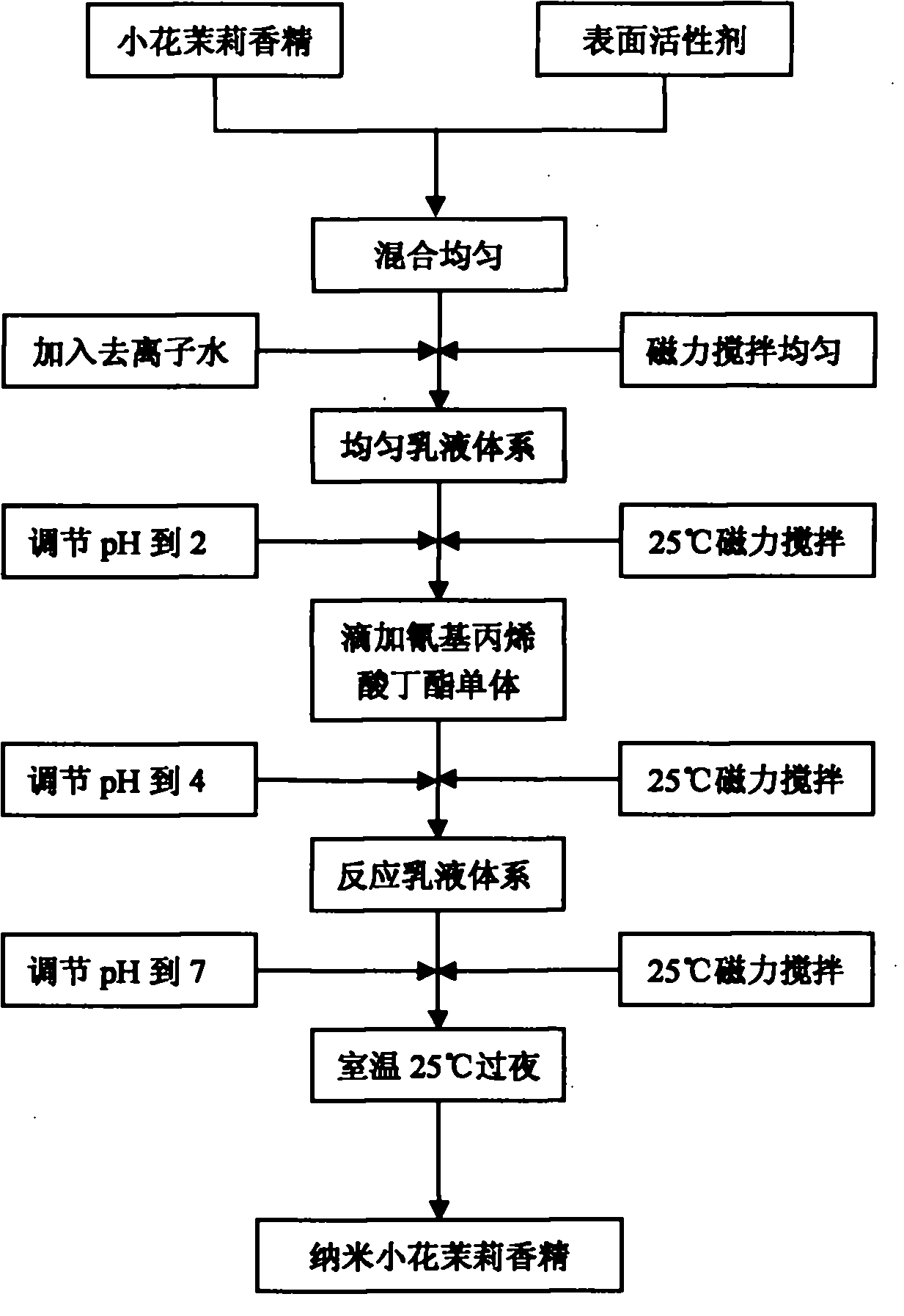

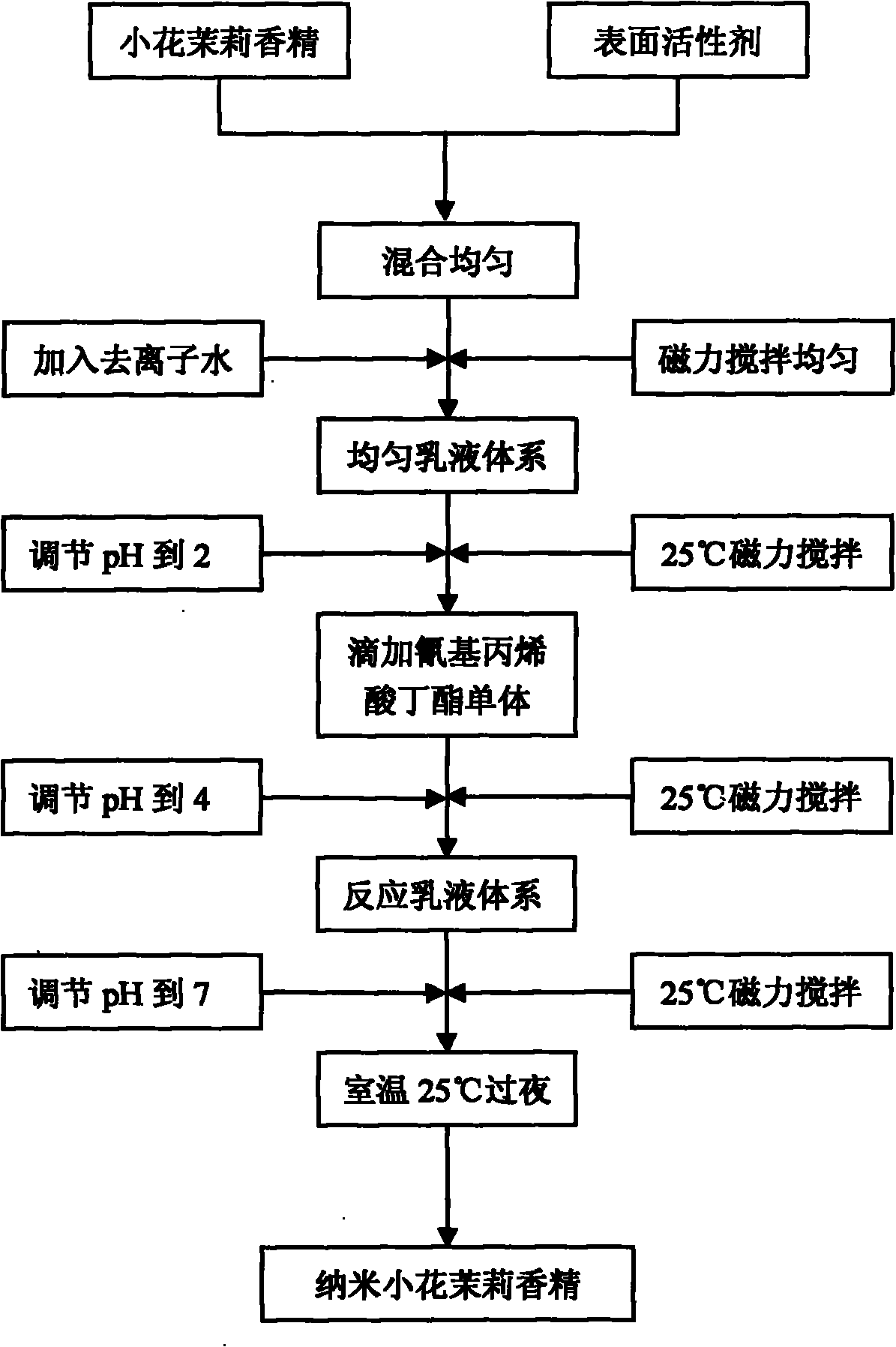

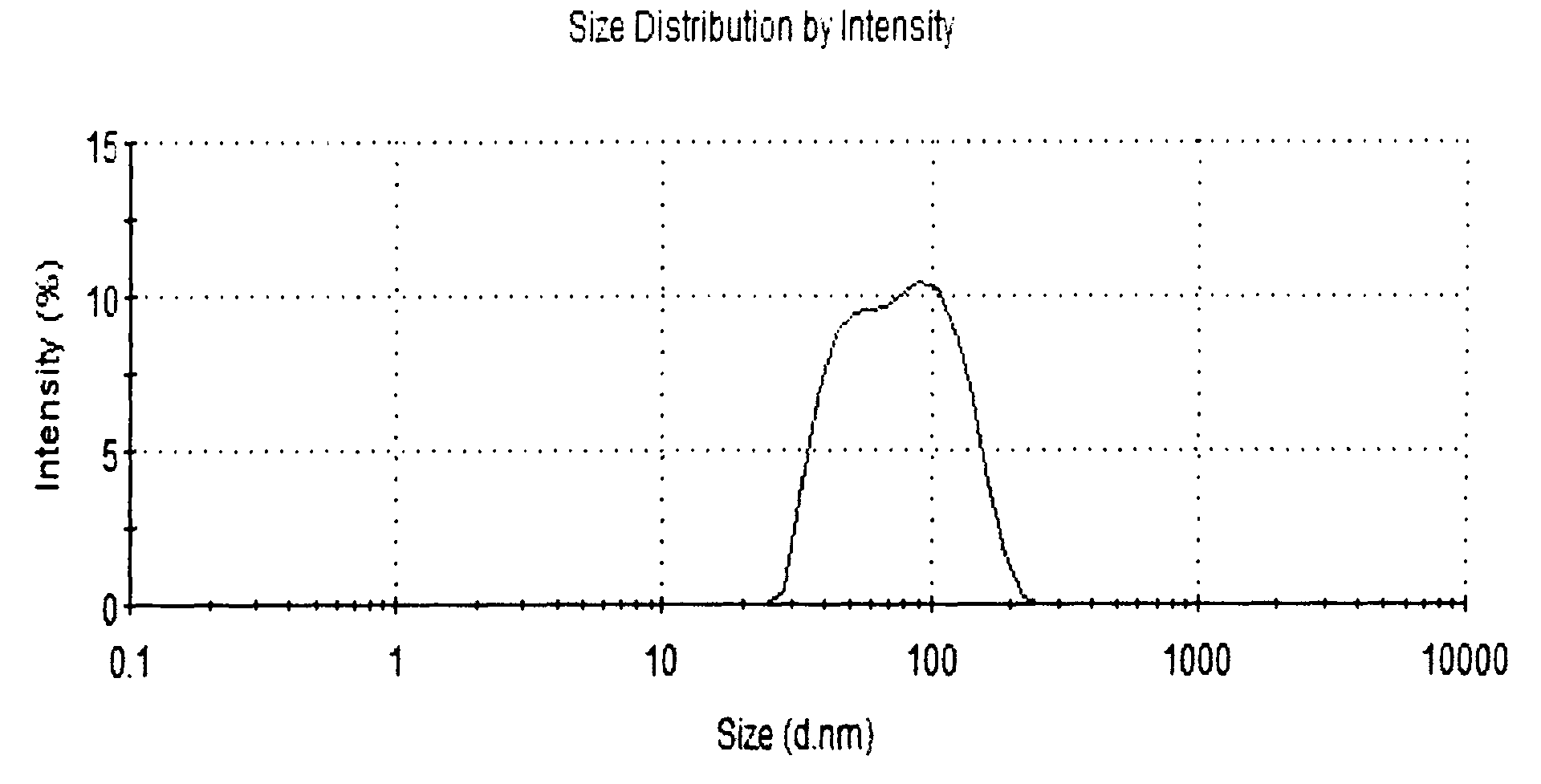

Preparation method of jasmine sambac essence capsule

InactiveCN101811015ADistinctive floral scent of jasmineAroma stabilityEssential-oils/perfumesMicroballoon preparationParticle-size distributionPOLYOXYETHYLENE ETHER

The invention discloses a preparation method of a jasmine sambac essence capsule. The nanometer essence consists of the following components by weight part: 0.66 to 1.06 jasmine sambac essences, 0.54 to 2.4 NBCA, 2 to 3.2 surfactants (selected from polyoxyethylene (20) sorbitan mono-laurate, polyoxyethylene sorbitan palmitate and polyoxyethylene sorbitan monooleate), and 93.62 to 96.26 deionized water. The nanometer jasmine sambac essence emulsion prepared by the invention is milk white, blue light phenomenon is obvious, and the system is uniform and stable. Jasmine flowers have obvious perfume and graceful and delicate fragrance. Tested by dynamic laser light scattering, the nanometer jasmine sambac essence has uniform particle size distribution, the average particle size is 70.8nm and the particle size distribution coefficient is 0.210.

Owner:SHANGHAI INST OF TECH

Moisturizing aloe vera gel and preparation method thereof

InactiveCN104983628AGood moisturizing effectIncreased Moisture LastingCosmetic preparationsToilet preparationsBiotechnologyPolythylene glycol

The invention discloses a moisturizing aloe vera gel and a preparation method thereof. The moisturizing aloe vera gel comprises the following raw materials in parts by weight: 80-140 parts of water, 50-80 parts of arbutin, 45-65 parts of hydrogenated castor oil, 60-70 parts of olive-pomace oil, 30-60 parts of tocopherol, 20-50 parts of carbomer, 25-55 parts of triethanolamine, 15-35 parts of sorbitan monooleate, 20-40 parts of allantoin, 10-20 parts of an aloe vera gel noumenon, 15-45 parts of methyl chloride isothiazolinone, 40-70 parts of low molecular weight chitosan and 35-55 parts of polyethylene glycol. The preparation method comprises the following steps: heating water, arbutin, hydrogenated castor oil, olive-pomace oil, tocopherol, carbomer, triethanolamine, sorbitan monooleate, allantoin, methyl chloride isothiazolinone, low molecular weight chitosan and polyethylene glycol to 40-50 DEG C, adding the aloe vera gel noumenon while cooling to 30-40 DEG C, and carrying out uniform stirring. The moisturizing aloe vera gel provided by the invention has the advantages that the water content can be kept unchanged for all day long and maintained at 46-47%.

Owner:JIANGSU QILIKANG SKIN PHARMA

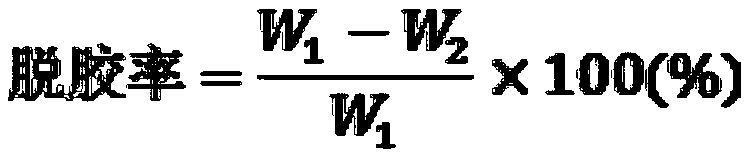

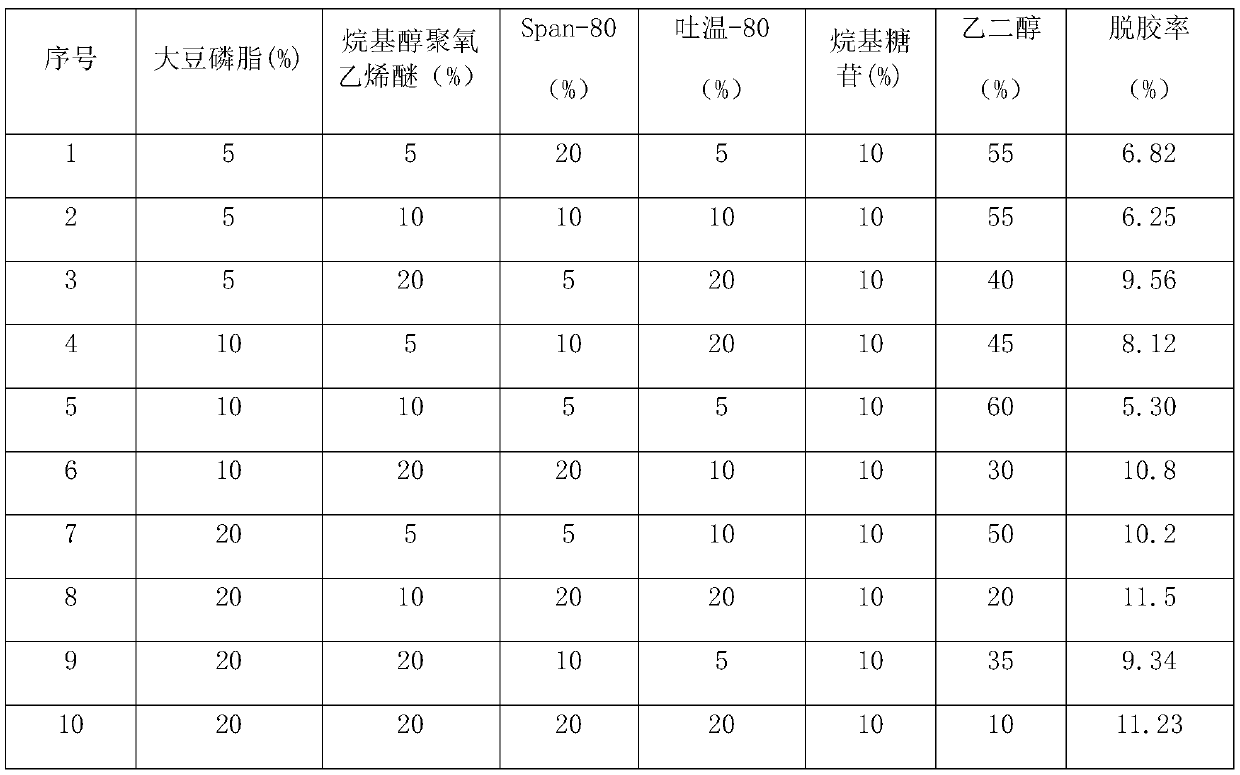

Degumming agent, preparation method of degumming agent, silkworm cocoon degumming method and application

InactiveCN111101207ADegumming is effectiveGood degumming effectClimate change adaptationSewage/sludge fertilisersSurface-active agentsSorbitan

The invention relates to the field of silk processing, and particularly discloses a degumming agent, a preparation method of the degumming agent, a silkworm cocoon degumming method and application. The degumming agent comprises the following raw materials: soybean phospholipid, sorbitan fatty acid ester, polyoxyethylene anhydro sorbitan monooleate, alkyl alcohol polyoxyethylene ether, alkyl polyglucoside and ethylene glycol. The degumming agent provided by the invention has an excellent degumming effect; due to adoption of a biodegradable surfactant, generated degumming wastewater generated inthe degumming process can be further deep-processed into a sericin protein product, and also can be directly used as a fertilizer, so that secondary pollution for the environment can be avoided; anda degumming rate of the silk degumming method provided by the invention can reach over 10%, production requirements of the silk industry can be met, degummed silk can be used for researching and developing foods, cosmetics or medicines, an application range of silk products is further exploited, and a problem that an existing silkworm cocoon degumming method is liable to cause pollution for the environment is solved.

Owner:圣凯科技产业(辽宁)有限公司

Environment-friendly waterborne polyester coating and preparation method thereof

InactiveCN106147581ASmall free volumeIncreased weight loss temperatureFireproof paintsAntifouling/underwater paintsPolyesterAluminate

The invention discloses an environment-friendly waterborne polyester coating. The environment-friendly waterborne polyester coating is prepared from, by weight, 2-3 parts of oxidized polyethylene wax, 2-4 parts of calcium aluminate, 0.7-1 part of poly(butyl acrylate), 35-40 parts of rosin, 8-10 parts of fumaric acid, 6-7 parts of a 20-30% sodium hydroxide solution, 20-34 parts of ethanediol, 0.1-0.2 part of antimonous oxide, 2-3 parts of sodium polyacrylate, 13-20 parts of zinc chloride, 80-90 parts of polyether glycol, 100-130 parts of toluene diisocynate, 2-3 parts of 2,2-dimethylolpropionic acid, 4-5 parts of diethylene glycol, 1-2 parts of triethylamine, 0.2-0.4 part of 2-mercaptobenzimidazole, 0.1-0.3 part of sorbitan monooleate, 1-2 parts of tetrabutylammonium bromide, 2-3 parts of alkylolamide and 0.6-1 part of zinc diricinoleate. The coating is free of toxicity and pollution, high in safety and environmental friendliness and excellent in overall performance.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

Powder coating for aluminium profile

InactiveCN105482629AImprove resistance to media penetrationIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesEpoxyGlycoluril

The invention discloses powder coating for an aluminium profile, prepared from the following raw materials in parts by weight: 3-4 parts of ammonium polyphosphate, 1-2 parts of dibutyltin maleate, 1-3 parts of 1,3,4,6-Tetrakis(methoxymethyl)glycoluril, 3-4 parts of PTMG, 7-8 parts of magnet powder, 14-16 parts of light calcium carbonate, 2-3 parts of ferric oxide, 0.6-0.8 part of sorbitan monooleate, 2-3 parts of carboxymethyl cellulose, 4-5 parts of adipic acid dihydrazide, 10-12 parts of polyurethane resin, 0.3-0.4 part of polyxyethylated alkylphenol, 84-95 parts of epoxy resin, 6-8 parts of phenolic resin, 1-2 parts of vaseline, 0.1-0.2 part of rare earth chloride, 15-18 parts of chitosan and 4-5 parts of polyvinyl alcohol. A prepared product is solvent-free, green and environment-friendly, is flat and smooth in paint film surface, also has the characteristics of high strength, good heat insulation property, high lustrousness and good attachment, and has good application prospect when being used for the aluminium profile.

Owner:TONGLING SIDE TECH

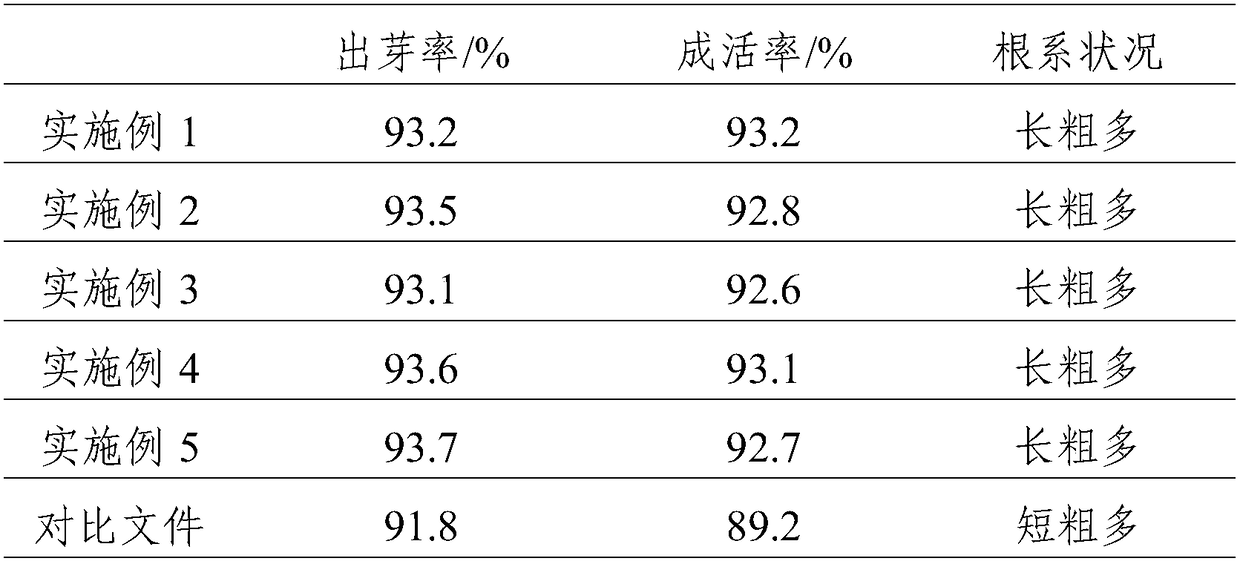

Vegetable seedling culture medium and preparation method thereof

InactiveCN108617466AStrong ability to degrade cellulosePromote seedling growthBio-organic fraction processingBioloigcal waste fertilisersDioxyethylene EtherSorbitan Monooleate

The invention relates to the technical field of agricultural production, in particular to a vegetable seedling culture medium and a preparation method thereof. The vegetable seedling culture medium comprises, by weight, 10-16 parts of vermiculite, 7-14 parts of perlite, 8-13 parts of coco coir powder, 20-28 parts of pine bark powder 1-5 parts of fermented vinegar residues, 4-9 parts of nonylphenolpolyoxyethylene ethers, 2-7 parts of polyoxyethylene dehydrated sorbitan monooleate and appropriate parts of water. The vegetable seedling culture medium has the advantages that vegetable root systems can absorb nutrients and moisture beneficially during growth, air permeability is high, corrosion of the vegetable root systems is avoided, vegetable growth is promoted, soil is protected, and sliming is avoided; initial water absorption capacity after trays are filled with the medium and the rewetting capability of the medium after drying in the seedling culture period are promoted, vegetable germination rate is increased, and vegetable growth is promoted.

Owner:和县中禾农业科技有限公司

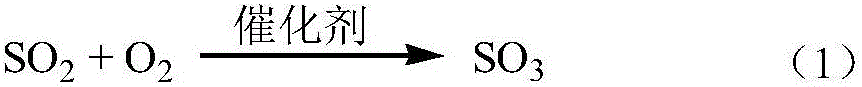

Multifunctional liquid efficient fuel-coal sulfur-fixing agent and preparation method thereof

InactiveCN107177387AEasy to useAccurate measurementSolid fuelsFuel additivesFatty alcoholVanadium oxide

The invention discloses a multifunctional liquid efficient fuel-coal sulfur-fixing agent and a preparation method thereof. The multifunctional liquid efficient fuel-coal sulfur-fixing agent comprises lanthanum oxide, cerium oxide, vanadium oxide, nano-titanium oxide, nano-zinc oxide, nano-nickel oxide, nano-calcium carbonate, nonylphenol polyoxyethylene ether, octylphenol polyoxyethylene ether, fatty alcohol-polyoxyethylene ether, oily penetrating agents, polydiethylene glycol monooleate, glycerol, polymeric glycol, propylene glycol polyoxyethylene polyoxypropylene ether, dimethyl polysiloxane polyether, dehydration sorbitol monooleate and the balance diethylene glycol. According to the technical scheme, yttrium oxide, aluminum acetylacetonate and polyoxyethylene ether are added. The sulfur-fixing efficiency of the multifunctional liquid efficient fuel-coal sulfur-fixing agent can reach 99% or more, the denitration efficiency of the sulfur-fixing agent can reach 50% or more, the combustion rate and the burn-off rate of coal can be sufficiently increased, the ignition point of the coal is remarkably reduced by 50 DEG C or more, the combustion efficiency of the coal is improved by 25% or more, so that combustion environments are reasonably improved, and boiler coking is prevented and removed.

Owner:NANJING RONGFENG ES&T CO LTD

Efficient wood preservative

InactiveCN104924392AImprove anti-corrosion performanceKill strongBiocideWood treatment detailsBiotechnologyEpoxy

An efficient wood preservative is prepared from, by weight, 6-11 parts of epoxy resin, 0.5-2 parts of acrylic acid, 6-8 parts of dioctyl dimethyl ammonium chloride, 3-5 parts of polyethylene glycol, 4-6 parts of disodium octaborate, 5-7 parts of glycerol monostearate, 8-10 parts of agastache rugosa, 7-8 parts of rhizoma imperatae, 11-15 parts of liquorice, 2-4 parts of sorbic acid, 3-8 parts of natamycin, 0.6-1 part of lactic acid, 6-15 parts of 43% ethyl alcohol and 6-12 parts of polyoxyethylene sorbitan monooleate. The efficient wood preservative has the advantages of no toxicity, no harm, good anti-corrosion effect and capabilities of killing and inhibiting decay fungi and pests effectively.

Owner:QINGDAO TOPLINK INFORMATION TECH

Nano flocculation material for water treatment and preparation method of nano flocculation material

InactiveCN105271495AImprove adsorption capacityGood flocculation effectWater/sewage treatment by flocculation/precipitationMethacrylateCellulose

The invention discloses a nano flocculation material for water treatment and a preparation method of the nano flocculation material. The nano flocculation material for water treatment comprises components in parts by weight as follows: 45-55 parts of dimethylamino ethyl methacrylate, 8-12 parts of diallyl dimethyl ammonium chloride, 8-11 parts of mannitol, 7-9 parts of N-(5-ethoxy) nicotinamide nitrate, 3-5 parts of hydroxypropyl methyl cellulose, 2-3 parts of polyoxyethylene sorbitan monooleate, 3-5 parts of cetyl alcohol, 1-1.5 parts of activated carbon fiber and 0.5-1 part of borax. The invention further provides a preparation method of the nano flocculation material for water treatment.

Owner:苏州书瑞环保科技有限公司

Anti-stripping bacteriostatic waterborne coating for glass doors and preparation method thereof

InactiveCN104449132AImprove antibacterial and anti-mildew effectImproved air purificationAntifouling/underwater paintsPaints with biocidesCarrageenanPhosphate

The invention discloses an anti-stripping bacteriostatic waterborne coating for glass doors. The coating is characterized by being prepared from the following raw materials in parts by weight: 23-26 parts of waterborne epoxy resin, 44-48 parts of waterborne amino acrylic resin, 1-2 parts of zinc powder, 0.4-0.7 part of monocrystalline silicon powder, 1-2 parts of elastic HDI (hexamethylene diisocyanate) curing agent E405-80T, 0.1-0.3 part of n-butyl phosphate defoaming agent, 0.3-0.6 part of white corundum powder, 0.2-0.4 part of potassium polyacrylate, 0.2-0.4 part of carrageenan, 0.1-0.3 part of organic silicon defoaming agent, 0.3-0.5 part of polyoxyethylene sorbitan monooleate, 0.5-1.0 part of silane coupling agent KH550, 1-3 parts of dipropylene glycol mono butyl ether, 3-5 parts of modified nano titanium dioxide photocatalyst, 1-2 parts of pigment, 2-3 parts of limonene, 2-4 parts of ethanol and 12-15 parts of deionized water. The added modified nano titanium dioxide photocatalyst can increase the functions of bacteriostasis, mildew resistance, air purification, deodorization, stain resistance, self cleanliness and the like for the coating; the added monocrystalline silicon powder can improve the hardness of the coating; the added zinc powder and white corundum powder have the performance of resisting rust, atmospheric corrosion, ageing and fire and the like; and therefore, the coating has the advantages of high adhesion, less stripping possibility, high hardness, abrasion resistance, good climate resistance, less ageing possibility, no toxicity and environmental friendliness, and can be widely applied to glass for household decoration and the like.

Owner:安徽省实防新型玻璃科技有限公司

High concentration organic zinc fertilizer and its preparing method

InactiveCN1944350AHigh biological availabilityRaw materials are easy to getZinc hydroxideHigh concentration

The high concentration organic zinc fertilizer is prepared with inorganic zinc compound 30-70 wt%, organic complex 10-30 wt%, assistant 10-20 wt% and water for the rest. The inorganic zinc compound is one or two of zinc oxide, zinc sulfate, zinc nitrate, zinc hydroxide, zinc sulfide and zinc chloride; the organic complex is at least one of ethylene diamine, diethylamine, diethanolamine, etc; and the assistant is at least one of sorbitan monooleate ethoxylate, alkylphenol ethoxylate, fatty alcohol ethoxylate and caster oil ethoxylate. The present invention can replenish zinc in crop to improve quality of crop, increase yield of crop and resist disease. The present invention also provides the preparation process of the high concentration organic zinc fertilizer.

Owner:四川省兰月农化科技开发有限责任公司

Fabric rust inhibitor and preparation method thereof

The invention discloses a fabric rust inhibitor and a preparation method thereof. The fabric rust inhibitor is prepared from the following components in parts by weight of: 20-40 parts of dialkyl group polyoxyethylene phosphonate, 4-9 parts of sodium aliphatate, 3-5 parts of diethanol amine, 10-20 parts of fatty acid polyethylene glycol ester, 1-3 parts of sodium nitrite, 8-15 parts of sorbitol monooleate, 6-10 parts of stearic acid and 60-80 parts of water. Compared with the prior art, the fabric rust inhibitor has the beneficial effects that (1) the corrosion of a cationic surfactant can br restrained, and simultaneously, the color and luster of a fiber can not be influenced; (2) the smoothness of an oiling agent for spinning is not affected; and (3) the preparation process is simple and the cost is low.

Owner:WUJIANG DEKELI TEXTILE PROD

Light protective type finishing wax for leather surface and preparation method thereof

InactiveCN109294443AGood emulsifying effectIncrease surface tensionWax coatingsFatty alcoholPOLYOXYETHYLENE ETHER

The invention discloses a light protective type finishing wax for leather surface and a preparation method thereof; the finishing wax is prepared with Brazil palm wax and rice bran wax as raw materials by a water-in-wax emulsification method; at the same time, a lipophilic emulsifier, a hydrophilic emulsifier, a co-emulsifier, deionized water, a wetting agent, a regulator and a stabilizer are added; as the key, the lipophilic emulsifier and the hydrophilic emulsifier are simultaneously chosen on the selection of the emulsifiers, wherein the hydrophilic emulsifier is a mixture of fatty alcoholpolyoxyethylene (3) ether and sorbitol monooleate, while the hydrophilic emulsifier is selected from a mixture of fatty alcohol polyoxyethylene (25) ether and polyoxyethylene sorbitol monooleate. Thefinally prepared emulsified wax can be placed at room temperature of 25 DEG C for 2 years without stratification or precipitation, can resist low temperature and high temperature, acid and alkali, andhas high stability and long shelf life. The finishing wax can be used as a leather surface finishing auxiliary agent.

Owner:WENZHOU UNIVERSITY

Molybdenum disulfide-added stainless steel wire drawing liquid with good lubricity and preparation method thereof

The invention discloses a molybdenum disulfide-added stainless steel wire drawing liquid with good lubricity, which comprises the following raw materials by weight: 2-3 parts of molybdenum disulfide, 2.5-4 parts of cerium tetrafluoride, 1-2 parts of cobaltous naphthenate, 4-5.5 parts of fatty alcohol polyoxyethylene ether, 3-4 parts of glycol, 2.5-3.5 parts of citric acid, 3-5 parts of sorbitan mo-nooleate, 1-2 parts of lead naphthenate, 3.5-4.5 parts of vulcanized whale oil, 3-4 parts of bobbin oil, 5-7 parts of auxiliary agent and 900-950 parts of deionized water. The added molybdenum disulfide as a lubrication additive is mixed with a surfactant through grinding, powder has the advantages of uniform dispersion as well as stable and uniform quality, and the added auxiliary agent has good antiwear, dispersion, lubrication and film forming ability. The employed aqueous formula has good heat radiation and cleaning performance, the wire drawing liquid has advantages of good lubrication performance, low flow viscosity, good fluidity and stability, and low cost, and is suitable for wire drawing of the stainless steel.

Owner:ANHUI TATSU PRECISION ALLOY

Grease composition for assembling standard sections of tower crane and preparation method of grease composition

ActiveCN104164289AImprove wear reduction performanceGood adhesion resistanceLubricant compositionLithiumSulfonate

The invention relates to a grease composition for assembling standard sections of a tower crane and a preparation method of the grease composition. The grease composition comprises the following components in percentage by weight: 78.8%-94.8% of common lithium-based grease, 0.2%-0.8% of antioxidant, 0.8%-3.2% of graphite powder, 1.0%-4.5% of light calcium carbonate, 0.5%-3.0% of sorbitan monooleate, 0.4%-2.2% of phenolic resin, 2.0%-6.0% of sulfonate and 0.3%-1.5% of polyisobutene. The special grease composition for assembling the standard sections of the tower crane is obtained by adding additives such as the antioxidant, an antifriction agent, an anti-locking and anti-occluding agent, an anti-rust agent, a tackifying agent and the like into the common lithium-based grease taken as a carrier. According to the grease composition, the corrosion speed of shaft pins of the tower crane can be slowed, the shaft pins are prevented from being corroded and bonded with a shaft sleeve during building construction, and the pin shafts of the standard sections of the tower crane can be smoothly assembled and disassembled. The service cycle of the grease composition is within 1-2 years.

Owner:CHINA PETROLEUM & CHEM CORP

Coating material thickener preparation method

The present invention discloses a coating material thickener preparation method, which is characterized by comprising: 1) uniformly mixing 1 part by mass of span S-80, 3 parts by mass of hydroxymethyl cellulose, 0.1 part by mass of azobisisobutyronitrile, 3 parts by mass of metacrylic acid hexadecaester, 1 part by mass of liquid paraffin, and 7 parts by mass of xylene to form an oil phase; 2) taking 10 parts by mass of acrylic acid, adding to ammonia water, neutralizing to achieve the PH value of 6.5-7, adding 2 parts by mass of N,N-methylene bisacrylamide, 2.5 parts by mass of acrylamide, and 3.5 parts by mass of distilled water, and uniformly stirring to form a water phase; 3) adding the water phase to the oil phase, stirring for 2 h, heating to a temperature of 100 DEG C under nitrogen protection, initiating a polymerization reaction, and carrying out pressure reducing azeotrope after carrying out the reaction for 8 h to remove water and xylene so as to obtain a polymer latex; and 4) adding 5 parts by mass of sorbitan monooleate polyoxyethylene ether to the polymer latex to obtain the coating material thickener. According to the present invention, the prepared coating material thickener has characteristics of significant thickening effect, good leveling property, good stability, low environmental pollution, and low waste of resources.

Owner:CHANGSHU MIAOQUAN SHENGDA AUX FACTORY

Bacteriostatic skin-care cream

InactiveCN104055983AGood treatment effectThorough curative effectAntibacterial agentsHeavy metal active ingredientsBiotechnologyEscherichia coli

Owner:孙占全

High-performance environmental-friendly metal cutting liquid

InactiveCN104046488ANo pollution in the processLubricant compositionO-Phosphoric AcidPolyvinyl alcohol

The invention discloses a high-performance environmental-friendly metal cutting liquid which is characterized by being prepared from the following raw materials in parts by weight: 3-8 parts of phosphoric acid, 8-13 parts of petroleum acid zinc, 3.5-9 parts of monoethanolamine, 1.5-2.8 parts of antirust agent, 1.5-3 parts of chromium sesquioxide, 1.2-2.5 parts of polyvinyl butyral resin, 1.5-4 parts of sorbitol monooleate and 30-45 parts of water. The cutting liquid has the beneficial effects of security, efficiency and no environmental pollution.

Owner:QINGDAO JIZHI ENERGY SAVING ENVIRONMENTAL PROTECTION

Barium-free antirust grease with thixotropy after dilution and preparation method of antirust grease

The invention discloses barium-free antirust grease with thixotropy after dilution. The barium-free antirust grease is characterized by comprising the following raw materials in parts by weight: 13-16 parts of beewax, 10-14 parts of spermaceti wax, 36-41 parts of vaseline, 12-15 parts of burning kerosene, 10-13 parts of 50# machine oil, 3-5 parts of attapulgite, 3-4 parts of asphalt, 2-4 parts of precipitated silicon dioxide, 6-8 parts of petroleum sodium sulfonate, 2-3 parts of high-density polyethylene powder, 2-2.5 parts of sorbitan monooleate and 2.5-4 parts of a protective agent. The precipitated silicon dioxide and other thixotropic agents are added into the formula, the phenomenon that waste is caused because the product is easy to flow when being diluted to be used can be avoided, the addition of the protective agent is matched, a firm protective film can be formed on the metal surface, rust caused by erosion of water and oxygen is avoided, and the barium-free antirust grease has the antibacterial, anticorrosive and ultraviolet radiation-resistant effects. Moreover, the antirust grease disclosed by the invention has barium-free and environment-friendly effects, is wide in application range and is suitable for sealing or machining metal parts, and can be used through multiple ways.

Owner:ANHUI WEISA HEAVY MACHINERY

Novel diesel additive composite

InactiveCN101624544ATransparent appearanceImprove performanceLiquid carbonaceous fuelsFuel additivesOleic Acid TriglycerideNaphthalene

The invention relates to a novel diesel additive composite, in particular to a diesel-saving synergist which is characterized by being prepared by the following raw materials by weight portion: 5-10 portions of depressant, 10-30 portions of cetane number depressant, 10-20 portions of non-ionic surfactant and 50-80 portions of organic acid. The depressant is alkyl naphthalene; the cetane number depressant is acetone; the non-ionic surfactant is sorbitol monooleate or alkylbenzene ethyoxyl ether; and the organic acid is oleic acid or naphthenic acid. The diesel-saving synergist has transparent appearance and good performance; the detection shows that the diesel-saving synergist can save the diesel by 25 percent; and the diesel-saving synergist can improve the diesel-saving effect, ensure good burning effect and reduce the tail gas emission which can pollute the environment, thereby having great social benefit.

Owner:乔新光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com