A kind of organic glass recycling equipment

A technology of plexiglass and equipment, applied in the field of plexiglass recycling equipment, can solve problems such as affecting the work efficiency of workers, low crushing efficiency, long residence time, etc., and achieve the effect of improving work efficiency, reducing crushing costs, and completely cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

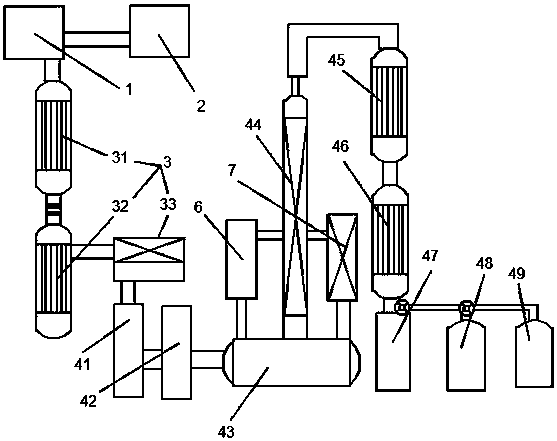

[0023] A kind of plexiglass recycling process equipment, as attached figure 1 , 2 As shown, it includes a crushing device 2, a cracking device, a crude product recovery device 3, a crude product purification device and a product recovery device arranged in sequence along the recovery direction.

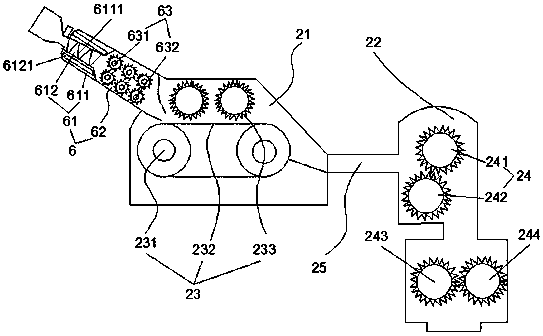

[0024] Among them, the crushing structure includes a closed primary crushing chamber 21 and a secondary crushing chamber 22, the two crushing chambers are connected by a flat neck 25, the primary crushing chamber 21 is provided with a primary crushing component 23, and the secondary crushing chamber 22 is A secondary crushing part 24 is provided to crush the plexiglass in sequence; the position of the primary crushing chamber 21 is higher than that of the secondary crushing chamber 22, which facilitates the transportation of materials. The primary crushing part 23 includes two driving rollers 231 driven by a driving motor, a conveyor belt 232 arranged on the outer rings of the two dr...

Embodiment 2

[0027] A recovery device for waste plexiglass, comprising an extrusion structure 6, a crushing device 2, a cracking device 1, a crude product recovery device 3, a crude product purification device and a product recovery device arranged in sequence. The extruding structure 6 includes a mixing chamber 61, an extruding chamber 62 communicating with the mixing chamber 61, and an extruding part 63 arranged in the extruding chamber 62, which extrudes the relatively fluffy material in the feeding structure and increases the crushing time. The density of the material improves the crushing effect; the extrusion part 63 includes an upper extrusion roller 631 and a lower extrusion roller 632 relative to the upper extrusion roller 631, and the mixing chamber 61 is provided with a heating tube 611 to give the plexiglass a certain temperature. Aids in breaking. The crushing structure 2 includes a closed primary crushing chamber 21 and a secondary crushing chamber 22, the two crushing chambe...

Embodiment 3

[0030]A recovery device for waste plexiglass, comprising an extrusion structure 6, a crushing device 2, a cracking device 1, a crude product recovery device 3, a crude product purification device and a product recovery device arranged in sequence. The extruding structure 6 includes a mixing chamber 61, an extruding chamber 62 communicating with the mixing chamber 61, and an extruding part 63 arranged in the extruding chamber 62, which extrudes the relatively fluffy material in the feeding structure and increases the crushing time. The density of the material improves the crushing effect; the extrusion part 63 includes an upper extrusion roller 631 and a lower extrusion roller 632 relative to the upper extrusion roller 631, and the mixing chamber 61 is provided with a heating tube 611 to give the plexiglass a certain temperature. Aids in breaking. The crushing structure 2 includes a closed primary crushing chamber 21 and a secondary crushing chamber 22, the two crushing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com