High-strength light high-toughness burr-free luminous punch with sterilization function

A high-strength, burr-free technology, applied in optics, light guides, optical components, etc., can solve problems such as lowering product quality, affecting the use of punches, and tool damage, and achieves increased connection strength, safe and reliable use, and convenient and fast installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

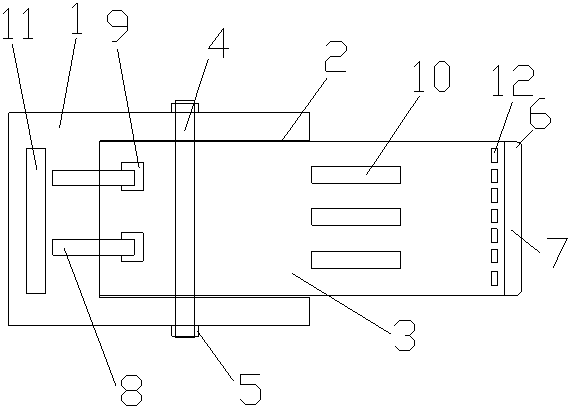

[0015] Such as figure 1 As shown, a high-strength, light, tough, high-burr-free sterilizing luminescent punch includes a punch seat 1, a screw 4, a nut 5 and a blade 3, and one side of the punch seat 1 is recessed inward to form a groove 2. A blade 3 is set in the groove 2, the screw 4 passes through the rear end of the blade 3 and the part of the punch seat 1 on both sides of the groove 2, and the part of the screw 4 passing through the punch seat 1 passes through the nut 5 is locked and fixed, and a blade 7 is arranged at the end of the blade 3, and the blade 7 is formed by laminating and pressing several steel sheets, and the two ends of the blade 7 are processed into rounded corners 6. The blade 3 is a rectangular blade. The punch seat 1 is made of stainless steel. The blade 7 is made of wear-resistant material. The blade 3 is made of tungsten steel material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com