Patents

Literature

216 results about "Monolaurin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

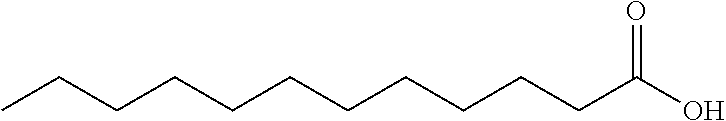

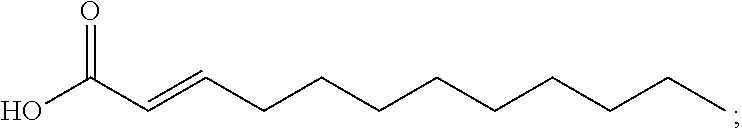

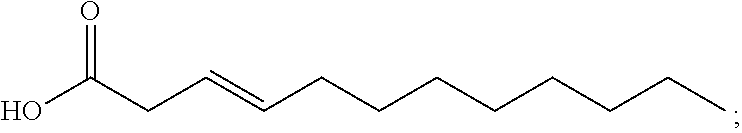

Monolaurin, also known as glycerol monolaurate (GML), glyceryl laurate or 1-lauroyl-glycerol, is a monoglyceride. It is the mono-ester formed from glycerol and lauric acid. Its chemical formula is C₁₅H₃₀O₄.

Aerosol formulations for buccal and pulmonary application

InactiveUS6436367B1Antibacterial agentsOrganic active ingredientsChamomile extractOleic Acid Triglyceride

A mixed micellar aerosol pharmaceutical formulation includes a micellar proteinic pharmaceutical agent, an alkali metal lauryl sulphate, at least three micelle forming compounds, a phenol and a propellant. The micelle forming compounds are selected from the group consisting of lecithin, hyaluronic acid, pharmaceutically acceptable salts of hyaluronic acid, glycolic acid, lactic acid, chamomile extract, cucumber extract, oleic acid, linoleic acid, linolenic acid, monoolein, monooleates, monolaurates, borage oil, evening of primrose oil, menthol, trihydroxy oxo cholanyl glycine and pharmaceutically acceptable salts thereof, glycerin, polyglycerin, lysine, polylysine, triolein, polyoxyethylene ethers and analogues thereof, polidocanol alkyl ethers and analogues thereof. The amount of each micelle forming compound is present in a concentration of from 1 to 20 wt. / wt. % of the total formulation, and the total concentration of micelle forming compounds are less than 50 wt. / wt. % of the formulation. The propellant, e.g. a fluorocarbon propellant, provides enhanced absorption of the pharmaceutical agent.

Owner:GENEREX PHARMA

Thermoplastic food casing

A porous food casing consisting essentially of a film of food grade thermoplastic having a plurality of interconnected interstices therein. The interstices are defined by a porosity modifier selected from the group consisting of soybean oil, peanut oil, corn oil, glycerin, polyethylene glycol, monolaurate, mineral oil, polyoxyethylene, sorbitan monostearate, sorbitan monooleate and glycerol monooleate. The interstices are in a range of approximately 0.002 to 1 micron and the casing has a water vapor permeability in a range of about 1 to 1500 gms / m2 / min.

Owner:YEN WILLIAM W

Oil well dispersive wax-proofing agent and preparation method thereof

The invention relates to an oil well dispersive wax-proofing agent which is applicable to wax proofing of a petroleum well. The invention is characterized in that the oil well dispersive wax-proofing agent comprises the following ingredients according to weight percentage: 5-7% of polyoxyethylenealkylphenol ether, 6.5-9.5% of sorbitan mono lauryl alcohol polyoxyethylene ether, 0.5-1.0% of potassium chloride, 0.05-0.1% of fluorocarbon surfactant FN-3, 0.5-1.0% of Vitamin C, 10-15.5% of polyoxyethylene alkylphenol ether carboxylic sodium, 0.005-0.01% of 6-chlorobenzotriazole-1,1,3,3-tetramethylcarbamidehexafluoroosphate, and the allowance of water. The invention has the effects that for an oil well with water content of high than 30%, the oil well dispersive wax-proofing agent can prolong the thermal cleaning cycle of the oil well by 2-4.5 times when the adding amount is 0.05-0.1% in daily oil well maintenance.

Owner:PETROCHINA CO LTD

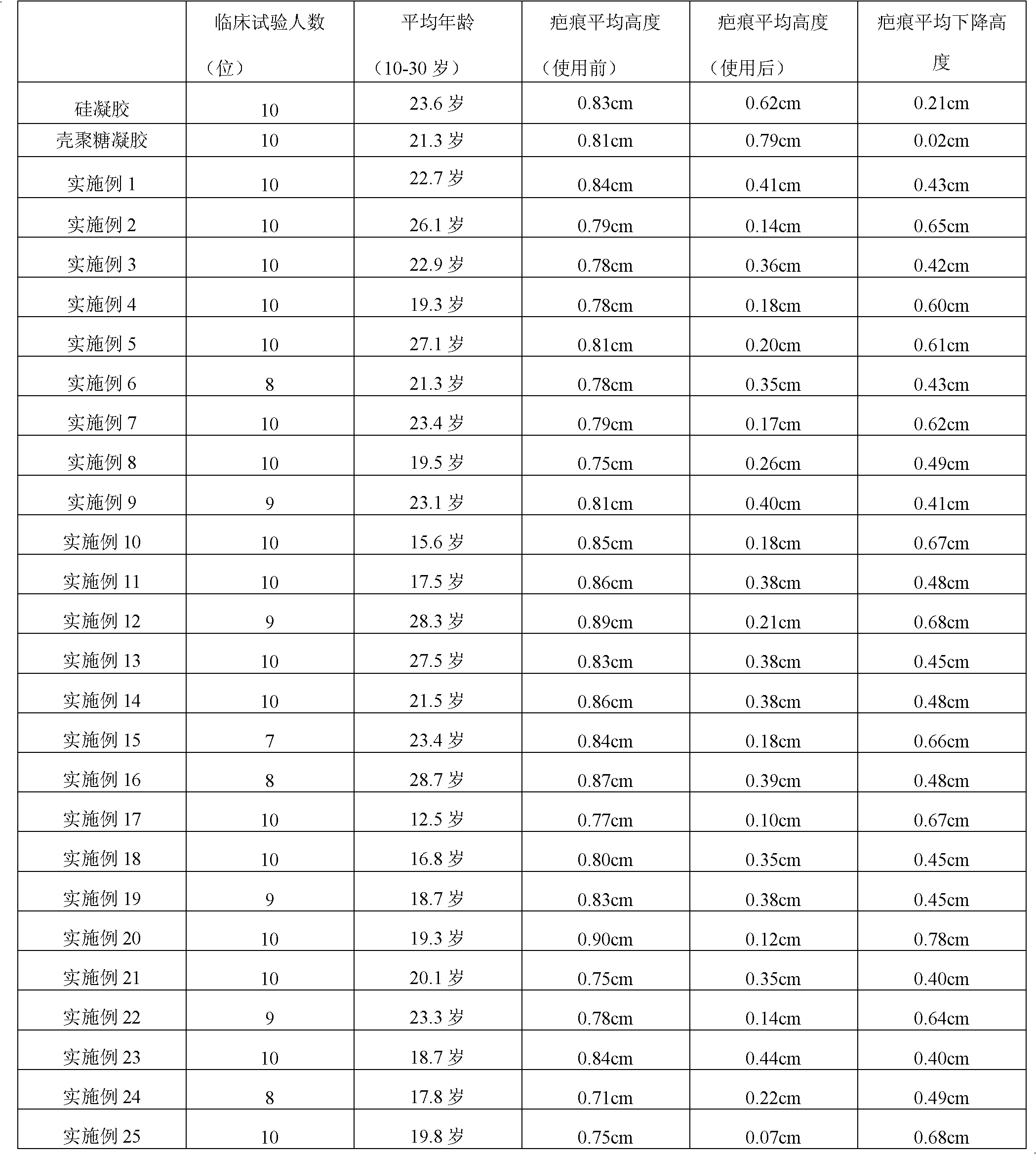

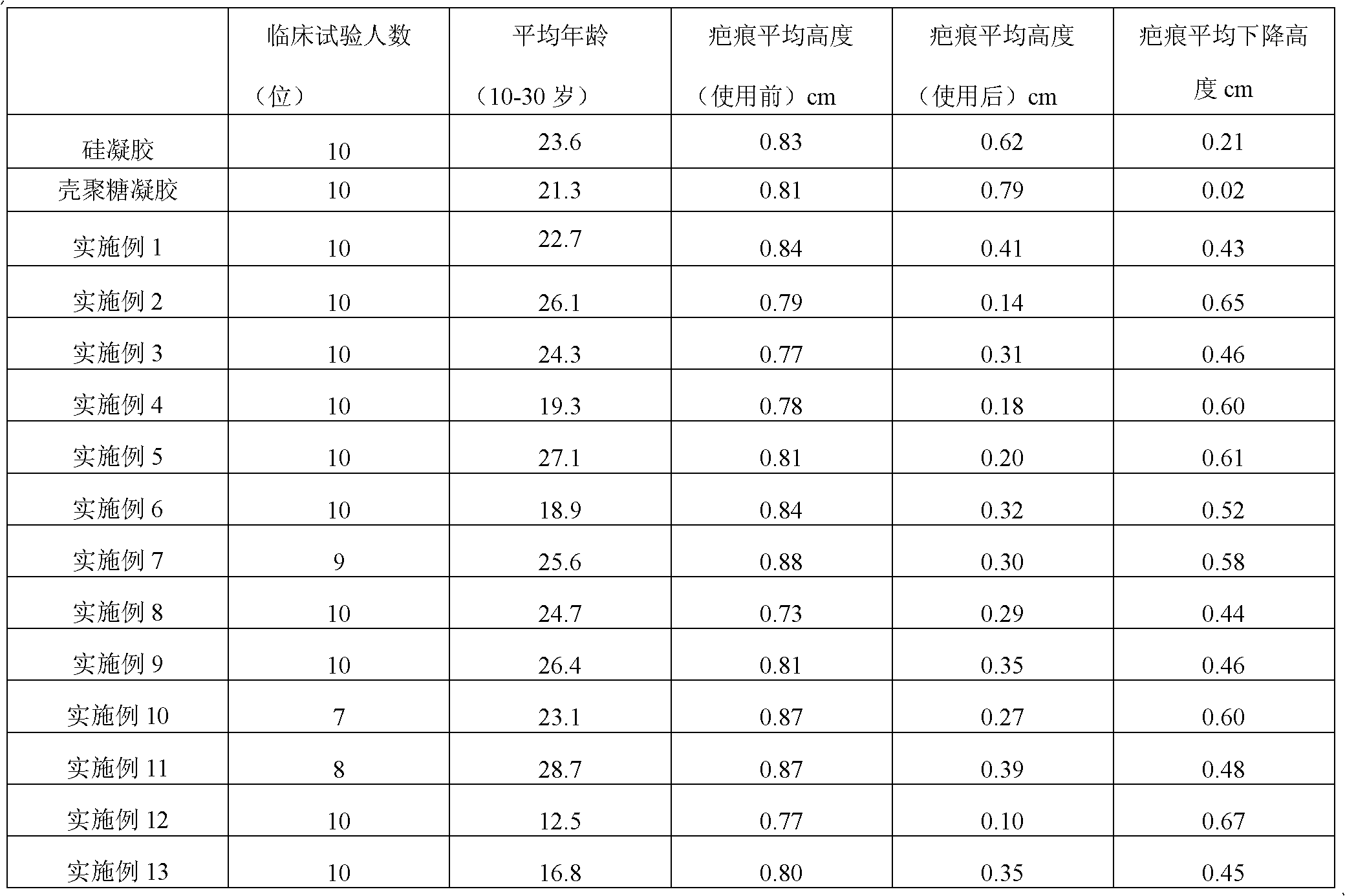

Scar repair material

The invention discloses a scar repair material which is prepared by the following method: dissolving 0.5-5 parts by weight of water-soluble chitosan or chitosan the deacetylation degree of which is 75-97% into 10-100 parts by weight of water or an acetic acid aqueous solution the mass concentration of which is 1-5% while stirring; adding 1-3 parts by weight of polyoxyethylene Sorbitan lauric acid monoester which has emulsifying action and 5-10 parts by weight of humectant glycerol to obtain a transparent gelatinous solution; adding 20-90 parts by weight of polydimethylsiloxane into the gelatinous solution under homogeneity; and evenly mixing to obtain the scar repair material. The scar repair material disclosed in the invention can actively and passively moisturize skin, has the efficacy on actively resisting and inhibiting bacteria, has the action on quickening the healing of skin wound surface, has better repair and protection actions on tiny flaws and infection on the scar surface as being used on the scar surface, and can inhibit the secretion of collagen type I in cheloid skin so as to lower the ratio of collagen type I / collagen type III.

Owner:TIANJIN JIASHITANG SCI & TECH

Preservative System for Cosmetic Formulations- Compositions and Methods Thereof

ActiveUS20120190744A1Good effectPromote proliferationBiocideCosmetic preparationsMedicinePreservative

The present invention relates to preservation of cosmetic formulations. More specifically, the present invention relates to a preservative composition for cosmetic formulations comprising thymol, monolaurin and magnolol obtained from supercritical fluid extracts of Magnolia officinalis.

Owner:SAMI LABS LTD

Method for preparing monolaurin

The invention discloses a method for preparing monolaurin, which comprises the following steps: taking camphor tree seed oil as a raw material; adding degumed and dehydrated camphor tree seed oil into an esterification and alcoholysis reactor, and adding acidic ionic liquid 1-methyl-3-(3-sulfopropyl) imidazole catalyst to reacting at the temperature of between 135 and 145 DEG C until the acid value is reduced to below 0.5, wherein the temperature the dosage of the catalyst is 3 to 4 percent of the weight of the oil and the molar ratio of the alcohol to the oil is 1.5-2.5:1; performing centrifugal separation, adding the esterified and alcoholized amphor tree seed oil into a catalysis and alcoholysis reactor, and adding the alkaline ionic liquid of 1-butyl-3-methyl imidazole salt to react at the temperature of between 165 and 175 DEG C until the total content of the monofatty glyceride is over 90.0 percent, wherein the dosage of the catalyst is 0.4 to 0.6 percent of the weight of the oil and the molar ratio of the alcohol to the oil is 6-7:1; performing centrifugal separation, washing with the water at the temperature of between 15 and 35 DEG C; and performing vacuum dehydration and decoloration. The monofatty glyceride content in the product is over 90.0 percent; the monolaurin content is over 85.0 percent; and the process of molecular distillation can be saved. The technology is reasonable, energy-saving and environment-friendly; and most of the glycerol can be recycled, and the discharge of acid, alkali and salt is greatly reduced.

Owner:南昌香樟林高科技有限公司

Pesticide emulsion and preparation method thereof

The invention provides a preparation method of a pesticide emulsion, which comprises the steps of preparing an avermectin molecular capsule system; preparing a water phase; preparing an oil phase; adding the oil phase into the water phase, adding the avermectin molecular capsule system after shear emulsion and carrying out the shear emulsion again, wherein, the avermectin molecular capsule systemis prepared by evenly mixing a capsule wall material, a cosolvent and the first part of water under the heating condition, adding avermectin and a first emulsifier for evenly mixing and cooling to the room temperature, the capsule wall material is beta-cyclodextrin and / or gamma-cyclodextrin, the first emulsifier is one or a plurality of fatty alcohol polyoxyethylene ether, sorbitan monooleate andpolyoxyethylene sorbitan monolaurate. Avermectin molecules in the pesticide emulsion containing avermectin molecular capsules prepared by the method greatly enhance the resistance of the avermectin molecules to oxygen, light, heat, acid, alkali and the like and simultaneously have the effects of sustained-release and solubilization, thereby solving the problem that the avermectin is instable to the light and further prolonging the effective period for prevention and treatment of the avermectin.

Owner:SHENZHEN NOPOSION AGROCHEM

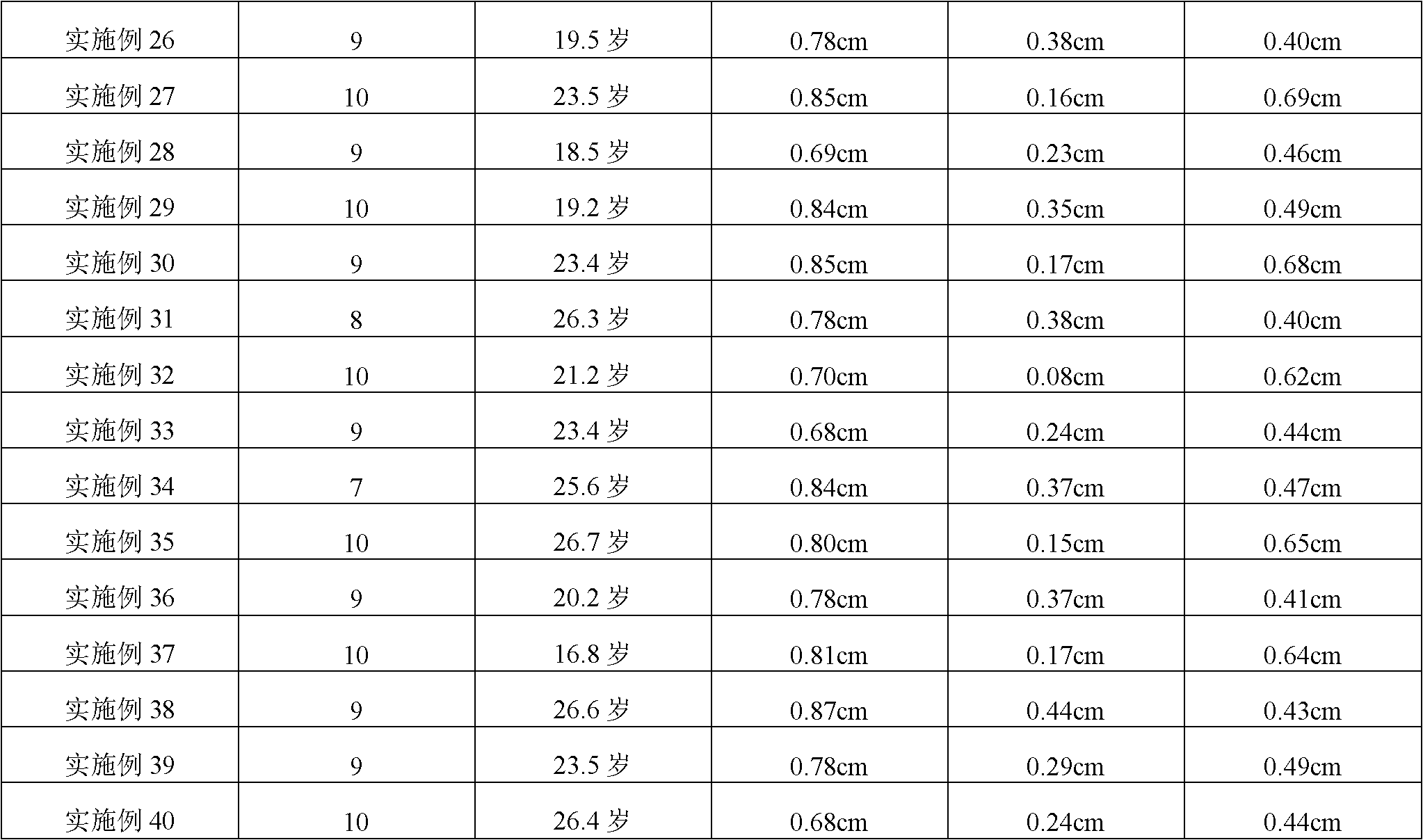

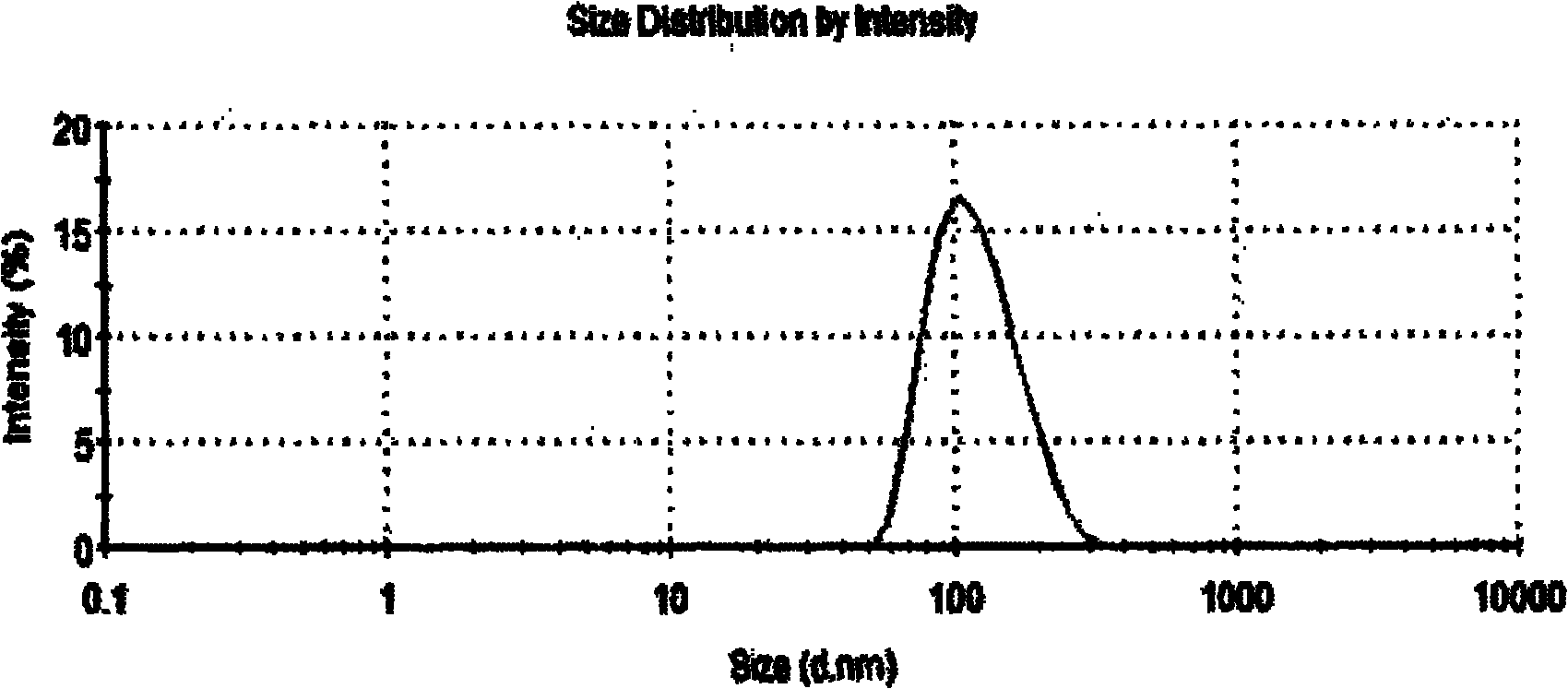

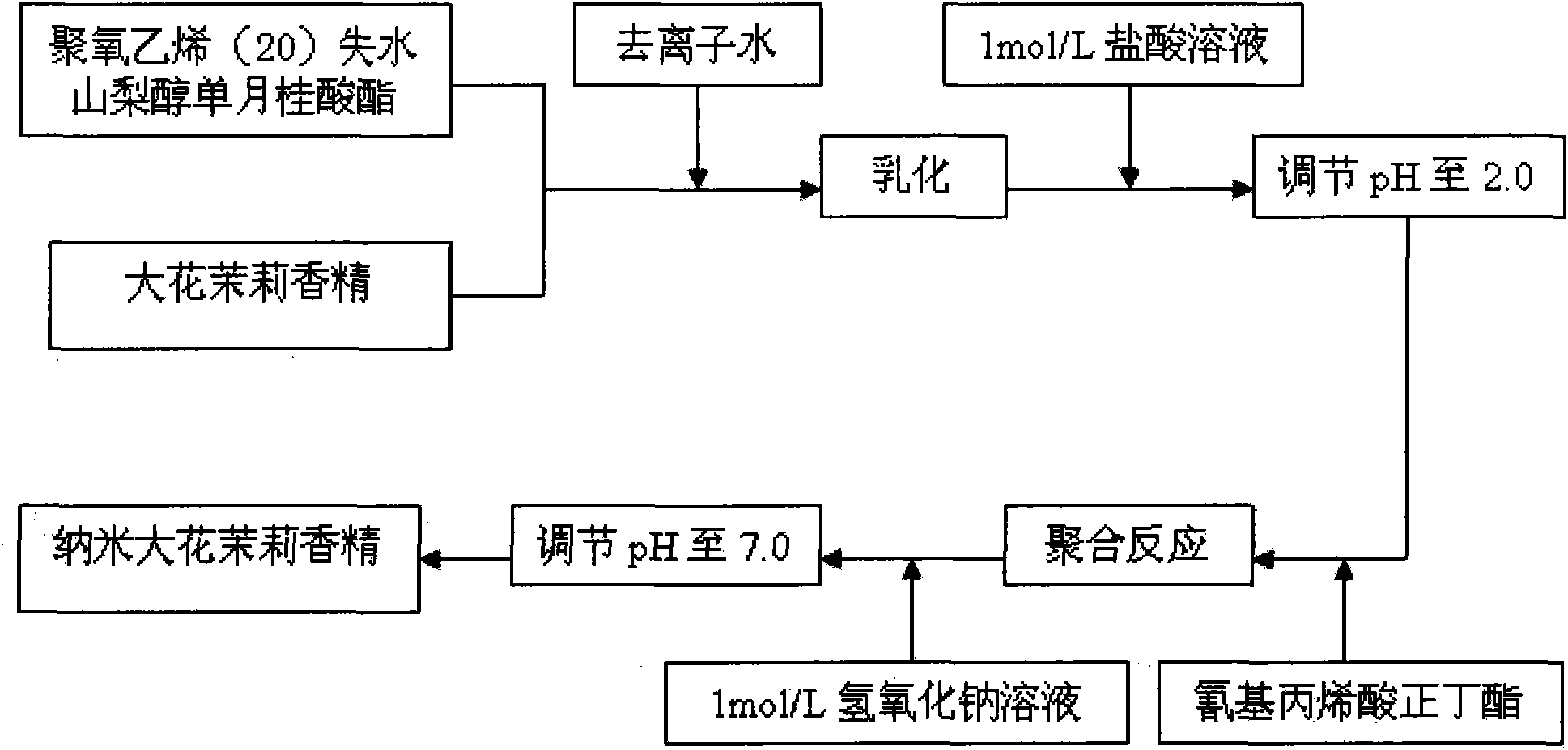

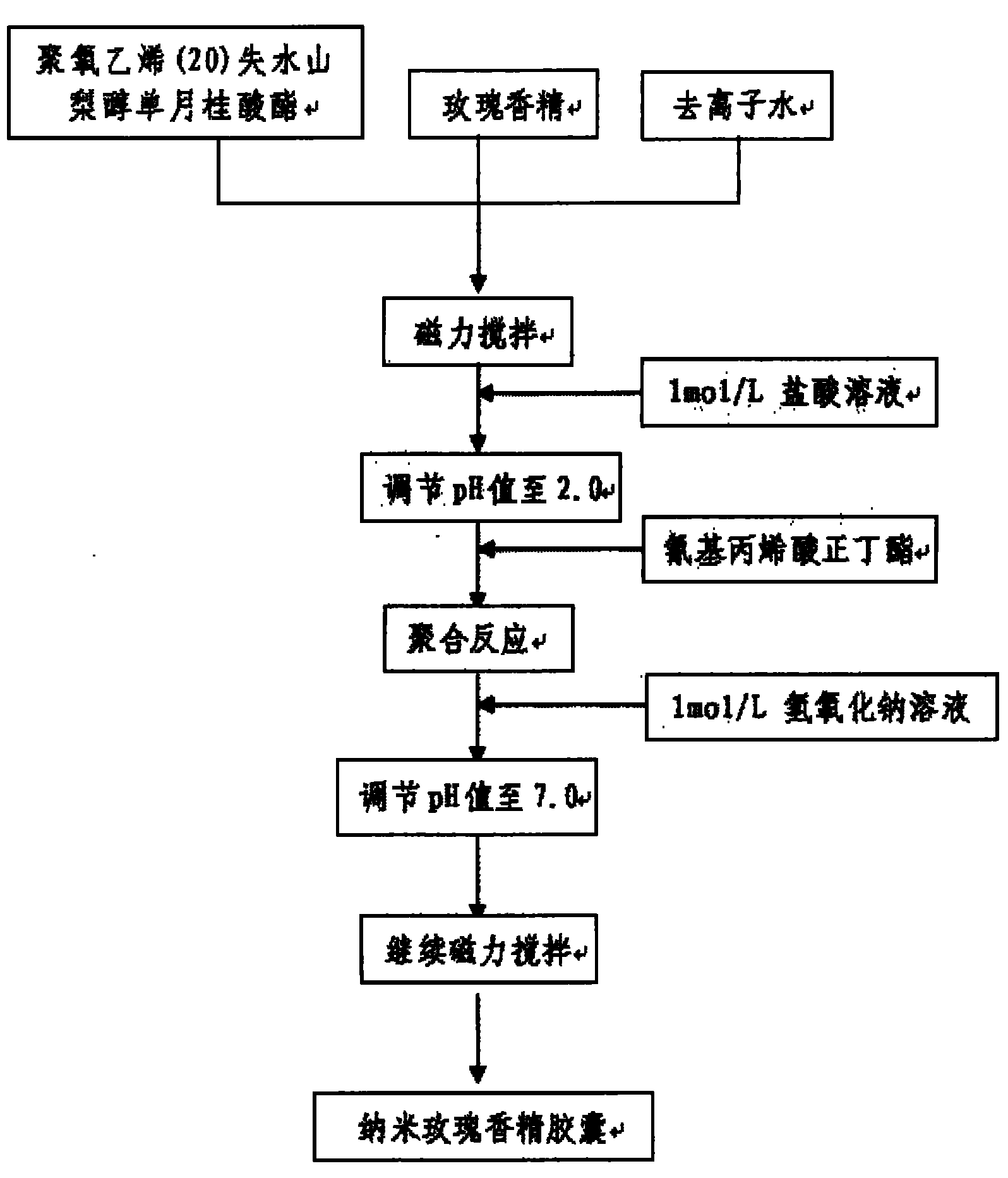

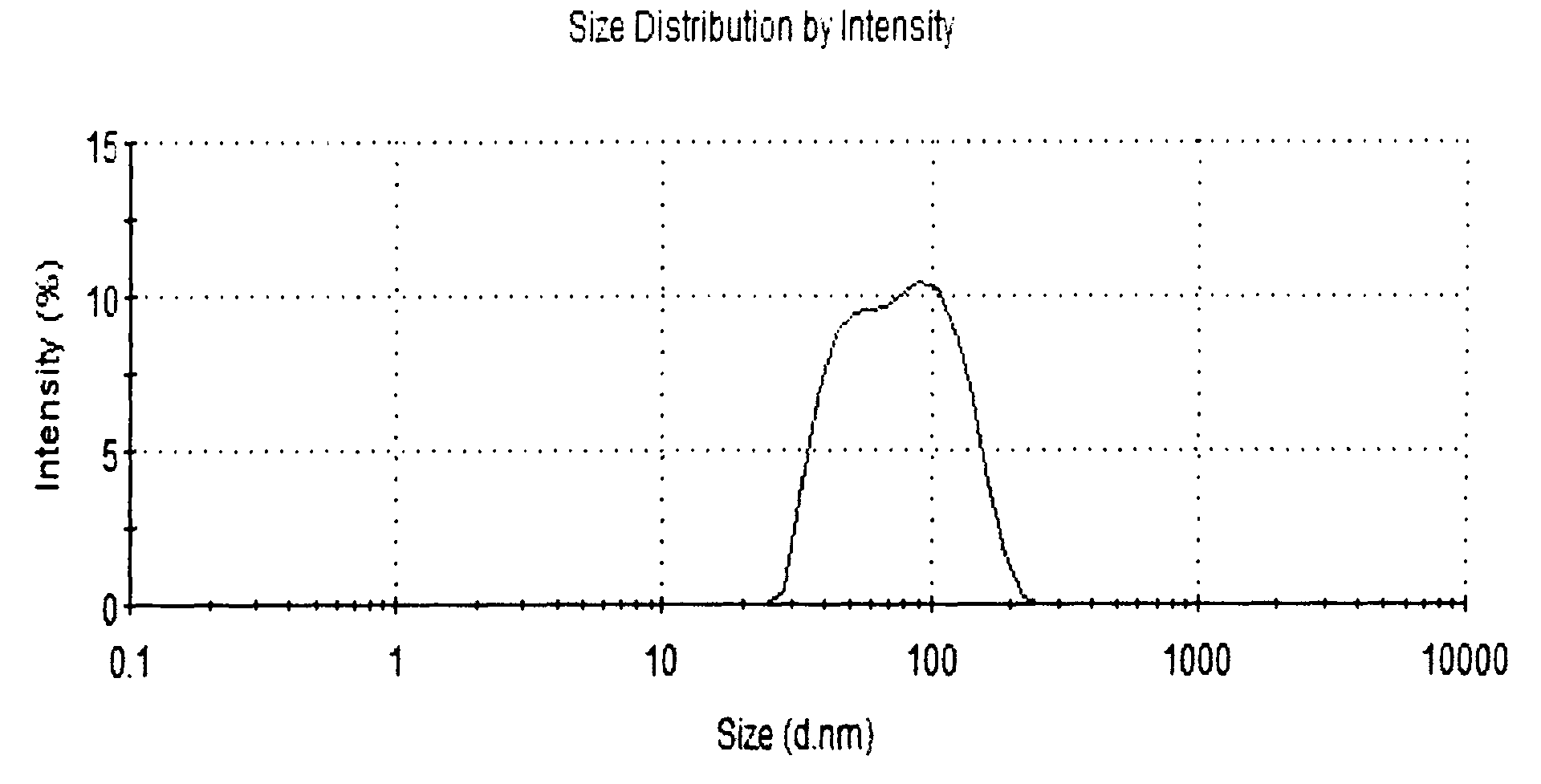

Preparation method of polybutylcyanoacrylate-encapsulated jasminum grandiflorum essence capsule

InactiveCN101818100ABiodegradableAdvantage thermal stabilityEssential-oils/perfumesJasminum grandiflorumGranularity

The invention discloses a preparation method of polybutylcyanoacrylate-encapsulated jasminum grandiflorum essence capsule, wherein the nano jasminum grandiflorum essence capsule is prepared by the following raw materials in parts by weight: 0.2-0.5 parts of jasminum grandiflorum essence, 1.0-2.3 parts of polyoxyethylene (20) sorbitan monolaurate, 0.4-1.0 part of butylcyanoacrylate monomer and 96-100 parts of deionized water. As tested by a dynamic laser particle sizer, the nano jasminum grandiflorum essence capsule prepared according to the method of the invention has the average particle diameter of 112nm, the particle size distribution coefficient of 0.104 and stable existence of system, and has the advantages of slow release of fragrance and long fragrance lasting time, etc.

Owner:SHANGHAI INST OF TECH

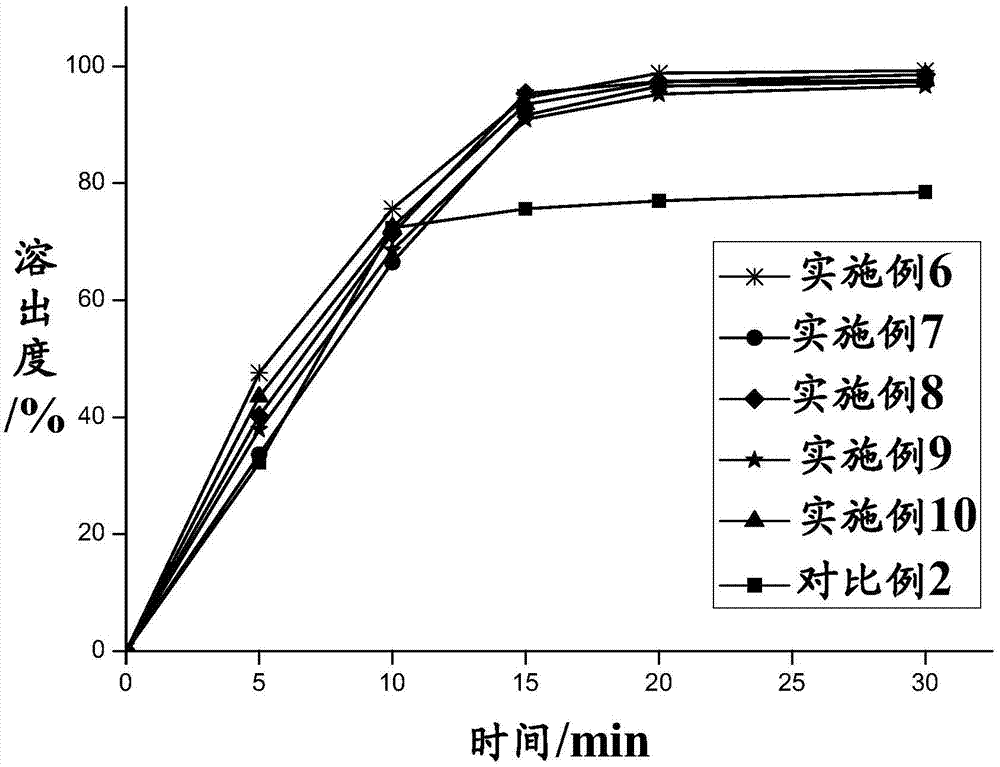

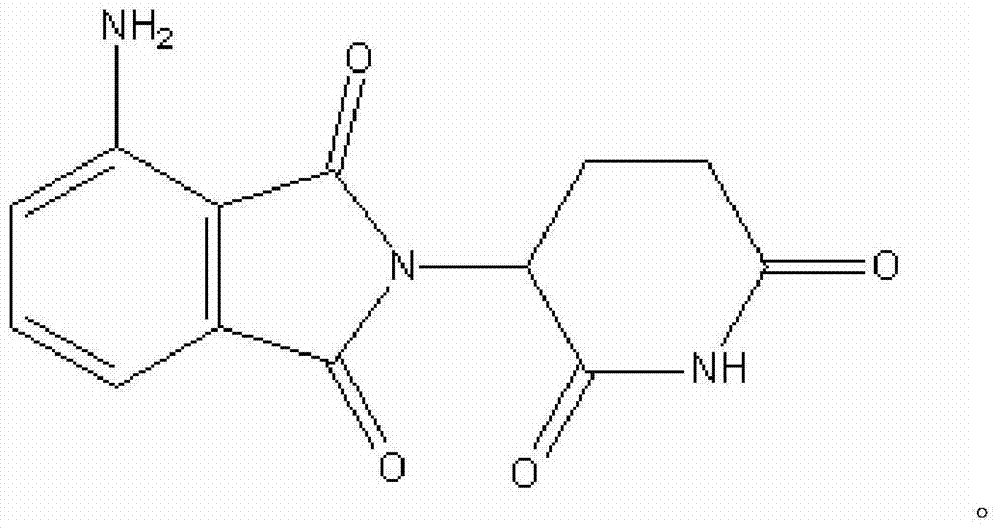

Pomalidomide nanoparticle and preparation and preparation method thereof

ActiveCN104224723ALarge specific surface areaHigh dissolution rateOrganic active ingredientsPowder deliveryPolyethylene glycolCyclodextrin

The invention relates to the technical field of medicines, and specifically relates to pomalidomide nanoparticle and preparation and a preparation method thereof. The pomalidomide nanoparticle comprises the following components in parts by weight: 0.5 to 1.5 parts of pomalidomide, and 10 to 100 parts of nano-carrier, wherein the nano-carrier comprises one or more of lecithin, povidone, polyalkylcyano-acrylate, acrylamide, N, N-methylene diacrylic acid amine, polysorbate, sorbitan monolaurate, lauryl alcohol polyoxyethylene, sodium dodecyl sulfate, poloxamer, polyethylene glycol, cyclodextrin and cyclodextrin derivates. The particle size of omalidomide nanoparticle is at nanometer level; on that basis, the prepared pomalidomide preparation is high in dissolution rate.

Owner:BEIJING COLLAB PHARMA

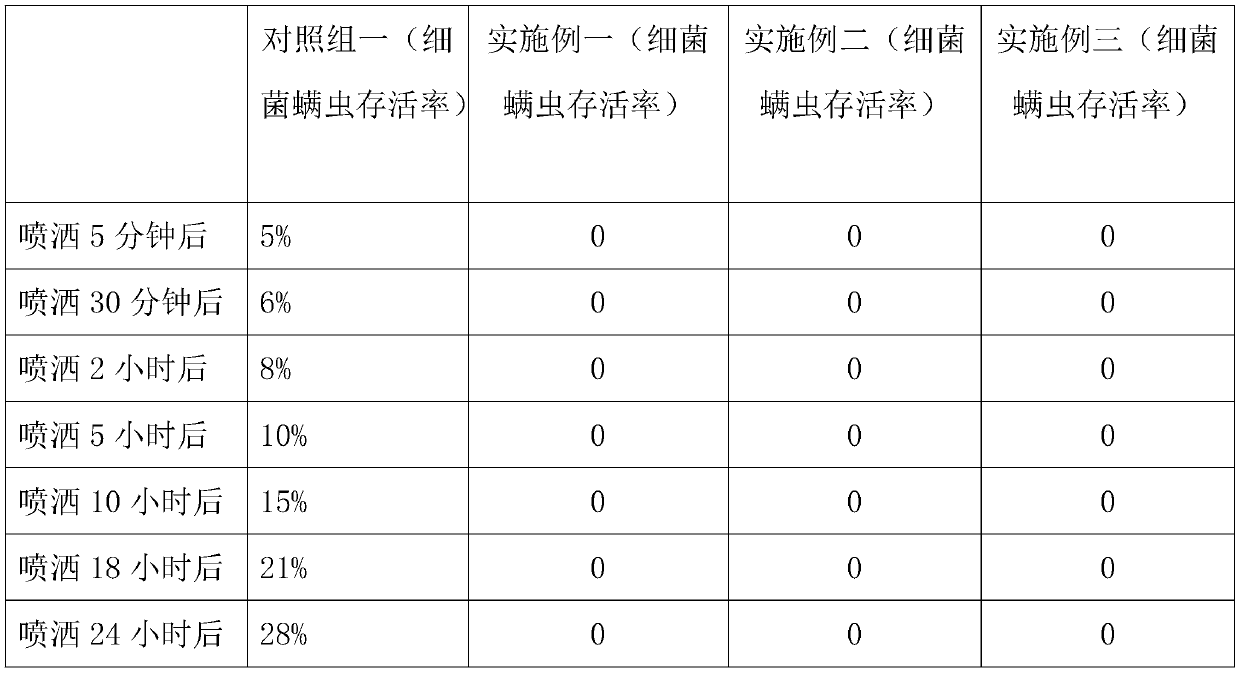

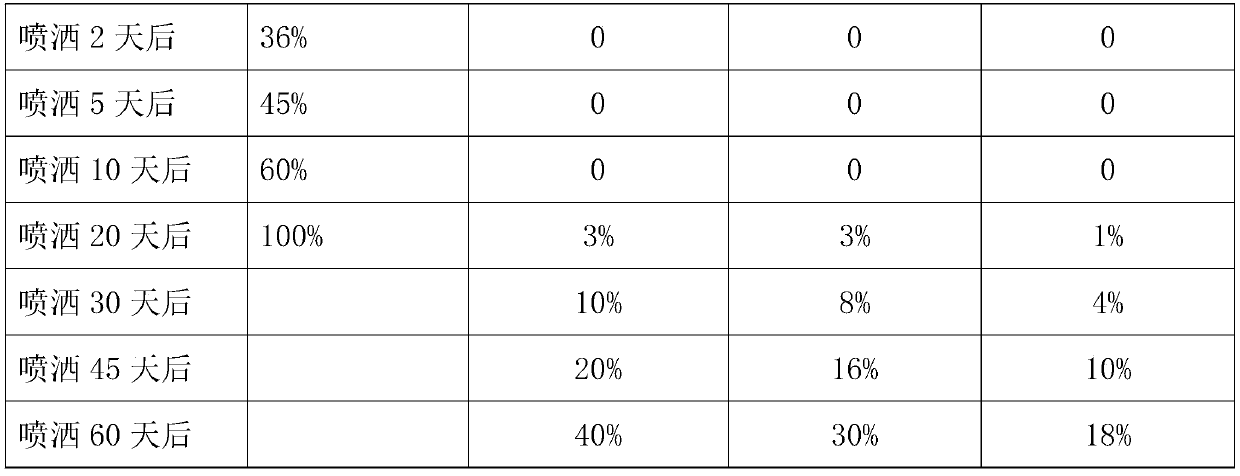

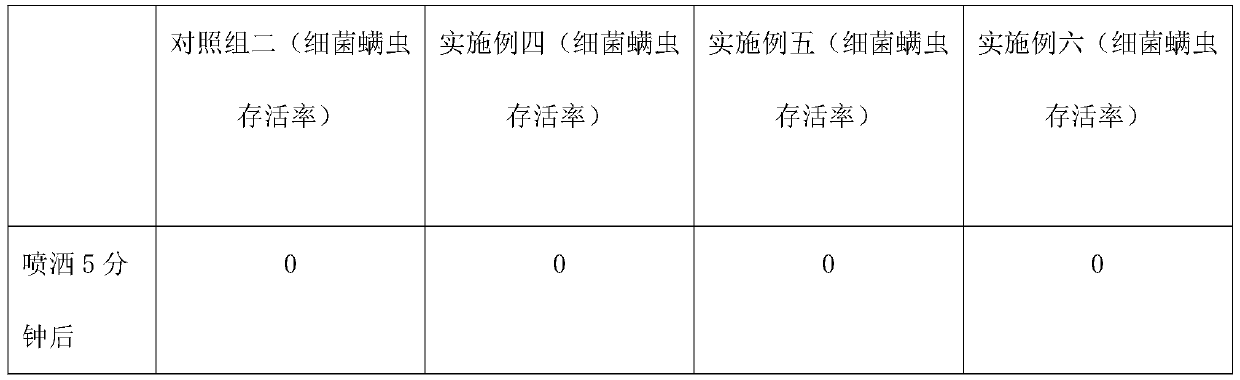

Environment-friendly bactericidal acaricide and preparation method thereof

InactiveCN111567575AAvoid harmWill not damage the structureBiocidePest repellentsBiotechnologyDioxyethylene Ether

The invention discloses an environment-friendly bactericidal acaricide and belongs to the technical field of daily chemical sterilization. The environment-friendly bactericidal acaricide is prepared from the following raw materials: eucalyptus leaf essential oil, folium artemisiae argyi essential oil, citronella essential oil, lemon essential oil, mint essential oil, orange essential oil, a rosemary extract, a fructus cnidii extract, a radix sophorae flavescentis extract, a sweet orange flower extract, a lavender extract, small molecular alcohol, deionized water, sorbitan monolaurate polyoxyethylene (20) ether and water-soluble polymer slow-release agent starch. According to the environment-friendly bactericidal acaricide of the invention, the durability of the product can be improved while the product is ensured to be rapidly applied for sterilization and acarus killing; main active substances in the product are natural plant extracts, and therefore, the product has the advantages ofgood environmental protection performance, freshness, naturalness, no toxic or side effect, mildness and no irritation to human skin, no harm to infants and young children, and good use experience; magnetic stirring and the ultrasonic treatment of an ultrasonic oscillator are adopted in a preparation process, and repeated cyclic staggered operation is carried out, and therefore, the bactericidal effect of the bactericidal acaricide can last longer, and the bactericidal acaricide has a good raw material combination effect and has a long shelf life.

Owner:WUXI HUOBAN COSMETIC TECH

Freshness-retentive film

InactiveUS20150359217A1Improve antimicrobial propertiesBiocideOrganic chemistryGlycerolDiethanolamine

The present invention provides a freshness-retentive film having high antibacterial characteristics. In the freshness-retentive film according to the present invention, at least one compound selected from the group consisting of palmityldiethanolamine, stearyldiethanolamine, glycerol monolaurate, and diglycerol monolaurate is present on at least one surface of the film at 0.002 to 0.5 g / m2.

Owner:MITSUI CHEM TOHCELLO INC

Fire extinguishing agent for edible oil fire disasters

InactiveCN107789783APrevent the spread of fireImprove fire resistanceFire extinguisherSuperabsorbent polymerSodium silicate

The invention discloses a fire extinguishing agent for edible oil fires, which is made of the following components in parts by weight: 20-30 parts of superabsorbent resin, 50-80 parts of sericite powder, 6-8 parts of diatomite, 2‑3 parts of titanium dioxide, 8‑10 parts of sodium silicate, 5‑10 parts of potassium hydroxide, 3‑5 parts of hydrophobic white carbon black, 3‑5 parts of silica gel, 2‑4 parts of sorbitan monolaurate , 0.3-0.6 parts of xanthan gum, 0.3-0.6 parts of sodium alginate, 0.2-0.4 parts of sodium hexametaphosphate, 10-15 parts of water. The fire extinguishing agent for edible oil fires of the present invention only takes a few seconds to extinguish edible oil fires, and has high fire extinguishing efficiency. When extinguishing a fire, the edible oil will not splash and cause the fire to spread. Non-polluting and easy to clean up after a fire.

Owner:TIANJIN SHENGAN XIAOKE TECH CO LTD

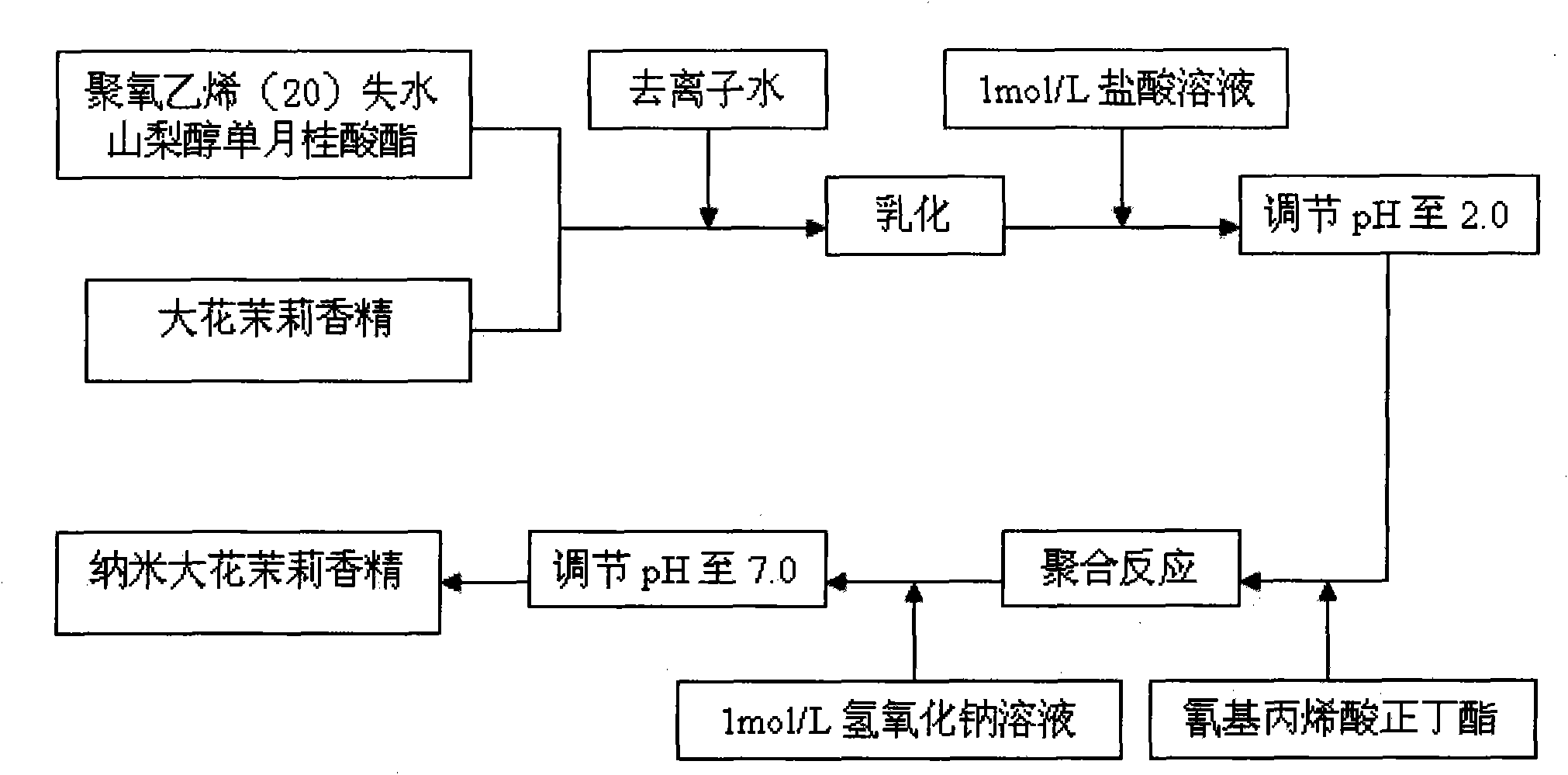

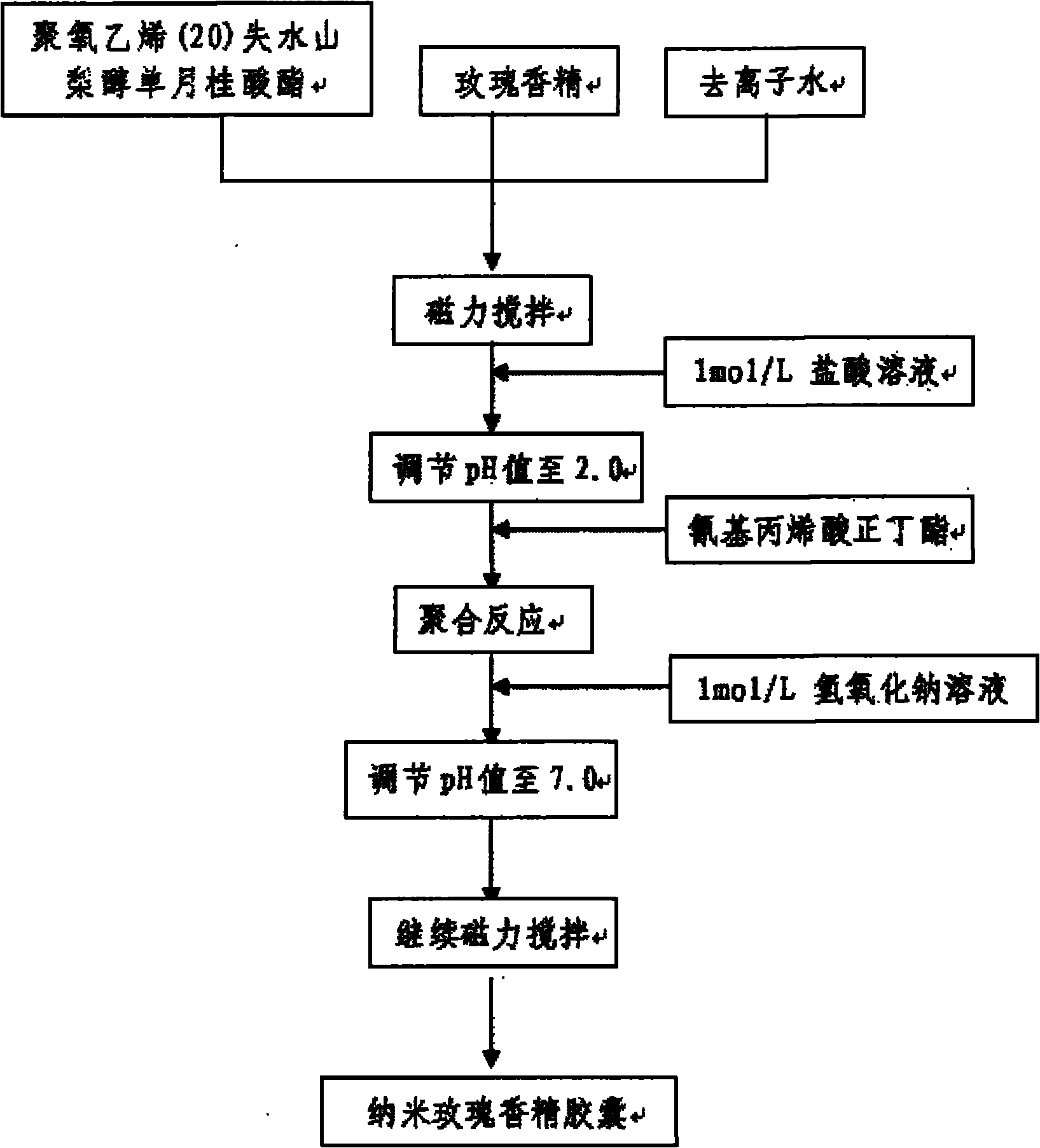

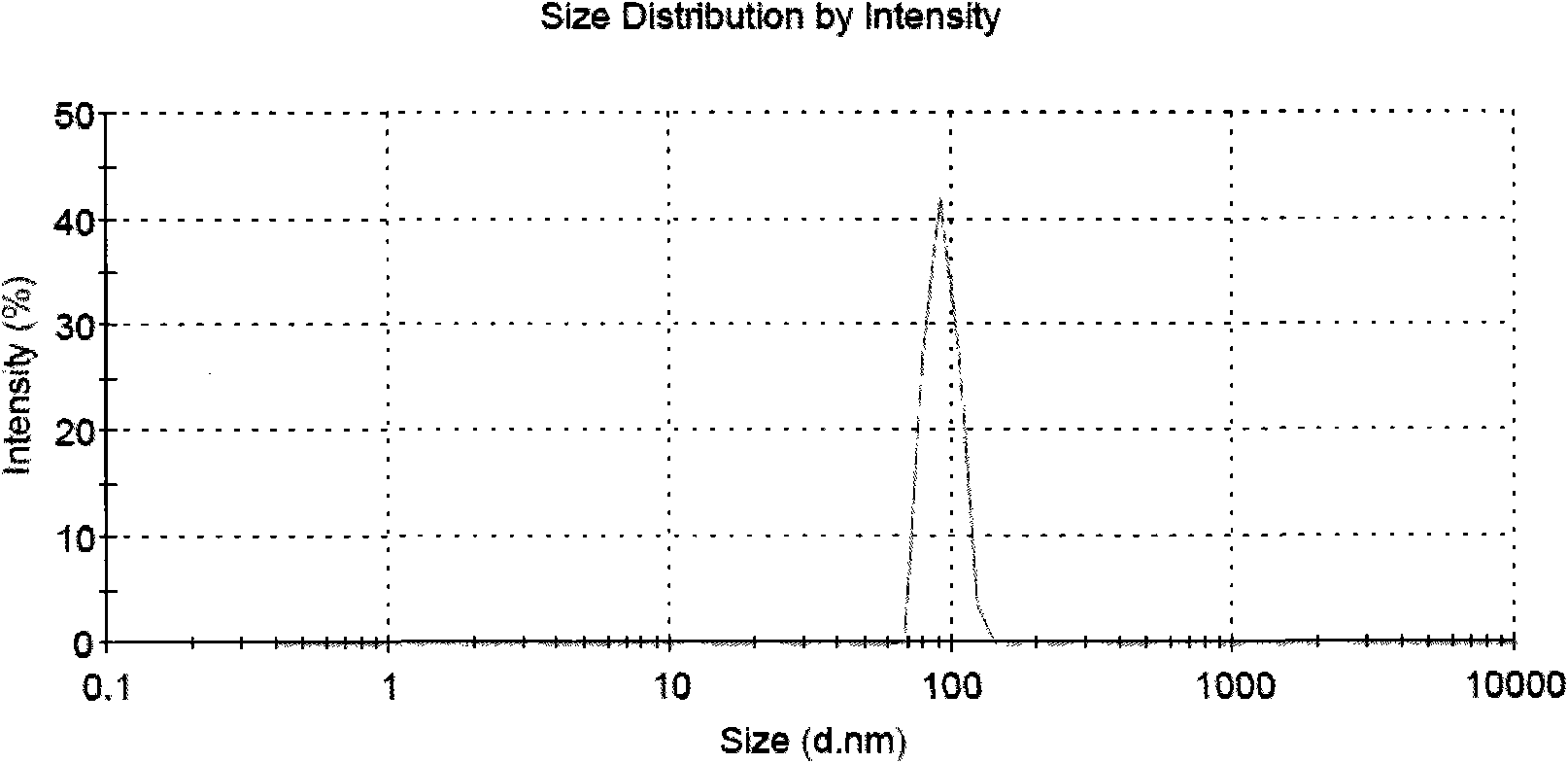

Method for preparing nano rose essence capsules

InactiveCN101816911AParticle size controllableUniform particle sizeEssential-oils/perfumesMicroballoon preparationEmulsionEmulsion polymerization

The invention discloses a method for preparing nano rose essence capsules, which comprises the following steps of: a, mixing 0.3 to 0.8 weight percent of rose essence and 2.0 to 3.2 weight percent of polyoxyethylene (20) sorbitan monolaurate, stirring the mixture at the rotation speed of 1,100rpm, adding deionized water into the mixture and stirring to form a uniform emulsion; and b, dripping 0.6 to 1.6 weight percent of N-butyl cyanoacrylate into the emulsion, reacting for 2 to 4 hours, adjusting the pH value of the system with 1mol / L solution of sodium hydroxide to 7.0, and continuously reacting for 0.5 hour until the reaction is completed. The nano rose essence capsules prepared by the emulsion polymerization method of the invention have an average particle size of 91nm and a peak width of 16.8nm, have uniform particle size distribution and can be applied to goods for everyday consumption, such as textiles, cosmetics and detergents and the like.

Owner:SHANGHAI INST OF TECH

Scar repair material

ActiveCN102406966AImprove repair effectPromote wound healingSurgeryCollagen Type IIIWater soluble chitosan

The invention discloses a scar repair material. A preparation method comprises the following steps of: dissolving water-soluble chitosan in water or dissolving chitosan with the deacetylation degree of 75 to 97 percent in an acetic acid aqueous solution under stirring, adding polyoxyethylene sorbitan monolaurate with an emulsifying effect and glycerin with a moisturizing effect, and uniformly mixing to obtain a transparent gel-like solution; and adding polydimethylsiloxane into the gel-like solution under homogenizing, and uniformly mixing to obtain the scar repair material. The scar repair material can actively and passively moisture skin, has a hydration effect on scar skin, has a good repair effect, has an effect of resisting and inhibiting bacteria, has a good effect of resisting and inhibiting the bacteria on the surfaces of scars and outside the scars, has an effect of accelerating skin wound healing, can have a good effect of repairing and protecting fine cracks on the surfacesof the scars, and can inhibit the secretion of collagen type I in keloid skin to reduce the proportion of the collagen type I or collagen type III.

Owner:TIANJIN JIASHITANG SCI & TECH

Long-acting wood fungicide

A long-acting wood fungicide comprises the following raw materials by weight: 6-10 parts of organic silicon, 3-5 parts water glass, 3-8 parts walnut green seedcase, 4-9 parts of sodium chloride, 6-8 parts of pinellia ternata, 7-9 parts of chitosan, 6-10 parts of hydroxyethyl urea, 6-8 parts of sodium dodecyl benzene sulfonate, 6-10 parts of ethylene-vinyl acetate copolymer, 4-8 parts of graphite, 3-5 parts of a drier, 4-9 parts of p-phenylenediamine, 4-6 parts of N-methylpyrrolidone, 4-7 parts of glycerol and 6-11 parts of dehydrated sorbitan monolaurate. The beneficial effects are that: the long-acting wood fungicide can well inhibit bacterial and microbial growth, and is non-toxic and harmless.

Owner:QINGDAO KELIKE INFORMATION TECH

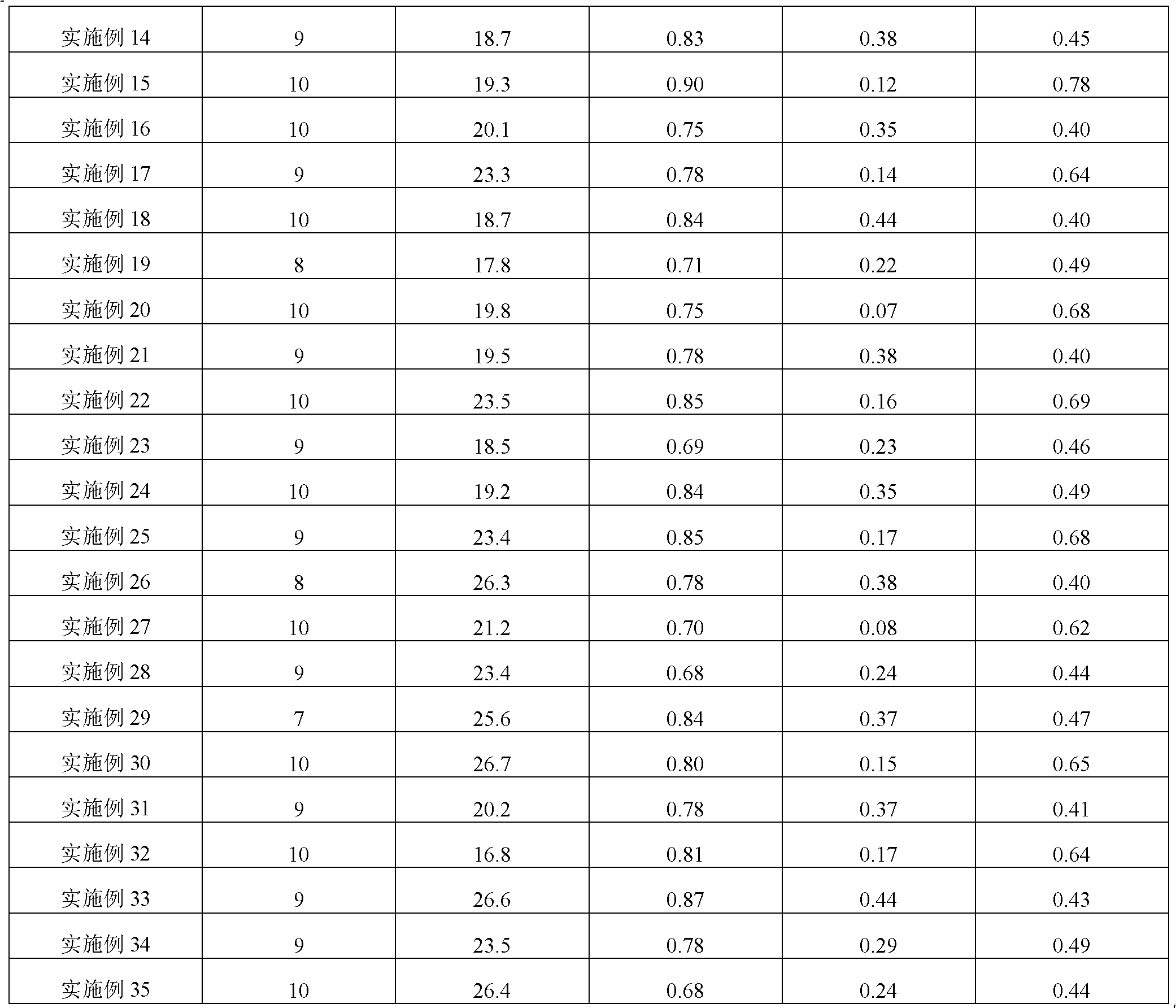

Fruit and vegetable washing salt and preparation and use method thereof

InactiveCN105950311ALubriciousDisperse fastInorganic/elemental detergent compounding agentsAmpholytes/electroneutral surface-active compoundsCocamidopropyl betainePollution

The invention relates to the technical field of washing salts, especially a novel green and environment-friendly fruit and vegetable washing salt. The washing salt comprises the following components by mass: 80-90 parts of sodium chloride, 1-6 parts of sodium citrate, 0.2-0.8 part of citric acid fatty acid glyceride, 0.5-1 part of polyoxyethylene sorbitan monolaurate, 4-8 parts of polyglucoside, and 2-8 parts of cocamidopropyl betaine. After use of the fruit and vegetable washing salt, ''oil-coated'' or ''water-coated'' macromolecules are easy to form, and are easily dispersed into the solution rapidly in an oscillation process, also the fruit and vegetable washing salt endows the surfaces of the fruits and vegetables with lubricity, thus greatly reducing the pesticides, oil and dustiness after adsorption washing, and preventing secondary pollution, the washing water is removed, and then the fruits and vegetables are rinsed clean with clear water.

Owner:CHINASALT JINTAN

Hederagenin-based facial milk cleanser

InactiveCN101756803ANo greasy feelingReduced oil bleedingCosmetic preparationsToilet preparationsGlycerolMoisture barrier

The invention relates to hederagenin-based facial milk cleanser. Each part of facial milk cleanser comprises the following components by percentage: 5.0% to 8.0% of glycerol, 4.0% to 6.0% of propylene glycol, 0.1% to 0.2% of oleyl alcohol, 1.5% to 2.0% of polyoxyethylene sorbitan mono-laurate, 0.5% to 1.2% of polyoxyethylene lauryl alcohol, 1.0% to 2.0% of hederagenin, 10.0% to 12.0% of ethanol, 0.1% to 0.5% of essence and distilled water in balancing amount. The application method of the hederagenin-based facial milk cleanser comprises the following steps: wetting the face by water; holding a proper amount of the hederagenin-based facial milk cleanser in the palm; adding a small amount of water to the hederagenin-based facial milk cleanser, and lathering; lightly circling the hederagenin-based facial milk cleanser over the face for 1 to 2 minutes; and cleansing with clean water. The hederagenin-based facial milk cleanser targeting on greasy skin is capable of generating fine, smooth and abundant lather and thoroughly cleansing the pores, so that the skin can be clean, smooth and grease-free after the administration; and the hederagenin-based facial milk cleanser is also capable of improving the moisture barrier effect of the skin and keeping the balance of water and grease.

Owner:王若松

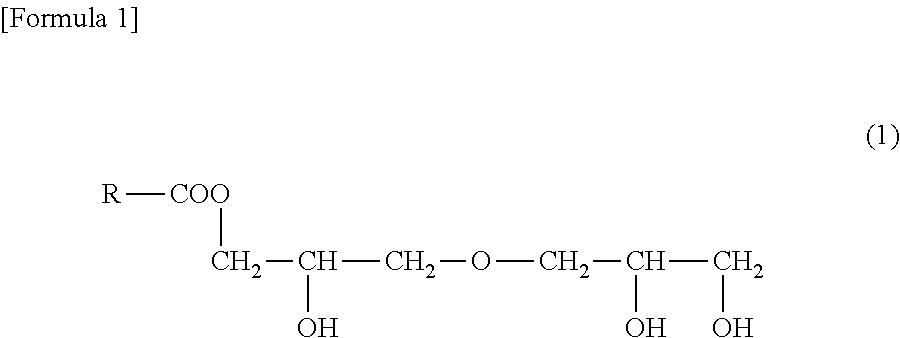

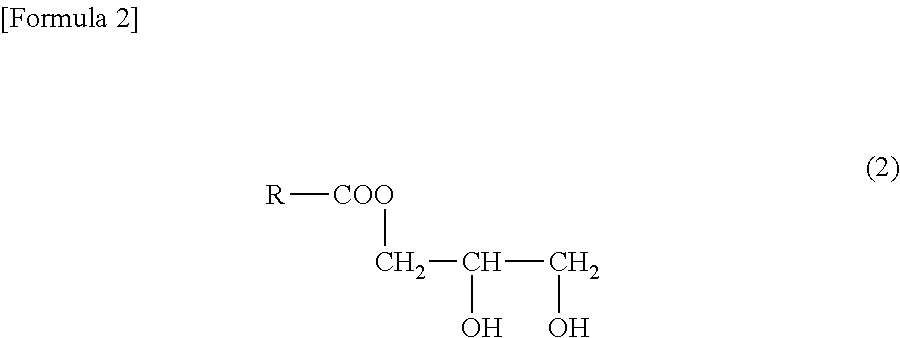

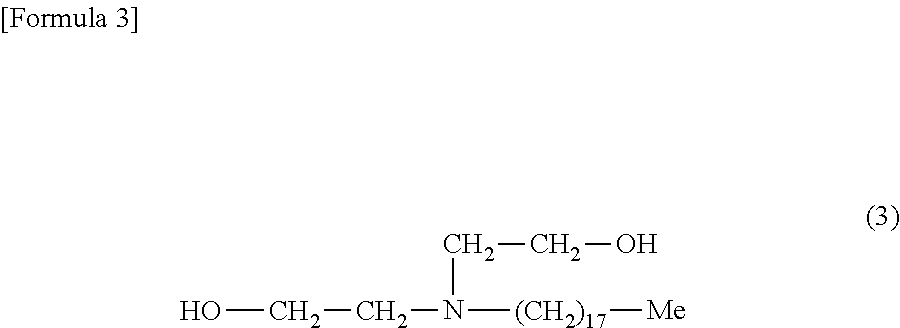

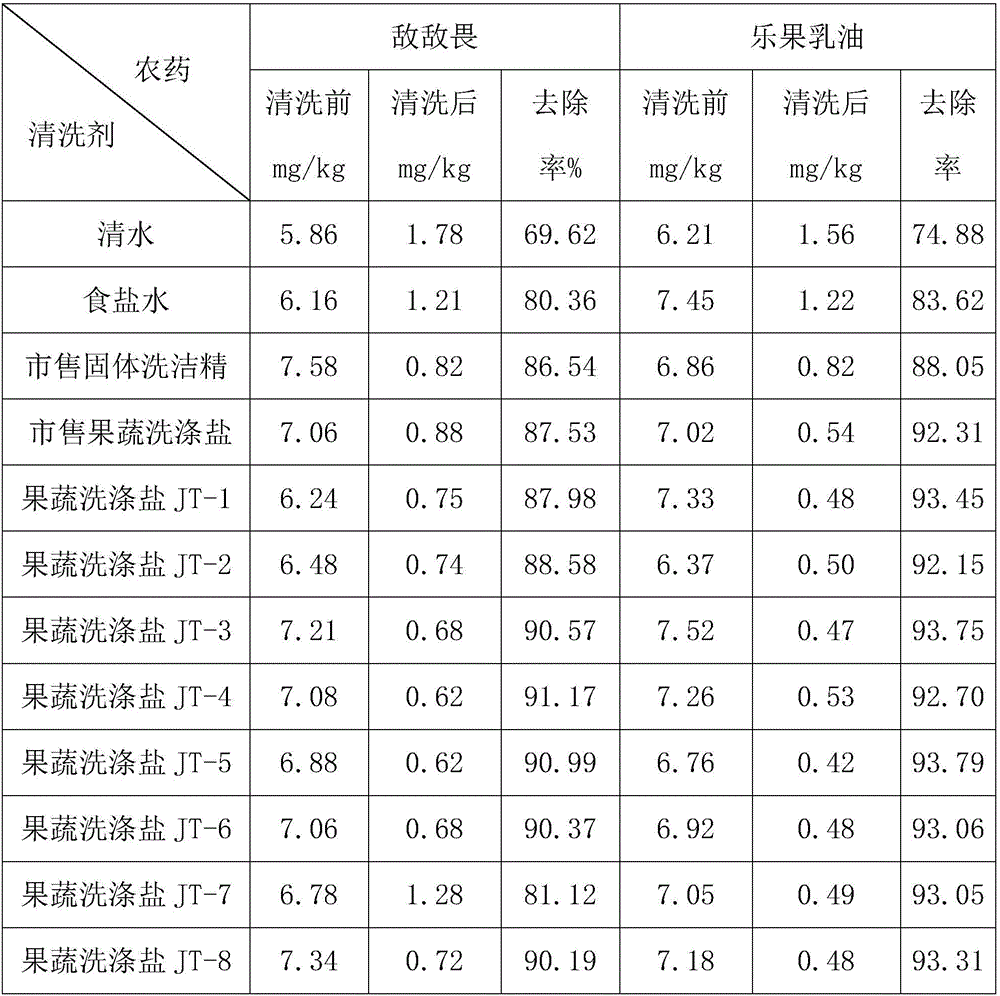

Developing agent for flat-panel display

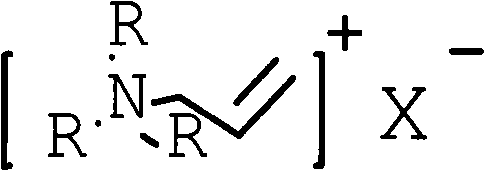

InactiveCN101566804AGood miscibilityExcellent developabilityPhotosensitive material processingPhotosensitive materials for photomechanical apparatusFlat panel displayStructural formula

Owner:绵阳艾萨斯电子材料有限公司

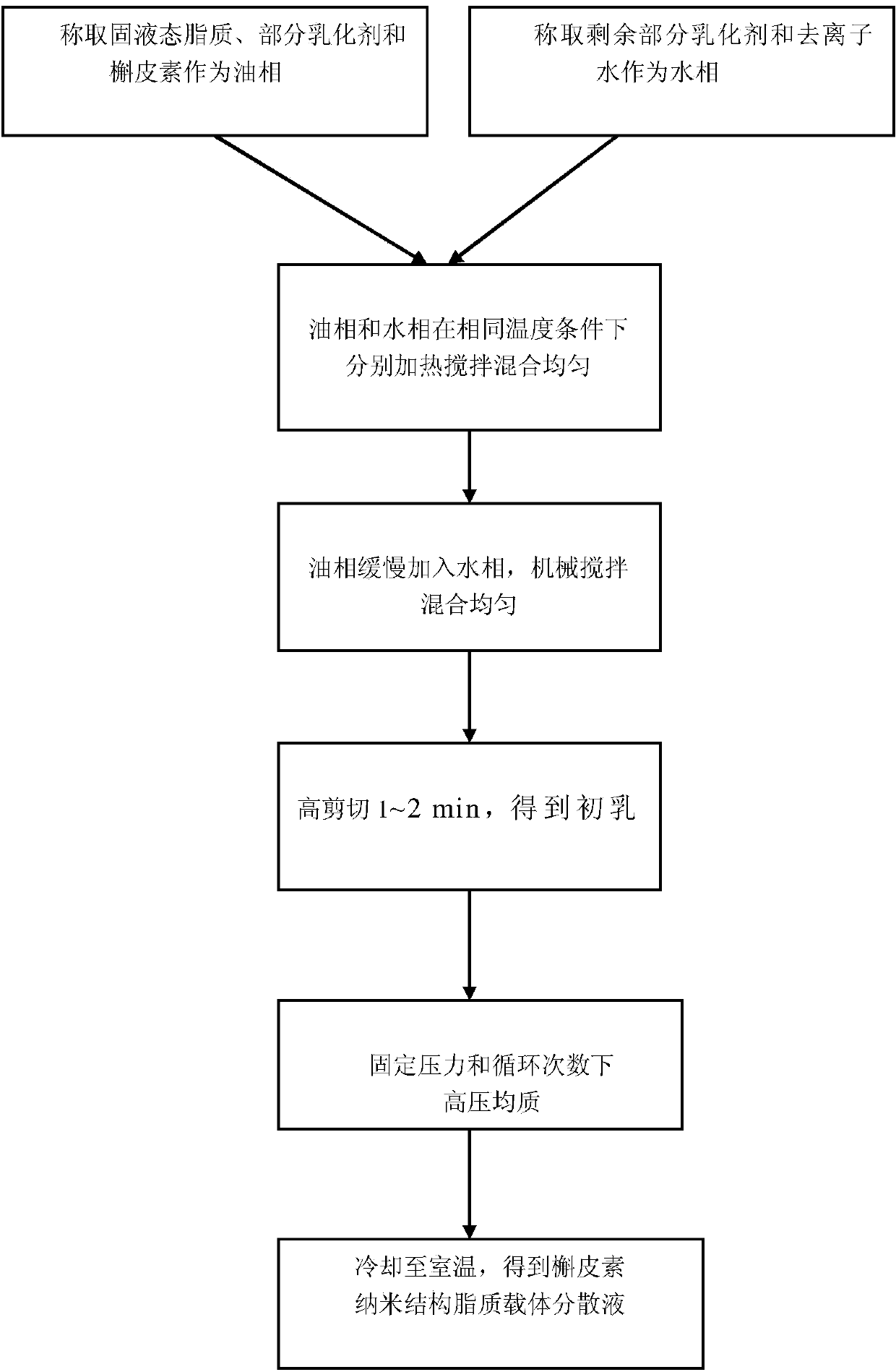

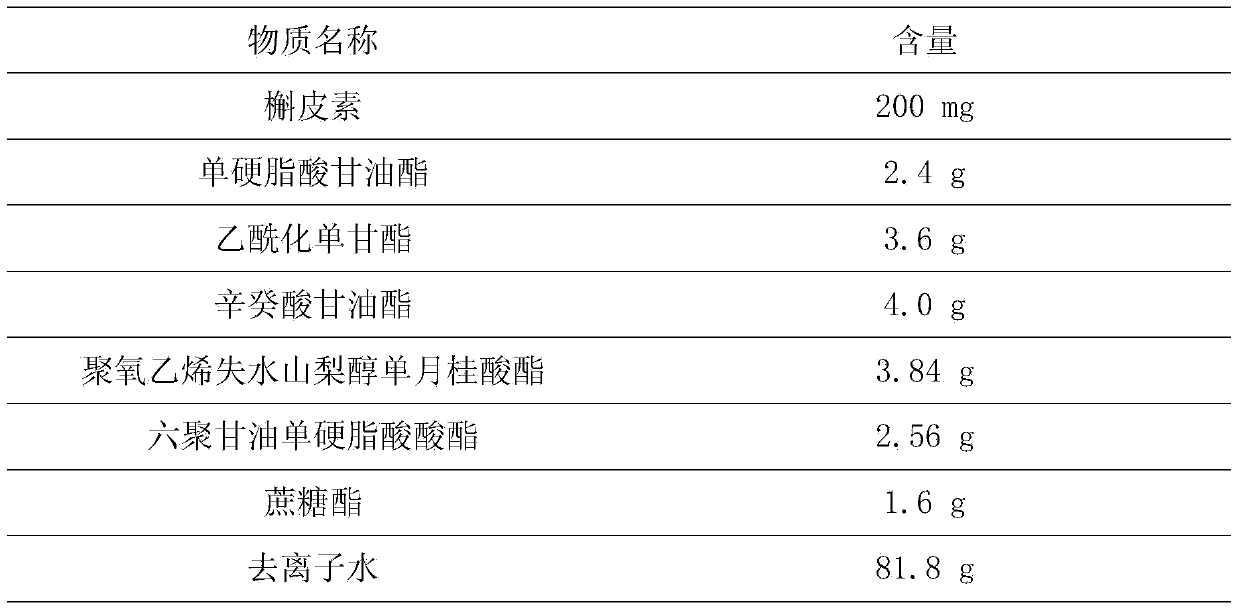

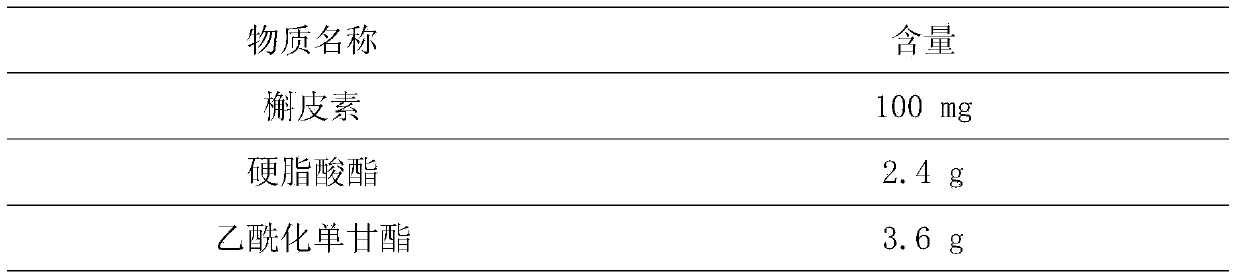

Quercetin nanostructured lipid carrier and preparation method thereof

InactiveCN104172184AThe preparation process is easy to controlGood chemical stabilityFood preparationFood ingredient as emulsifierSolubilityMonoglyceride

The invention discloses a quercetin nanostructured lipid carrier and a preparation method thereof, wherein the quercetin nanostructured lipid carrier comprises the following components by weight percent: 0.1-1% of quercetin, 2%-15% of an emulsifying agent, 2%-15% of compound lipid material and the balance being water. The compound lipid material is a solid-liquid state lipid mixture; the solid lipid is one or more of acetylation monoglyceride, stearate, glyceryl monostearate and monolaurate; the liquid lipid is one or more of decanoyl / octanoyl-glycerides, camellia oleosa seed oil, soybean oil and peanut oil. The quercetin is loaded by utilizing a nanostructured lipid carrier technique, on the one hand, the sensibility of the quercetin to the environmental factors such as illumination and temperature can be reduced, and the chemical stability is improved, and on the other hand, the solubility of the quercetin in water can be improved, thereby improving the bioavailability. The preparation method is simple and controllable, and is good in reproducibility; the quercetin nanostructured lipid carrier emulsion prepared by the method is suitable for being added into functional food beverages.

Owner:SOUTHEAST UNIV

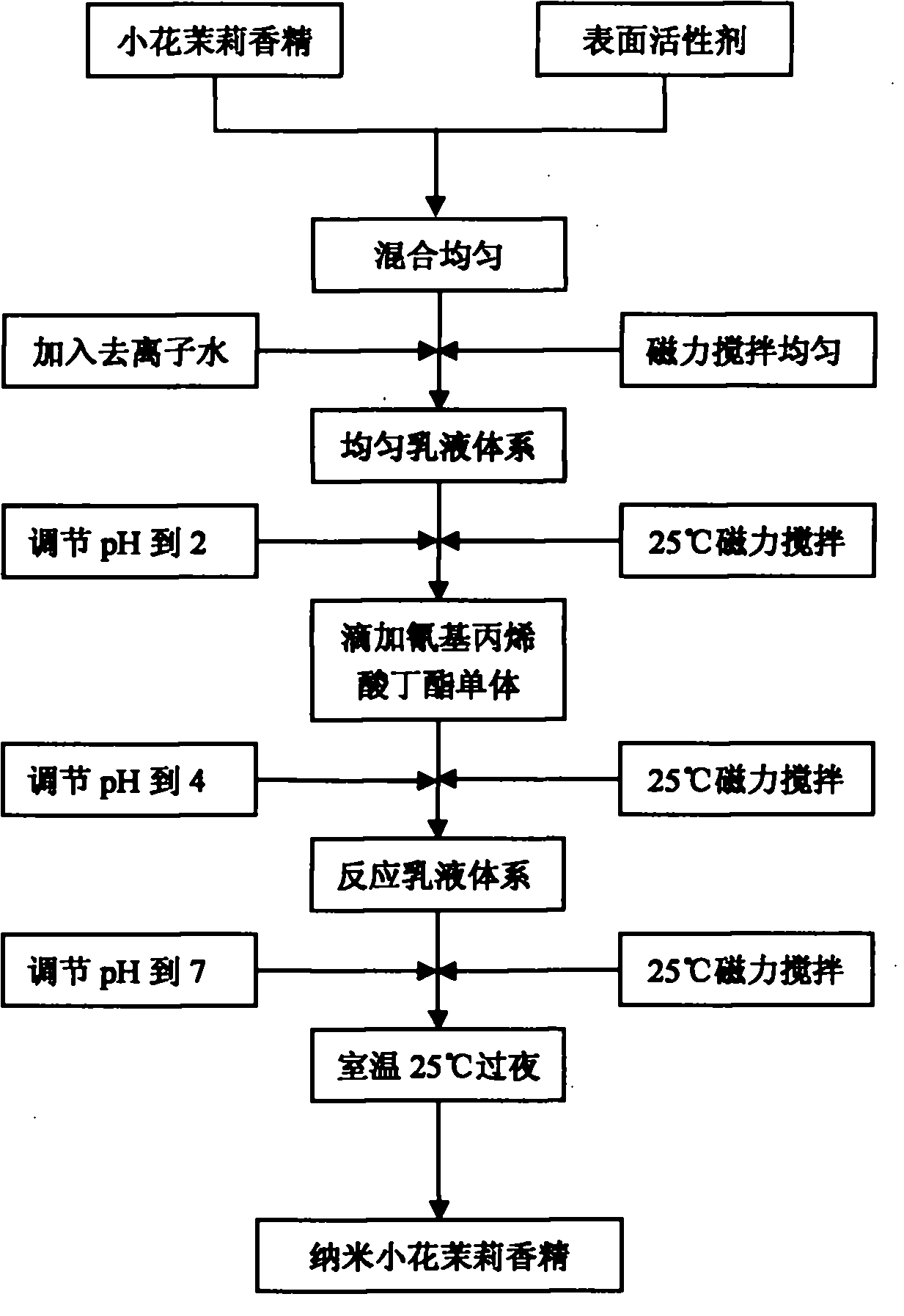

Preparation method of jasmine sambac essence capsule

InactiveCN101811015ADistinctive floral scent of jasmineAroma stabilityEssential-oils/perfumesMicroballoon preparationParticle-size distributionPOLYOXYETHYLENE ETHER

The invention discloses a preparation method of a jasmine sambac essence capsule. The nanometer essence consists of the following components by weight part: 0.66 to 1.06 jasmine sambac essences, 0.54 to 2.4 NBCA, 2 to 3.2 surfactants (selected from polyoxyethylene (20) sorbitan mono-laurate, polyoxyethylene sorbitan palmitate and polyoxyethylene sorbitan monooleate), and 93.62 to 96.26 deionized water. The nanometer jasmine sambac essence emulsion prepared by the invention is milk white, blue light phenomenon is obvious, and the system is uniform and stable. Jasmine flowers have obvious perfume and graceful and delicate fragrance. Tested by dynamic laser light scattering, the nanometer jasmine sambac essence has uniform particle size distribution, the average particle size is 70.8nm and the particle size distribution coefficient is 0.210.

Owner:SHANGHAI INST OF TECH

Preparation method of hydrophobic modified polyacrylamide

The invention belongs to the field of water-soluble macromolecular materials, and particularly relates to a preparation method of hydrophobic modified polyacrylamide. Hydrophobic modified polyacrylamide inverse emulsion is prepared by adopting acrylamide and 2-acrylamido-2-methylpropanesulfonic acid as monomers, adopting sorbitan mono-laurate and octaphenyl polyoxyethylene as emulsifiers, adopting kerosene or cyclohexane as an oil phase, preparing polyacrylamide inverse emulsion by virtue of chemical initiation or ultraviolet illumination, and adding a hydrophobic modification reagent containing a benzene ring into the inverse emulsion to perform the modification. The polyacrylamide inverse emulsion is hydrophobically modified, and the hydrophobic group containing the benzene ring is introduced, so that not only can the viscosity of the polyacrylamide be remarkably improved, but also the temperature resistance and salt resistance of the polyacrylamide are greatly improved. A product prepared by the method is convenient to use, low-cost, and has high in application prospect, and industrialized production is easy.

Owner:SHANDONG UNIV

Fish oil topical composition

Disclosed is a method of reducing the rancid fish odor smell in a topical composition comprised of fish oil which comprises mixing the composition with monolaurin. Also disclosed are various anhydrous topical compositions comprising fish oil. One comprises fish oil, cetyl ester, palm olein, medium-chain triglyceride(s) of a mixture of C8 and C10 fatty acids, mixture of C8 / C10 fatty acids, and monolaurin, another one comprises fish oil, cetyl ester, palm olein, medium-chain triglyceride(s) of a mixture of C8 and C10 fatty acids, mixture of C8 / C10 fatty acids, monolaurin, collagen and sea salt, an a third one comprises fish oil, cetyl ester, palm olein, medium-chain triglyceride(s) of a mixture of C8 and C10 fatty acids, mixture of C8 / C10 fatty acids, monolaurin and hydrocolloid. These compositions are useful for treating wounds and skin conditions.

Owner:OMEZA LLC

Environment-friendly pavement dust suppressant and preparation method thereof

InactiveCN103450852AQuick condensationAvoid flyingOther chemical processesSorbitan monostearateSODIUM PYRROLIDONE CARBOXYLATE

The invention provides an environment-friendly pavement dust suppressant and a protection method thereof. The dust suppressant is prepared from the following raw materials in parts by mass: 4 to 18 parts of sorbitan monolaurate, 5 to 24 parts of sorbitan monostearate, 2 to 6 parts of sodium lactate, 3 to 5 parts of sodium pyrrolidone-carboxylate, 3 to 7 parts of glycerin, and 150 to 160 parts of water. By adopting the environment-friendly pavement dust suppressant, the dust particles which are easy to fly can be quickly conglomerated into large particles to sink, thus the flying of dust on a pavement can be effectively prevented, and the acting efficiency is high; the dust suppressing effect can last for more than 6 days; the dust suppressing rate is up to 95%.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

Compositions, kits and methods for nutritional supplementation with twelve carbon chain fatty acids and twelve carbon chain acylglycerols

The present invention relates to compositions, kits and methods for the administration of compositions and kits for supplementation with twelve carbon chain fatty acids or twelve carbon chain acylglycerols; and specifically for the supplementation with twelve carbon chain fatty acids such as lauric acid and twelve carbon chain acylglycerols such as monolaurin; and specifically for the co-supplementation with other vitamins, minerals and nutrients.

Owner:CHEMO FRANCE

Skin care cosmetic containing liposome recombinant human growth hormone and preparation method thereof

InactiveCN101711729AHigh encapsulation efficiencyThe activity can be maintained for a long timeCosmetic preparationsToilet preparationsGlycerolAlpha-Lipoic Acid

The invention relates to a skin care cosmetic, in particular to a skin care cosmetic containing liposome recombinant human growth hormone. The cosmetic comprises polyoxyethylene fatty alcohol ether, polysorbate 60, monolaurin, hexadecanol, liquid paraffin, glycerol, sodium polyacrylate, polyvinylpyrrolidone K30, alpha-lipoic acid, perfume, preservative, ionized water, liposome human growth hormone. A surface active agent is introduced in the preparation process of liposome so that the encapsulation rate of the liposome human growth hormone is obviously improved. The invention can emulsify a product by a production technology of micro-emulsion to prepare millimicro-emulsion with the grain diameter of 100-200mm, thereby improving the local penetrability of the cosmetic on the skin, enabling an active substance to directly act on the horny layer to be uniformly distributed and showing more favorable effects of aging resistance, facial care, and the like and being more suitable for sensitive skin.

Owner:江西宇骏生物工程有限公司

Acne-removing repairing emulsion containing essential oil

InactiveCN107412107ABalance secretionUndisturbedCosmetic preparationsToilet preparationsGlycerolEssence oil

The invention discloses acne-removing repairing emulsion containing essential oil, relating to the field of skin-care products. The acne-removing repairing emulsion comprises the following materials in parts by weight: 8 parts of glycerinum, 2 parts of propylene glycol, 1 part of silk protein, 0.4 part of triethanolamine, 78 parts of deionized water, 0.3 part of lavender essential oil, 0.3 part of rose essential oil, 0.3 part of tea tree essential oil, 0.3 part of chamomile essential oil, 0.3 part of cypress essential oil, 0.3 part of bergamot essential oil, 0.3 part of lily essential oil, 0.3 part of green tea extract, 0.3 part of scutellaria baicalensis extract, 0.3 part of paris polyphylla extract, 0.3 part of aloe stock solution, 0.3 part of radix salviae miltiorrhizae extract, 0.3 part of gloilpeltis furcata extract, 1 part of antler collagen, 1.5 parts of methyl silicone oil, 2 parts of glycerol stearate, 1.2 parts of polyoxyethylene sorbitan monolaurate, 0.8 part of a composite emulsifying agent AC-402 and 0.4 part of xanthan gum. The acne-removing repairing emulsion disclosed by the invention has high natural components, and is easy to absorb and good in acne-removing effect.

Owner:安徽省中日农业环保科技有限公司

Method for modifying ultrafine light calcium carbonate and application of ultrafine light calcium carbonate in plastics

ActiveCN107629487AComplete crystal formNarrow particle size rangeCalcium/strontium/barium carbonatesPigment treatment with non-polymer organic compoundsDiethylene glycol monobutyl etherPropanoic acid

The invention discloses a method for modifying ultrafine light calcium carbonate and application of the ultrafine light calcium carbonate in plastics, and belongs to the technical field of calcium carbonate manufacture. The modifying method comprises the steps of pulping, treating surface and preparing a finished product, wherein the pulping step comprises the steps of preparing Ca(OH)2 suspension, adding crystal form controlling agent and performing carbonization reaction; the crystal form controlling agent is prepared from the following raw materials in parts by weight: 4-8 parts of sodium nitrate, 5-10 parts of citric acid, 3-5 parts of glycolic acid, 1-3 parts of propionic acid and 1-3 parts of lactic acid; a surface activation coating agent is prepared from the following raw materialsin parts by weight: 14-20 parts of phthalic acid ethylene glycol monobutyl ether ester sodium salt, 2-6 parts of isopropyl alcohol, 3-7 parts of diethylene glycol monobutyl ether, 8-12 parts of octadecylamine, 4-8 parts of lauryl amine and 5-9 parts of sorbitan monolaurate. The ultrafine light calcium carbonate can be used for improving the toughness and strength of PVC, and solving the problemsof uniform dispersing difficulty and poor compatibility with PVC when traditional nano-calcium carbonate is mixed with PVC.

Owner:广西华洋矿源材料有限公司

Hemp yarn softening agent

A hemp yarn softening agent comprises components in parts by mass as follows: 5-15 parts of limonene, 12-20 parts of dimethyl distearylammonium chloride, 5-10 parts of mineral oil, 4-10 parts of a Gemini cation softening agent, 2-5 parts of an emulsifying agent and 20-35 parts of water, wherein the Gemini cation softening agent is a hydroxypropyl Gemini cation surface active agent; and the emulsifying agent is sorbitan monolaurate or oil-based sodium amino acid. The components are mixed proportionally and uniformly and added in the hemp yarn spinning process, so that the span yarn is uniformly coated with a protection film, the fast softening effect is realized, and the hand feeling of a hemp article can be remarkably improved.

Owner:SUZHOU QISHUO INFORMATION TECH CO LTD

Facial cleanser and making method thereof

InactiveCN103599051AClean thoroughlyHas the function of whitening and moisturizingCosmetic preparationsToilet preparationsBiotechnologyCastor Seed

The invention relates to a facial cleanser which comprises the following components: 6-12 parts of polyoxyethylene sorbitan monolaurate, 6-8 parts of cocoamidopropyl betaine, 1-4 parts of vitamin E, 1-3 parts of pearl powder, 0.1-0.5 part of glycerinum, 3-7 parts of sodium monofluorophosphate, 3-8 parts of clove oil and 4-9 parts of castor bean oil. The making method of the facial cleanser comprises the following steps: dissolving 6-12 parts of polyoxyethylene sorbitan monolaurate and 6-8 parts of cocoamidopropyl betaine into water to obtain a mixed solution; mixing 1-4 parts of vitamin E, 1-3 parts of pearl powder, 0.1-0.5 part of glycerinum, and then putting into a reactor for 1-2 hours; then adding into the mixed solution of the 6-12 parts of polyoxyethylene sorbitan monolaurate and 6-8 parts of cocoamidopropyl betaine, and filtering by using a filter to obtain clear liquid; and adding the sodium monofluorophosphate, the clove oil and the castor bean oil into the clear liquid. The facial cleanser made by the making method is green, purely natural and non-allergic and also has whitening and moistening functions and can thoroughly clean pores.

Owner:潘永

Acrylic resin polyurethane powder coating for ceramics

The invention discloses an acrylic resin polyurethane powder coating for ceramics. The acrylic resin polyurethane powder coating comprises the following raw materials: dimethyl glutarate, methacrylic acid, diethanol amine, lead naphthenate, carbon black, polysiloxane, ultraviolet ray absorber, polycarbodiimide, calcium stearate, azelaic acid, flatting agents, sorbitol anhydride monolaurate, butyl maleic acid, dimethyl dodecyl amine and methyl methacrylate; a melting point of the product is 180-200 DEG C and the density is130-150 g / cm<3>, and the phenomena of bubbling and dropping are avoided after the product is soaked for 40-50 days in water; the tensile strength is 20-40 MPa, the elongation rate is 300-400 percent, and the product is soaked for 25-35 days in a 5% hydrochloric acid solution and the abnormal phenomenon is avoided; the lustrousness is 115-135 percent, and the product is soaked for 20-30 days in saturated calcium hydroxide, and the phenomena of bubbling and wrinkling are avoided; the drying time is 20-30 minutes, and the time of the washing fastness is 1,600-2,000 times.

Owner:苏州非特兄弟新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com