Synthetic method for porous silicon dioxide hollow micro ball

A technology of porous silica and synthesis method, applied in the direction of silica, silica, etc., can solve the problems of poor product stability, cumbersome operation, easy collapse of empty walls, etc., achieve mild reaction conditions and improve production efficiency , product quality and the effect of yield guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

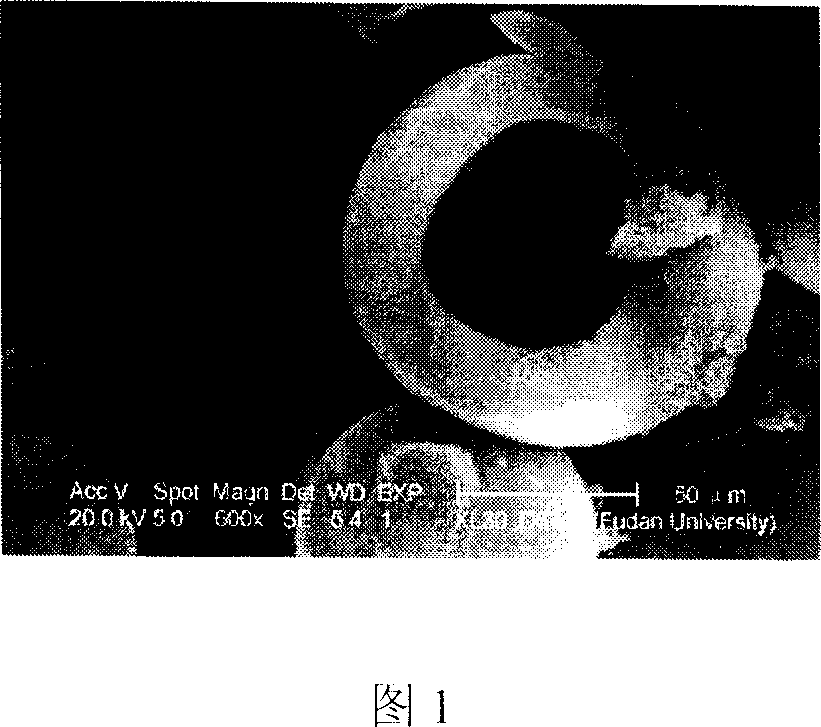

[0021] In TEOS(mol):C 2 h 5 OH (mol): H 2 O (mol): Span-80 (g): kerosene (g) = 1: 3: 20: 15: 40, change and add HNO 3 moles of n(HNO 3 ) / n(TEOS) is 0.5, the product is a hollow sphere, as shown in Figure 1.

Embodiment 2

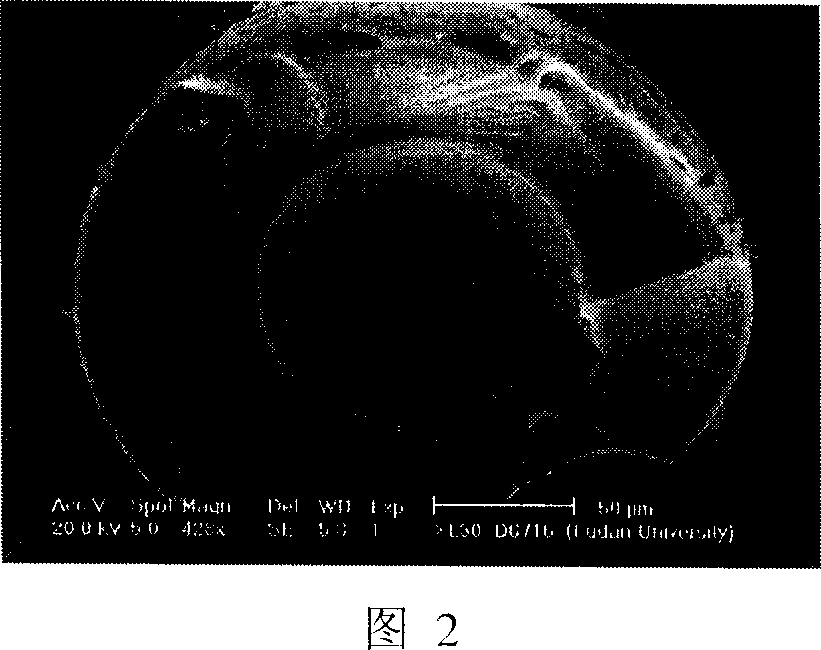

[0023] In TEOS(mol):H 2 O (mol): HNO 3 (mol): Span-80 (g): kerosene (g) = 1: 20: 0.5: 15: 40 conditions, the amount of TEOS is 6ml, change C 2 h 5 The amount of OH added, in n(C 2 h 5 When OH) / n(TEOS) is 2, the product is a hollow sphere, and the SEM photo of the product is shown in Figure 2.

Embodiment 3

[0025] In TEOS(mol): C 2 h 5 OH (mol): H 2 O (mol): HNO 3 (mol): kerosene (g)=1:3:20:0.5:40, the amount of TEOS was 6ml, and the amount of Span-80 was changed. When the Span-80 was 20g / mol TEOS, the product was a hollow sphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com