Modifying reprocessing craft for recycled plastic

A technology for recycling plastics and reprocessing, which is applied in plastic recycling, mechanical material recycling, recycling technology, etc. It can solve the problems of poor performance and difficult removal of plastic particles, and achieve the effects of easy handling, easy cleaning, and accelerated effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

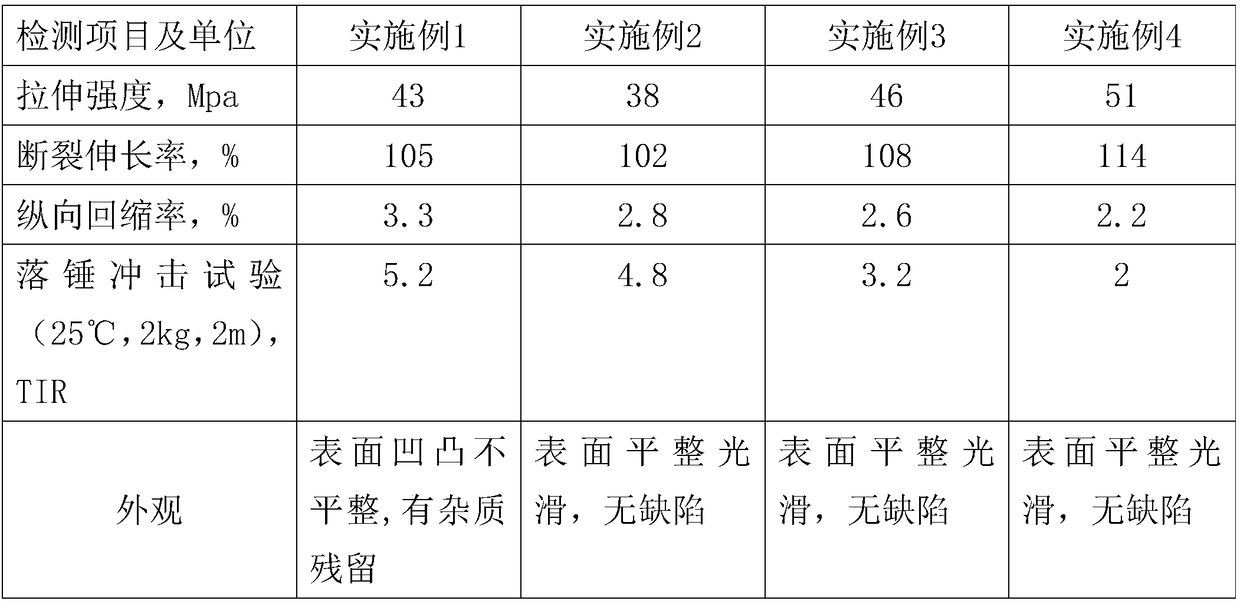

Examples

Embodiment 1

[0027] A modification and reprocessing process of recycled plastics, the specific process steps are as follows:

[0028] (1) Put the recycled plastic into the cleaning solution, heat it to 60 degrees, and soak for 1 hour;

[0029] The cleaning solution is made of the following raw materials in parts by weight: 100 parts of water, 20 parts of starch, 10 parts of rice bran, 5 parts of soda ash, 5 parts of alginate, 3 parts of triglycerides, 2 parts of octyldodecyl alcohol, cyclic 1 part of polydimethylsiloxane;

[0030] (2) Put the plastic and the soaking liquid into the mixer for stirring treatment, the stirring speed is 600r / min, and the stirring time is 20 minutes. Rinse the plastic with a high-pressure water gun;

[0031] (3) Put the plastic processed in step 2 into the crushing machine for crushing treatment, then put the crushed material into the high-speed mixer, add additives, pass in ozone, and carry out mixing. The mixing temperature is 180 degrees , the mixing time...

Embodiment 2

[0040] A modification and reprocessing process of recycled plastics, the specific process steps are as follows:

[0041] (1) Put the recycled plastic into the cleaning solution, heat it to 70 degrees, and soak it for 2 hours;

[0042] The cleaning solution is made of the following raw materials in parts by weight: 150 parts of water, 30 parts of modified starch glue, 15 parts of rice bran, 15 parts of soda ash, 10 parts of alginate, 6 parts of triglycerides, 4 parts of octyldodecyl alcohol Parts, 3 parts of cyclomethicone;

[0043](2) Put the plastic and the soaking liquid into the mixer for stirring treatment, the stirring speed is 800r / min, and the stirring time is 30 minutes. Rinse the plastic with a high-pressure water gun;

[0044] (3) Put the plastic processed in step 2 into the crushing machine for crushing treatment, then put the crushed material into the high-speed mixer, add additives, inject ozone, and carry out mixing. The mixing temperature is 220 degrees , the...

Embodiment 3

[0052] A modification and reprocessing process of recycled plastics, the specific process steps are as follows:

[0053] (1) Put the recycled plastic into the cleaning solution, heat it to 65 degrees, and soak for 1.5 hours;

[0054] (2) Put the plastic and the soaking liquid into the mixer for stirring treatment, the stirring speed is 700r / min, and the stirring time is 25 minutes. Rinse the plastic with a high-pressure water gun;

[0055] The cleaning solution is made of the following raw materials in parts by weight: 130 parts of water, 25 parts of modified starch glue, 13 parts of rice bran, 10 parts of soda ash, 8 parts of alginate, 5 parts of triglycerides, 3 parts of octyldodecyl alcohol Parts, 2 parts of cyclomethicone;

[0056] (3) Put the plastic processed in step 2 into the crushing machine for crushing treatment, then put the crushed material into the high-speed mixer, add additives, pass in ozone, and carry out mixing. The mixing temperature is 200 degrees , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com