Reinforced organic-inorganic composite concrete external curing agent and preparation method thereof

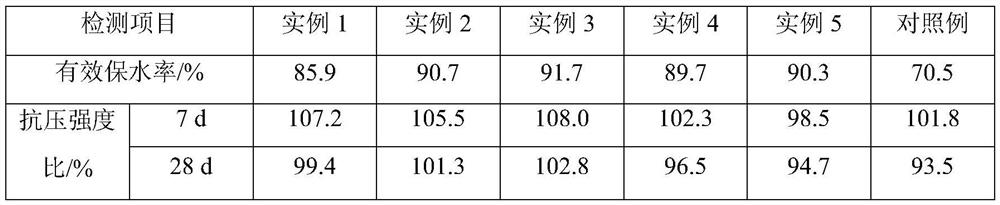

An inorganic composite and concrete technology, applied in the field of concrete external curing agent, reinforced organic-inorganic composite concrete external curing agent, the preparation field of the reinforced organic-inorganic composite concrete external curing agent, can solve the problem of not giving guidance, increasing High viscosity, high price of organic fluorine monomer, etc., to achieve the effect of improving the effective water retention rate and compressive strength ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The reinforced organic-inorganic composite concrete external curing agent of the present invention is made of the following components and raw materials in parts by weight: 20 parts of paraffin wax, 10 parts of microcrystalline wax, 5 parts of stearic acid, Polymer emulsion is 20 parts of styrene-acrylic emulsion, strengthening component is 10 parts of triethanolamine, 8 parts of compound emulsifier, and the compound emulsifier is 6.4 parts of nonylphenol polyoxyethylene ether and 1.6 parts of sorbitan fatty acid ester. A combination of raw materials, 1 part of polyether type defoamer, 0.5 part of pure acrylic leveling agent, 100 parts of deionized water.

[0022] The preparation method of the reinforced organic-inorganic composite concrete external curing agent comprises the following process steps: ①Add 20 parts of paraffin wax, 10 parts of microcrystalline wax, 5 parts of stearic acid, and 10 parts of triethanolamine as a strengthening component in the r...

Embodiment 2

[0023] Embodiment 2: the reinforced organic-inorganic composite concrete external curing agent of the present invention is made of the following components and raw materials in parts by weight: 20 parts of paraffin wax, 10 parts of microcrystalline wax, 5 parts of stearic acid, The polymer emulsion is 20 parts of ethylene-propylene emulsion, 10 parts of strengthening component, the strengthening component is a combination of 5 parts of polyether-calcium silicate hydrate organic-inorganic composite material and 5 parts of triethanolamine, 7 parts of composite emulsifier, and 7 parts of composite emulsifier The agent is a combination of 2.1 parts of monoglycerides of fatty acids and 4.9 parts of sorbitan monostearate, the defoamer is 1 part of polyether type defoamer (can be GPES type), and the leveling agent is silicone leveling agent (It can be polydimethylsiloxane) 0.5 parts, deionized water 100 parts.

[0024] The preparation method of the reinforced organic-inorganic compos...

Embodiment 3

[0025] Embodiment 3: The reinforced organic-inorganic composite concrete external curing agent of the present invention is made of the following components and raw materials in parts by weight: 20 parts of paraffin wax, 15 parts of microcrystalline wax, 5 parts of stearic acid, Polymer emulsion is 20 parts of pure acrylic emulsion, reinforcing component is polyether-hydrated calcium silicate organic-inorganic composite material 10 parts, composite emulsifier 7 parts, composite emulsifier is 2.1 parts of monoglyceride and 4.9 parts of sorbitol The combination of anhydride monostearate, 1 part of defoaming agent, i.e. silicone defoaming agent (can be silicone oil), 0.5 part of leveling agent, i.e. pure acrylic leveling agent, 100 parts of deionized water.

[0026] The preparation method of the reinforced organic-inorganic composite concrete external curing agent comprises the following process steps: ①Add 20 parts of paraffin wax, 15 parts of microcrystalline wax, 5 parts of stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com