Burr-free bidirectional detachable luminous punch with sterilization function

A burr-free, punch-free technology, used in optics, light guides, optical components, etc., can solve the problems of increasing the burden on enterprises, increasing the cost of use, and small scope of application, to ensure firmness and reliability, easy to use and operate, and convenient. The effect of changing the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

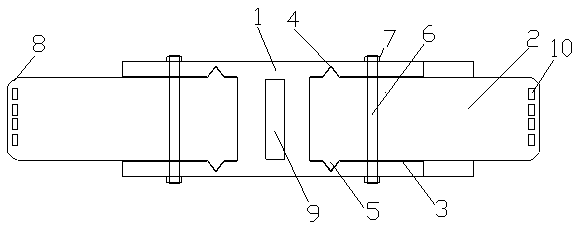

[0014] Such as figure 1 As shown, a burr-free two-way detachable sterilizing luminescent punch includes a punch seat 1, a blade 2, a screw 6 and a nut 7, and an opening 3 is recessed inward at both ends of the punch seat 1, and each A blade 2 is arranged in each opening 3, and the screw rod 6 passes through the rear end of the corresponding blade 2 and the part of the punch seat 1 on both sides of the opening 3, and the part of the screw rod 6 passing through the punch seat 1 is locked by a nut 7 For fixing, slots 4 are respectively arranged on both sides of each opening 3 , and the two pairs of slots 4 are located between two screw rods 6 . Protruding undercuts 5 are respectively provided on both sides of the rear end of the blade 2, and the undercuts 5 on both sides are matched with the slots 4 on the corresponding side to be clamped, and the two sides of the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com