Preparation method of mint-flavor novel cigarette core material not burning under heating

A heat-not-burn and flavor technology, which is applied in the preparation of tobacco, tobacco, and tobacco treatment, can solve the problems that affect the aroma quality of new heat-not-burn cigarettes, cannot release aroma stably from the beginning to the end, and reduce the aroma. Loss of volatilization, stability of aroma, and effect of increasing attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

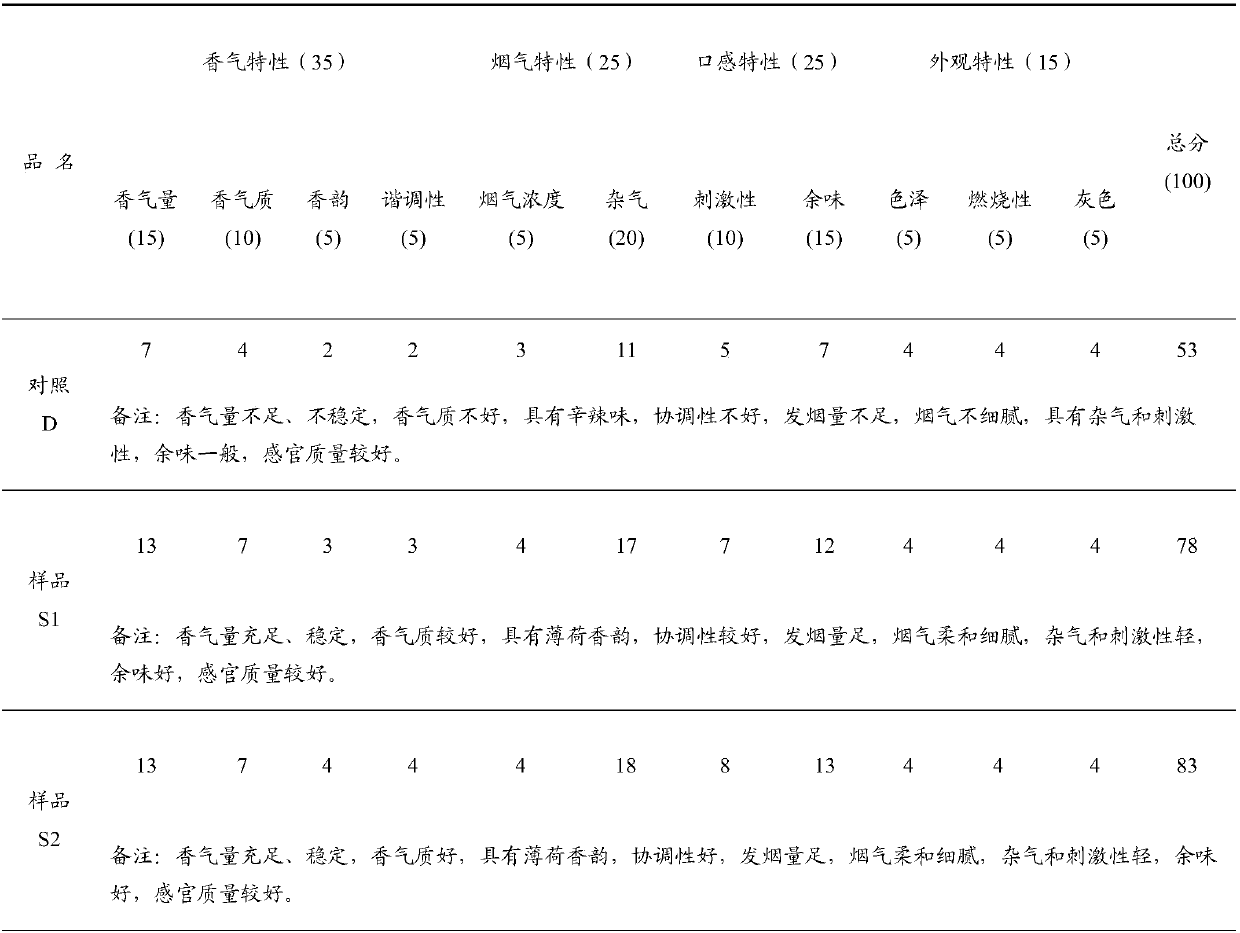

Examples

Embodiment 1

[0016] A method for preparing a mint-flavored heat-not-burn novel cigarette core material, comprising the following steps:

[0017] 1) Tobacco raw materials are taken, and according to the ratio of material to liquid 1:5, extraction is carried out with 70% ethanol solution to obtain an extract;

[0018] 2) Rotary evaporation of the extract to 1 / 2 of the volume of the original solution to prepare a concentrated solution;

[0019] 3) Extract and beat the solid residue in step 1, add 20% wood pulp, and obtain a quantitative value of 55 ± 1g / m after papermaking 2 Film base;

[0020] 4) Take the coating solution to coat the film base for sample preparation. After coating, the sample is placed in an oven at 100° C. and baked until the moisture content is 11.5%. The sample is taken out and put into a ziplock bag for sealed storage.

[0021] In step 1), the tobacco raw material is composed of materials in the following weight percentages: 30% of tobacco stems, 30% of shreds, 20% of ...

Embodiment 2

[0024] A method for preparing a mint-flavored heat-not-burn novel cigarette core material, comprising the following steps:

[0025] 1) Tobacco raw materials are taken, extracted with 50% concentration of ethanol solution according to the ratio of material to liquid of 1:10, to obtain the extract;

[0026] 2) Rotary evaporation of the extract to 1 / 4 of the volume of the original solution to prepare a concentrated solution;

[0027] 3) Extract and beat the solid residue in step 1, add 20% wood pulp, and obtain a quantitative value of 55 ± 1g / m after papermaking 2 Film base;

[0028] 4) Take the coating solution to coat the film base for sample preparation. After coating, the sample is placed in an oven at 100° C. and baked until the moisture content is 11.5%. The sample is taken out and put into a ziplock bag for sealed storage.

[0029] In step 1), the tobacco raw material is composed of materials in the following weight percentages: 50% of tobacco stems, 20% of shreds, 10% o...

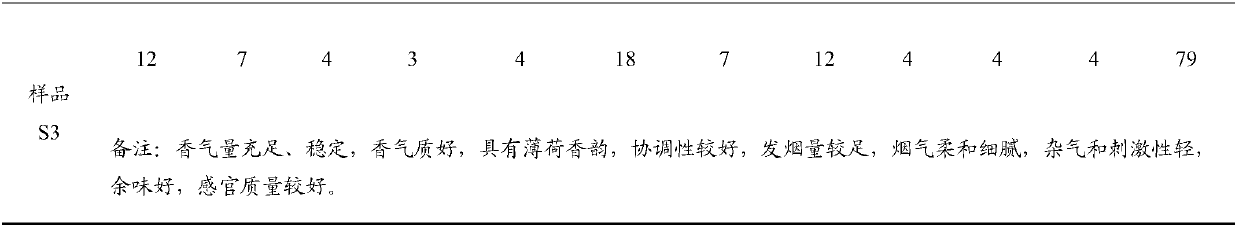

Embodiment 3

[0032] A method for preparing a mint-flavored heat-not-burn novel cigarette core material, comprising the following steps:

[0033] 1) Tobacco raw materials were taken, extracted with 60% concentration of ethanol solution according to the ratio of material to liquid of 1:7, to obtain the extract;

[0034] 2) Rotary evaporation of the extract to 1 / 3 of the volume of the stock solution to prepare a concentrated solution;

[0035] 3) Extract and beat the solid residue in step 1, add 20% wood pulp, and obtain a quantitative value of 55 ± 1g / m after papermaking 2 Film base;

[0036] 4) Take the coating solution to coat the film base for sample preparation. After coating, the sample is placed in an oven at 100° C. and baked until the moisture content is 11.5%. The sample is taken out and put into a ziplock bag for sealed storage.

[0037] In step 1), the tobacco raw material is composed of materials in the following weight percentages: 50% of tobacco stems, 30% of shreds, 10% of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com