Water-based diamond wire silicon wafer cutting fluid

A silicon wafer cutting fluid and diamond wire technology, applied in the petroleum industry, fine working equipment, manufacturing tools, etc., can solve the problems of poor silicon powder sedimentation, slow cutting speed, low silicon wafer yield, etc., and achieve silicon powder residual The effect of less, less equipment requirements, and fast cutting speed of silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A water-based diamond wire silicon chip cutting fluid, which is calculated as the following components in parts by weight: 8 parts of fatty acid methyl ester, 10 parts of polyethylene glycol 400 monolaurate, and di-sec-octyl maleate sulfonic acid 5 parts of sodium, 4 parts of polyoxyethylene sorbitan monooleate, 0.5 parts of sodium xylene sulfonate, 2.5 parts of decynediol polyoxyethylene ether and 70 parts of deionized water.

[0019] The preparation method of the water-based diamond wire silicon chip cutting fluid in the present embodiment is:

[0020] Add fatty acid methyl ester, polyethylene glycol 400 monolaurate, sodium di-sec-octyl sulfonate maleate, polyoxyethylene sorbitan monooleate, and decynediol polyoxyethylene ether to the stirring Stir in the tank evenly, then slowly add deionized water while stirring to obtain a translucent emulsion, and finally add sodium xylene sulfonate and stir evenly to obtain a water-based diamond wire silicon wafer cutting fluid. ...

Embodiment 2

[0022] A kind of water-based diamond wire silicon chip cutting fluid, calculated as the following components in parts by weight:

[0023] 10 parts of fatty acid methyl ester, 8 parts of polyethylene glycol 400 monolaurate, 5 parts of sodium di-sec-octyl maleate sulfonate, 5 parts of polyoxyethylene sorbitan monooleate, xylene sulfonic acid 1 part of sodium, 5 parts of decynediol polyoxyethylene ether and 66 parts of deionized water.

[0024] The preparation method of the water-based diamond wire silicon chip cutting fluid in the present embodiment is:

[0025] Add fatty acid methyl ester, polyethylene glycol 400 monolaurate, sodium di-sec-octyl sulfonate maleate, polyoxyethylene sorbitan monooleate, and decynediol polyoxyethylene ether to the stirring Stir in the tank evenly, then slowly add deionized water while stirring to obtain a translucent emulsion, and finally add sodium xylene sulfonate and stir evenly to obtain a water-based diamond wire silicon wafer cutting fluid. ...

Embodiment 3

[0027] 5 parts of fatty acid methyl ester, 15 parts of polyethylene glycol 400 monolaurate, 10 parts of sodium di-sec-octyl maleate sulfonate, 2 parts of polyoxyethylene sorbitan monooleate, xylene sulfonic acid 0.1 part of sodium, 1 part of decynediol polyoxyethylene ether and 66.9 parts of deionized water.

[0028] The preparation method of the water-based diamond wire silicon chip cutting fluid in the present embodiment is:

[0029] Add fatty acid methyl ester, polyethylene glycol 400 monolaurate, sodium di-sec-octyl sulfonate maleate, polyoxyethylene sorbitan monooleate, and decynediol polyoxyethylene ether to the stirring Stir in the tank evenly, then slowly add deionized water while stirring to obtain a translucent emulsion, and finally add sodium xylene sulfonate and stir evenly to obtain a water-based diamond wire silicon wafer cutting fluid.

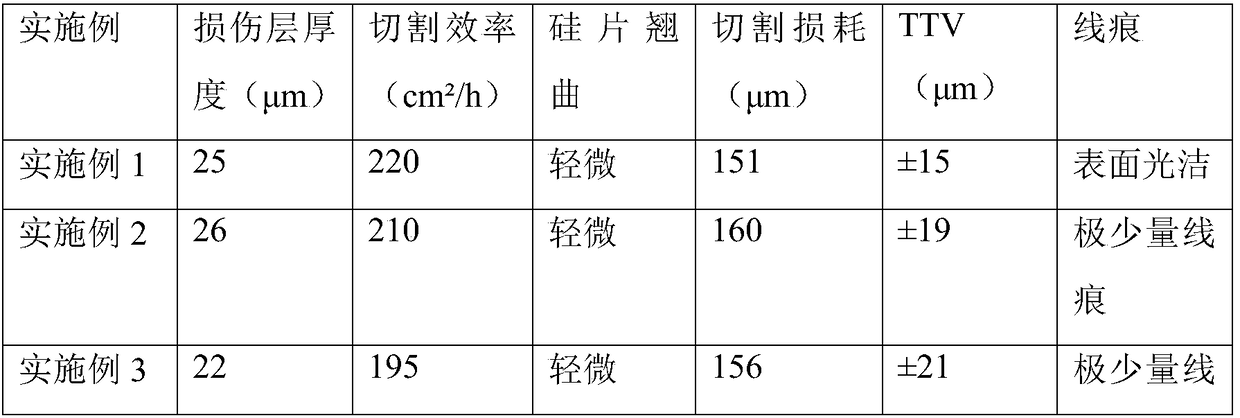

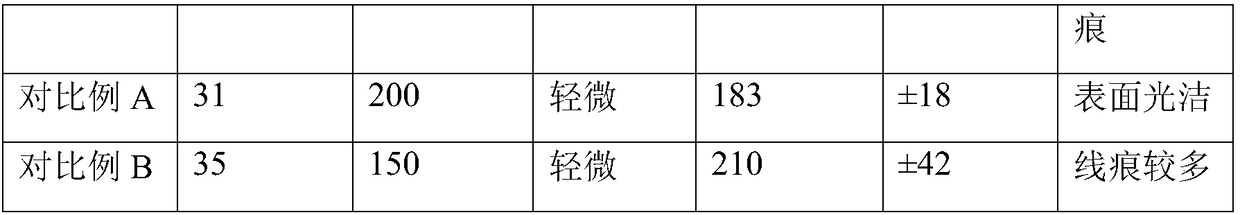

[0030] After the cutting liquid of above-mentioned each embodiment is diluted 400 times with deionized water respectively, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com