Degumming agent, preparation method of degumming agent, silkworm cocoon degumming method and application

A degumming agent and silkworm cocoon technology, which is applied in the field of silk processing, can solve problems such as environmental pollution, and achieve the effects of avoiding secondary pollution, expanding the scope of application and good degumming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

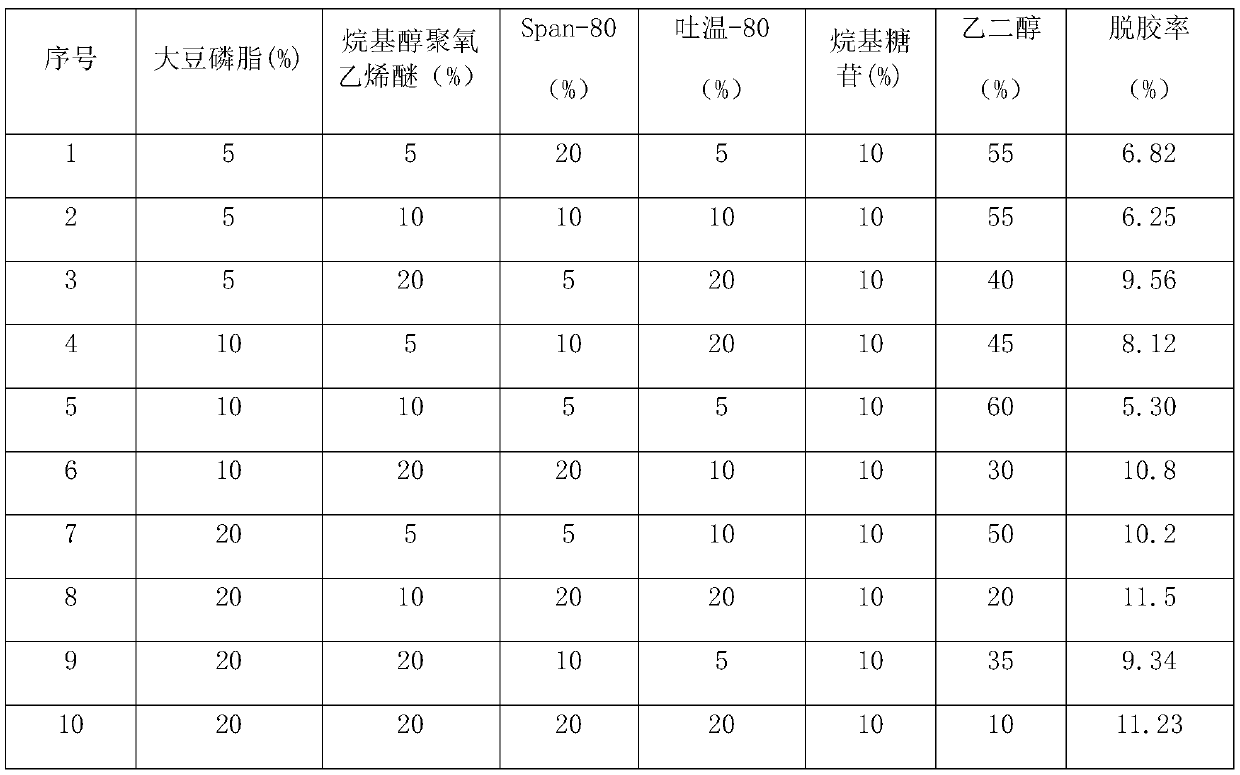

Examples

Embodiment 1

[0035] A degumming agent comprising the following raw materials: soybean lecithin 5kg, sorbitan fatty acid ester 5kg, polyoxyethylene sorbitan monooleate 5kg, alkyl alcohol polyoxyethylene ether 5kg, alkyl glycoside 9kg, Ethylene glycol 9kg.

[0036] In the present embodiment, the preparation method of described degumming agent, comprises the following steps:

[0037] Weigh soybean lecithin, sorbitan fatty acid ester, polyoxyethylene sorbitan monooleate, alkyl alcohol polyoxyethylene ether, alkyl glucoside and ethylene glycol, and mix them evenly.

[0038] In this embodiment, a silkworm cocoon degumming method, using the degumming agent, specifically includes the following steps:

[0039] Immerse the silkworm cocoons to be degummed in water for wetting, add the degumming agent according to the mass ratio of the degumming agent to the water of 1:20, mix evenly, heat to 30°C and stir to obtain the mixture. Said water is deionized water;

[0040] Cool the mixture to 20°C and c...

Embodiment 2

[0048] A degumming agent comprising the following raw materials: soybean lecithin 30kg, sorbitan fatty acid ester 30kg, polyoxyethylene sorbitan monooleate 30kg, alkyl alcohol polyoxyethylene ether 30kg, alkyl glycoside 11kg, Ethylene glycol 60kg.

[0049] The preparation method of described degumming agent, comprises the following steps:

[0050] Weigh soybean lecithin, sorbitan fatty acid ester, polyoxyethylene sorbitan monooleate, alkyl alcohol polyoxyethylene ether, alkyl glucoside and ethylene glycol, and mix them evenly.

[0051] In this embodiment, a silkworm cocoon degumming method, using the degumming agent, specifically includes the following steps:

[0052] Immerse the cocoon to be degummed in water for wetting, add the degumming agent according to the mass ratio of the degumming agent to the water of 1:500, mix evenly and heat to 100°C for stirring to obtain a mixture. Said water is deionized water;

[0053] Cool the mixture to 60°C, centrifuge to obtain degumme...

Embodiment 3

[0061] A degumming agent comprising the following raw materials: soybean lecithin 20kg, sorbitan fatty acid ester 20kg, polyoxyethylene sorbitan monooleate 20kg, alkyl alcohol polyoxyethylene ether 20kg, alkyl glycoside 10kg, Ethylene glycol 10kg.

[0062] In the present embodiment, the preparation method of described degumming agent, comprises the following steps:

[0063] Weigh soybean lecithin, sorbitan fatty acid ester, polyoxyethylene sorbitan monooleate, alkyl alcohol polyoxyethylene ether, alkyl glucoside and ethylene glycol, and mix them evenly.

[0064] A silkworm cocoon degumming method, using the degumming agent, specifically comprises the following steps:

[0065] Immerse the cocoon to be degummed in water for wetting, add the degumming agent according to the mass ratio of the degumming agent to the water of 1:50, mix evenly and heat to 80°C for stirring to obtain a mixture. Said water is deionized water;

[0066] Cool the mixture down to 25°C and centrifuge to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com