Developing agent for flat-panel display

A flat-panel display and developing solution technology, which is applied in the direction of photosensitive materials used in optomechanical equipment, photosensitive material processing, etc., can solve the problems affecting the image display quality of flat-panel display and reduce the yield rate of panel production lines, etc., and achieve good mutual solubility and operation The effect of wide temperature range and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Taking the glass substrate as an example, the glass substrate can be processed as follows according to the conventional method, and the desired image can be obtained on the glass substrate:

[0048] 1) Cleaning and drying;

[0049] 2) Use Freehand software to design graphics, the width of microchannel graphics is designed to be 80um, and laser high-resolution printing masks are used for backup;

[0050] 3) Place the glass substrate in a KW-4A glue spreader, and evenly coat a layer of photoresist with a thickness of 2.3um at a glue spread speed of 3500r / min;

[0051] 4) Dry and cool the coated glass sheet to room temperature for use. Place the mask on a glass slide protected by photoresist, and expose it with a 500W UV light source for 25sec;

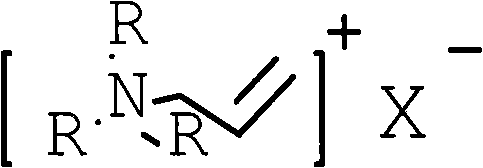

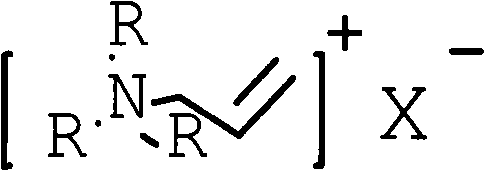

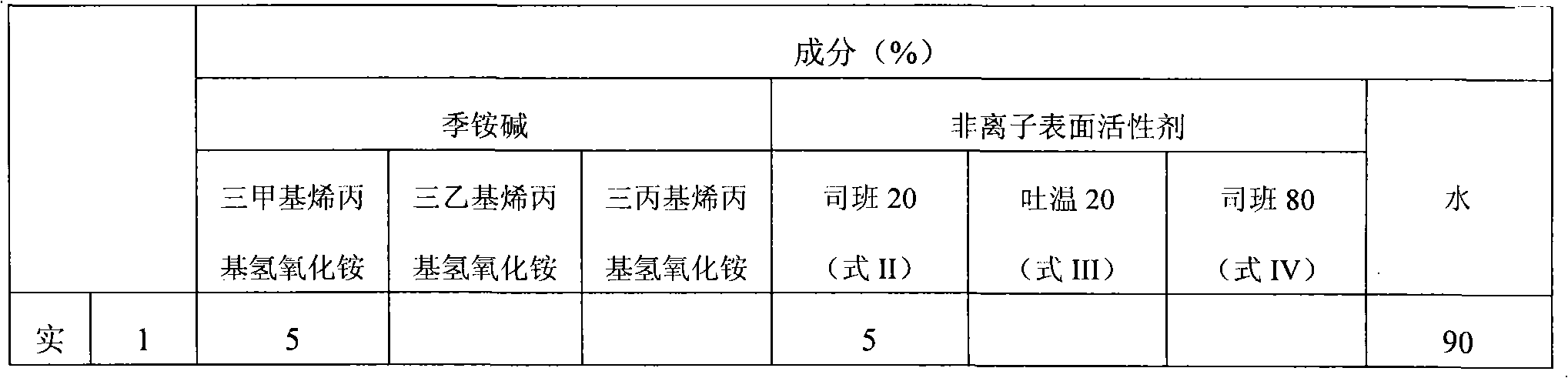

[0052] 5) The developer solution composition required for deployment, its specific composition is: a kind of quaternary ammonium base shown in formula I, the weight ratio of trimethylallyl ammonium hydroxide is 5%, the dehydrati...

Embodiment 11

[0063] Embodiment 11, preparation trimethyl allyl ammonium hydroxide

[0064] Trimethylallyl ammonium hydroxide used in the foregoing examples is prepared according to the following method:

[0065] In a 3-liter three-necked flask, 271.0 g (2.0 mol) of trimethylallyl ammonium chloride and 1000 ml of methanol were added, and after uniform stirring, a colorless transparent liquid was obtained. Then, gradually add 80 g (2 mol) of solid sodium hydroxide within 30 minutes, and stir at room temperature for 2 hours. Under the protection of nitrogen, it was separated by filtration to obtain solid by-products and mother liquor. Among them, the solid by-product is mainly sodium chloride, and the solid by-product is suspended in 1000ml of methanol, and after adding a small amount of concentrated hydrochloric acid to neutralize it, the precipitated sodium chloride solid is filtered; the mother liquor is trimethylallyl hydroxide The methanol solution of ammonium is 925g in total, the mas...

Embodiment 12

[0066] Embodiment 12, preparation triethylallyl ammonium hydroxide

[0067] Triethylallyl ammonium hydroxide used in the foregoing examples is prepared according to the following method:

[0068] In a 3-liter three-necked flask, 363.0 g (2.0 mol) of triethylallyl ammonium chloride and 1000 ml of methanol were added, and after uniform stirring, a colorless transparent liquid was obtained. Then, gradually add 80 g (2 mol) of solid sodium hydroxide within 30 minutes, and stir at room temperature for 2 hours. Under the protection of nitrogen, it was separated by filtration to obtain solid by-products and mother liquor. Among them, the solid by-product is mainly sodium chloride, and the solid by-product is suspended in 1000ml of methanol, and after adding a small amount of concentrated hydrochloric acid to neutralize it, the precipitated sodium chloride solid is filtered; the mother liquor is triethylallyl hydroxide Methanol solution of ammonium, 1120g in total, mass percentage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com