Patents

Literature

45results about How to "Meet the needs of subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing mid-high voltage corrosion foil by using pulse DC superposed current

ActiveCN104505260AAdaptable to changesImprove electrostatic capacityElectrolytic capacitorsAluminum IonMechanical property

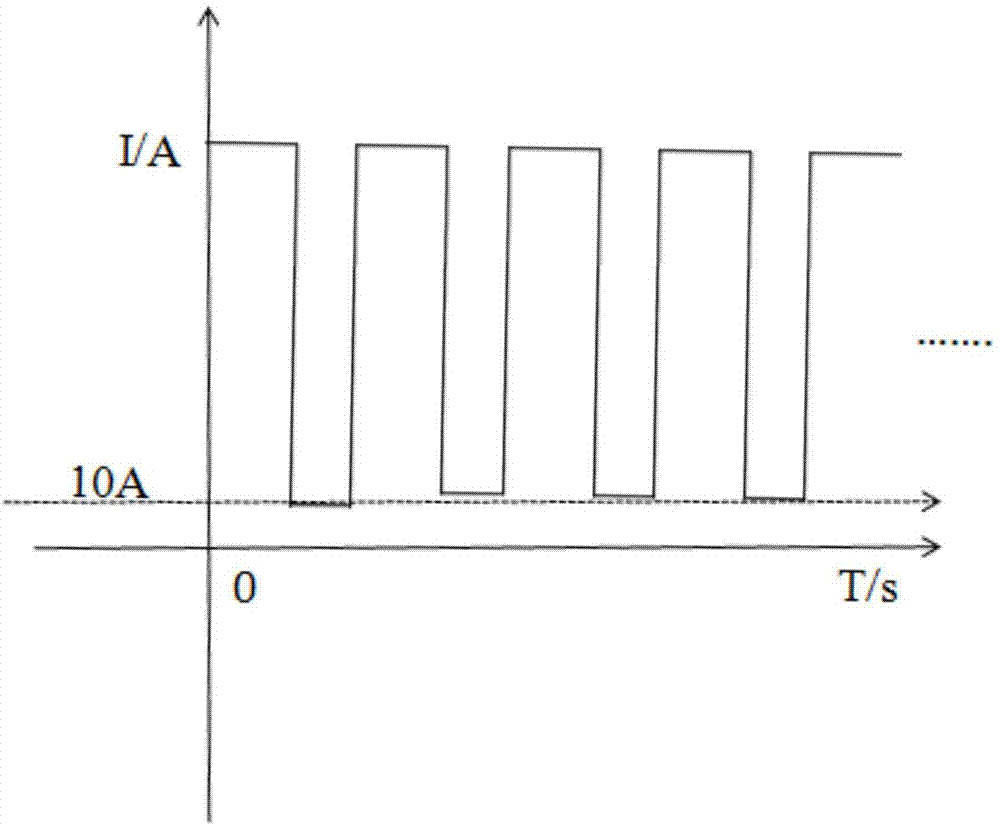

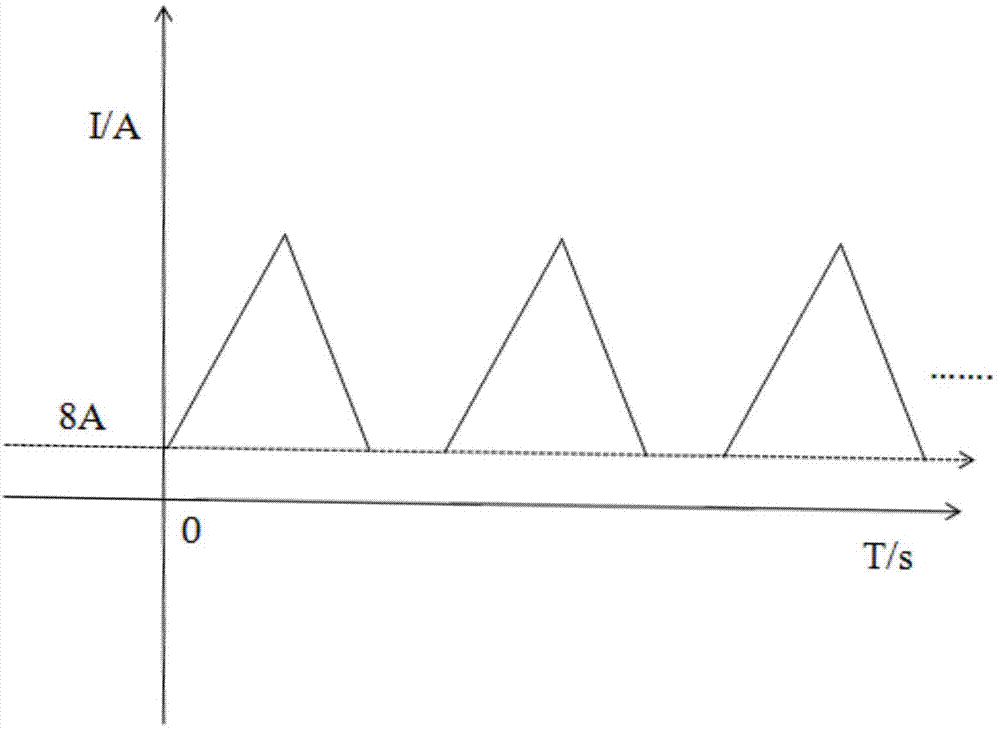

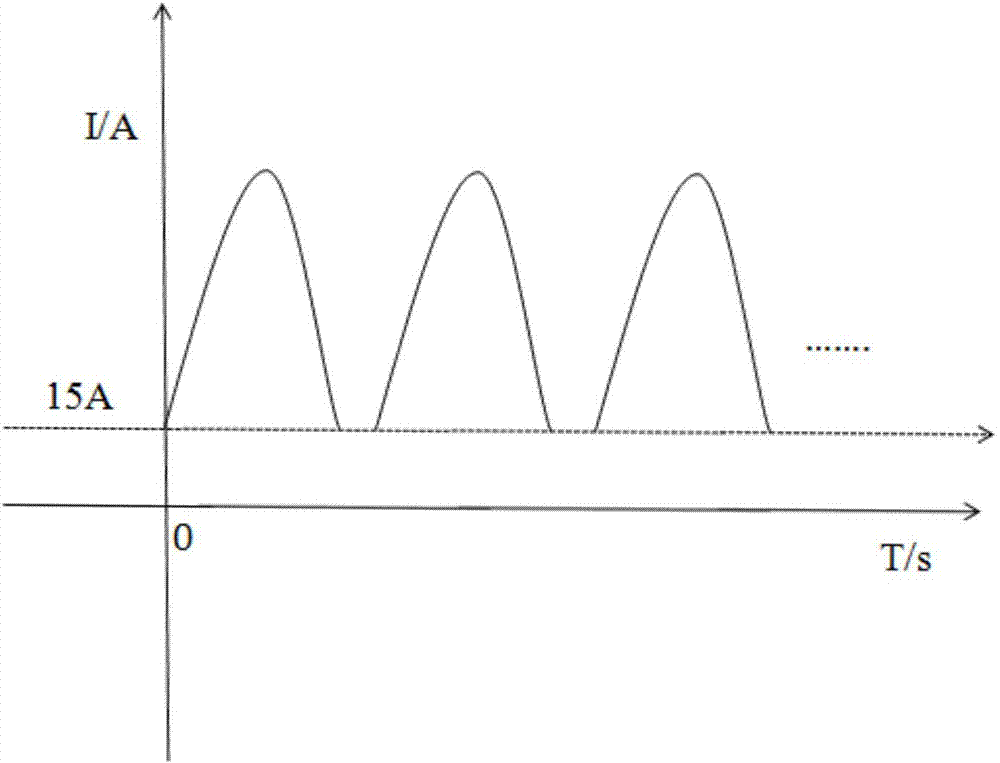

The invention relates to a method for preparing a mid-high voltage corrosion foil by using pulse DC superposed current. The method comprises the following steps of first pretreatment, second pretreatment, first-stage hole generation, intermediate treatment, second-stage hole generation and after-treatment. According to the method, an oxidation film on the surface of an aluminum foil is removed by strongly alkaline solution via the first pretreatment, residual alkaline solution on the surface of the aluminum foil is neutralized by strongly acid solution via the second pretreatment, holes are generated by a pulse DC superposed current method via first-stage hole generation, radius and depth of the holes are further enlarged by direct current via intermediate treatment, and residual aluminum ions on the surface of the aluminum foil are chemically eroded by after-treatment via second-stage hole generation. The whole technical process is simple, adaptability to change of corrosion tank liquid is high and the generated corrosion holes are uniform and smooth so that electrostatic specific volume of the corrosion foil is greatly enhanced, mechanical property is excellent, and the limit that the hole generation process in the conventional corrosion technology cannot be performed in case of power outage is solved.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

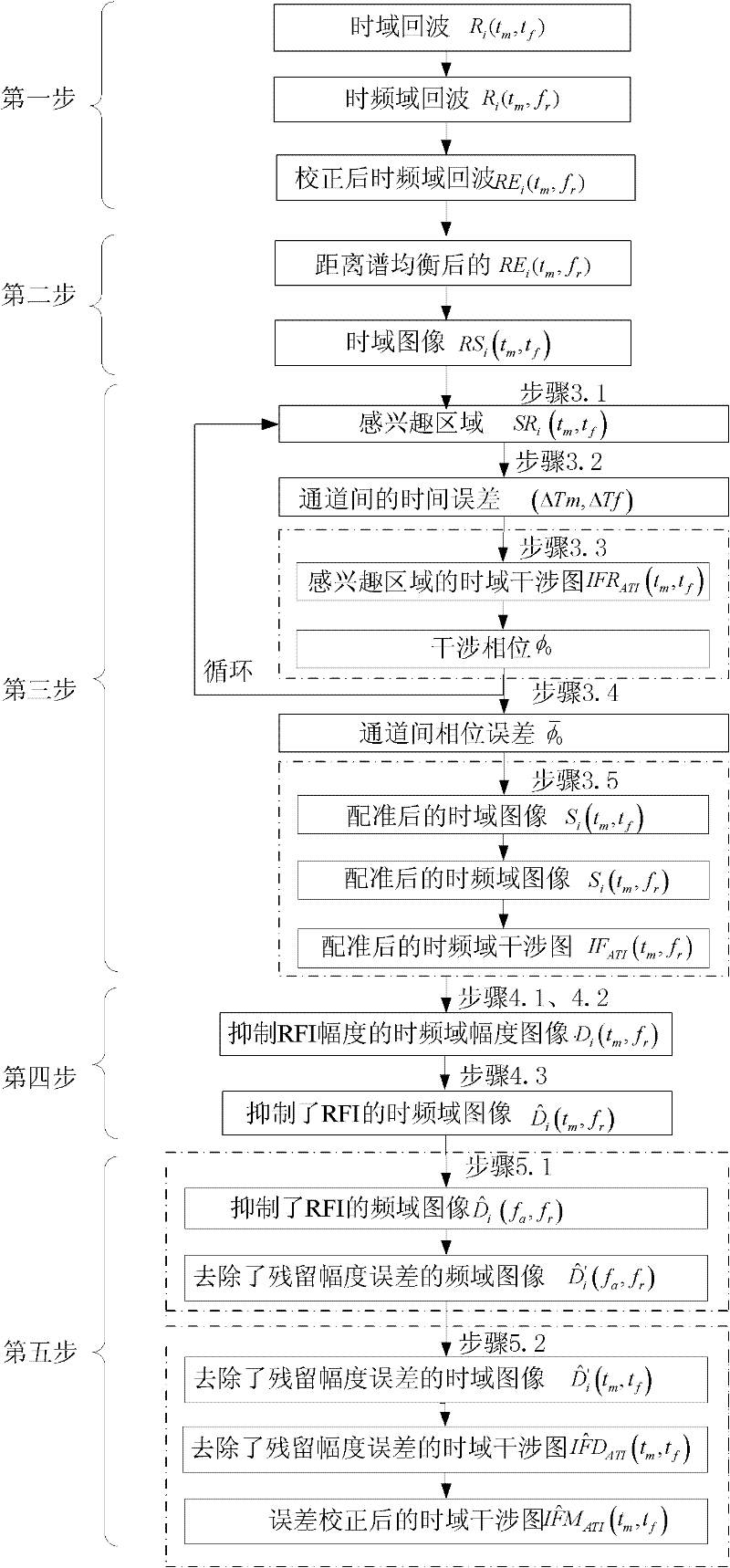

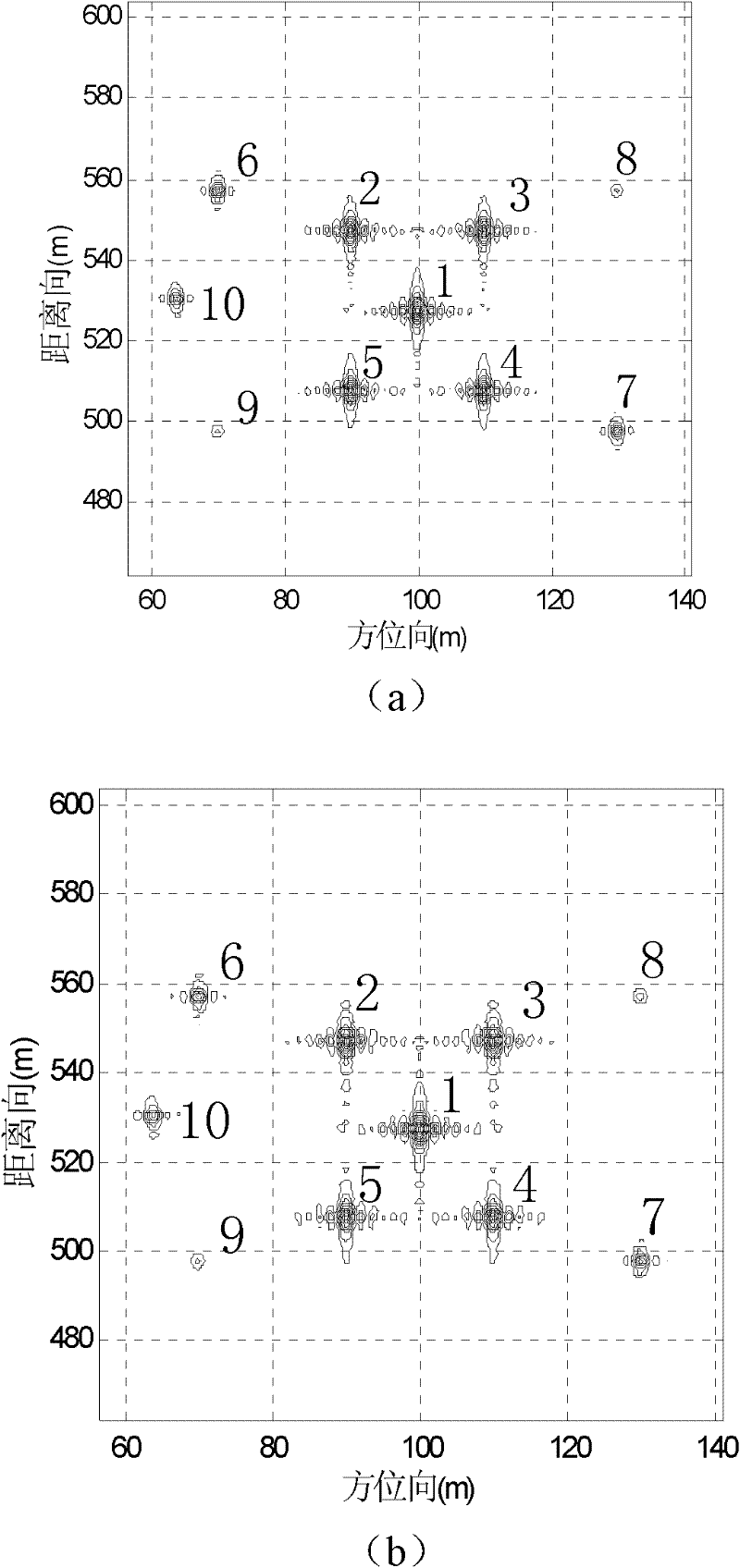

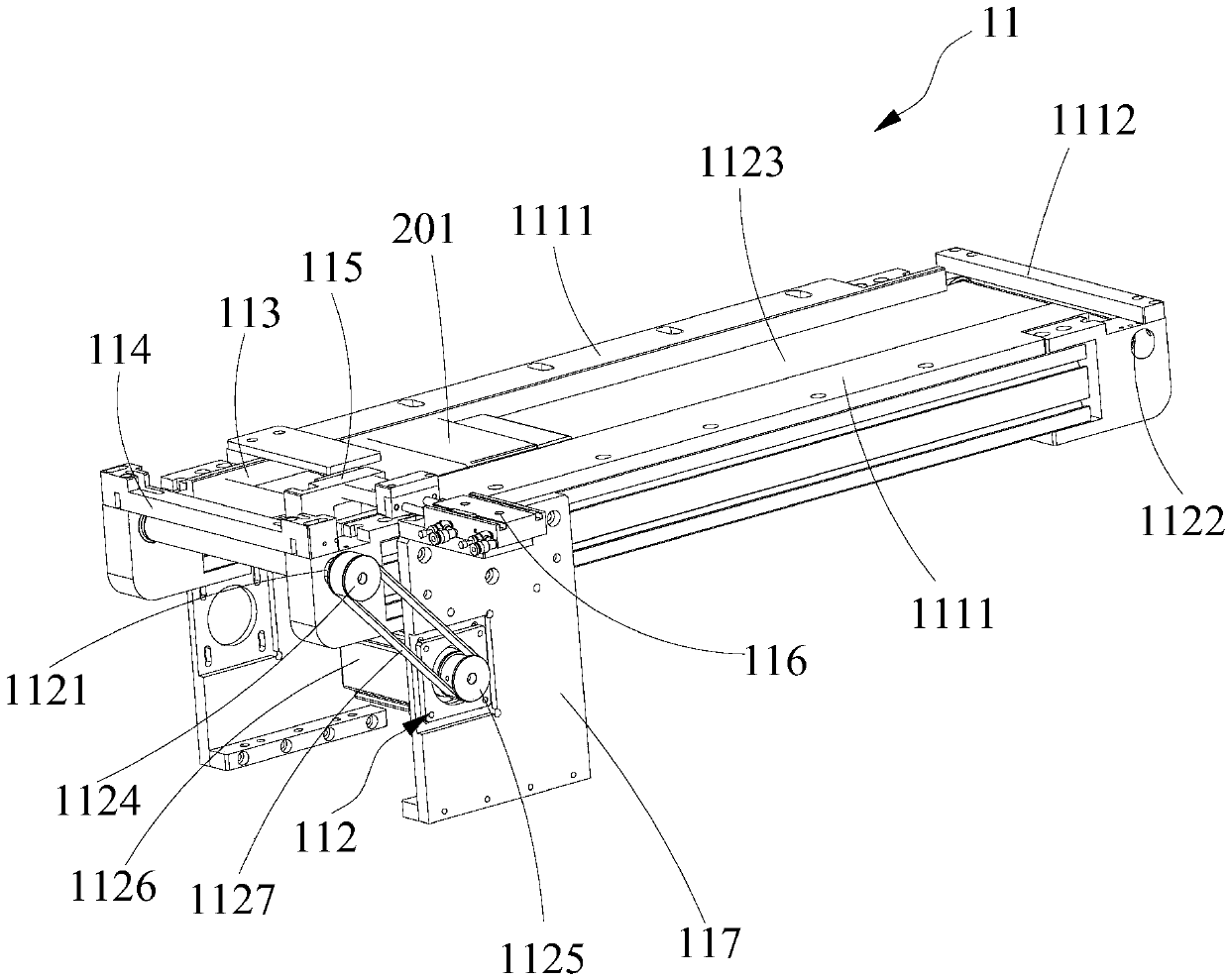

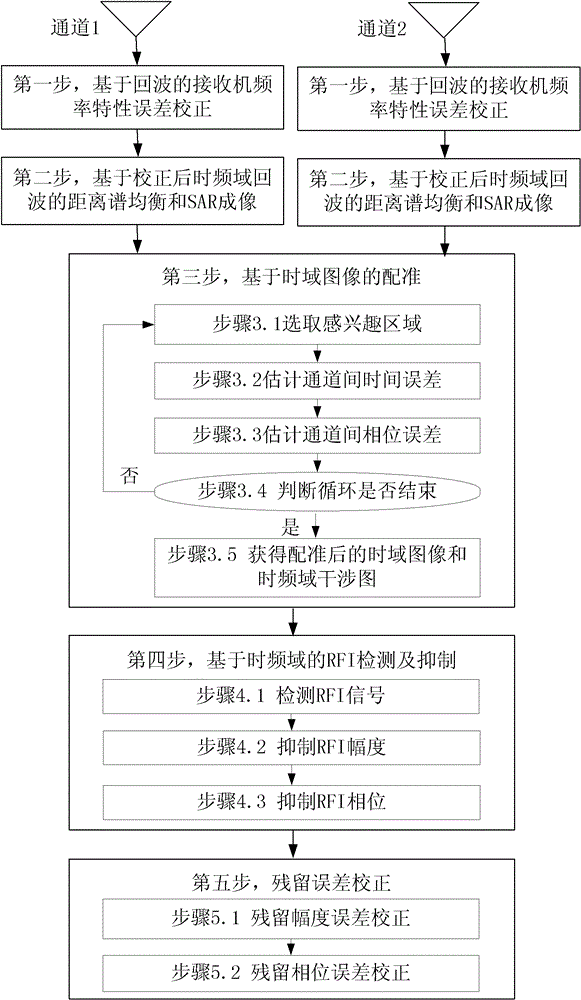

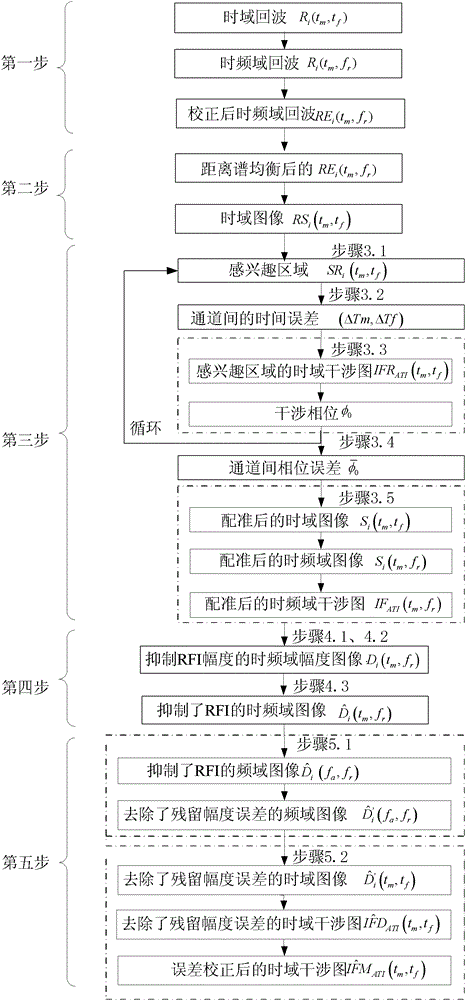

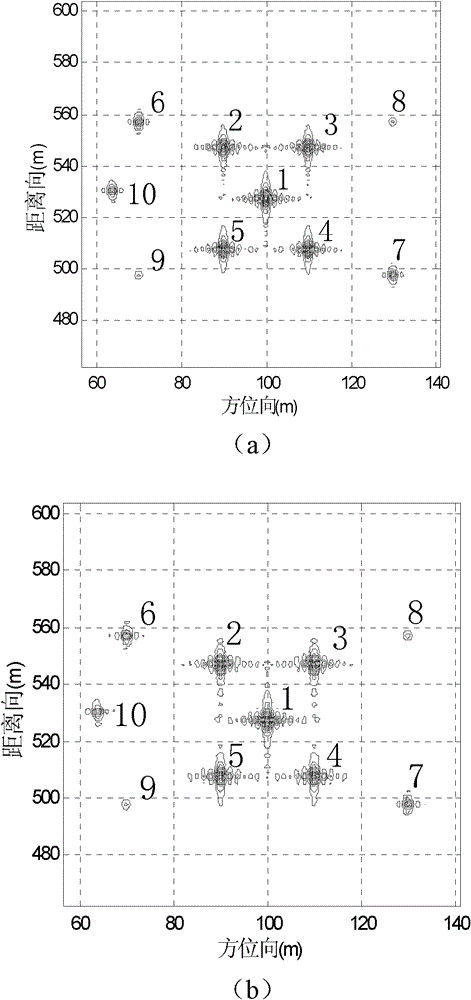

Method for radio frequency interference suppression and error correction of low-frequency synthetic aperture radar

InactiveCN102243300AEfficient detectionAvoid complex calculationsWave based measurement systemsTime domainSynthetic aperture radar

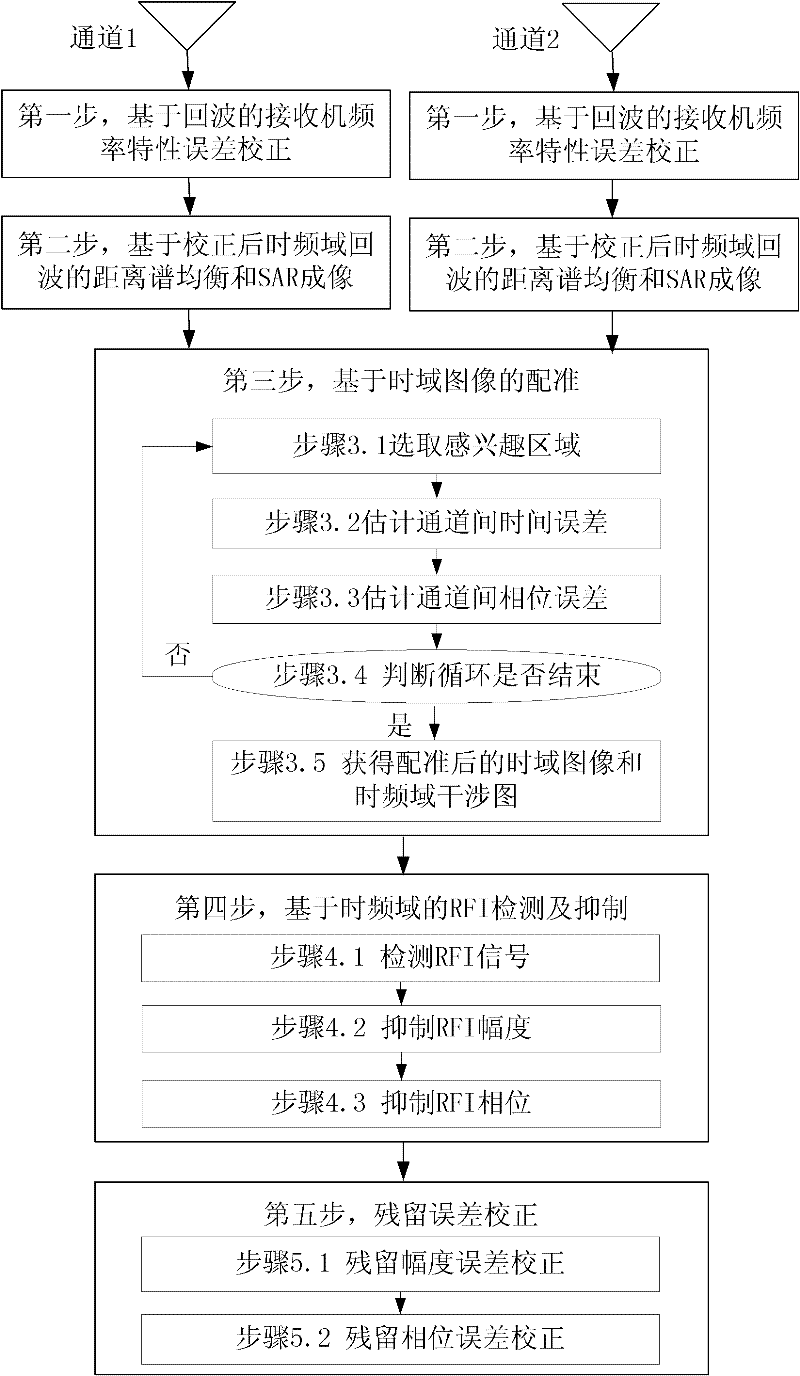

The invention provides a method for the RFI (radio frequency interference) suppression and error correction of a low-frequency SAR (synthetic aperture radar). The technical scheme comprises five steps of: step 1, receiver frequency characteristic error correction based on an echo; step 2, distance spectrum equalization suppression and SAR imaging based on a corrected time-frequency domain echo; step 3, registration based on a time domain image; step 4, RFI detection and suppression based on a time-frequency domain; and step 5, residual error correction. The method provided by the invention can solve the RFI detection and suppression of a double-channel low-frequency SAR interferogram, as well as various error correction problems, increase the performance of an along-track interferometry method, and lay a good foundation for the follow-up associated processing.

Owner:NAT UNIV OF DEFENSE TECH

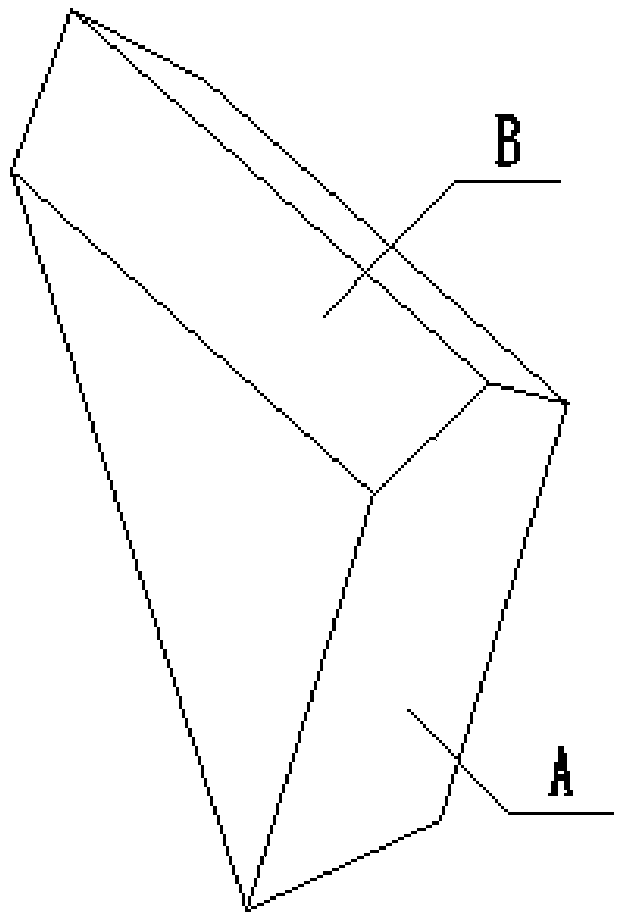

Schmidt roof prism processing method and positioning tool thereof

PendingCN108422286APositioning is simple and fastGuaranteed accuracyOptical surface grinding machinesGlass productionProduction ratePrism

The invention discloses a Schmidt roof prism processing method and a positioning tool thereof, and belongs to the technical field of optical prisms. In the positioning tool, a first backrest positioning block with a first backrest positioning surface and a second backrest positioning block with a second backrest positioning surface are fixed on the upper surface of a substrate, the first backrestpositioning surface and the second backrest positioning surface are perpendicular to the upper surface of the substrate, and a prism side processing block is positioned above the substrate and provided with a prism side processing surface perpendicular to the upper surface of the substrate. The processing method includes the steps: firstly, processing a first side surface of a prism, and positioning and processing a second side surface of the prism through the positioning tool; secondly, positioning and initially processing two roof surfaces through the positioning tool; finally, taking one roof surface as a standard to grind the other reference surface, and enabling the accuracy of a roof angle to be within 1''. According to the method, process steps are optimized without changing an existing processing device, the method ensures that the processed roof angle is within 1'', the accuracy of surfaces is high, technical requirements are low, and production efficiency is high.

Owner:马鞍山市江南光学有限公司

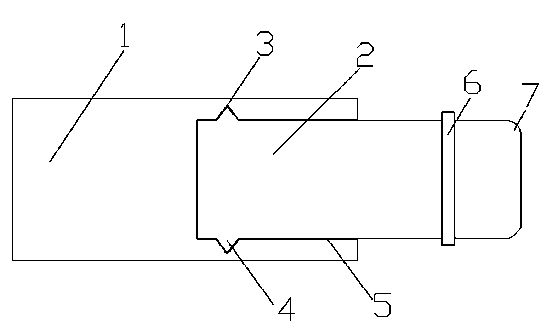

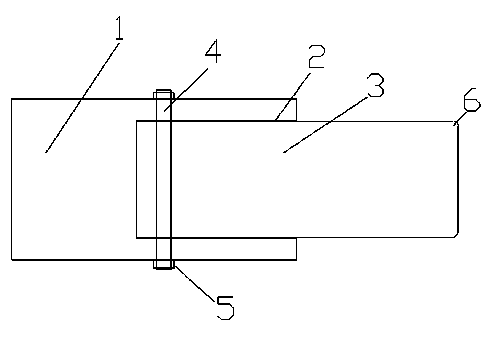

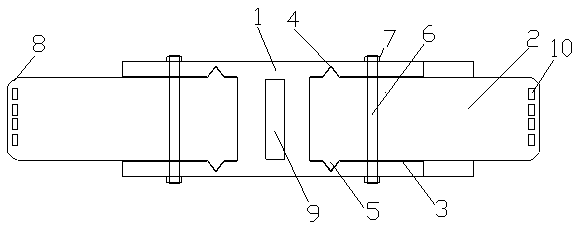

Buffer detachable punching head

The invention discloses a buffer detachable punching head. The buffer detachable punching head comprises a punching head seat, and is characterized by further comprising a blade and a buffer gasket; an opening is formed in the front end of the punching head seat; an open slot is respectively formed in each of two sides of the opening of the punching head seat; a convex reverse buckle is respectively arranged on each of two sides of the rear end of the blade; the reverse buckles on the two sides are matched and tightly clamped with the open slots on the corresponding sides; the buffer gasket is sleeved on the part, extending out of the opening, of the blade; the buffer gasket is made of rubber material; the thickness of the buffer gasket is 0.5cm; rounded angles are formed in the two sides of the processing end of the blade. The buffer detachable punching head solves the problems that the punching head is integrally formed, the blade is gradually consumed and damaged due to abrasion so as to cause that the whole punching head is scrapped, the punching head needs be replaced, the use cost is greatly increased, the punching head is used for punching products so as to be easily damaged, burrs are formed on the broken surfaces of the products, and the product quality is reduced. The invention provides the buffer detachable punching head which is convenient to use, capability of dismantling the blade and reducing the cost and improving the quality.

Owner:KUNSHAN BAOLIANGHENG PRECISION MOLD

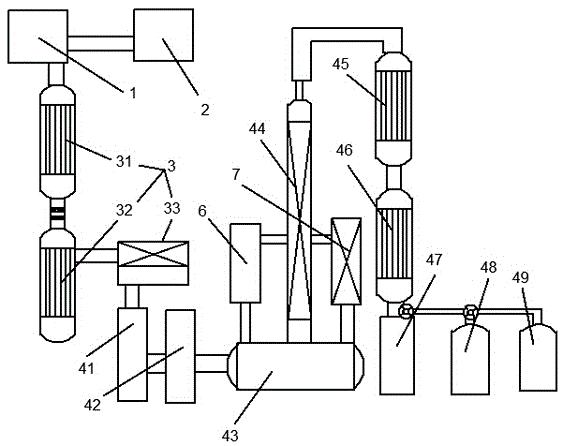

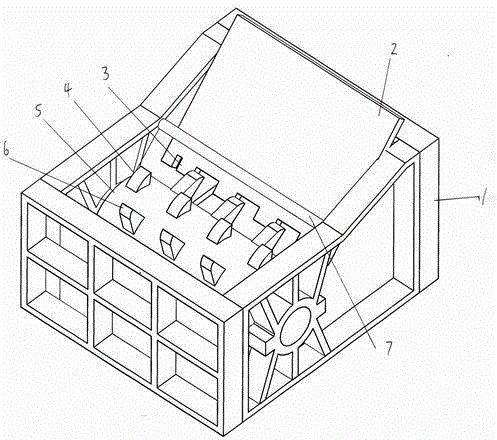

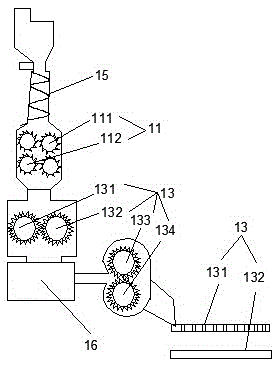

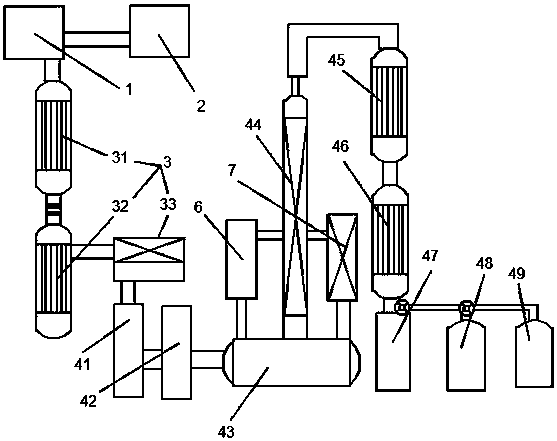

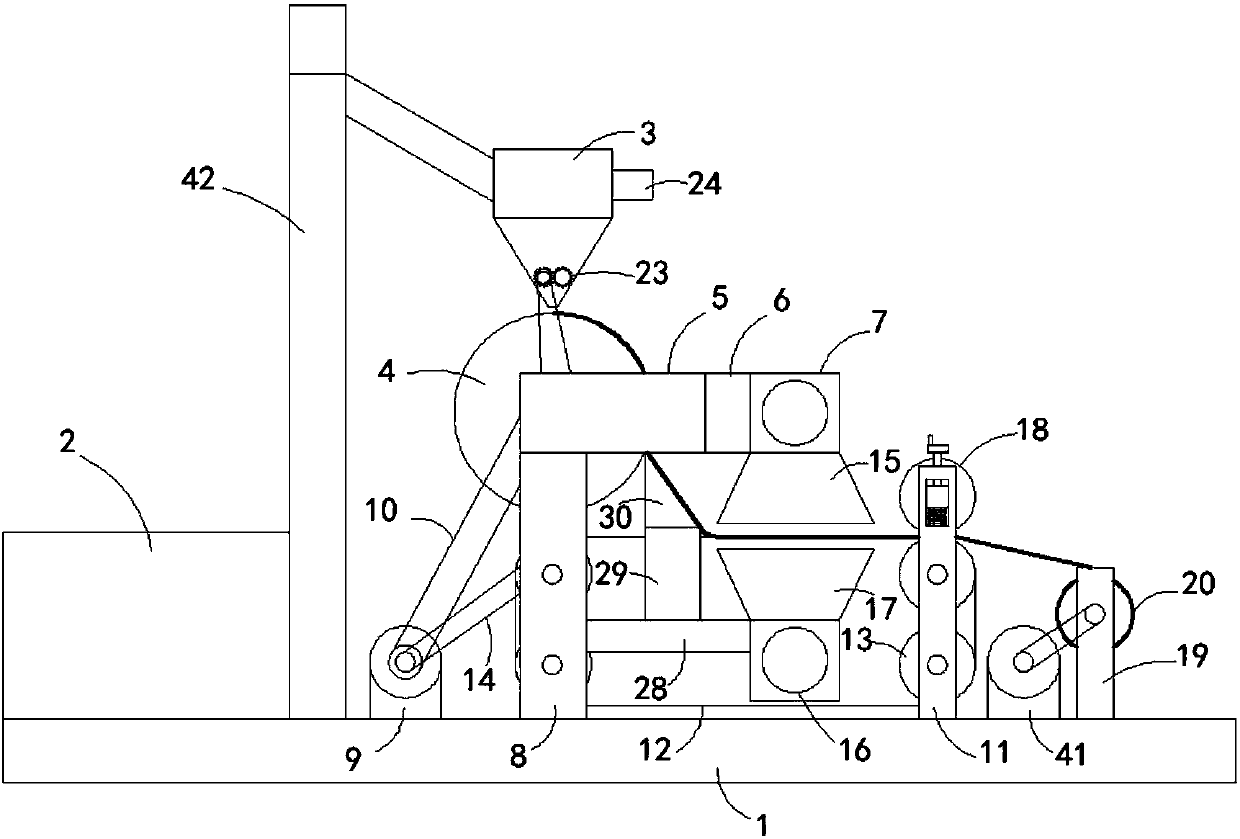

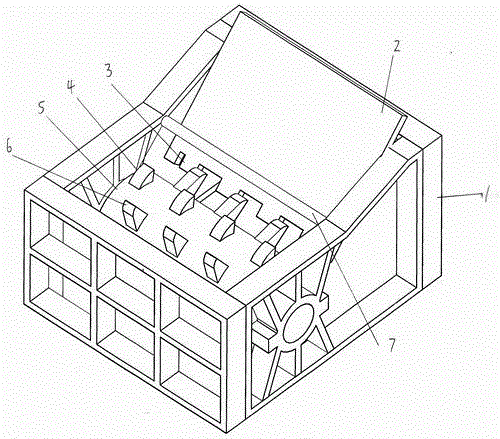

Recycling device for organic glass

ActiveCN105619644AEfficient crushingReduce noisePlastic recyclingGrain treatmentsElectric machineryDrive motor

The invention discloses to a recycling device for organic glass. The recycling device comprises a crushing device, a cracking device, a crude product recycling device, a crude product purification device and a product recycling device, all of which are sequentially arranged. The crushing device comprises a primary crushing cavity, a secondary crushing cavity, a primary crushing part arranged in the primary crushing cavity, and a secondary crushing part arranged in the secondary crushing cavity. The primary crushing part comprises two drive rollers driven by a drive motor, a conveying belt arranged on the outer rings of the two drive rollers, and cutting rollers arranged above the conveying belt. Cutting blades are installed on the cutting rollers. The cutting points of the cutting blades are located on the surface of the conveying belt. The drive rollers drive the conveying belt to move. The recycling device is used for efficiently crushing waste organic glass, noise is low, the waste organic glass is efficiently cracked, the working efficiency is improved, and the crushing cost is reduced.

Owner:青岛耀恩玻璃制品有限公司

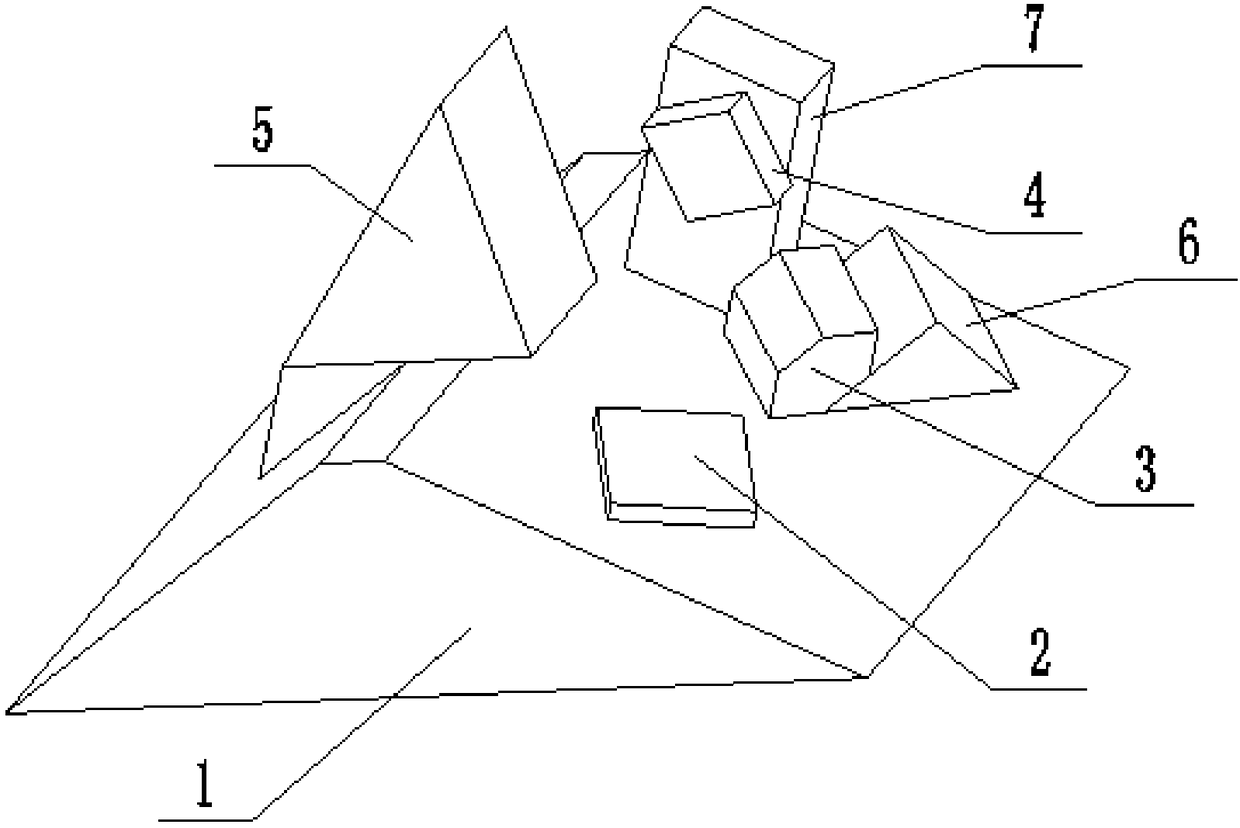

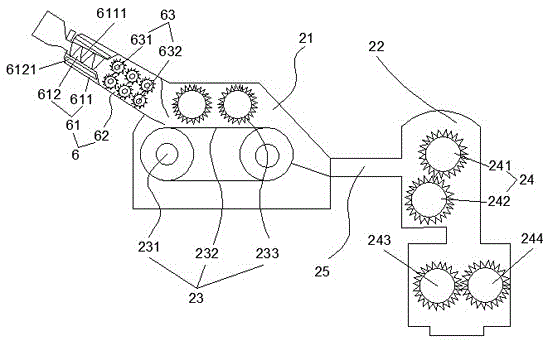

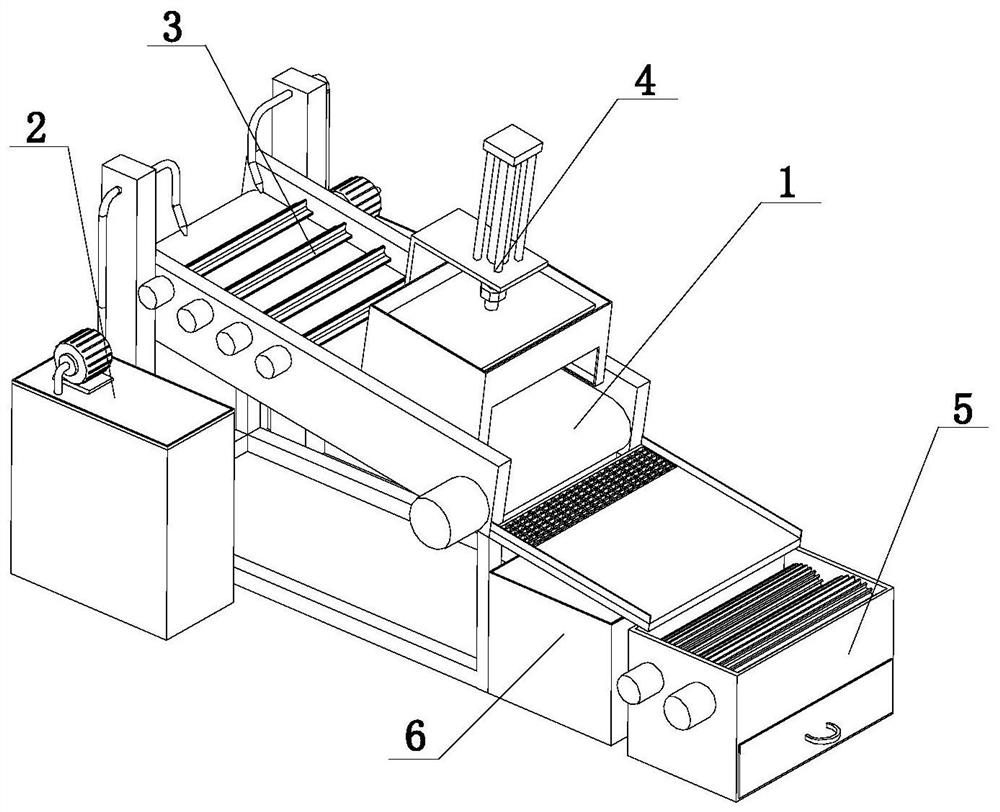

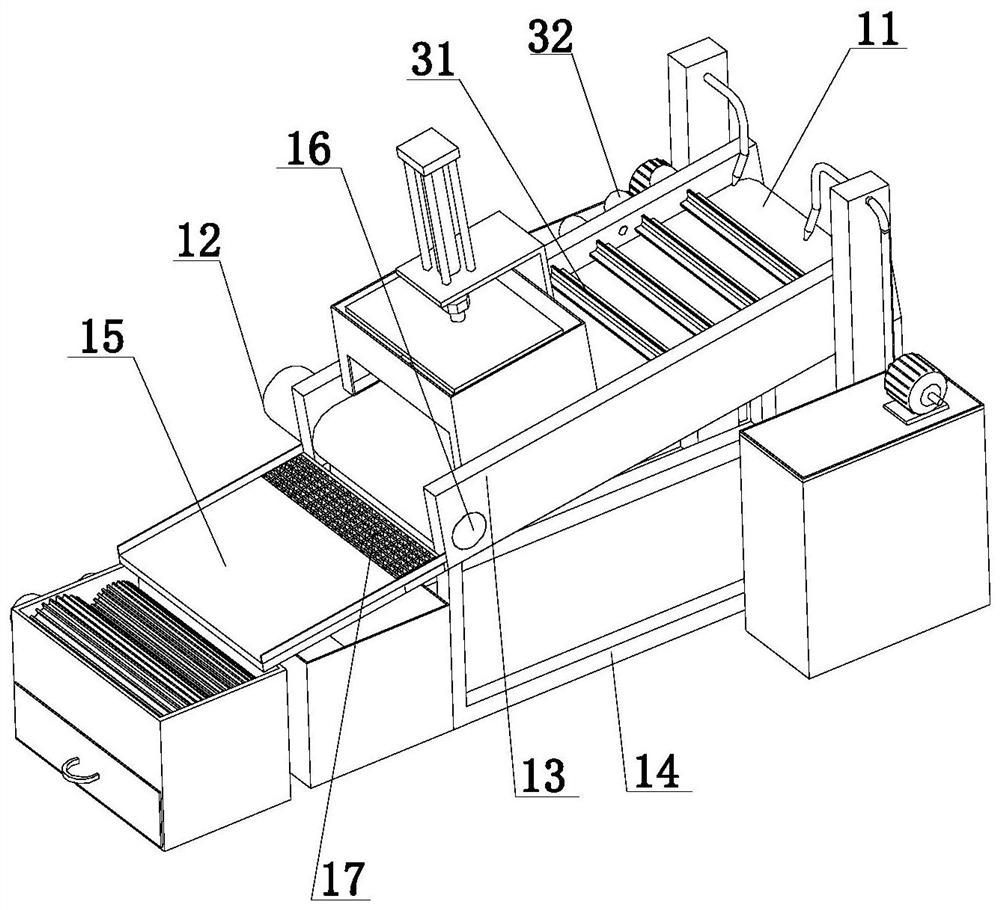

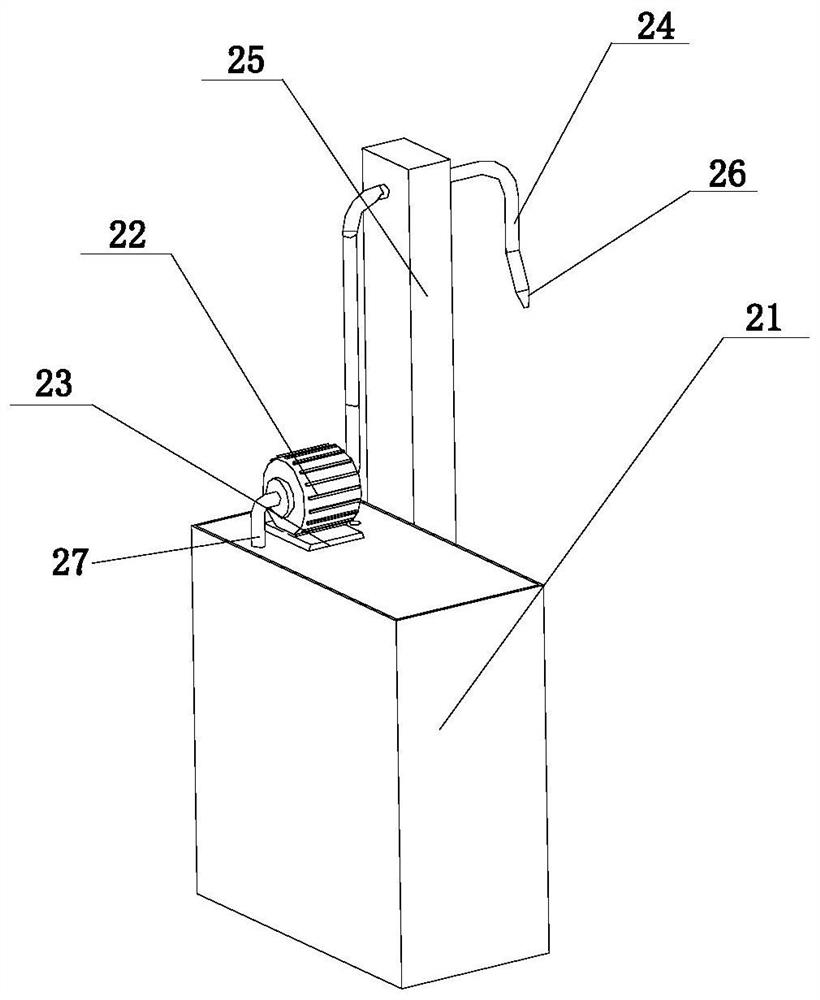

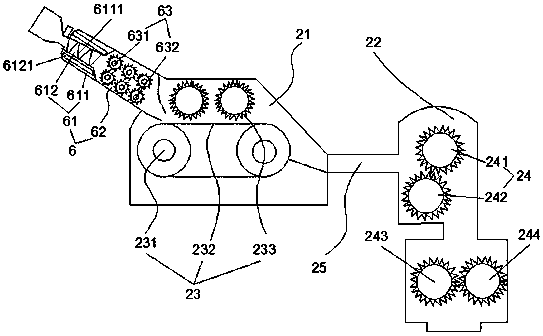

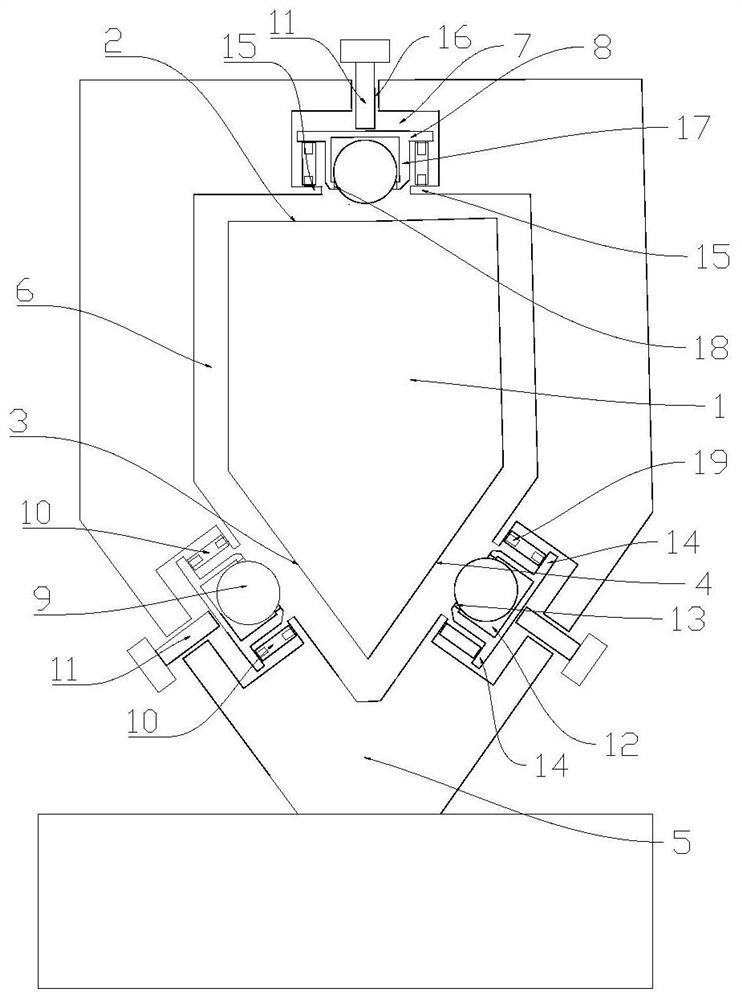

Crushing treatment device for waste plastics

InactiveCN112248303AMeet the needs of subsequent processingAll-round cleaningPlastic recyclingMechanical material recoveryEnvironmental geologyWater tanks

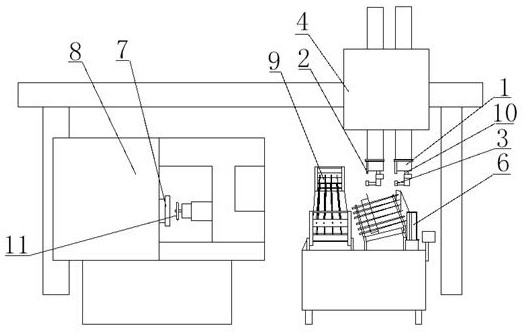

The invention discloses a crushing treatment device for waste plastics, and belongs to the technical field of mechanical equipment. The device comprises a conveying device, two cleaning devices, a rotary cleaning device, an extrusion device, a crushing device and a water receiving tank, wherein the conveying device is horizontally arranged on the ground, the two cleaning devices are symmetricallyinstalled on the side walls of the two ends of the conveying device, the water outlet end of each cleaning device faces the top of the conveying device, the rotary cleaning device is installed at thetop of one end of the conveying device, the extrusion device is installed at the top of the other end of the conveying device, the water receiving tank is horizontally arranged beside the conveying device, and the crushing device is arranged beside the water receiving tank. According to the crushing treatment device for the waste plastics, extrusion movement is carried out downwards through an extrusion plate, so that the plastics with different shapes can be extruded, the space occupied by the plastics is reduced, meanwhile, the plastics are convenient to crush, and the cleaning devices can clean other substances brought by the plastics, so that the later treatment is facilitated.

Owner:芜湖多帮新材料科技有限公司

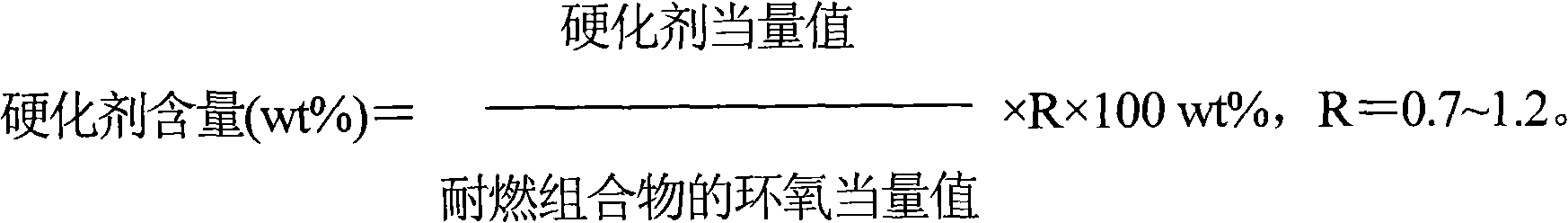

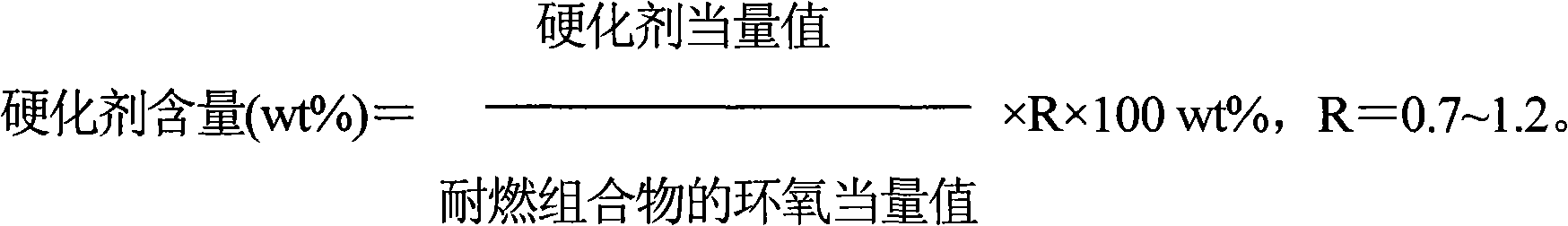

Prepreg with flame resistance

InactiveCN101338065AMeet the needs of subsequent processingCompliance with flame resistanceLayered productsEpoxyFiber

The invention discloses prepreg with flame retardance; the prepreg contains a reinforcing material and a flame retardance compound. The reinforcing material is selected from reinforcing fiber or reinforcing fabric; the epoxy equivalent value of the flame retardant compound is between 190g / eq to 270g / eq, and the flame retardant compound is provided with epoxy resin, inorganic flame retardant, thermoplastic resin and hardener, wherein, calculated by 100 weight percent of the total weight of the flame retardant compound, the content of the inorganic flame retardant is 12 weight percent to 18 weight percent. The prepreg with flame retardance of the invention is applicable in manufacturing the inner parts of all transportation tools or all buildings materials, partition boards, etc.

Owner:ADVANCED INT MULTITECH CO LTD

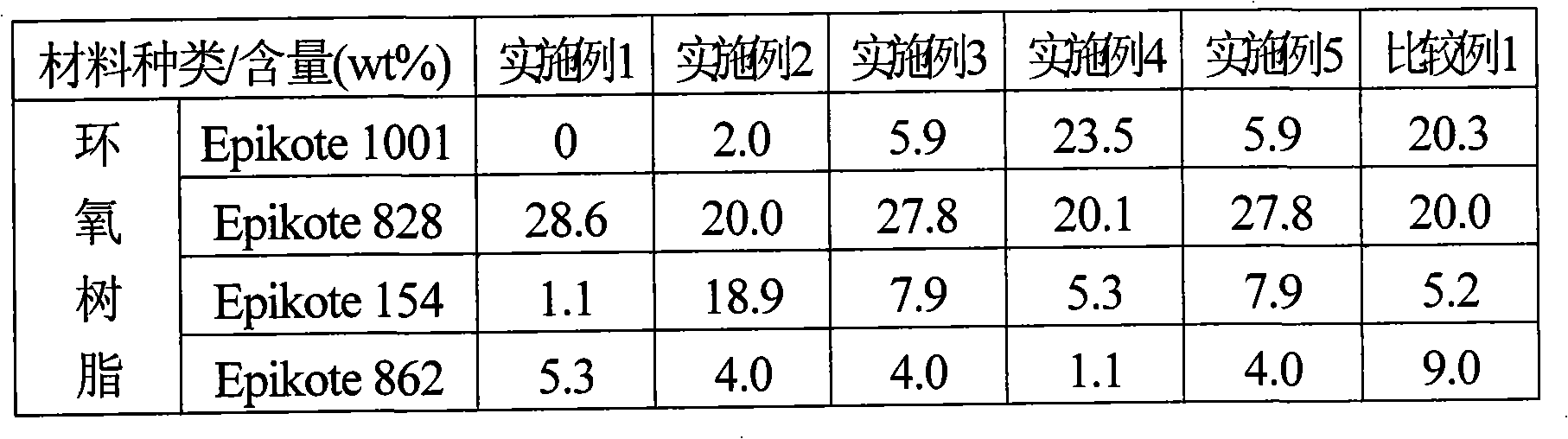

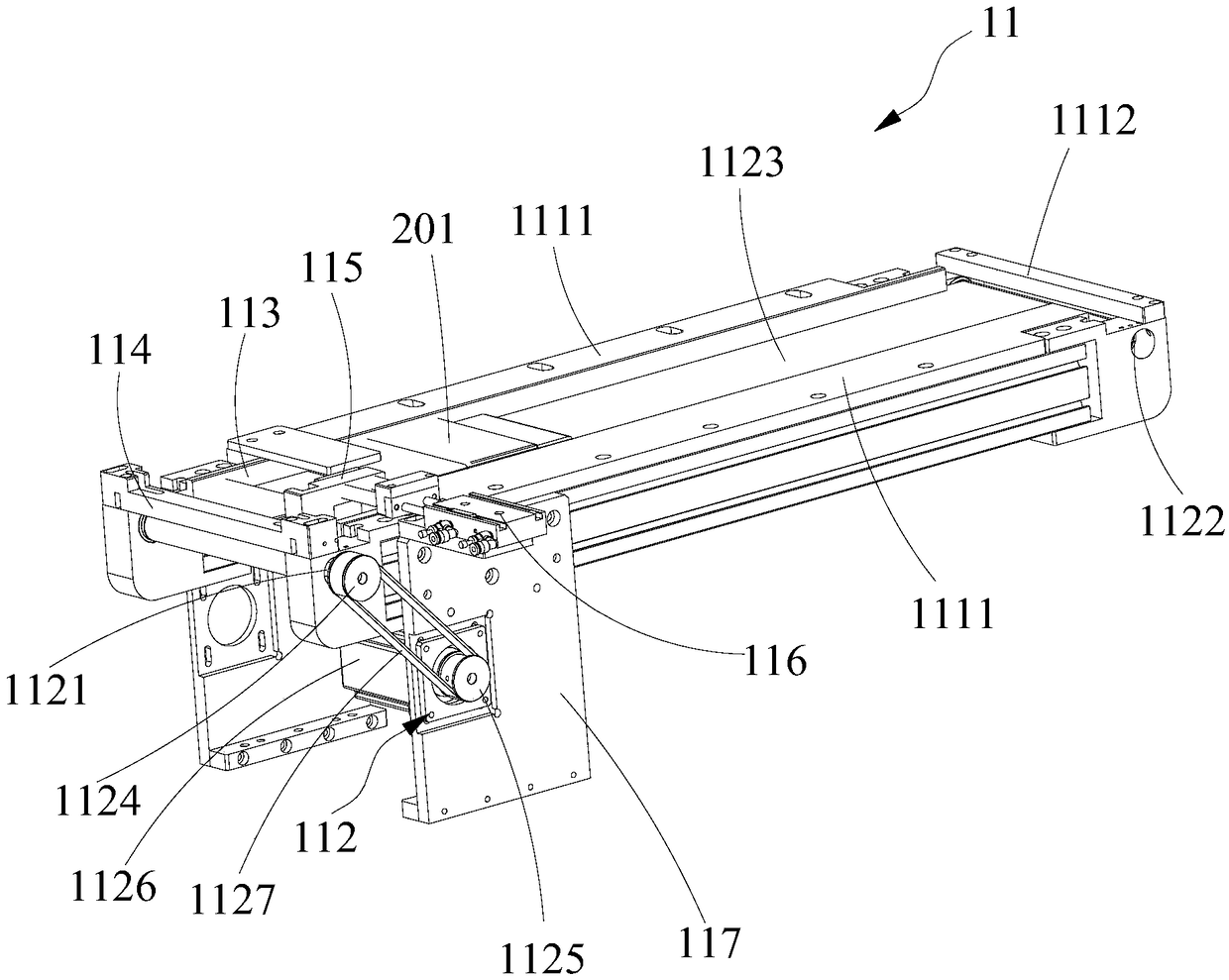

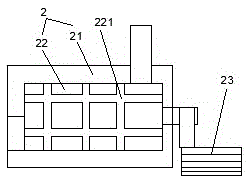

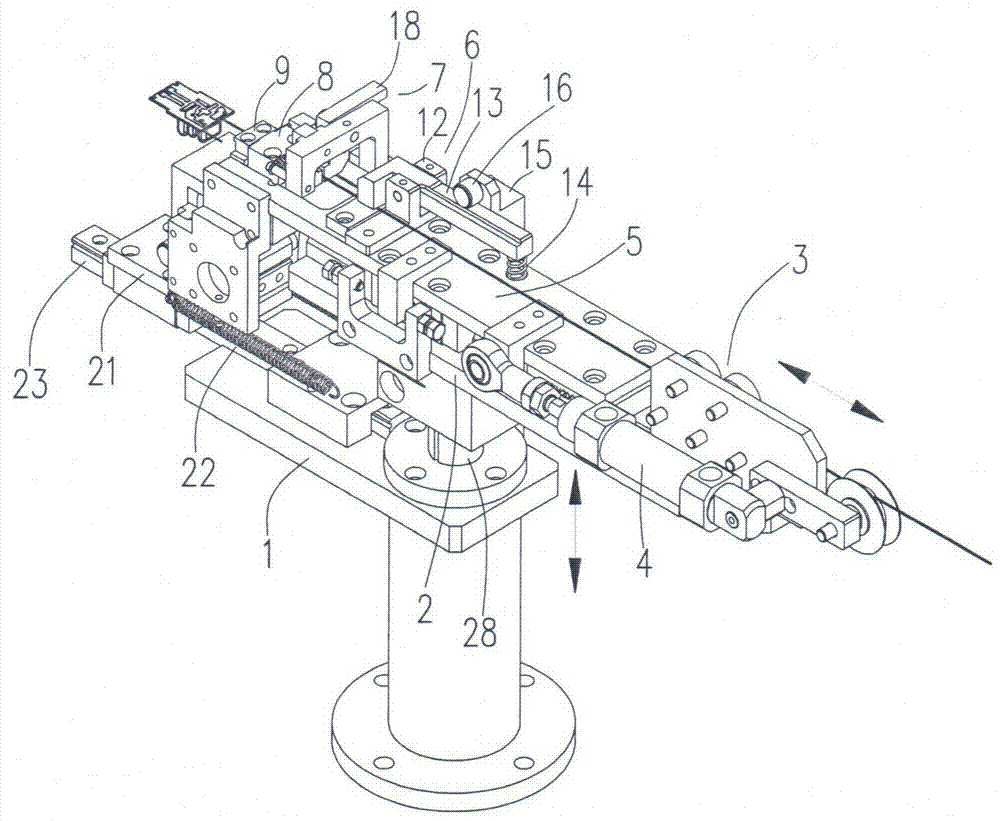

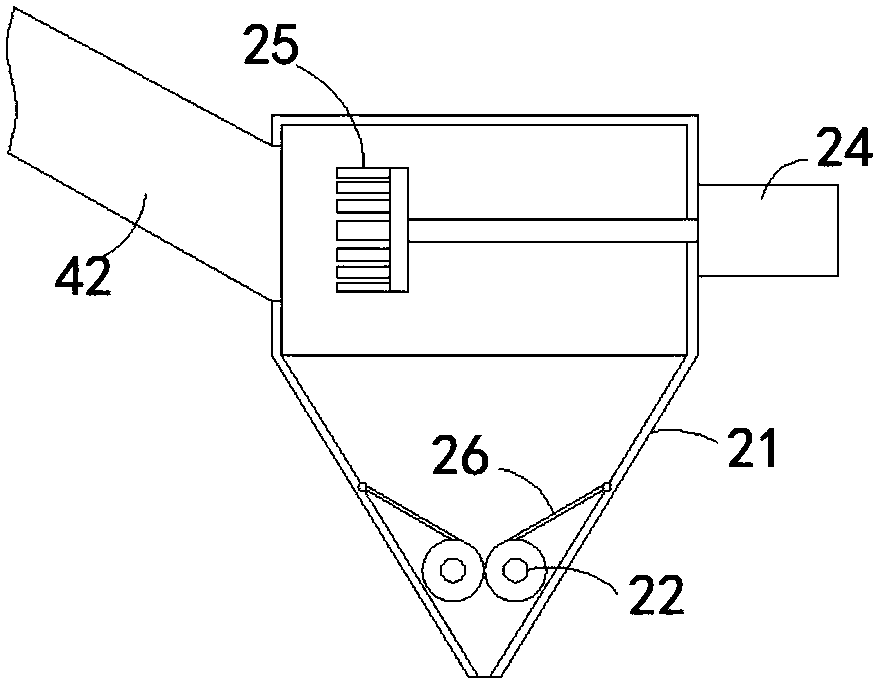

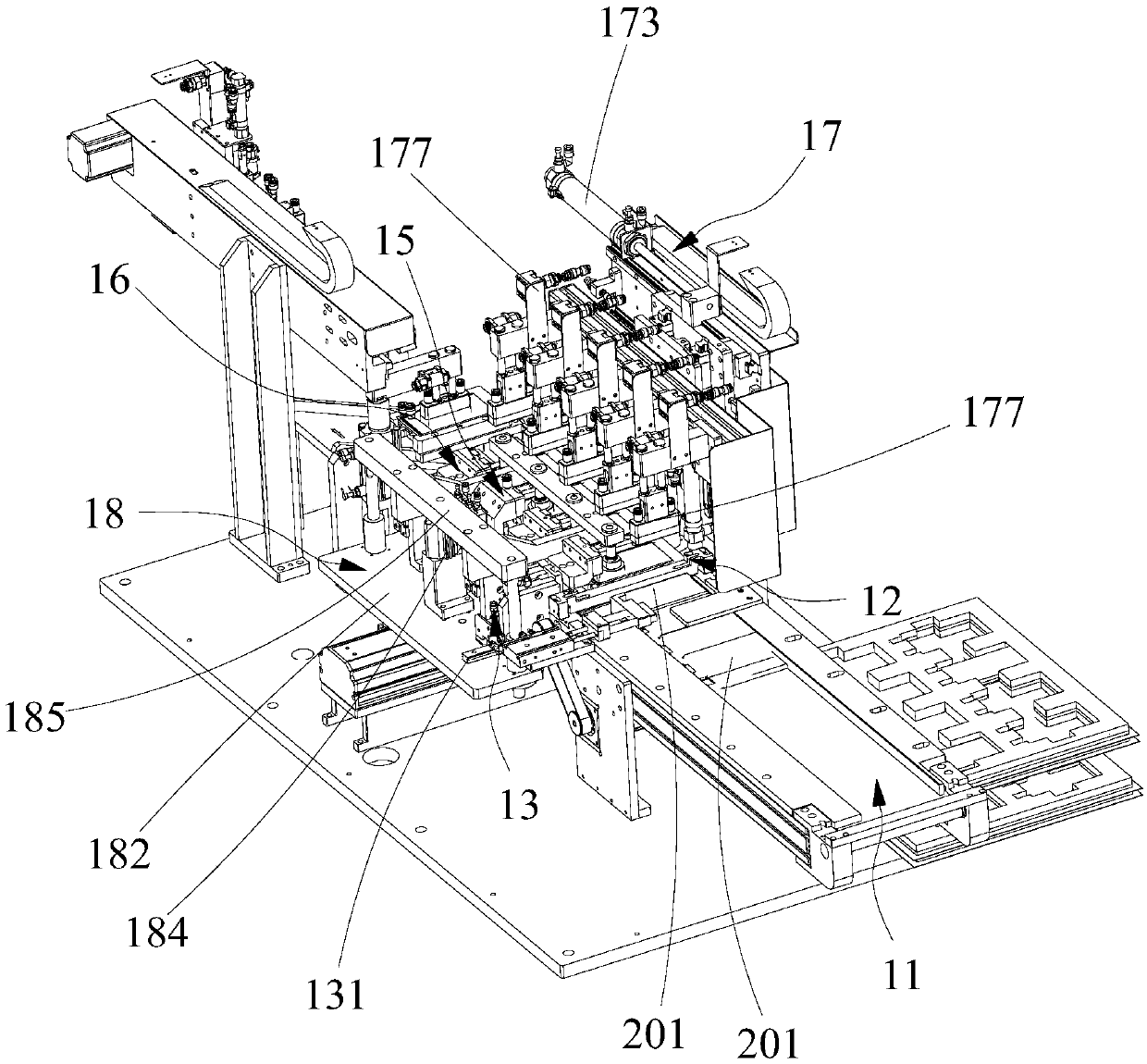

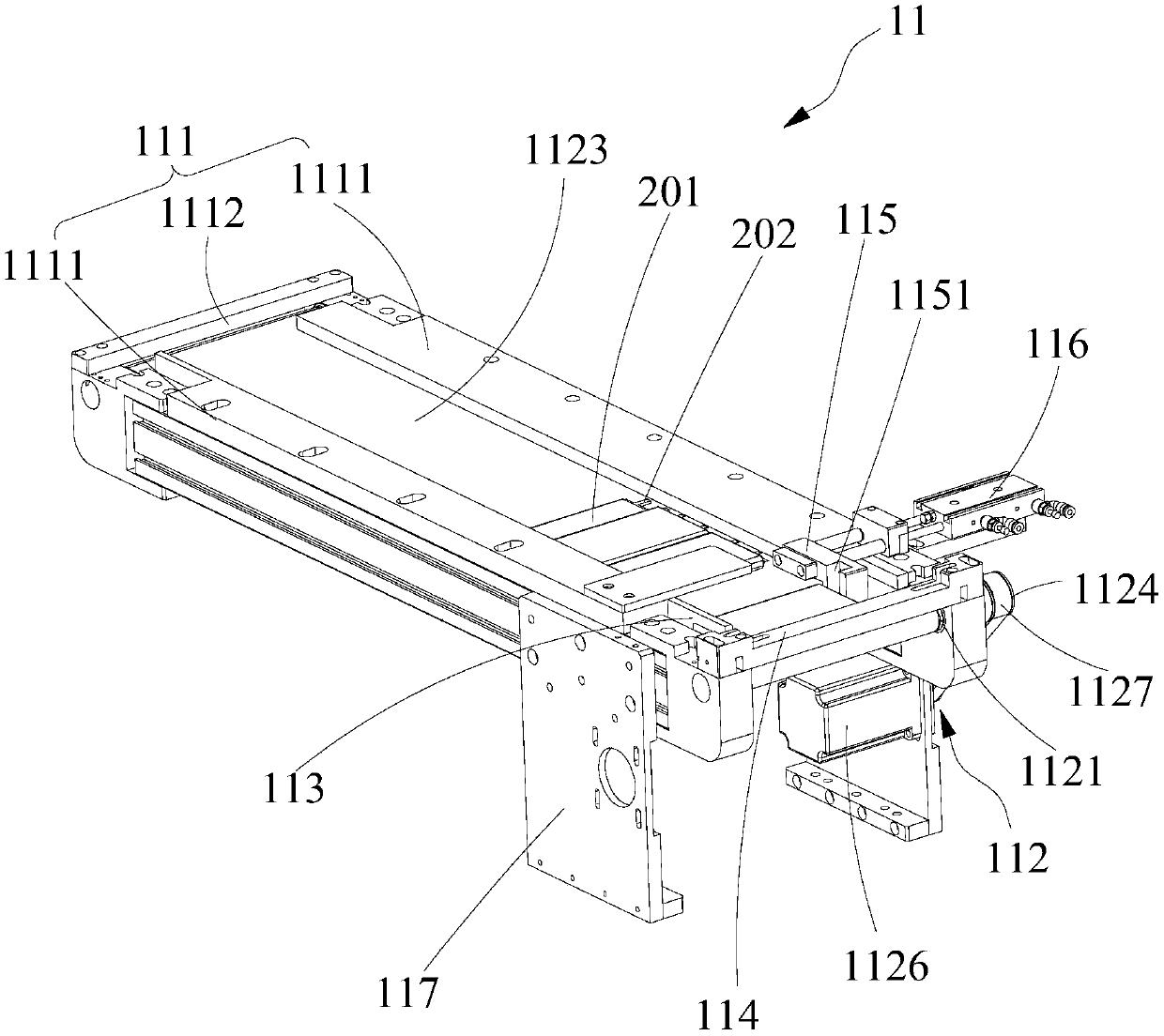

Battery cell pretreatment device

PendingCN109301306AMeet the needs of subsequent processingFinal product manufactureSecondary cells manufactureEngineeringSlide plate

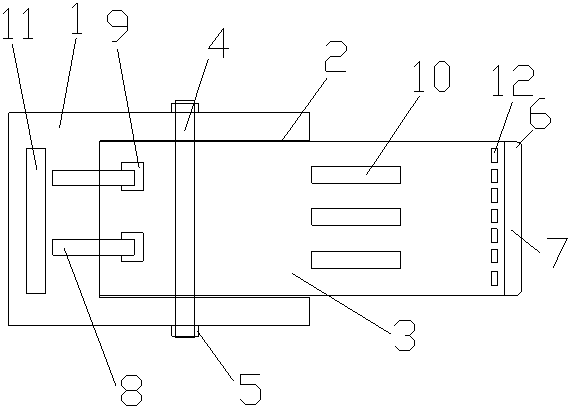

The invention discloses a battery cell pretreatment device, which comprises a battery cell pre-positioning mechanism, a shaping and placing frame, a straightening mechanism, a flattening mechanism, acutting mechanism, a shaping and pressing mechanism and a shaping and transferring component, wherein the shaping and pressing mechanism comprises a shaping and pressing base seat, a shaping and pressing sliding plate, a shaping and pressing driving component and a shaping and pressing component; the battery cell pre-positioning mechanism firstly pre-positions battery cells; the shaping and transferring component transfers the pre-positioned battery cells to a first shaping and placing plate corresponding to a processing station of the straightening mechanism; the straightening mechanism firststraightens lugs on the battery cells; the straightened battery cells are transferred to the first shaping and placing plate corresponding to a processing station of the flattening mechanism; the flattening mechanism flattens the lugs on the battery cells; and the cutting mechanism cuts the flattened lugs on the battery cells to a preset length to meet the subsequent processing demands.

Owner:深圳市智联智造自动化有限公司

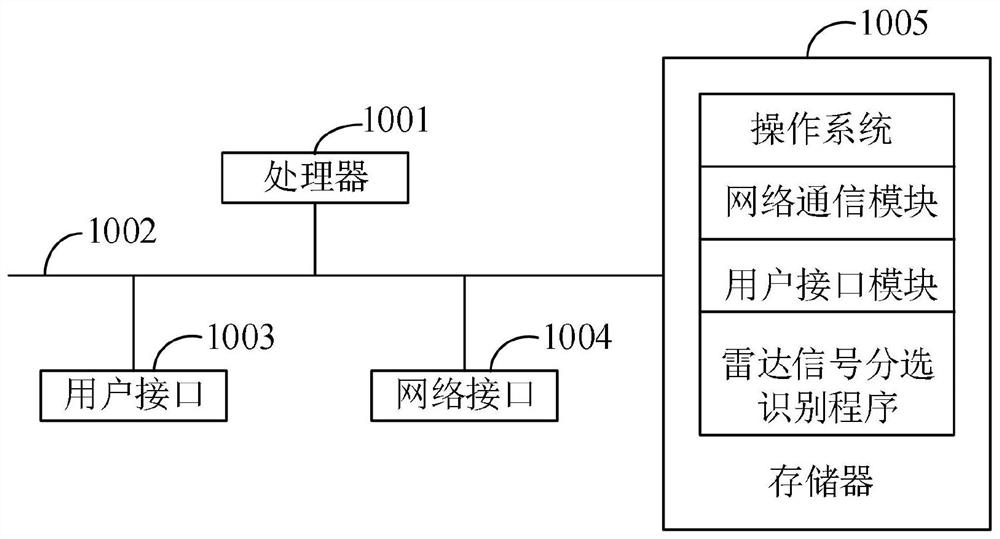

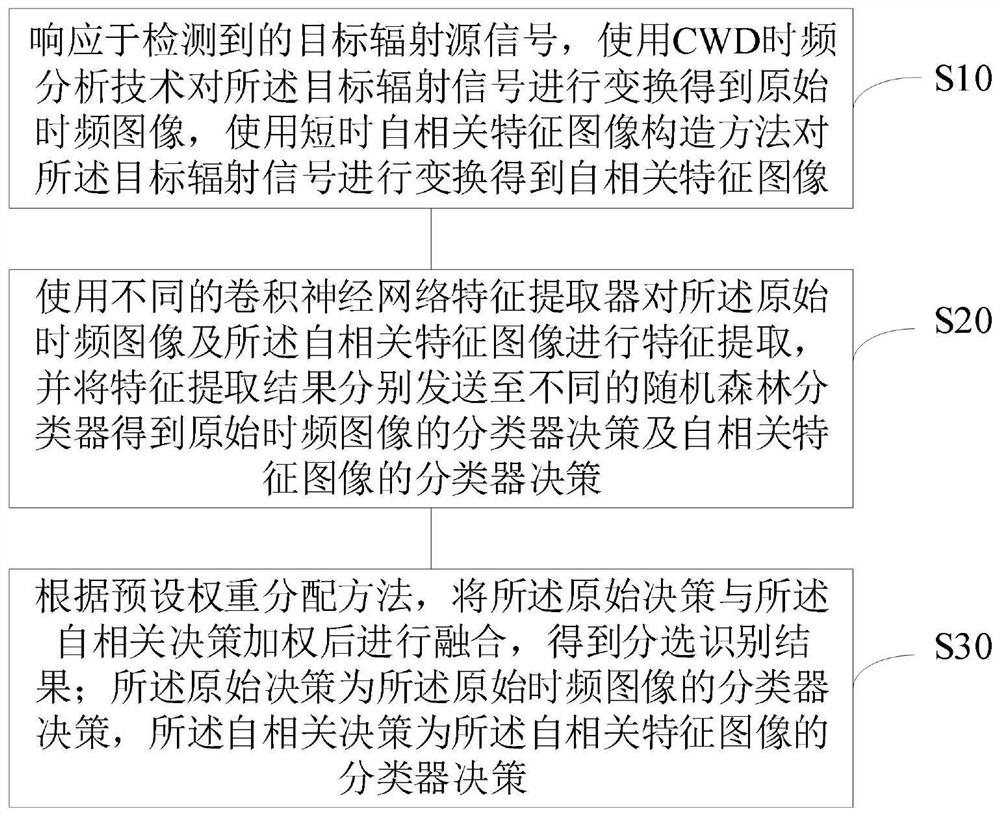

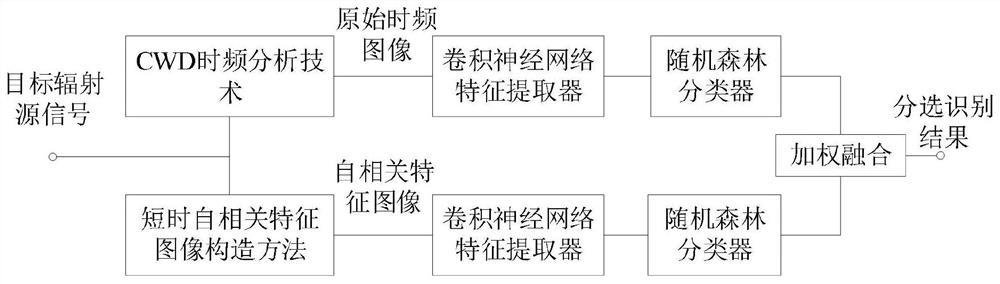

Radar signal sorting identification method and device, detector and storage medium

PendingCN112149524AImprove the recognition success ratePerfect technical solutionCharacter and pattern recognitionArtificial lifeRadar signalsRandom forest

The invention relates to a radar signal sorting identification method and device, a detector and a readable storage medium, and the method comprises the steps: processing a target radiation source signal through employing a CWD time-frequency analysis technology and a short-time autocorrelation feature image construction method, and obtaining an original time-frequency image and an autocorrelationfeature image; and obtaining a classification result through a convolutional neural network feature extractor and a random forest classifier, and after the classification result is subjected to weighted fusion, obtaining a sorting identification result, so that the technical problem of relatively low accuracy of identifying unknown radar waveforms by using a CWD time-frequency analysis technologyin the prior art is solved And the recognition rate of unknown radar signals is greatly improved by only using less radar sample information.

Owner:NAVAL UNIV OF ENG PLA

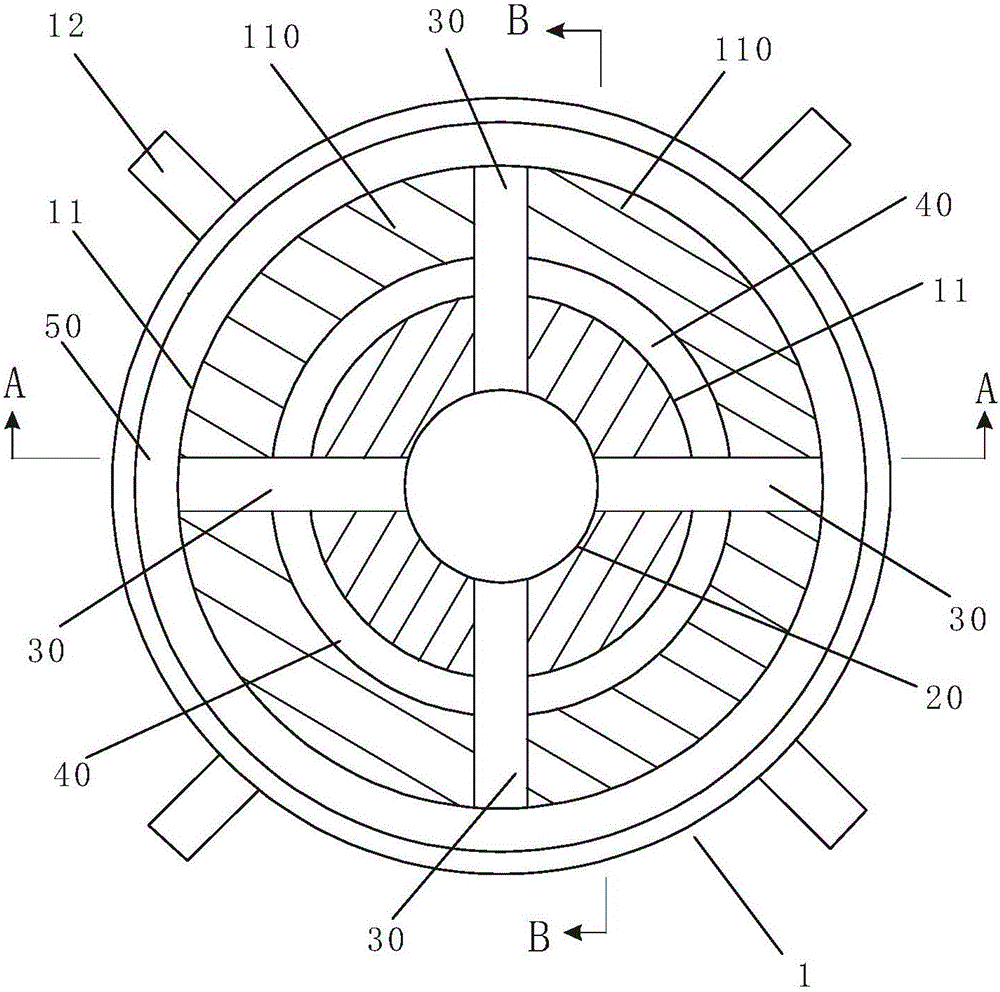

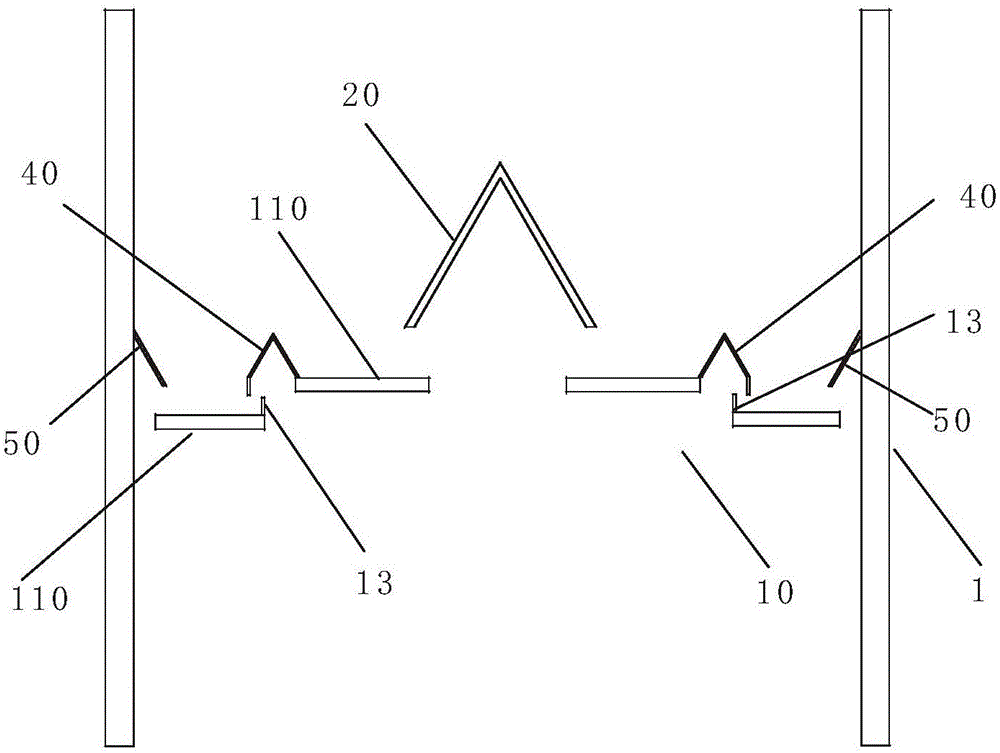

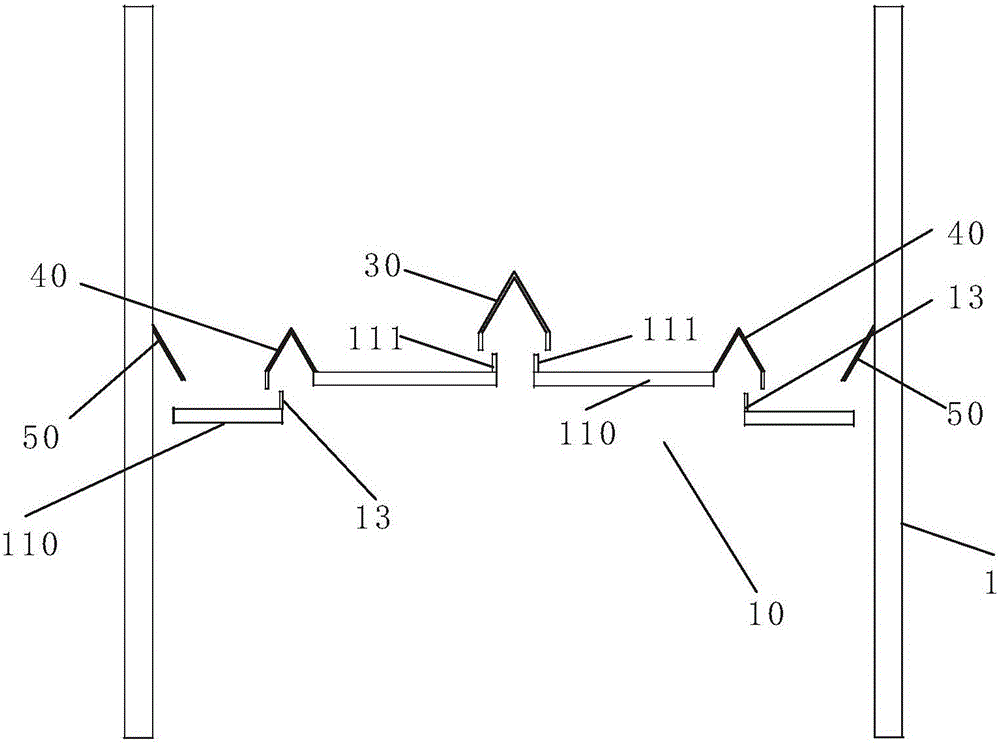

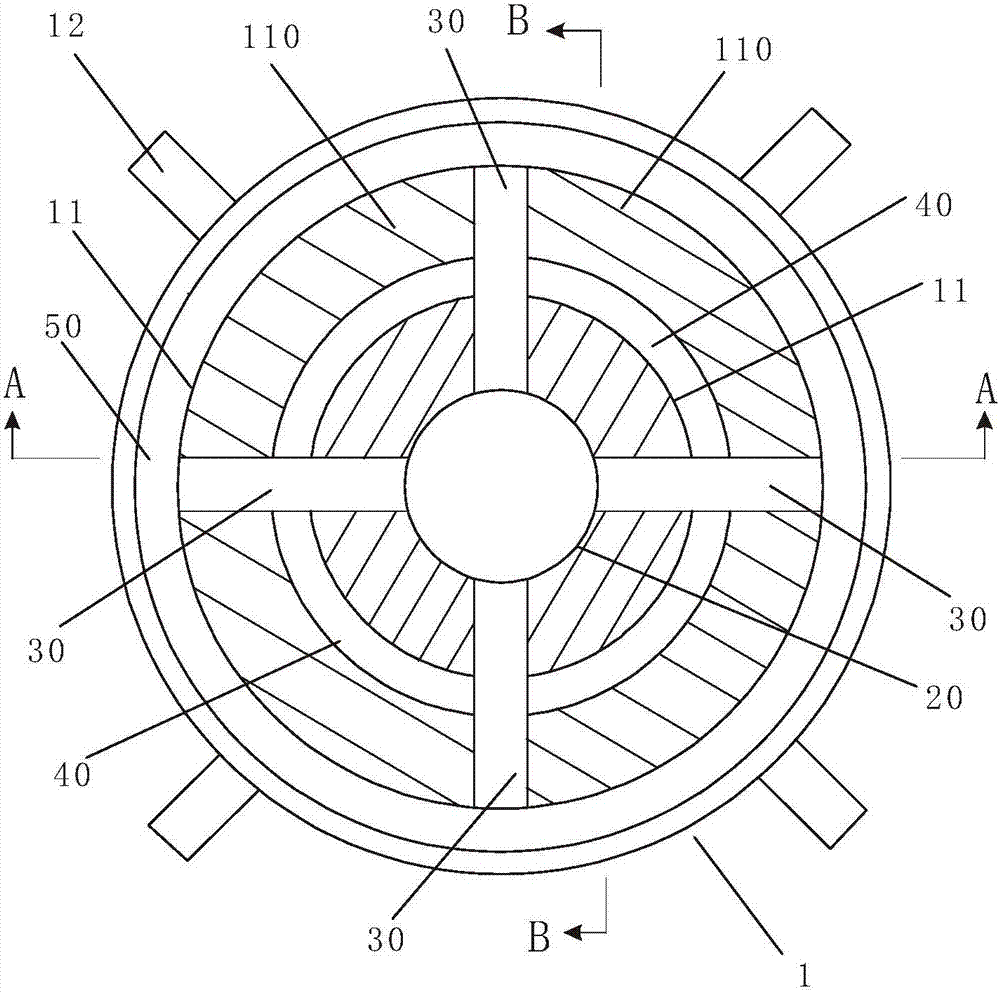

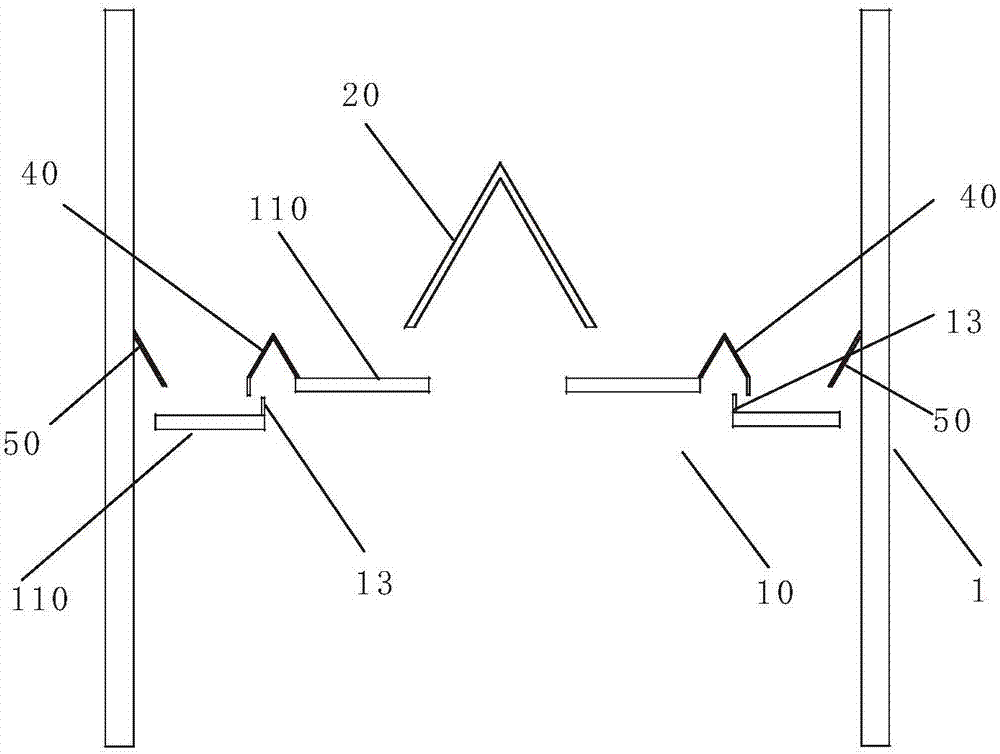

Discharging device in material cylinder

ActiveCN105674749ASmooth unloadingEasy to controlCharge composition/stateCharge manipulationEngineeringMechanical engineering

The invention discloses a discharging device in a material cylinder, which can uniformly discharge materials as required. The discharging device comprises a discharging plate mechanism, a central material cover, radial leakage-proof covers and a side plate, which are connected with the material cylinder respectively, wherein the discharging plate mechanism is mounted on a support member inside the material cylinder, covers a material channel of the material cylinder, and comprises an annular discharging plate and reciprocating drivers; the annular discharging plate is formed by splicing a plurality of sectorial moving plate units, and each moving plate unit is connected with the material cylinder through the corresponding reciprocating driver; the central material cover is tapered, and a through hole in the center of the annular discharging plate is covered with the central material cover; the side plate obliquely extends downwards towards the axis of the material cylinder from the wall of the material cylinder, and a gap between the annular discharging plate and the wall of the material cylinder is covered with the side plate; each radial leakage-proof cover covers a gap between the adjacent moving plate units, and the top end of each radial leakage-proof cover is in a left-turned E shape.

Owner:TIANJIN ZHENGYUANHE TECH DEV CO LTD

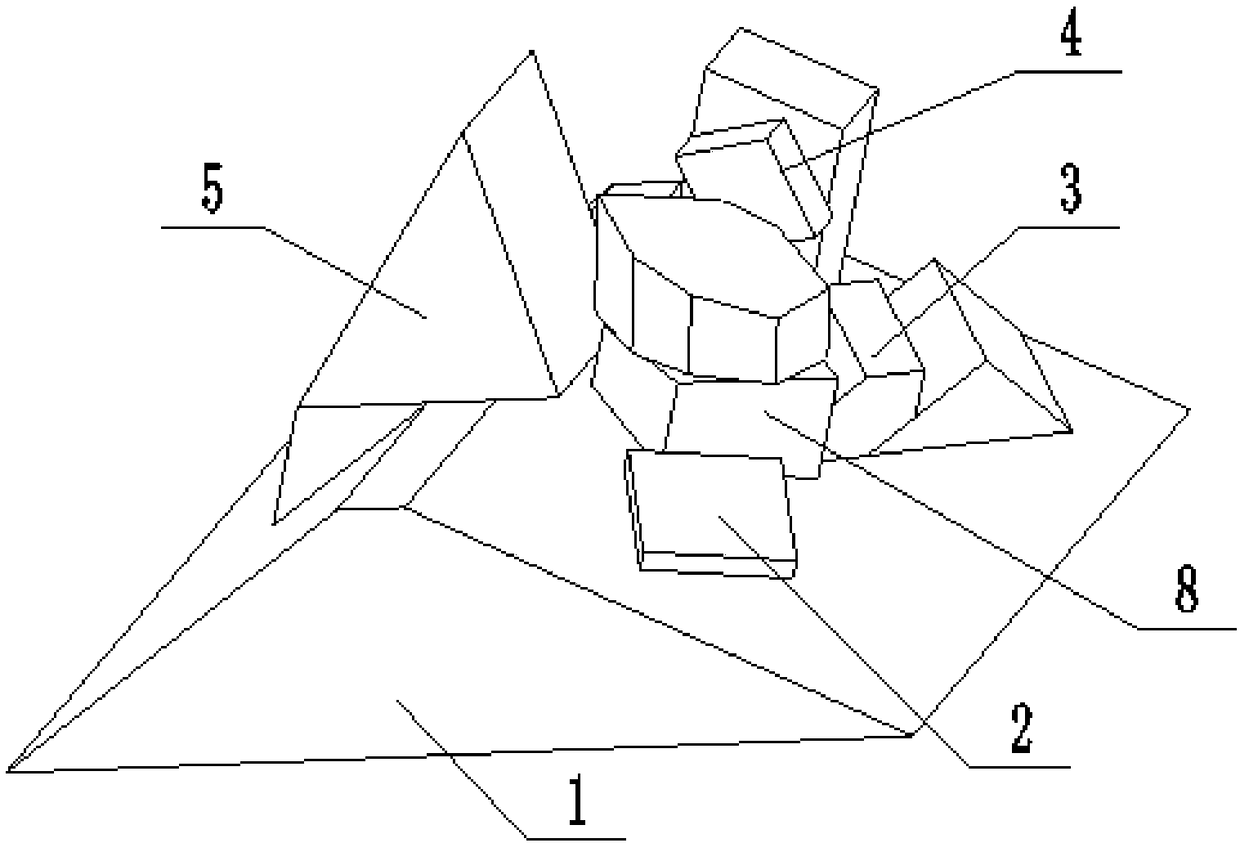

Ferrosilicon block crushing device

The invention aims at providing a ferrosilicon block crushing device with a reasonable structure and a good using effect. According to the technical scheme, the ferrosilicon block crushing device comprises a stander, wherein a fixed tooth plate is arranged at a material inlet of the stander; grinding teeth are arranged on the lower part of the fixed tooth plate; a tooth roller is arranged in the stander; high and low anti-abrasion teeth are uniformly distributed on the tooth roller; the tooth roller is driven by a motor; a material press is mounted above the fixed tooth plate. The grinding teeth are made of high-intensity materials. The ferrosilicon block crushing device is reasonable in structure and good in using effect, can quickly and uniformly process a whole ferrosilicon block into square blocks with the thicknesses being 50-80mm, meets a subsequent processing requirement of a ferrosilicon production enterprise, and is low in processing cost.

Owner:新乡市锦泰达冶金设备有限公司

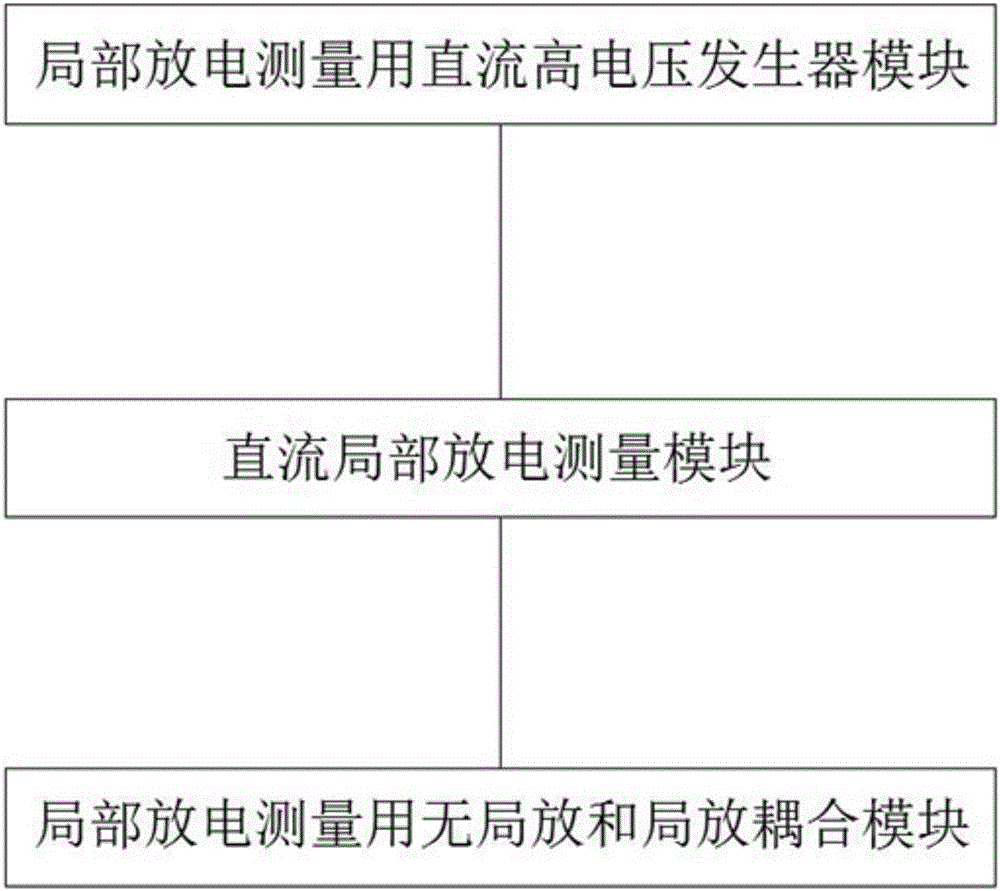

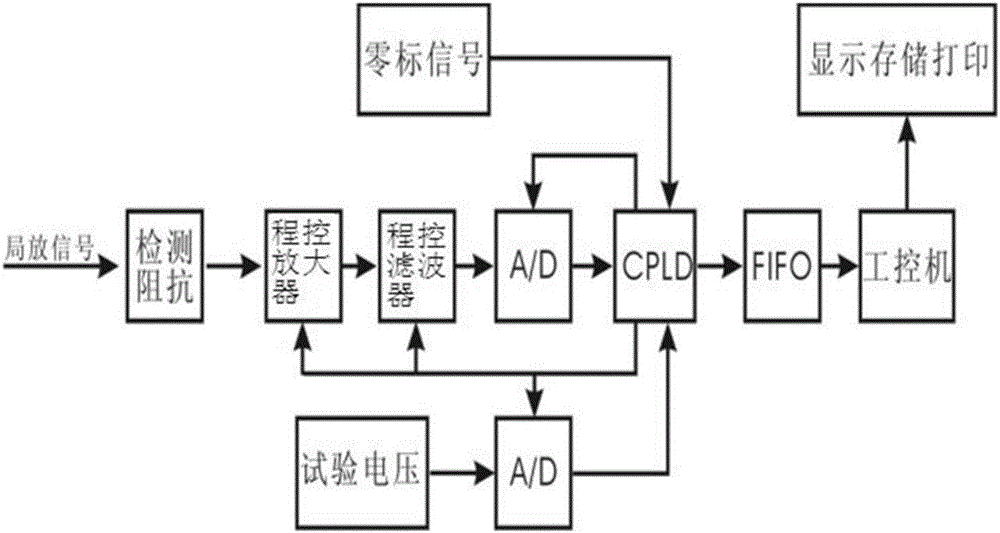

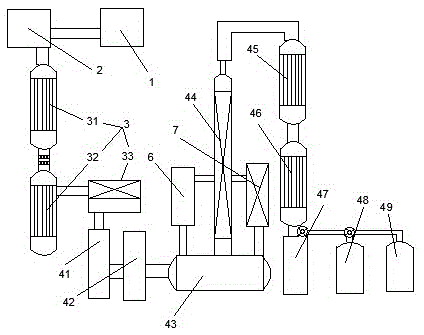

Direct-current partial discharge testing system and method for extra-high-voltage power transmission and transformation equipment

ActiveCN106405357ALow costAccurate analysisTesting dielectric strengthMass storageContinuous/uninterrupted

The invention discloses a direct-current partial discharge testing system for extra-high-voltage power transmission and transformation equipment. The direct-current partial discharge testing system comprises a direct-current partial discharge measurement module, a direct-current high voltage generator module for partial discharge measurement and a non-partial-discharge and partial-discharge coupling module for partial discharge measurement which are electrically connected. In the system, a hardware pipeline formed by a CPLD chip and an FIFO memory chip runs synchronously at the high speed of A / D sampling, so it is guaranteed that a hardware system is able to read while carrying out high-speed sampling under the condition that main waveform data of partial discharge is retained, thereby realizing long-term continuous storage and analysis of partial discharge data. In addition, a windows platform mass memory is used to cache the partial discharge data read from the FIFO memory chip, so as to meet the need of follow-up processing.

Owner:GUIYANG BUREAU OF CHINA SOUTHERN POWER GRID CO LTD EHV TRANSMISSION CO +1

Unloading device in the barrel

ActiveCN105674749BSmooth unloadingEasy to controlCharge composition/stateCharge manipulationEngineeringMechanical engineering

The invention discloses a discharging device in a material cylinder, which can uniformly discharge materials as required. The discharging device comprises a discharging plate mechanism, a central material cover, radial leakage-proof covers and a side plate, which are connected with the material cylinder respectively, wherein the discharging plate mechanism is mounted on a support member inside the material cylinder, covers a material channel of the material cylinder, and comprises an annular discharging plate and reciprocating drivers; the annular discharging plate is formed by splicing a plurality of sectorial moving plate units, and each moving plate unit is connected with the material cylinder through the corresponding reciprocating driver; the central material cover is tapered, and a through hole in the center of the annular discharging plate is covered with the central material cover; the side plate obliquely extends downwards towards the axis of the material cylinder from the wall of the material cylinder, and a gap between the annular discharging plate and the wall of the material cylinder is covered with the side plate; each radial leakage-proof cover covers a gap between the adjacent moving plate units, and the top end of each radial leakage-proof cover is in a left-turned E shape.

Owner:TIANJIN ZHENGYUANHE TECH DEV CO LTD

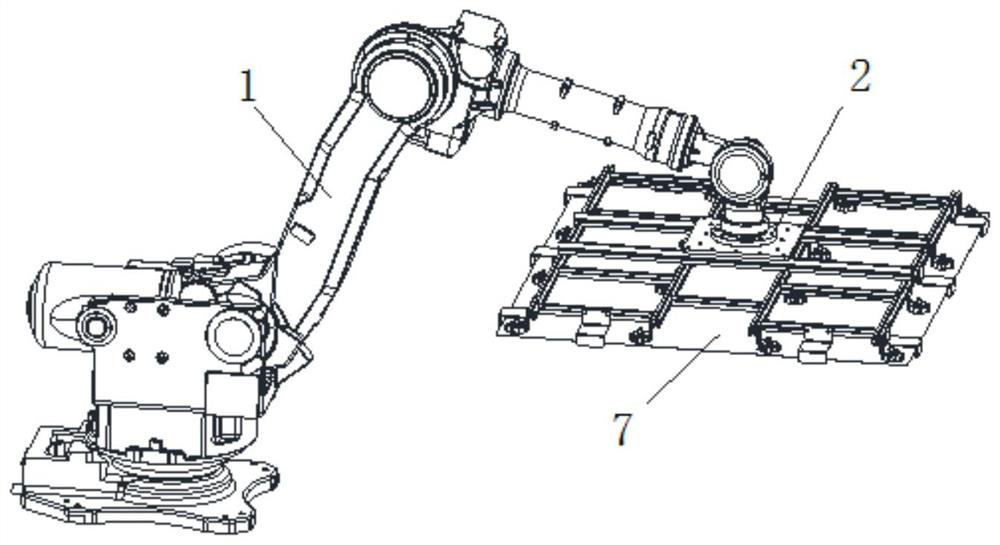

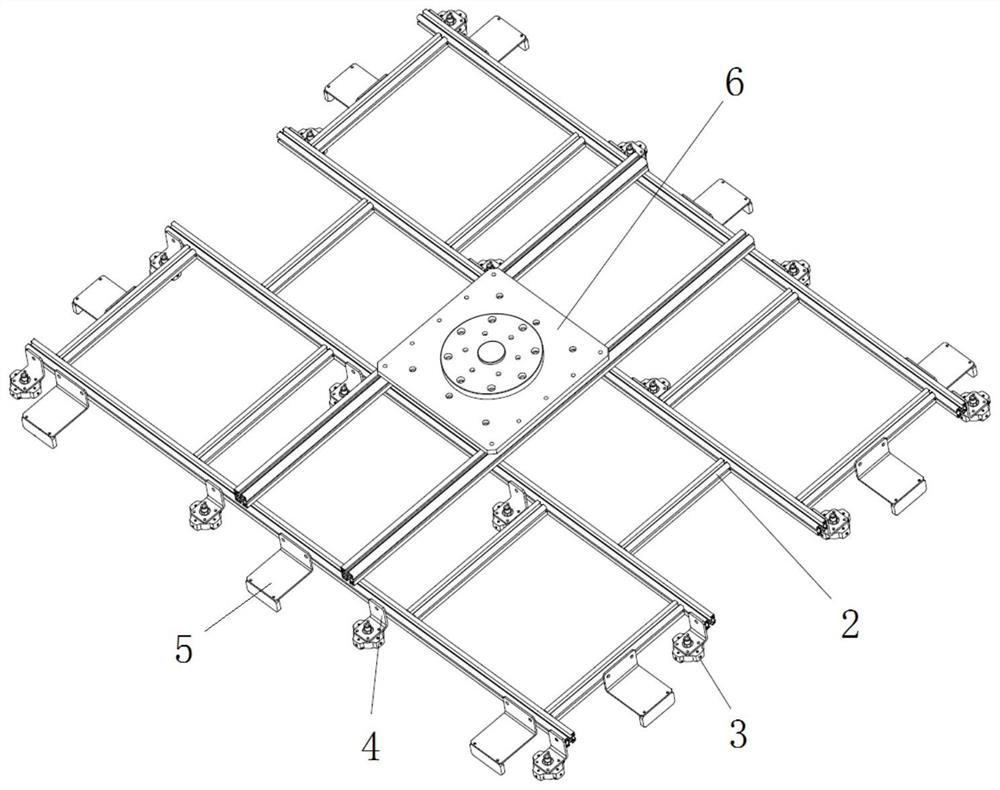

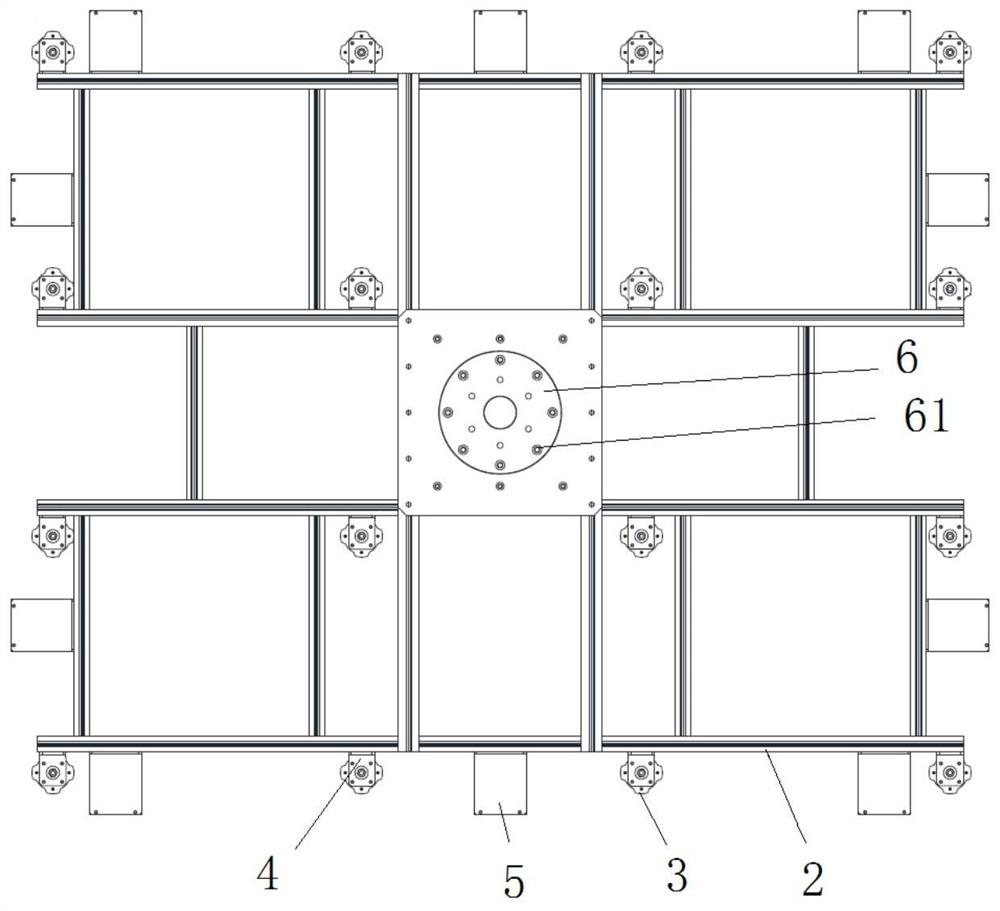

Non-contact robot gripper

PendingCN111824774AQuality assuranceEasy to produceCharge manipulationConveyor partsSuction forceControl engineering

The invention provides a non-contact robot gripper and belongs to the technical field of mechanical grippers. The non-contact robot gripper comprises a robot, a frame and a plurality of non-contact suckers. According to the non-contact robot gripper, an arm of the robot is connected with the frame with the multiple non-contact suckers, and the bottom of a sucker body of each non-contact sucker isprovided with an annular groove and a third channel which is tangentially arranged along the side wall of the groove and communicates with the groove, so that gas can flow out from the third channel in the tangential direction of the side wall of the concave cavity and forms spiral motion under the constraint of the inner wall of the concave cavity, thereby generating vacuum suction force. A glasssubstrate is adsorbed, grabbed and transferred without contact, so that the problems of surface pollution, scratches, damage and deformation caused by contact are avoided, the quality of the glass substrate is guaranteed, the requirement of subsequent processing is met, and production and manufacturing of the glass substrate are facilitated.

Owner:SHANGHAI TONSAIL ROBOT CO LTD

Organic glass recycling process equipment

InactiveCN105541622AEfficient crushingFully lysedOrganic compound preparationCarboxylic acid esters preparationProcess equipmentProcess engineering

The invention relates to the field of organic glass recycling, and relates to organic glass recycling process equipment. The organic glass recycling process equipment comprises a crushing device, a cracking device, a coarse product recycling device, a coarse product purifying device and a product recycling device which are sequentially arranged; the coarse product recycling device comprises a first-stage condenser, a second-stage condenser and a deep condenser; the coarse product purifying device comprises a cleaning part, a settling part and a rectifying assembly, the rectifying assembly comprises a heating kettle, a rectifying tower, a first condenser, a second condenser and a finished product tank which are sequentially connected with the settling part, and a head fraction tank and a tail fraction tank are further connected to the second condenser by being parallel to the finished product tank. The organic glass recycling process equipment conducts efficient crushing and thorough cracking on waste organic glass, and the obtained recycled materials are high in purity and meet subsequent processing requirements.

Owner:湖州丰瑞塑化有限公司

Portable punching head without burr

The invention discloses a portable punching head without burr. The portable punching head without burr comprises a punching head base, and is characterized by further comprising a threaded rod, a nut and a blade, wherein one side of the punching head base is sunk inwards to form a groove; the blade is arranged in the groove; the threaded rod penetrates the back end of the blade and the punching head base part on the two sides of the groove; the part of the threaded rod penetrating the punching head base is fastened and fixed by the nut; circular beads are arranged on the two sides of the processing end of the blade; the diameter of each circular bead is 0.1 cm to 0.4 cm. The portable punching head without burr solves the problems that the punching head is scrapped and the cost is added as the blade of the punching head in the prior art is integrally molded with the punching head base and is gradually consumed due to abrasion, and the product quality is reduced as burrs are easily formed on a breakage surface of a product when the punching head is used for punching the product; the portable punching head without burr, which is simple in structure, has the blade detached rapidly and is low in use cost, is provided.

Owner:KUNSHAN BAOLIANGHENG PRECISION MOLD

A kind of organic glass recycling equipment

ActiveCN105619644BEfficient crushingEfficient crackingPlastic recyclingGrain treatmentsDrive motorOrganic glass

The invention discloses to a recycling device for organic glass. The recycling device comprises a crushing device, a cracking device, a crude product recycling device, a crude product purification device and a product recycling device, all of which are sequentially arranged. The crushing device comprises a primary crushing cavity, a secondary crushing cavity, a primary crushing part arranged in the primary crushing cavity, and a secondary crushing part arranged in the secondary crushing cavity. The primary crushing part comprises two drive rollers driven by a drive motor, a conveying belt arranged on the outer rings of the two drive rollers, and cutting rollers arranged above the conveying belt. Cutting blades are installed on the cutting rollers. The cutting points of the cutting blades are located on the surface of the conveying belt. The drive rollers drive the conveying belt to move. The recycling device is used for efficiently crushing waste organic glass, noise is low, the waste organic glass is efficiently cracked, the working efficiency is improved, and the crushing cost is reduced.

Owner:青岛耀恩玻璃制品有限公司

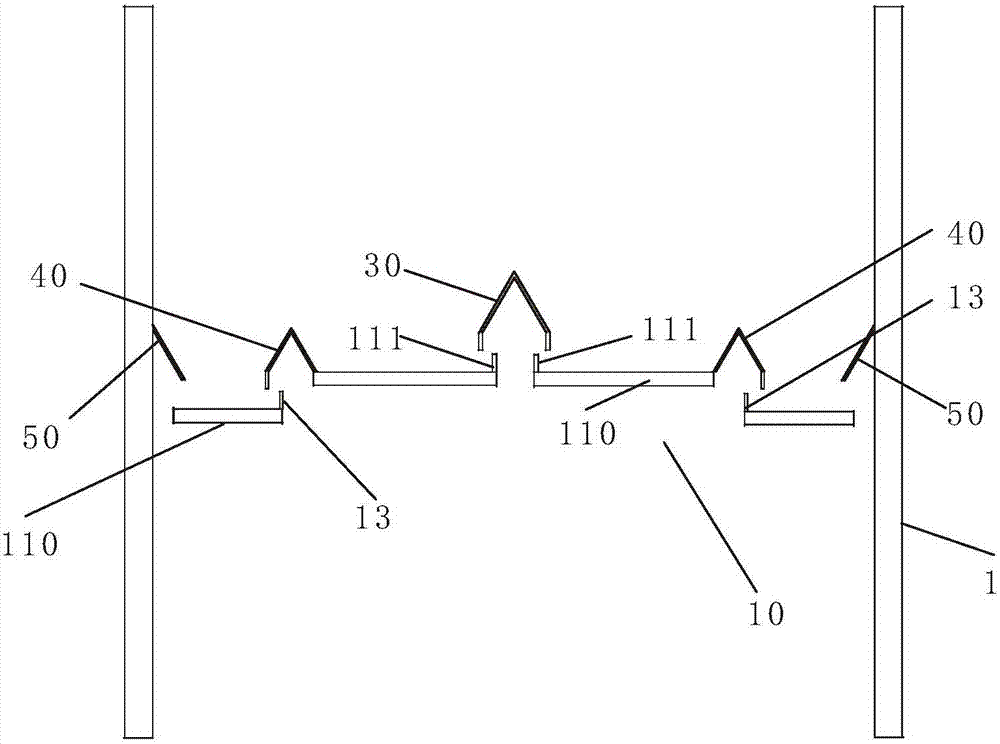

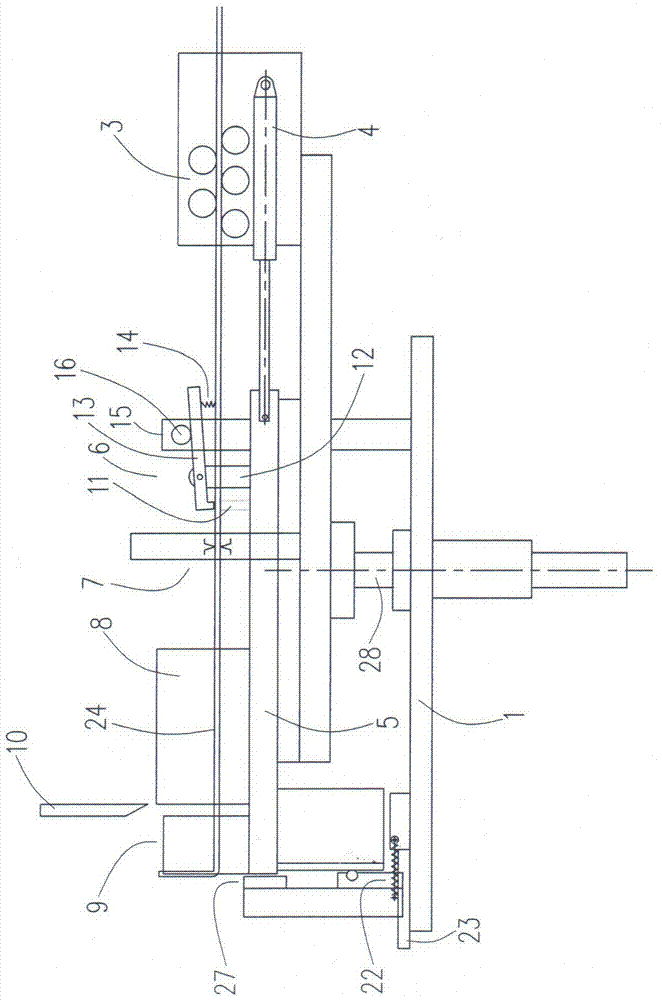

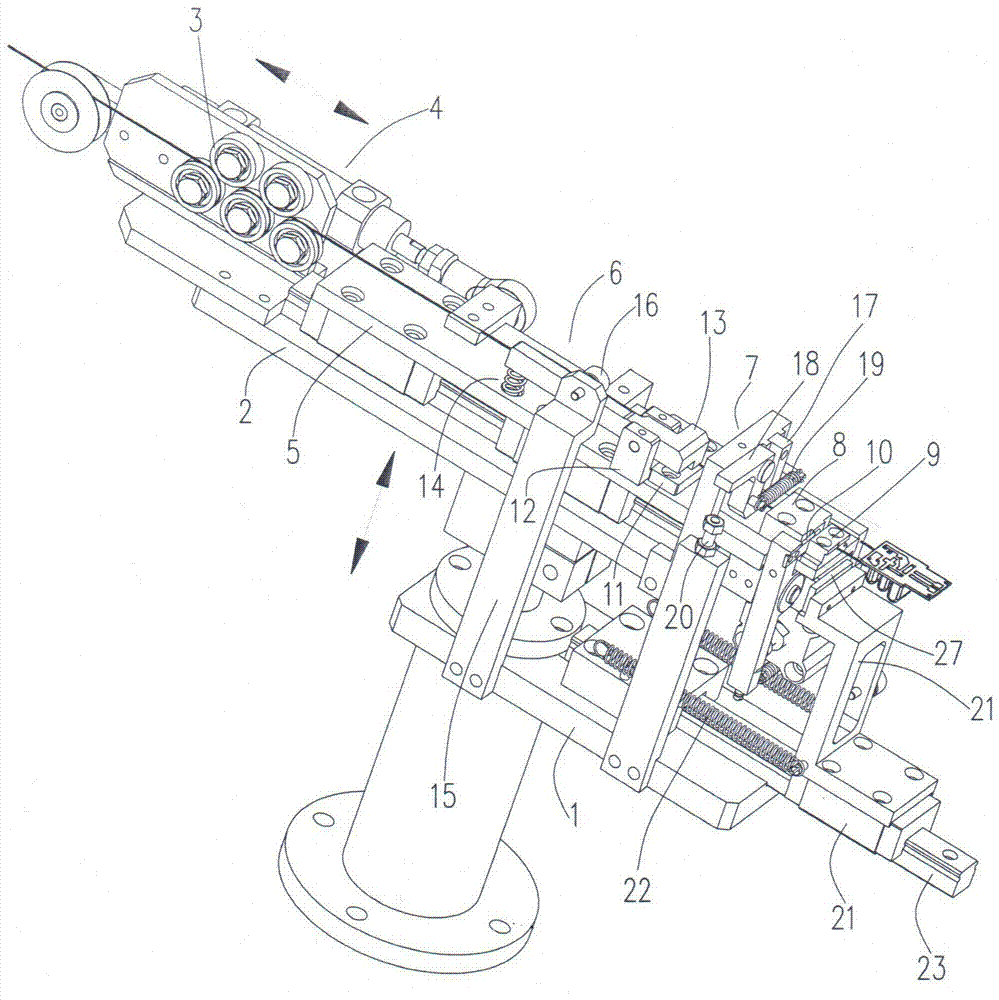

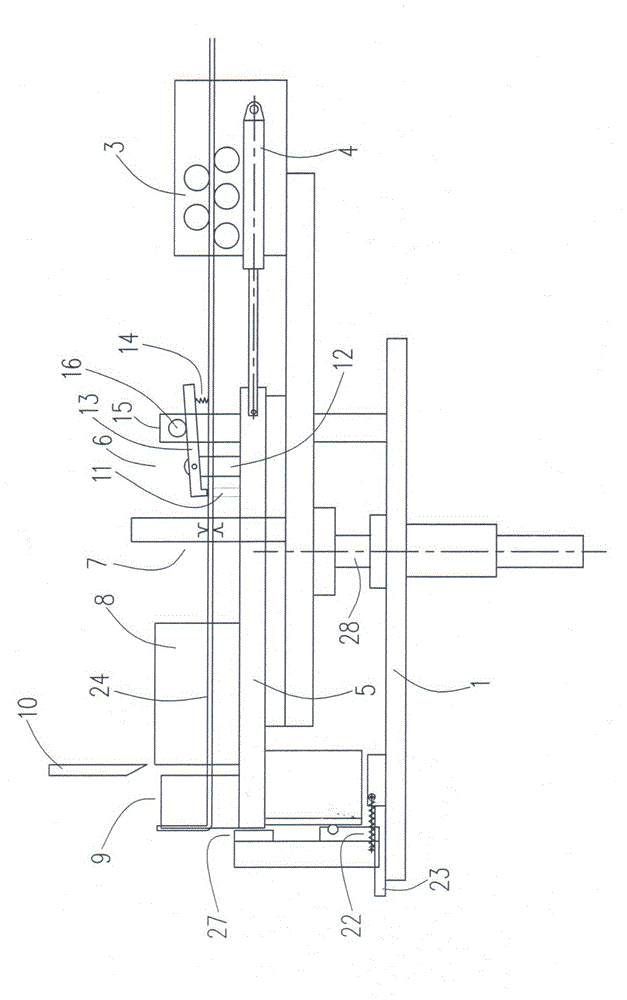

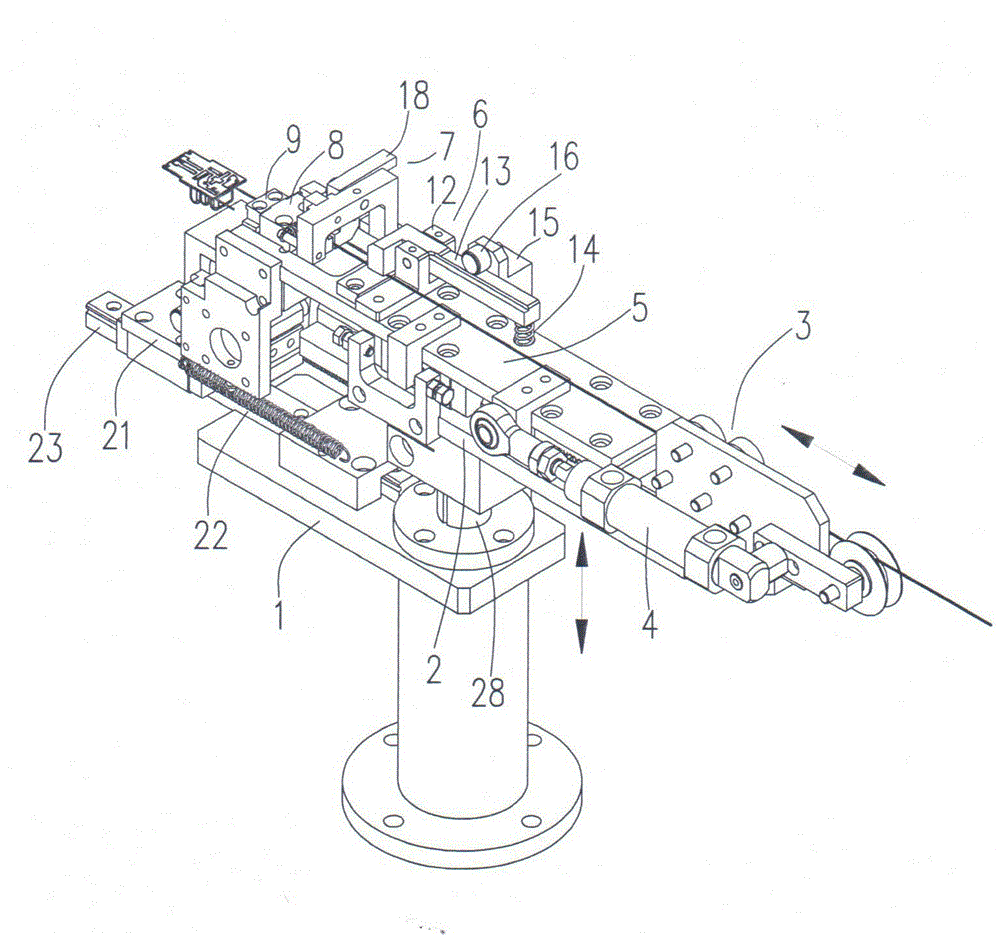

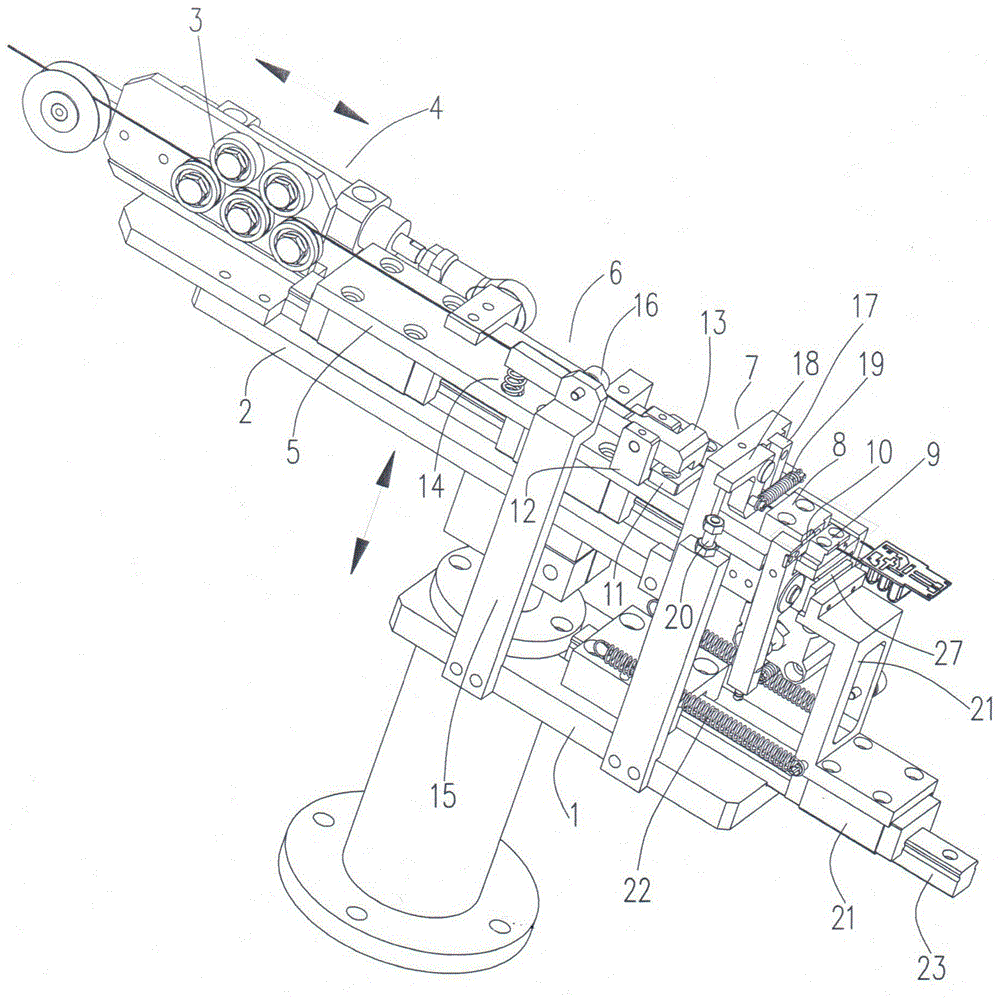

Automatic wire feeding and forming device for producing led energy saving lamps

An automatic conveying, cutting and molding device for conducting wires used for producing LED energy saving lamps is characterized by comprising a base and a molding block, wherein a lifting seat is arranged on the base, a first end of the lifting seat is provided with a conducting wire straightening roller group and a first cylinder seat, a first cylinder is fixed to the first cylinder seat, a second end of the lifting seat is provided with a sliding plate, the sliding plate can be pushed by a pushing head of the first cylinder to slide leftwards and rightwards on the lifting seat, and a first clamping mechanism, a second clamping mechanism, a conducting wire guiding seat, a molding die and a cylinder type cutter are arranged on the sliding plate. The automatic conveying, cutting and molding device further comprises a PLC, wherein the PLC can control the lifting seat, the first cylinder and the cylinder type cutter to finish conducting wire pushing, conducting wire molding and conducting wire cutting action. Through the skillful combination of the lifting seat, the sliding plate and the two clamping mechanisms, the automatic conveying, cutting and molding device realizes automatic straightening, 90-degree bending molding and cutting for the machining of L-shaped conducting wire sections. The automatic conveying, cutting and molding device is exquisite in structural design, high in efficiency and reliable in performance.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

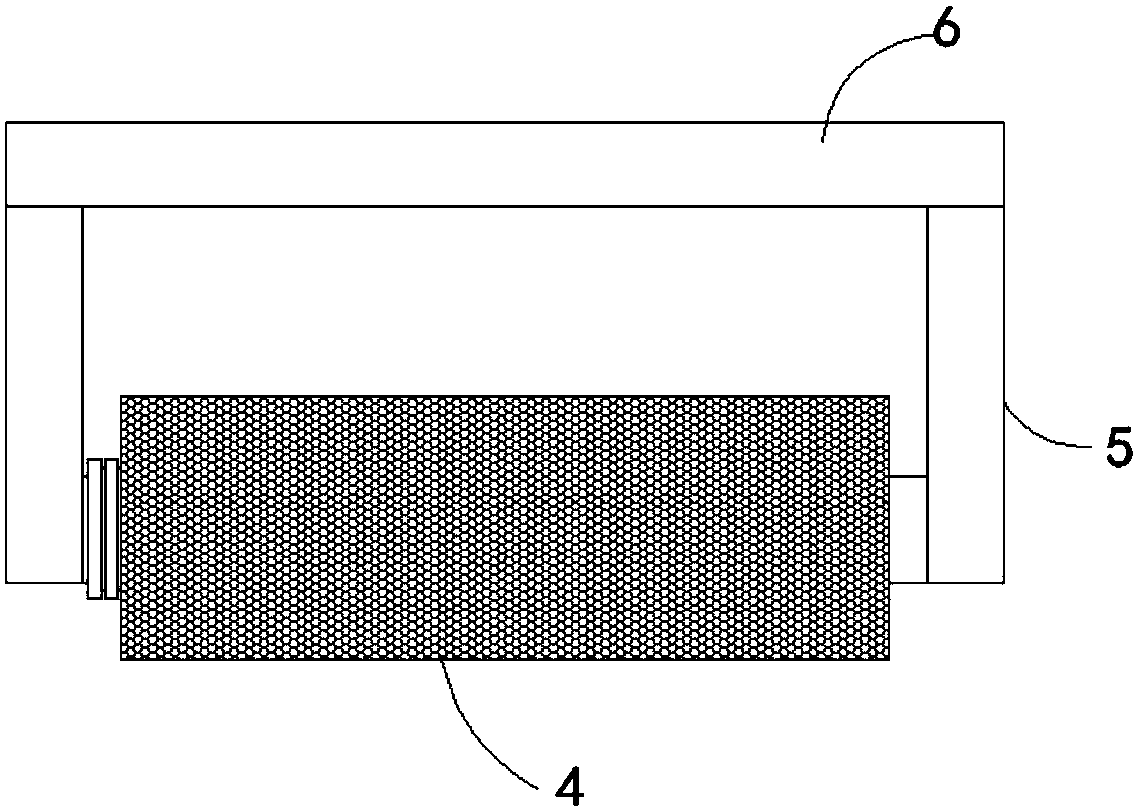

Fiber netforming device

ActiveCN107620159AGuaranteed uniformitySufficient tensile strengthNon-woven fabricsFiberTechnology/technique

The invention belongs to the technical field of fiber processing technologies, and particularly relates to a fiber netforming device. The fiber netforming device comprises a base, the base is providedwith a material storage bin, the material storage bin is connected with a feeding mechanism through a vertical elevator, the lower side of the feeding mechanism is provided with a negative pressure rotating cylinder, through holes are evenly formed in the surface of the negative pressure rotating cylinder, the two ends of the negative pressure rotating cylinder are both rotatably connected with two exhaust pipelines through bearings, the vent ends of the two exhaust pipelines are connected to a same air collection pipeline, the air collection pipeline is connected with a first cross flow fan,the exhaust pipelines are erected on the base through two first brackets, the base is also provided with a first driving motor, and the first driving motor is in transmission connection with the negative pressure rotating cylinder through a first transmission mechanism; the base is vertically provided with two second brackets, and a conveying mechanism is arranged between the two first brackets and the two second brackets. The fiber netforming device has the advantages of being wide in application range, low in purchase, use and maintenance cost and suitable for popularization in middle and small fiber processing enterprises.

Owner:MAANSHAN HUBIN NONWOVEN CLOTH TECH

Biological decolorization process of human hair fiber dyed by oxidation method

The invention belongs to the technical field of human hair product processing, and in particular relates to a biological decolorization process for human hair fiber dyed with oxidation method. The present invention uses the oxidation-processed hair-dyeing pigment as the only carbon source for fermentation, adds an organic solvent to prepare a fermentation medium, screens and ferments facultative microorganisms that can grow and metabolize using the oxidation-processed hair-dyeing pigment as a carbon source, and obtains a fermentation liquid. Then, adding the pretreated oxidized oil-dyed human hair fiber into the fermentation broth for treatment, thereby removing the pigment in the oxidized oil-dyed human hair fiber. The invention solves the long-term problem that human hair products enterprises cannot decolorize human hair fibers dyed with oxidation method, greatly expands the raw material sources of human hair products enterprises, and reduces the cost of human hair products. In addition, the invention has simple process, good effect, little damage to hair quality, and has very good industrial application prospect.

Owner:SHANDONG UNIV OF TECH

Burr-free bidirectional detachable luminous punch with sterilization function

InactiveCN105363881AGuaranteed stabilityGuaranteed reliabilityMechanical apparatusLighting elementsLight guideUltraviolet lights

The invention discloses a burr-free bidirectional detachable luminous punch with a sterilization function. The two ends of a punch base are each provided with an opening in an inwards concave mode. Each opening is provided with one blade inside, and screws penetrate through the rear ends of the corresponding blades and the parts, located on the two sides of the openings, of the punch base. Moreover, the parts, penetrating out of the punch base, of the screws are locked and fixed by nuts. The two sides of each opening are each provided with a slot. The two sides of the rear end of each blade are each provided with a convex inversed buckle, and the inversed buckles on the two sides are tightly clamped to the slots in the corresponding sides in a matched mode. The two sides of the machining end of each blade are arranged to be fillets, a light source is arranged on the punch base and generates ultraviolet light, and a plurality of light guide pieces are arranged on the blades, located on the edges of the cutting edges of the blades and perpendicular to the cutting edges. The light guide pieces absorb light emitted by the light source and guide the light to the cutting edges.

Owner:殷霄

Novel special-shaped wire guider

PendingCN113385618AEffective posture adjustmentHigh accuracy of attitude adjustmentScrew threadAbnormal shaped

The invention discloses a novel special-shaped wire guider which comprises a body, a wire channel is arranged in the body, a top fine adjustment mechanism, a left fine adjustment mechanism and a right fine adjustment mechanism are installed on the body, the top fine adjustment mechanism, the left fine adjustment mechanism and the right fine adjustment mechanism are the same in structure, the top fine adjustment mechanism comprises an installation chamber and a plurality of adjusting screw rods, an adjusting plate is arranged in the installation chamber, a plurality of balls are mounted in the adjusting plate, a plurality of springs are arranged in the installation chamber, an opening is formed in a ball chamber, a plurality of threaded holes are formed in the body, and the adjusting screw rods are screwed into the threaded holes respectively and abut against the adjusting plate. According to the special-shaped wire guider, the posture of a special-shaped wire can be effectively adjusted to the set requirement, and the subsequent machining requirement is met. The posture adjusting precision of the special-shaped wire is high, the guiding stability is high, and the scratch influence on the special-shaped wire is reduced.

Owner:JIASHAN JIANGNAN MACHINERY & ELECTRICAL INSTR LTD

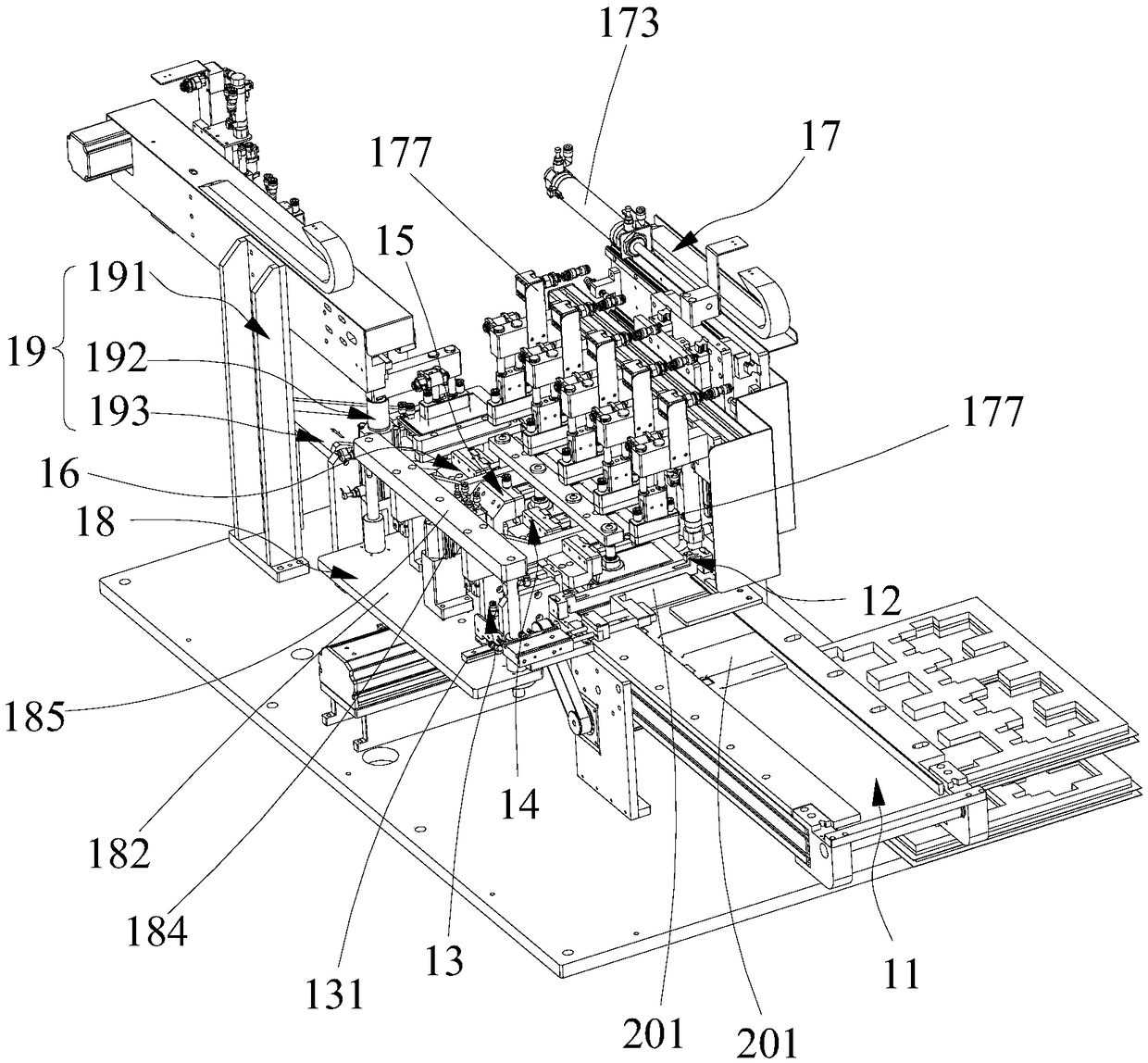

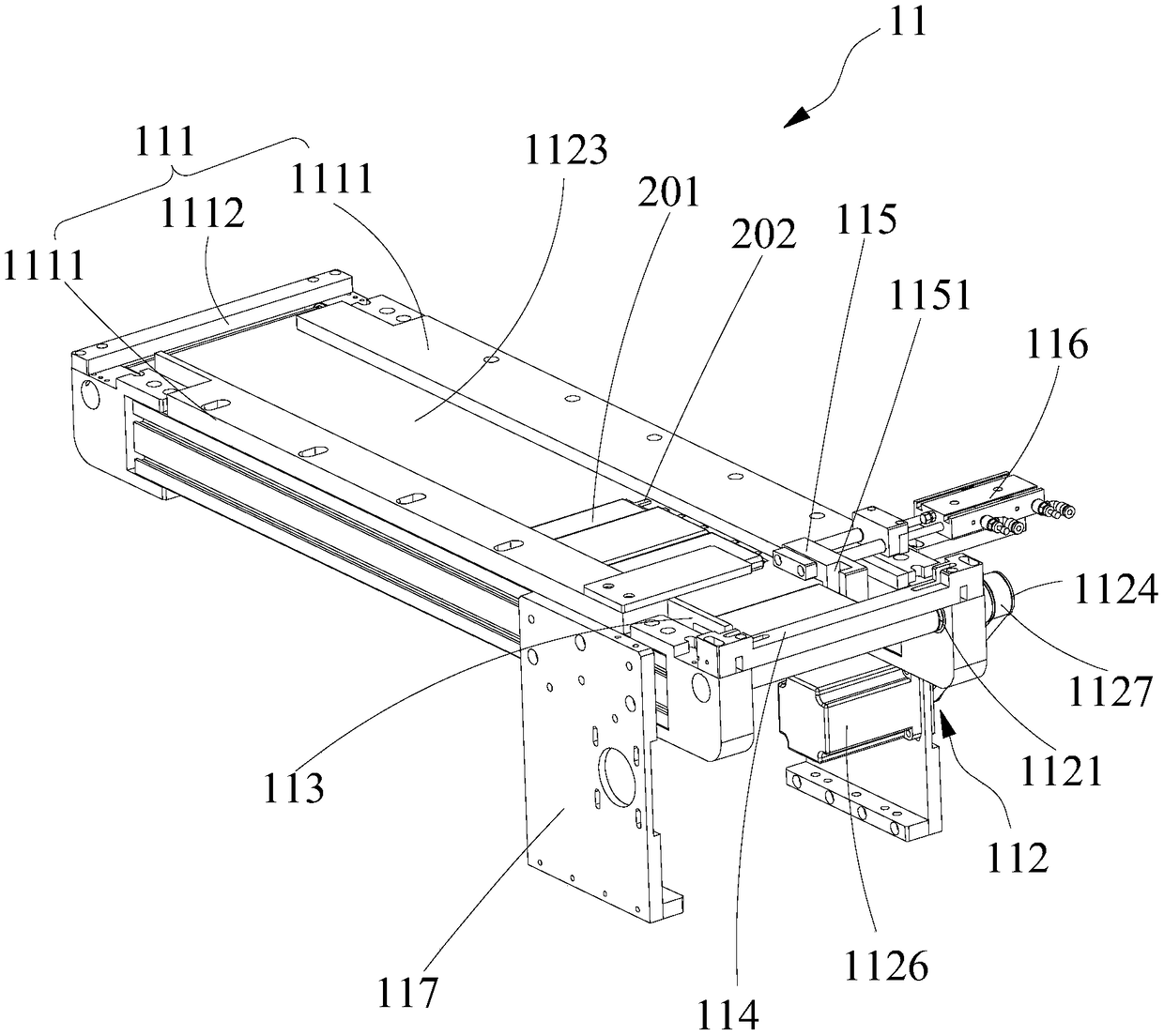

Cell pretreatment device

PendingCN109546198AMeet the needs of subsequent processingAssembling battery machinesFinal product manufactureSlide plateEngineering

The invention discloses a cell pretreatment device, comprising a cell pre-positioning mechanism, shaping placement frames, a straightening mechanism, a cutting mechanism, a shaping pressing mechanism,and a shaping transfer component. The shaping pressing mechanism comprises a shaping pressing base, a shaping pressing sliding plate, a shaping pressing drive assembly, and a shaping pressing assembly. The straightening mechanism comprises a straightening bottom plate, a straightening pneumatic finger, a straightening clamping plate, and a straightening driving member. The cell pre-positioning mechanism includes a pre-positioning bracket, a pre-positioning belt assembly, a first pre-positioning reference plate, a second pre-positioning reference plate, a pre-positioning push plate, and a pre-positioning push drive device. The cell pre-positioning mechanism pre-positions a cell, transfers the pre-positioned cell to the first shaping placement plate corresponding to a processing station ofthe straightening mechanism, and the shaping pressing mechanism clamps and fixes the cell. The straightening mechanism firstly straightens tabs on the cell, and the cutting mechanism cuts the tabs that have been straightened on the cell.

Owner:深圳市智联智造自动化有限公司

Method for radio frequency interference suppression and error correction of low-frequency synthetic aperture radar

InactiveCN102243300BEfficient detectionAvoid complex calculationsWave based measurement systemsTime domainSynthetic aperture radar

The invention provides a method for the RFI (radio frequency interference) suppression and error correction of a low-frequency SAR (synthetic aperture radar). The technical scheme comprises five steps of: step 1, receiver frequency characteristic error correction based on an echo; step 2, distance spectrum equalization suppression and SAR imaging based on a corrected time-frequency domain echo; step 3, registration based on a time domain image; step 4, RFI detection and suppression based on a time-frequency domain; and step 5, residual error correction. The method provided by the invention can solve the RFI detection and suppression of a double-channel low-frequency SAR interferogram, as well as various error correction problems, increase the performance of an along-track interferometry method, and lay a good foundation for the follow-up associated processing.

Owner:NAT UNIV OF DEFENSE TECH

Automatic conveying, cutting and molding device for conducting wires used for producing LED energy saving lamps

An automatic conveying, cutting and molding device for conducting wires used for producing LED energy saving lamps is characterized by comprising a base and a molding block, wherein a lifting seat is arranged on the base, a first end of the lifting seat is provided with a conducting wire straightening roller group and a first cylinder seat, a first cylinder is fixed to the first cylinder seat, a second end of the lifting seat is provided with a sliding plate, the sliding plate can be pushed by a pushing head of the first cylinder to slide leftwards and rightwards on the lifting seat, and a first clamping mechanism, a second clamping mechanism, a conducting wire guiding seat, a molding die and a cylinder type cutter are arranged on the sliding plate. The automatic conveying, cutting and molding device further comprises a PLC, wherein the PLC can control the lifting seat, the first cylinder and the cylinder type cutter to finish conducting wire pushing, conducting wire molding and conducting wire cutting action. Through the skillful combination of the lifting seat, the sliding plate and the two clamping mechanisms, the automatic conveying, cutting and molding device realizes automatic straightening, 90-degree bending molding and cutting for the machining of L-shaped conducting wire sections. The automatic conveying, cutting and molding device is exquisite in structural design, high in efficiency and reliable in performance.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

A ferrosilicon block crushing device

The invention aims at providing a ferrosilicon block crushing device with a reasonable structure and a good using effect. According to the technical scheme, the ferrosilicon block crushing device comprises a stander, wherein a fixed tooth plate is arranged at a material inlet of the stander; grinding teeth are arranged on the lower part of the fixed tooth plate; a tooth roller is arranged in the stander; high and low anti-abrasion teeth are uniformly distributed on the tooth roller; the tooth roller is driven by a motor; a material press is mounted above the fixed tooth plate. The grinding teeth are made of high-intensity materials. The ferrosilicon block crushing device is reasonable in structure and good in using effect, can quickly and uniformly process a whole ferrosilicon block into square blocks with the thicknesses being 50-80mm, meets a subsequent processing requirement of a ferrosilicon production enterprise, and is low in processing cost.

Owner:新乡市锦泰达冶金设备有限公司

Wet strength copper clad laminate base paper and preparation process

InactiveCN101864701AGood water resistanceHigh strengthReinforcing agents additionMetal coatingsWater resistanceEucalyptus

The invention aims to provide wet strength copper clad laminate base paper to meet the requiremetn of a subsequent process for flame retardance. The wet strength bleached wood pulp copper clad laminate base paper is prepared by using eucalyptus wood pulp as papermaking wood pulp and adding a wet strength agent which is 0.18 to 0.32 percent of the total weight of the eucalyptus wood pulp. A preparation process of the wet strength bleached wood pulp copper clad laminate base paper is characterized in that the wet strength agent is added into a head box of a paper machine by a measuring pump. The invention has the advantage that by selection of the paper pulp and addition of the wet strength agent, the base paper has excellent water resistance and the strength is greatly improved so as to meet the requirement in the treatment process of the subsequent process.

Owner:宝鸡科达特种纸业有限责任公司

Feeding and discharging device for bearing outer ring machining

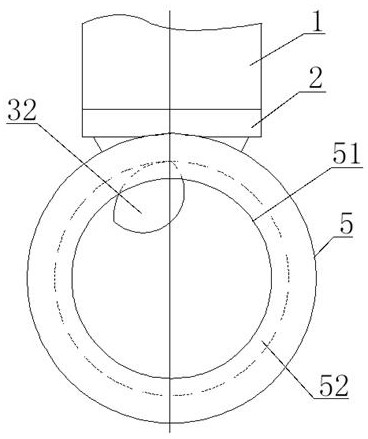

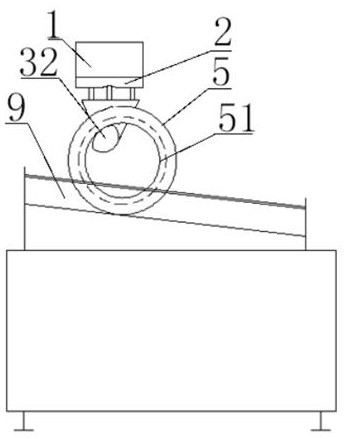

PendingCN112536652AMeet the needs of subsequent processingCutting is effectiveRevolution surface grinding machinesGrinding drivesEngineeringCam

The invention relates to a feeding and discharging device for bearing outer ring machining. The feeding and discharging device comprises an air cylinder, an upper clamping jaw and a lower clamping jaw, the telescopic end of the air cylinder is downwards installed at the lower end of a telescopic cantilever of a truss mechanism, the lower clamping jaw is installed at the telescopic end of the lowerportion of the air cylinder, the upper clamping jaw is installed at the position, close to one side, of the lower portion of the air cylinder, the lower clamping jaw comprises a round rod and a cam block, one end of the round rod is horizontally installed on one side of the telescopic end of the air cylinder, and the cam block is installed at the other end of the round rod. The feeding and discharging device has the advantages that the cam block is designed at one end of the round rod, the cam block meets the requirements that when a large double-flange straight raceway bearing outer ring isclamped, the highest point of the cam block abuts against the middle of the inner side of the bearing outer ring, the bearing outer ring cannot incline in the hooking process, and the bearing outer ring cannot deflect when clamped to the upper clamping jaw finally, and the subsequent machining requirements of a grinding machine are met; and the original gravity rolling discharging mode cannot be met due to the design of the cam block, however, through the arc-shaped surface design and the installation position of the cam block, it is ensured that effective discharging can be achieved even if the front end of the round rod tilts, and the cam block cannot interfere with an annular catch of the bearing outer ring during discharging.

Owner:JIANGSU WANDA SPECIAL BEARING CO LTD

High-strength light high-toughness burr-free luminous punch with sterilization function

InactiveCN105363876AAvoid wastingNot easy to wasteMechanical apparatusLighting elementsLight guideUltraviolet lights

The invention discloses a high-strength light high-toughness burr-free luminous punch with a sterilization function. A screw penetrates through the rear end of a blade and the parts, located on the two sides of a groove, of the punch base. Moreover, the part, penetrating out of the punch base, of the screw is locked and fixed by nuts. A cutting edge is arranged at one end of the blade and formed by laminating and pressing a plurality of steel discs. The two ends of the cutting edge are machined to be fillets. Two joining pieces are welded to the punch base. The free end of each joining piece is provided with a hook, two slots are formed in the rear end of the blade, and the hooks of the joining pieces can stretch into the corresponding grooves of the blade to be connected with the blade in a matched mode. A light source is arranged on the punch base and generates ultraviolet light. A plurality of light guide pieces are arranged on the blade and located on the edge of the cutting edge. The light guide pieces are perpendicular to the cutting edge and absorb light emitted by the light source and guide the light to the cutting edge. A plurality of weight reducing grooves are formed in the middle portion of the blade.

Owner:殷霄

Preparation method of plastic shower curtain with good air permeability

The invention discloses a preparation method of a plastic shower curtain with good air permeability, the preparation method is as follows: S01, metal aluminum powder, titanium dioxide powder, UV epoxyresin, ethylene glycol diacrylate, paraffin wax having a carbon number of 18-20, polypropylene mesh fiber and a photoinitiator are mixed to obtain a blending component; S02, the blending component isblended with PVC resin to obtain a multi-component masterbatch; and S03, the multi-component masterbatch is plasticized, extruded, cured and rolled to obtain the plastic shower curtain with good airpermeability. The plastic shower curtain with good air permeability prepared by the preparation method has a microscopic porous structure, and greatly improves the air permeability of a shower curtainproduct.

Owner:FOSHAN RICH FIELD COMMODITIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com