A kind of preparation method of apricot wine

A technology of apricot wine and fresh apricot, applied in the field of winemaking, can solve the problems of adverse effects on consumers, excessive food additives, uneven quality, etc., and achieve the effects of maintaining fruit flavor, reducing viscosity and improving internal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

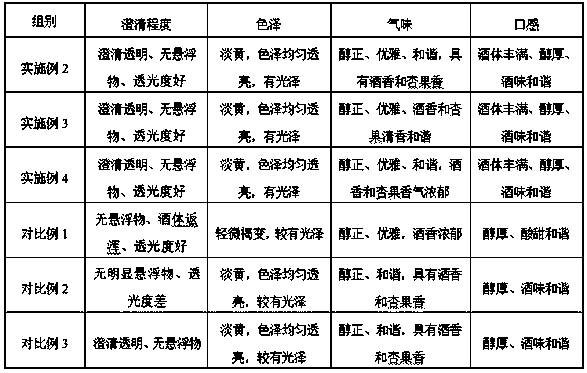

Examples

Embodiment 1

[0025] Preparation of attapulgite-loaded chitosan particles: Activation of attapulgite: attapulgite was calcined at 700°C for 4 h, taken out, added to 1 mol / L hydrochloric acid, stirred at 90°C for 4 h, then centrifuged to discard the acid solution, and used Wash with deionized water until neutral, and dry at 120°C to obtain modified attapulgite; preparation of chitosan sol: add chitosan to slowly stirring oxalic acid aqueous solution with a mass fraction of 10%, and place in a water bath at 50°C until chitosan The sugar was completely dissolved to obtain light yellow viscous chitosan sol; chitosan loading: take 10 mL chitosan sol and slowly add 5 g of modified attapulgite at room temperature, stir at 50 °C for 6 h, centrifuge, and suction filter. Vacuum-dried at 55°C to constant weight, then soaked in 1mol / L NaOH aqueous solution for 1h, washed with water until neutral, then soaked in 0.03% and 0.05% potassium hydrogen tartrate-tannic acid aqueous solution for 1-2h, After sti...

Embodiment 2

[0027] A kind of preparation method of apricot wine, comprises the following steps:

[0028] 1) Pick ripe golden sun apricots and fresh apricots, wash and remove the core, squeeze the juice, and collect the juice and pomace separately;

[0029] 2) Pomace pretreatment: adjust the water content of pomace to 26%, then add cellulase, hemicellulase, acid protease, α-amylase and mucormycetes and mix evenly. The cellulase, hemicellulase, The concentrations of acid protease, α-amylase and mucormyces in pomace are 50mg / L, 32mg / L, 38mg / L, 28mg / L, 26mg / L respectively, fermented at 28-32°C for 4 days, and then extinguished at 90°C Bacteria 1h, beating and passing through a 250 mesh sieve to obtain pomace pulp; add sucrose to the pomace pulp to adjust the sugar content to 20Brix, then add pomace pulp mass fraction 0.3% (NH 4 ) 2 SO 4 1. Sodium phytate with 0.3% mass fraction of pomace pulp and Aspergillus niger M228 strain with 0.9% mass fraction of pomace pulp, ferment at 28-35°C for 2...

Embodiment 3

[0036] A kind of preparation method of apricot wine, comprises the following steps:

[0037]1) Pick ripe golden sun apricots and fresh apricots, wash and remove the core, squeeze the juice, and collect the juice and pomace separately;

[0038] 2) Pomace pretreatment: adjust the water content of pomace to 28%, then add cellulase, hemicellulase, acid protease, α-amylase and mucormycetes and mix evenly. The cellulase, hemicellulase, The concentrations of acid protease, α-amylase and mucormyces in pomace were 45mg / L, 30mg / L, 35mg / L, 25mg / L, 25mg / L respectively, fermented at 25°C for 3 days, and then sterilized at 90°C for 1h , beating and passing through a 250-mesh sieve to obtain pomace pulp; adding sucrose to the pomace pulp to adjust the sugar content to 18brix, and then adding 0.3% (NH 4 ) 2 SO 4 , sodium phytate with a mass fraction of 0.3% of pomace pulp and Aspergillus niger M228 strain with a mass fraction of pomace pulp of 0.8%, ferment at 28°C for 1 day until the suga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com