Automatic conveying, cutting and molding device for conducting wires used for producing LED energy saving lamps

A technology of LED energy-saving lamps and wires, applied in the field of LED energy-saving lamps production equipment, can solve the problems of low efficiency, high cost, poor quality accuracy, etc., and achieve the effects of high efficiency, reliable performance and exquisite structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

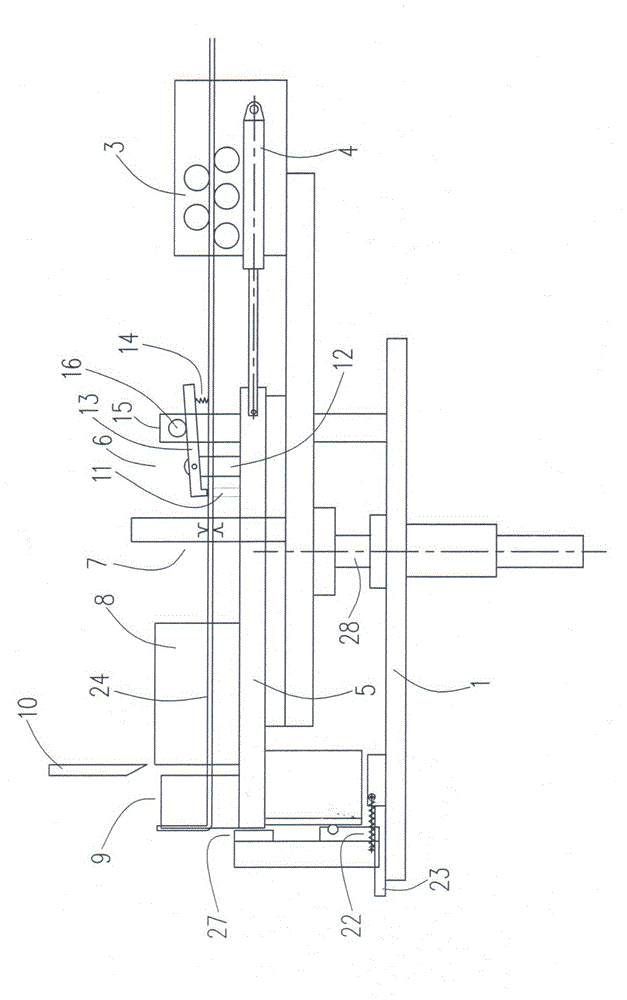

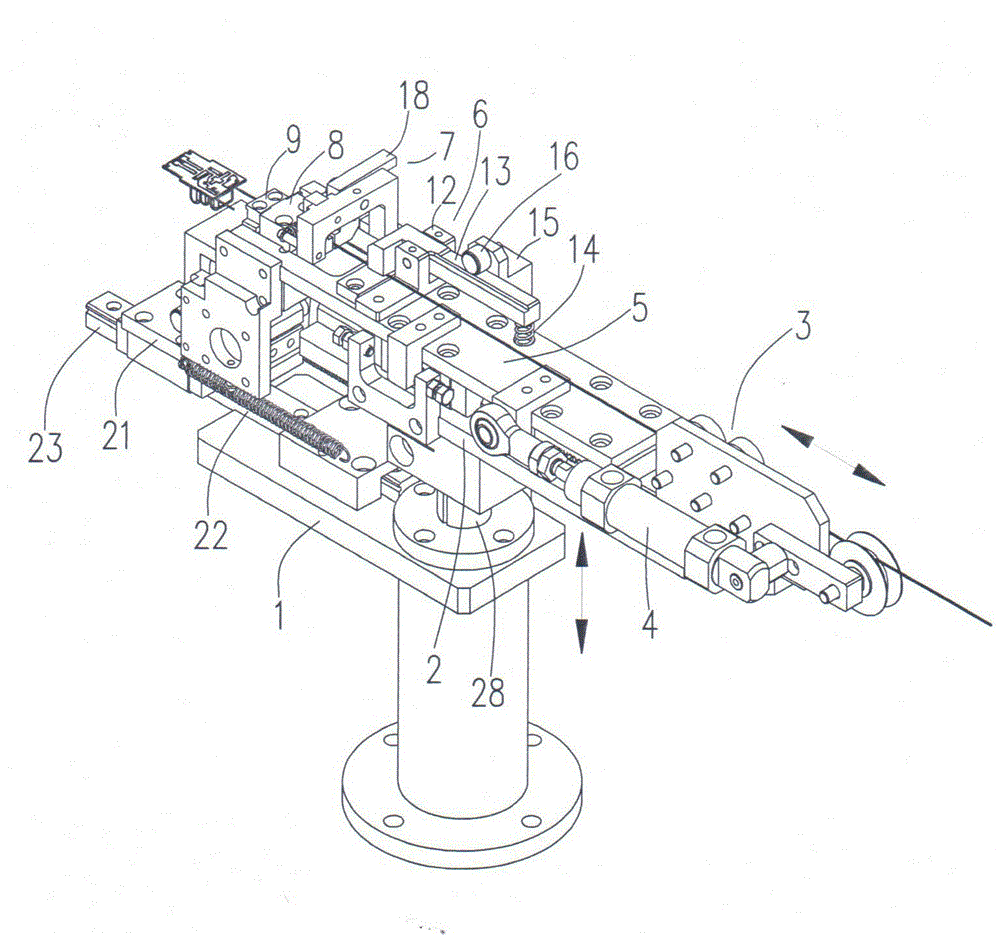

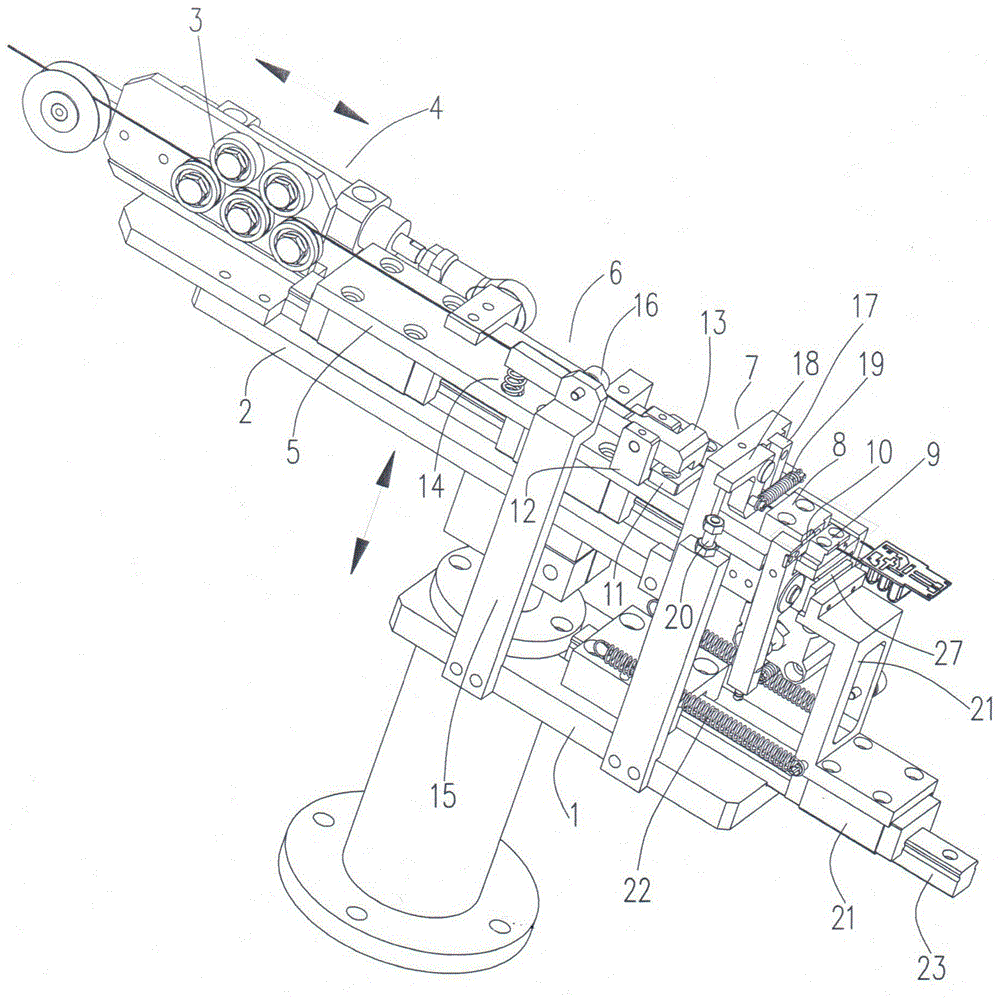

[0034] Such as Figure 1 to Figure 10As shown, an embodiment of the present invention includes a base 1 and a forming block 27, the base 1 is provided with a lifting base 2, and the first end of the lifting base 2 is provided with a wire straightening roller group 3 and a first The cylinder seat, the first cylinder 4 is fixed on the first cylinder seat, the second end of the lift seat 2 is provided with a slide plate 5, the slide plate 5 is pushed by the push head of the first cylinder 4 and can slide left and right on the lift seat 2 along the linear guide rail, The slide plate 5 is provided with a first clamping mechanism 6, a second clamping mechanism 7, a wire guide seat 8, a molding die 9, and a cylinder cutter 10; 1) The first clamping mechanism 6 includes: a horizontal platform seat 11 , support seat 12, L-shaped pressing arm 13, compression spring 14, the support 1 on one side of the L-shaped pressing arm 13 is fixed with a pressing wheel arm 15, and the L-shaped press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com