Method for preparing nano rose essence capsules

A technology of essence capsules and nano roses, which is applied in the preparation of microspheres, microcapsule preparations, essential oils/flavors, etc., can solve the problems that the aroma of end products is not stable enough, the fragrance holding time is short, and achieve good biodegradability and compatibility. The effect of stability, aroma stability and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

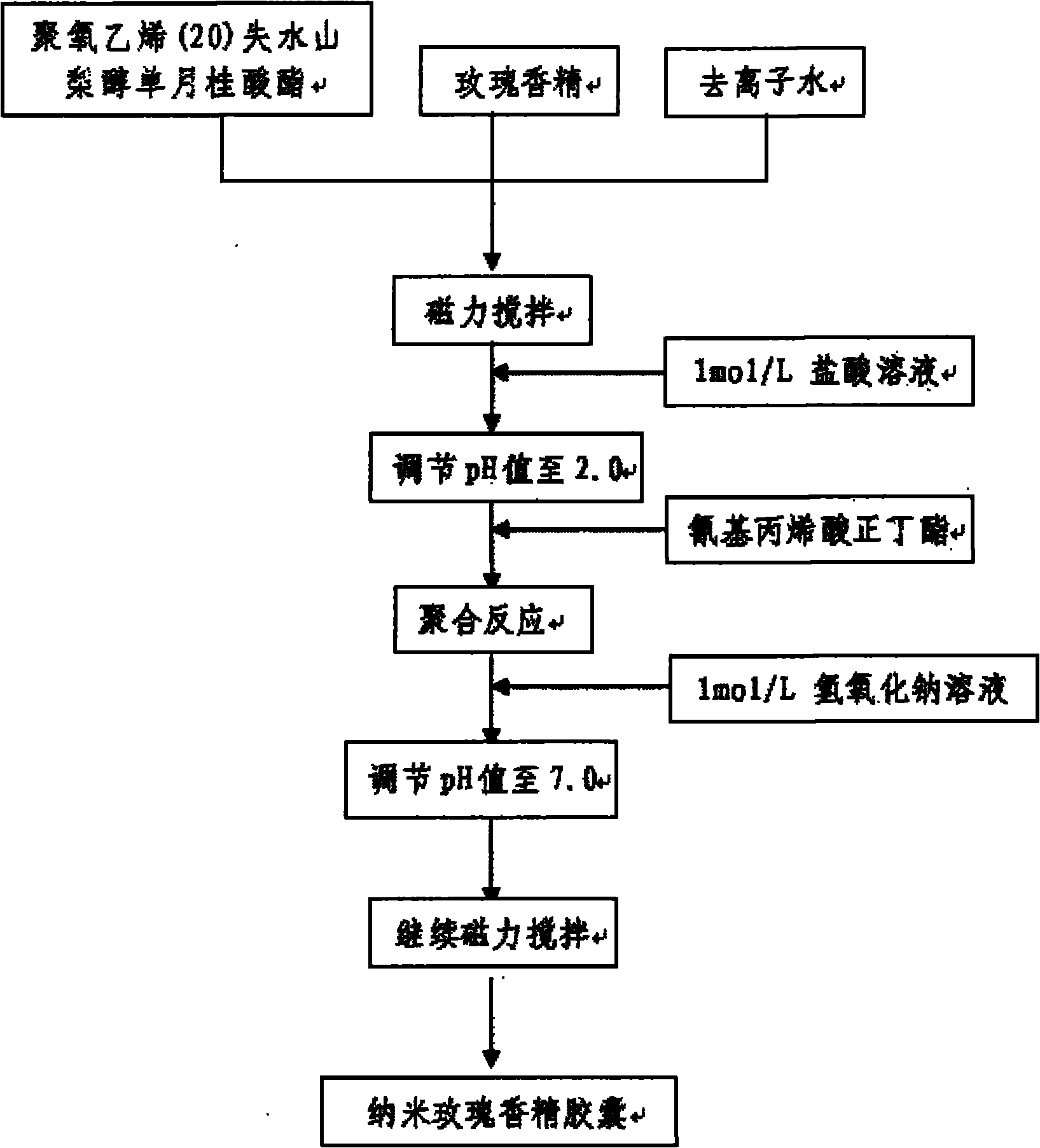

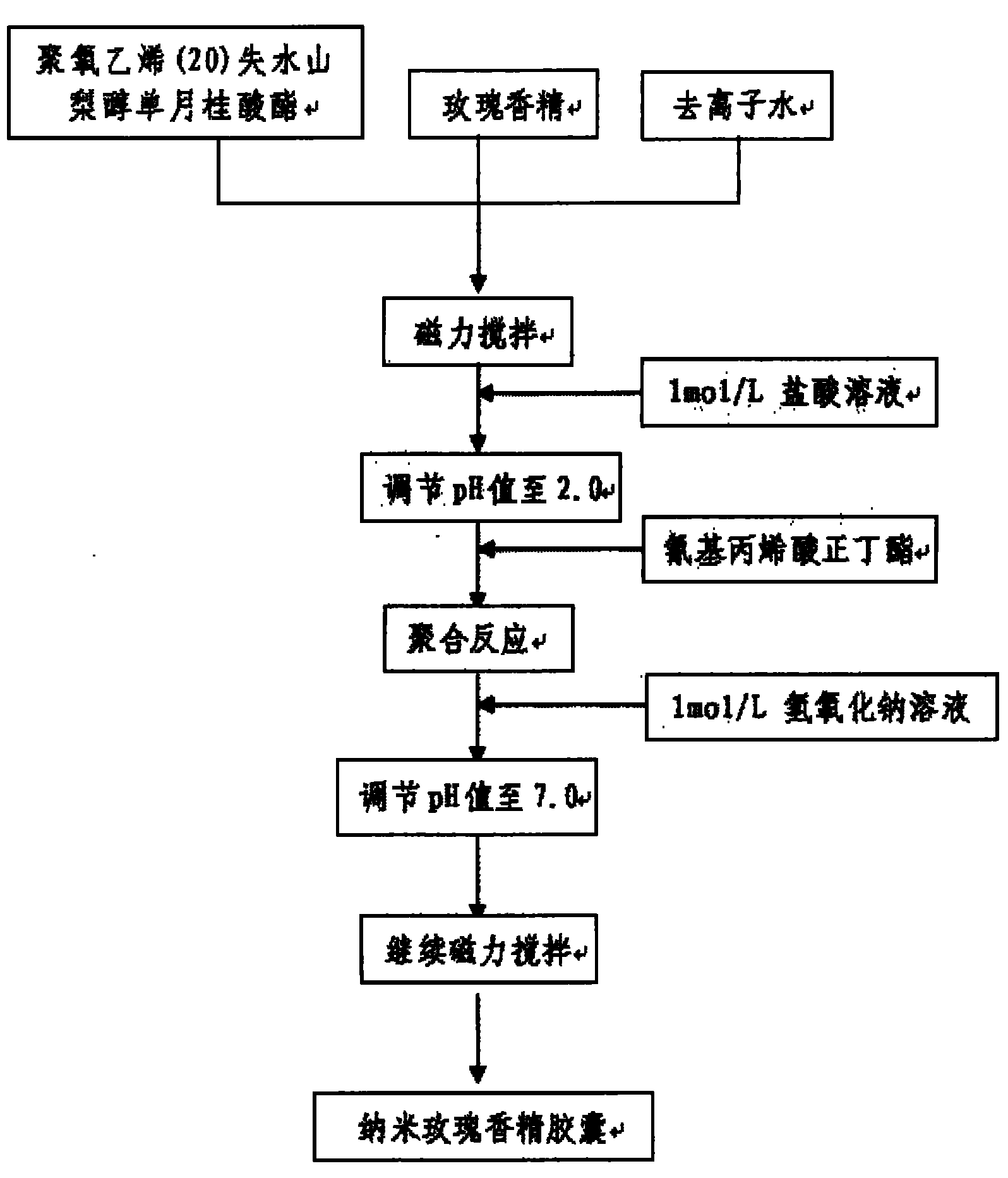

[0020] The preparation method of described nano-rose sustained-release essence capsule comprises the following steps:

[0021] a. Mix 0.3-0.8% by weight of rose essence and 2.0-3.2% by weight of polyoxyethylene (20) sorbitan monolaurate, stir for five minutes under 1100rpm magnetic stirring, and slowly inject deionized water along the beaker wall water, stirring magnetically until a homogeneous emulsion forms. Then adjust the pH value of the system to 2.0 with a 1mol / L hydrochloric acid solution;

[0022] b. Slowly add 0.6-1.6 weight percent n-butyl cyanoacrylate into the emulsion prepared in step a at a rate of 3 drops / min under stirring. After the dropwise addition is completed, react for 2 to 4 hours under stirring conditions, adjust the pH value of the system to 7.0 with 1 mol / L sodium hydroxide solution, and react for 0.5 hours under stirring conditions until the reaction is terminated.

Embodiment 1

[0024] In the beaker, add the rose essence of 0.6 weight percent and the polyoxyethylene (20) sorbitan monolaurate of 2.6 weight percent, mix and fully stir five minutes under the speed of magnetic stirring 1100rpm, and slowly add in the beaker Ionized water, continue to stir at the same speed until the emulsion is uniform. Then slowly add 1mol / L hydrochloric acid solution dropwise under magnetic stirring to adjust the pH value of the system to 2.0, then slowly add 1.2% by weight of n-butyl cyanoacrylate, stir while dropping, after the dropwise addition is completed, close the bottle mouth, Continue to stir to make it fully polymerized, terminate the reaction after 4 hours, adjust the pH value of the system to 7.0 with 1mol / L sodium hydroxide solution, and continue to stir for 0.5 hours to prepare the nano-rose essence capsule emulsion.

[0025] The nano-flavor capsule emulsion was obtained in the experiment, and the system existed stably, but the blue light phenomenon was not...

Embodiment 2

[0027] Add 0.8% by weight of rose essence and 2.0% by weight of polyoxyethylene (20) sorbitan monolaurate in the beaker, mix and fully stir for five minutes at a speed of 1100rpm with magnetic stirring, and slowly add to the beaker Ionized water, continue to stir at the same speed until the emulsion is uniform. Then slowly add 1mol / L hydrochloric acid solution dropwise under magnetic stirring to adjust the pH value of the system to 2.0, then slowly add 1.6% by weight of n-butyl cyanoacrylate, stir while dropping, after the dropwise addition is completed, close the bottle mouth, Continue to stir to make it fully polymerized, terminate the reaction after 2 hours, adjust the pH value of the system to 7.0 with 1mol / L sodium hydroxide solution, and continue to stir for 0.5 hours to prepare the nano-rose essence capsule emulsion.

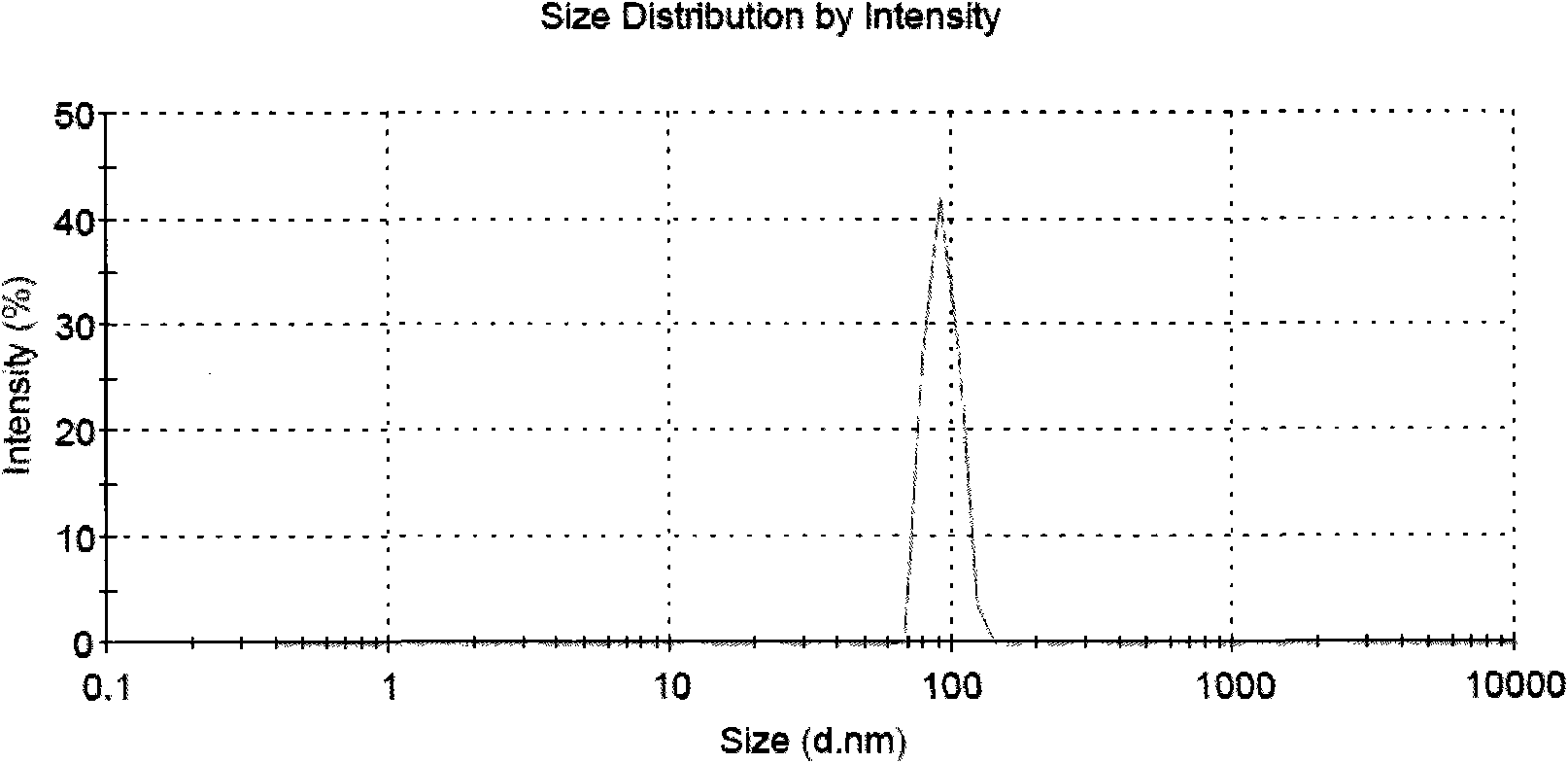

[0028] The experiment obtained the nano essence capsule emulsion with blue light, and the system existed stably. After being tested by a dynamic laser l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com