Fiber netforming device

A web forming and fiber technology, applied in the field of fiber processing, can solve the problems of limited scope of application, complex structure, high cost of purchase, use and maintenance, and achieve the effect of ensuring tensile resistance and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

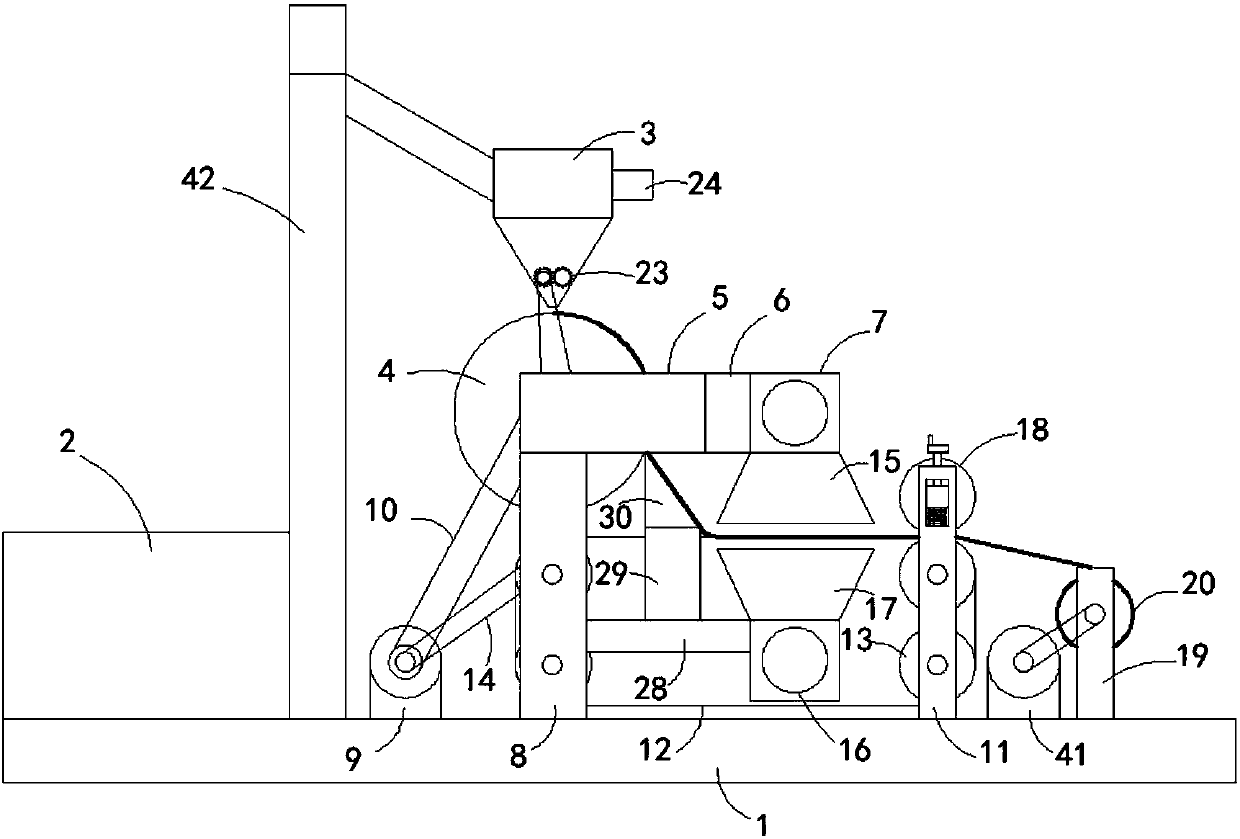

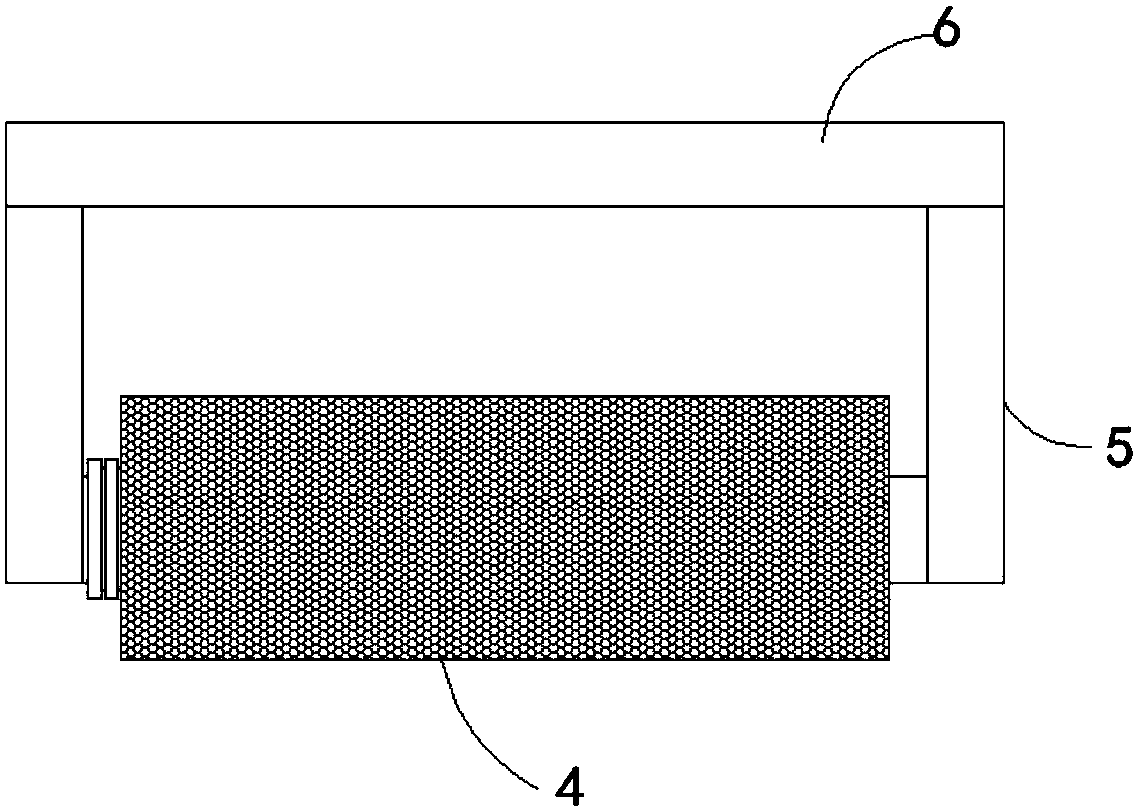

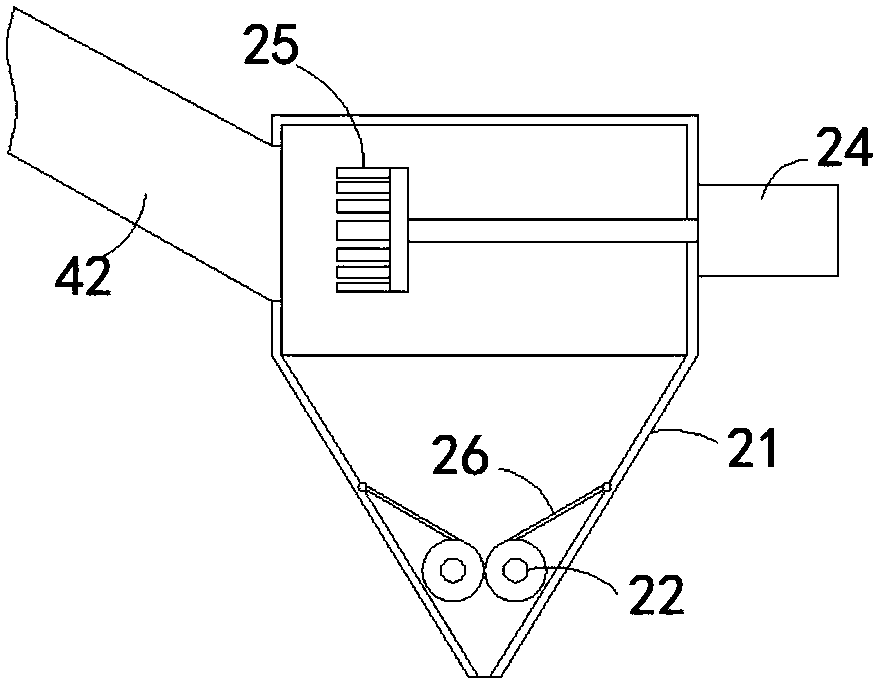

[0023] Such as Figure 1-5 As shown, a fiber-forming device includes a base 1, and a storage bin 2 is provided on the base 1. The storage bin 2 is connected to a feeding mechanism 3 through a vertical elevator 42, and the lower side of the feeding mechanism 3 is provided There is a negative pressure drum 4, the surface of the negative pressure drum 4 is evenly distributed with through holes, both ends of the negative pressure drum 4 are rotatably connected with an exhaust pipe 5 through a bearing 27, and the air outlet ends of the two exhaust pipes 5 Connected to the same air-gathering pipe 6, the air-gathering pipe 6 is connected to the first cross-flow fan 7. Specifically, the air-gathering pipe 6 has multiple air outlets on the side close to the air inlet of the first cross-flow fan 7 , The air outlet can ensure the uniformity of airflow input; the exhaust duct 5 is erected on the base 1 through two first brackets 8. The base 1 is also provided with a first drive motor 9 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com