Light protective type finishing wax for leather surface and preparation method thereof

A leather and finishing technology, applied in the direction of coating, wax coating, etc., can solve the problems of short shelf life, high production cost, poor emulsion stability, etc., and achieve the effect of improving surface tension, good emulsification, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

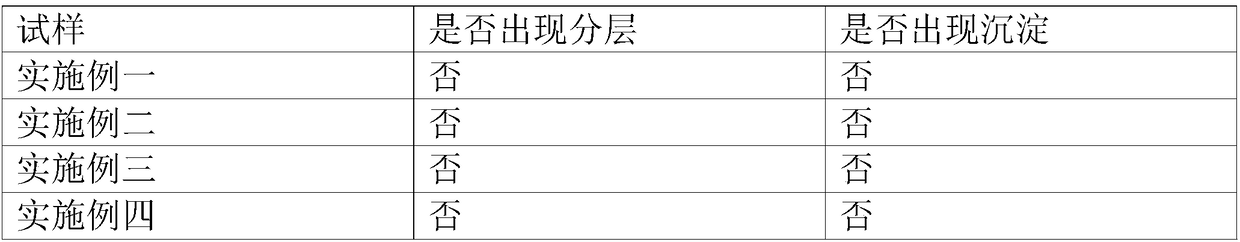

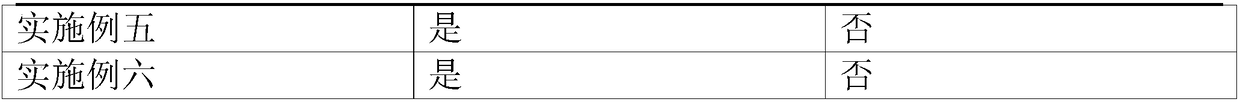

Examples

Embodiment 1

[0032] Embodiment 1: a kind of leather surface gloss-retaining type finishing wax, comprises the following material composition of parts by weight:

[0033] 30 parts carnauba wax;

[0034] 0 parts of rice bran wax;

[0035] 2 parts of lipophilic emulsifier;

[0036] 8 parts of hydrophilic emulsifier;

[0037] 0.6 parts of co-emulsifier;

[0038] 80 parts of deionized water;

[0039] 1.2 parts of wetting agent;

[0040] Regulator 0.3 parts;

[0041] 1.5 parts of stabilizer;

[0042] The lipophilic emulsifier is a mixture of fatty alcohol polyoxyethylene (3) ether and sorbitan monooleate, and its mass ratio is 1:1; the hydrophilic emulsifier is fatty alcohol polyoxyethylene (25) A mixture of ether and polyoxyethylene sorbitan monooleate, the mass of which is 1:7.

[0043] The co-emulsifier is oleic acid.

[0044] The regulator is triethanolamine.

[0045] The stabilizer is (1R,2R)-(-)-N-(p-toluenesulfonyl)-1,2-diphenylethylenediamine, trimethylsilyl 2-(fluorosulfonyl)d...

Embodiment 2

[0052] Embodiment 2: a kind of leather surface gloss-retaining type finishing wax, comprises the following material composition of parts by weight:

[0053] 40 parts carnauba wax;

[0054] 0 parts of rice bran wax;

[0055] 3 parts of lipophilic emulsifier;

[0056] 9 parts of hydrophilic emulsifier;

[0057] 0.8 parts of co-emulsifier;

[0058] 90 parts of deionized water;

[0059] 1.6 parts of wetting agent;

[0060] Regulator 0.4 parts;

[0061] 2 parts of stabilizer;

[0062] The lipophilic emulsifier is a mixture of fatty alcohol polyoxyethylene (3) ether and sorbitan monooleate, and its mass ratio is 1:1; the hydrophilic emulsifier is fatty alcohol polyoxyethylene (25) A mixture of ether and polyoxyethylene sorbitan monooleate, the mass of which is 1:7.

[0063] The co-emulsifier is oleic acid.

[0064] The regulator is triethanolamine.

[0065] The stabilizer is (1R,2R)-(-)-N-(p-toluenesulfonyl)-1,2-diphenylethylenediamine, trimethylsilyl 2-(fluorosulfonyl)di ...

Embodiment 3

[0072] Embodiment three: a kind of leather surface gloss-retaining type finishing wax, comprises the following material composition of parts by weight:

[0073] 25 parts carnauba wax;

[0074] 2 parts rice bran wax;

[0075] 1.5 parts of lipophilic emulsifier;

[0076] 6 parts of hydrophilic emulsifier;

[0077] 0.5 parts of co-emulsifier;

[0078] 75 parts of deionized water;

[0079] 1 part of wetting agent;

[0080] Regulator 0.2 parts;

[0081] 1 part of stabilizer;

[0082] The lipophilic emulsifier is a mixture of fatty alcohol polyoxyethylene (3) ether and sorbitan monooleate, and its mass ratio is 1:1; the hydrophilic emulsifier is fatty alcohol polyoxyethylene (25) A mixture of ether and polyoxyethylene sorbitan monooleate, the mass of which is 1:7.

[0083] The co-emulsifier is oleic acid.

[0084] The regulator is triethanolamine.

[0085] The stabilizer is (1R,2R)-(-)-N-(p-toluenesulfonyl)-1,2-diphenylethylenediamine, trimethylsilyl 2-(fluorosulfonyl)di ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com