Preparation method of jasmine sambac essence capsule

A technology of jasmine essence and florets, which is applied in the field of preparation of floret jasmine essence capsules, to achieve the effects of uniform particle size distribution, stable essence aroma, and elegant aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

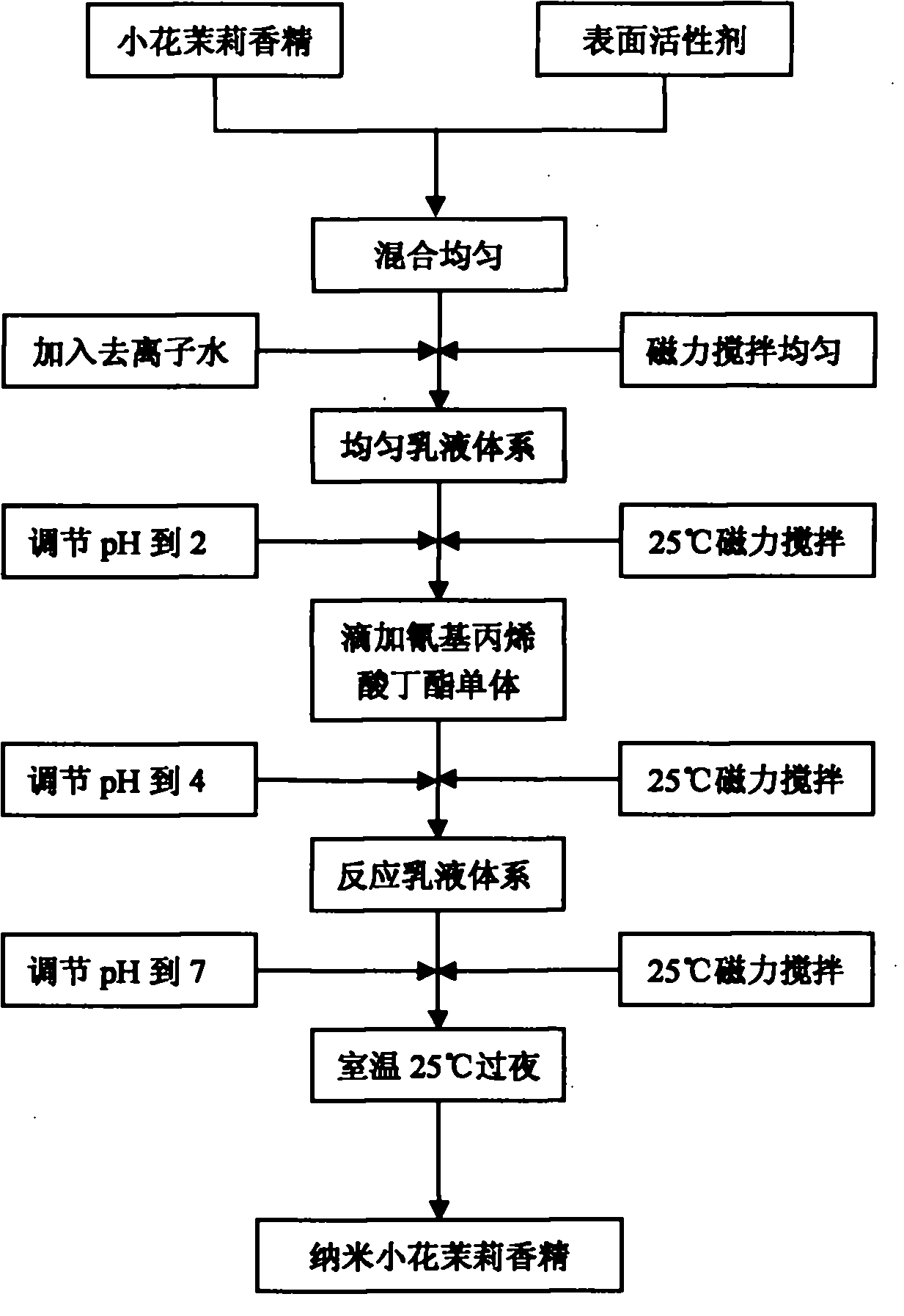

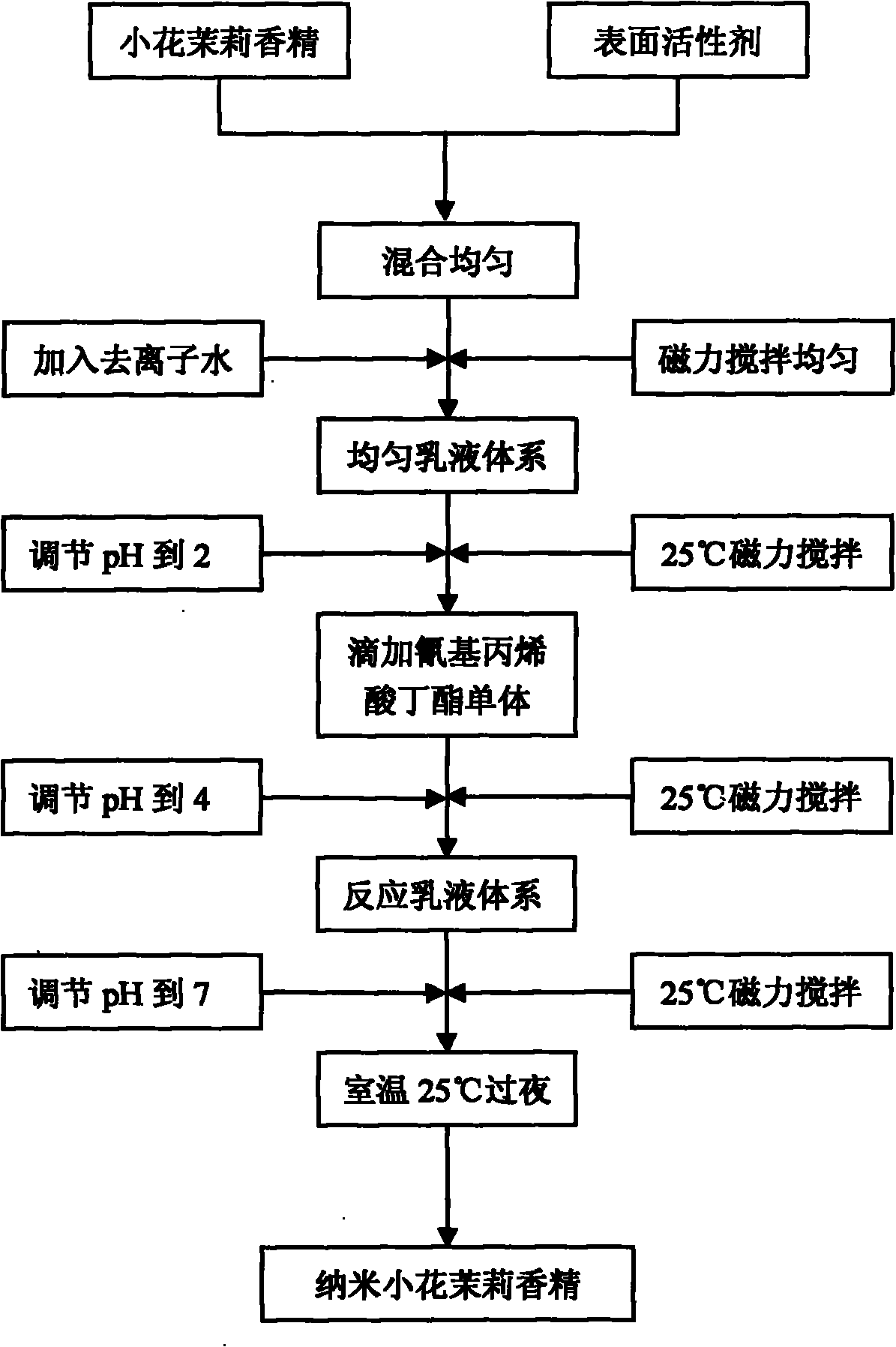

Method used

Image

Examples

Embodiment 2

[0032] Embodiment 2 allotment is used to prepare the jasmine jasmine essence of nanometer essence

[0033] 25.2 parts by weight of 100% concentration of methyl-hexyl cinnamaldehyde, 1.8 parts by weight of 100% concentration of benzyl propionate, 18 parts by weight of 100% concentration of benzyl acetate, 0.25 parts by weight were added to the beaker at one time 100% concentration of cis-jasmone, 1 part by weight of 100% concentration of leaf alcohol, 1.7 parts by weight of 100% concentration of geraniol 980, 5.8 parts by weight of 100% concentration of linalool, 4.1 parts by weight of 100% linalyl acetate, 0.26 parts by weight of 100% concentration of 2,3-benzopyrrole (indole), 11 parts by weight of 100% concentration of methyl dihydrojasmonate Esters, 3.89 parts by weight of 100% phenylethyl alcohol, 0.2 parts by weight of 100% concentration of eugenol, 0.35 parts by weight of 100% concentration of methyl ionone, 2 parts by weight of 100% concentration of hydroxyl Citronella...

Embodiment 3

[0034] Embodiment 3 is used to prepare the jasmine essence of jasmine flower for the preparation of nano essence

[0035] 25 parts by weight of methyl-hexyl cinnamaldehyde at a concentration of 100%, 2 parts by weight of benzyl propionate at a concentration of 100%, 16 parts by weight of benzyl acetate at a concentration of 100%, and 0.5 parts by weight were added to the beaker at one time. 100% cis-jasmone in several parts, 0.75 parts by weight of 100% foliol, 1.5 parts by weight of 100% geraniol 980, 6 parts by weight of 100% linalool, 4 parts by weight of 100% linalyl acetate, 0.25 parts by weight of 100% concentration of 2,3-benzopyrrole (indole), 10 parts by weight of 100% concentration of methyl dihydrojasmonate Esters, 5 parts by weight of 100% phenethyl alcohol, 0.25 parts by weight of 100% concentration of eugenol, 0.3 parts by weight of 100% concentration of methyl ionone, 1.75 parts by weight of 100% concentration of hydroxyl Citronellal methyl anthranilate diyl (n...

Embodiment 4

[0037] Example 4 Preparation of nanometer jasmine essence

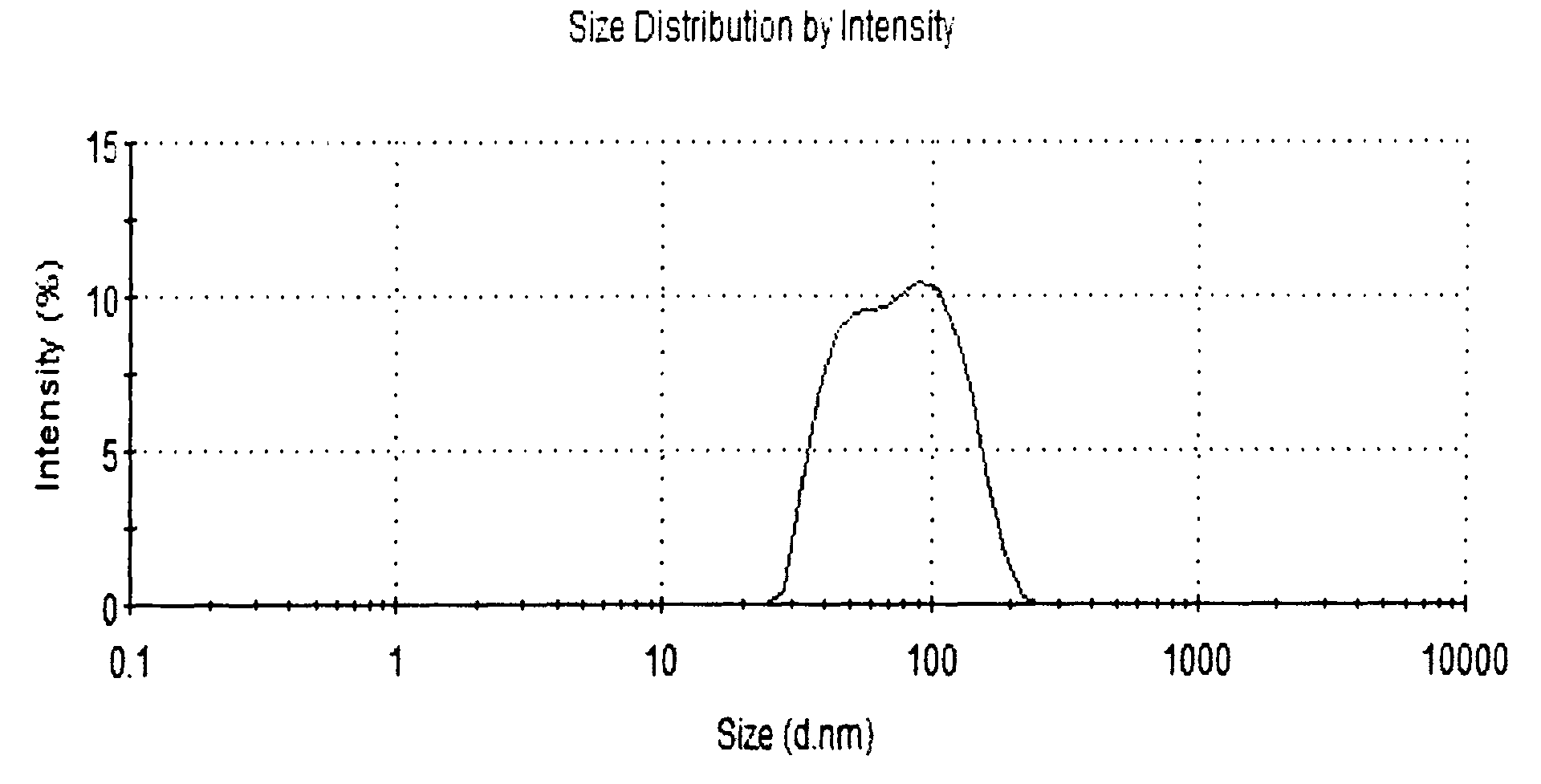

[0038] After adding 0.66 parts by weight of the jasmine jasmine essence prepared in Example 3 and 2 parts by weight of polyoxyethylene (20) sorbitan monolaurate magnetically stirred evenly, add 96.02 parts by weight of Deionized water, magnetic stirring at 25°C until a homogeneous and stable jasmine essence emulsion is obtained. The pH of the resulting emulsion was adjusted to 2 with 1 mol / L hydrochloric acid solution. Then, 1.32 parts by weight of n-butyl cyanoacrylate was slowly added dropwise to the system at a rate of 3 drops / min under the condition of magnetic stirring at 25°C, and the polymerization was carried out under the condition of magnetic stirring at 25°C for 5 h. Then adjust the pH value of the system to 4 with 1 mol / L sodium hydroxide solution and continue the reaction for 1 h under the condition of magnetic stirring at 25 °C. Finally, adjust the pH value to 7 with 0.1 mol / L sodium hydroxide solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com