Feeding and discharging device for bearing outer ring machining

A bearing outer ring, intermediate position technology, applied in the direction of grinding drives, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

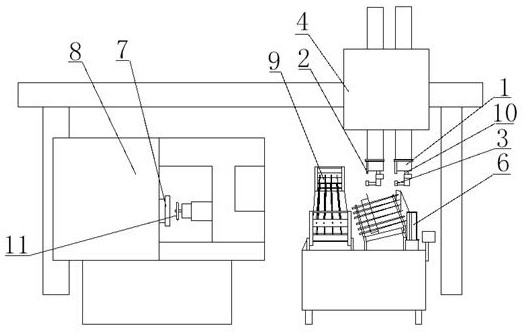

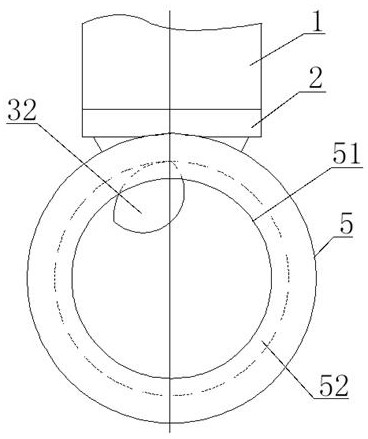

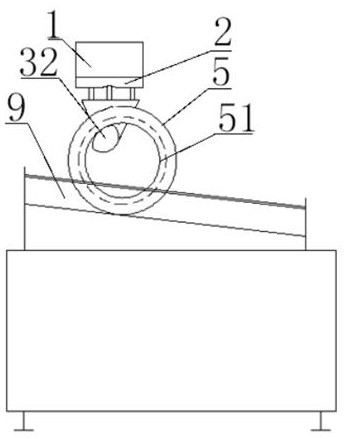

[0024] Refer to attached Figure 1-6 , a loading and unloading device 10 for bearing outer ring processing, which includes a cylinder 1, an upper jaw 2 and a lower jaw 3, the telescopic end of the cylinder 1 is installed downward on the lower end of the telescopic cantilever of the truss mechanism 4, and the cylinder 1 A lower jaw 3 is installed at the telescopic end below, and an upper jaw 2 is installed at a position close to one side below the cylinder 1. The lower jaw 3 includes a round rod 31 and a cam block 32, and one end of the round rod 31 is horizontally installed on the side of the cylinder 1. One side of the telescopic end, the other end of the round rod 31 is equipped with a cam block 32, the arc of the upward arc surface 33 of the cam block 32 is less than or equal to the inner diameter arc of the bearing outer ring 5, the outer side of the round rod 31 and the cam block The inner side of the arc surface 33 of 32 is tangent, when the lower jaw 3 is installed, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com