Schmidt roof prism processing method and positioning tool thereof

A Technology of Smit Roof and Positioning Tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

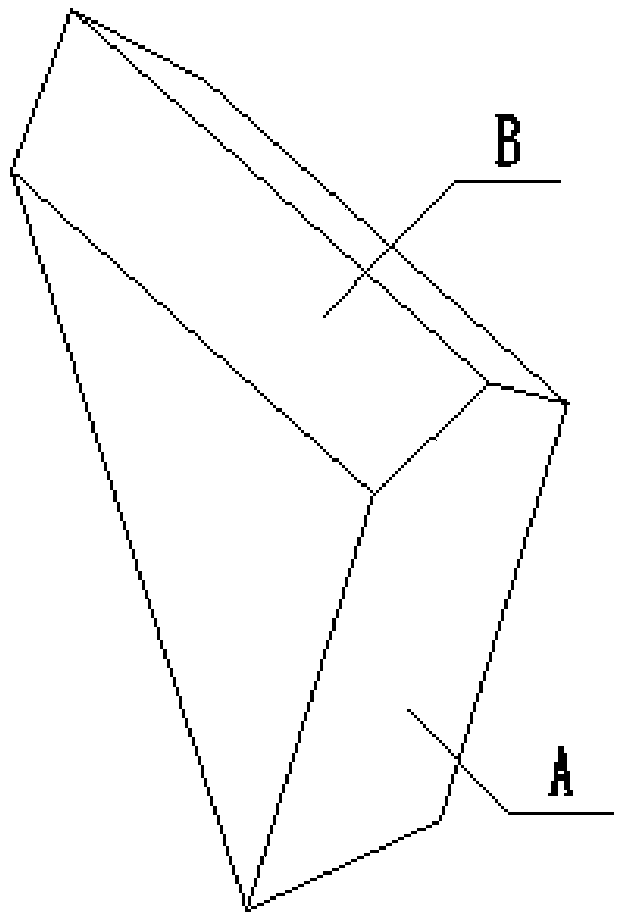

[0050] like figure 2 As shown, the positioning tool of a Schmidt roof prism in this embodiment is specially designed for the controlled positioning of the included angle grinding of the roof surface of the Schmidt roof prism, namely figure 1 The accuracy of the 90° angle of the roof surface B of the shown Schmidt roof prism (before each edge is chamfered) is controlled within 1″. The structure of the tooling will be described below in conjunction with the accompanying drawings.

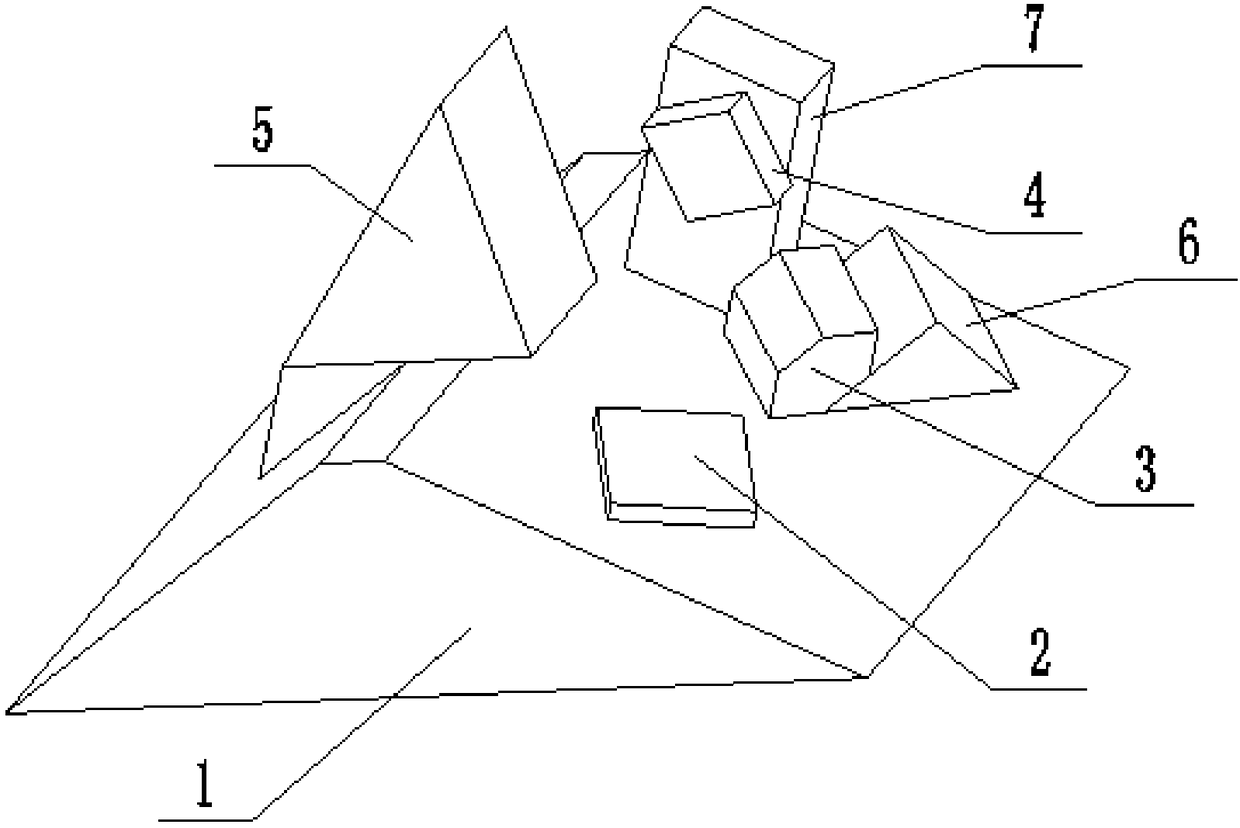

[0051] The positioning tool of this embodiment includes a base plate 1 , a body positioning block 1 , a body positioning block 2 3 , a prism side positioning block 4 , a limit block 5 , a fixed adjustment block 6 and a support block 7 . Among them, the substrate 1 is used as a support base, and the body positioning block 1 2, the body positioning block 2 3, the limit block 5, the fixed adjustment block 6 and the support block 7 are all fixed on the substrate 1 by optical glue, and the substrate 1 Th...

Embodiment 2

[0057] This embodiment provides a kind of processing method of Schmidt roof prism, which is used to process the semi-finished Schmidt roof prism blank, that is, grinding side A and roof surface B, and ensuring that the accuracy of the roof angle is within 1 ". Here The so-called Schmidt roof prism blank means that it has a preliminary shape, but each surface is rough, and generally the margin of each surface is within 0.2mm.

[0058] The specific operation steps of the processing method of the Schmidt roof prism are:

[0059] 1. The first side processing

[0060] Take a square brick body with a 90° accuracy within 20″, wipe the surface with a dust-free paper, and glue one end face of the Schmidt roof prism blank to be processed to the square brick body with 417# optical glue. 4 pieces of prisms can be attached to the body of each square brick, and 40 pieces of prisms are evenly arranged on a glass plate with a diameter of 300mm. They are bonded with 417# optical glue, and the...

Embodiment 3

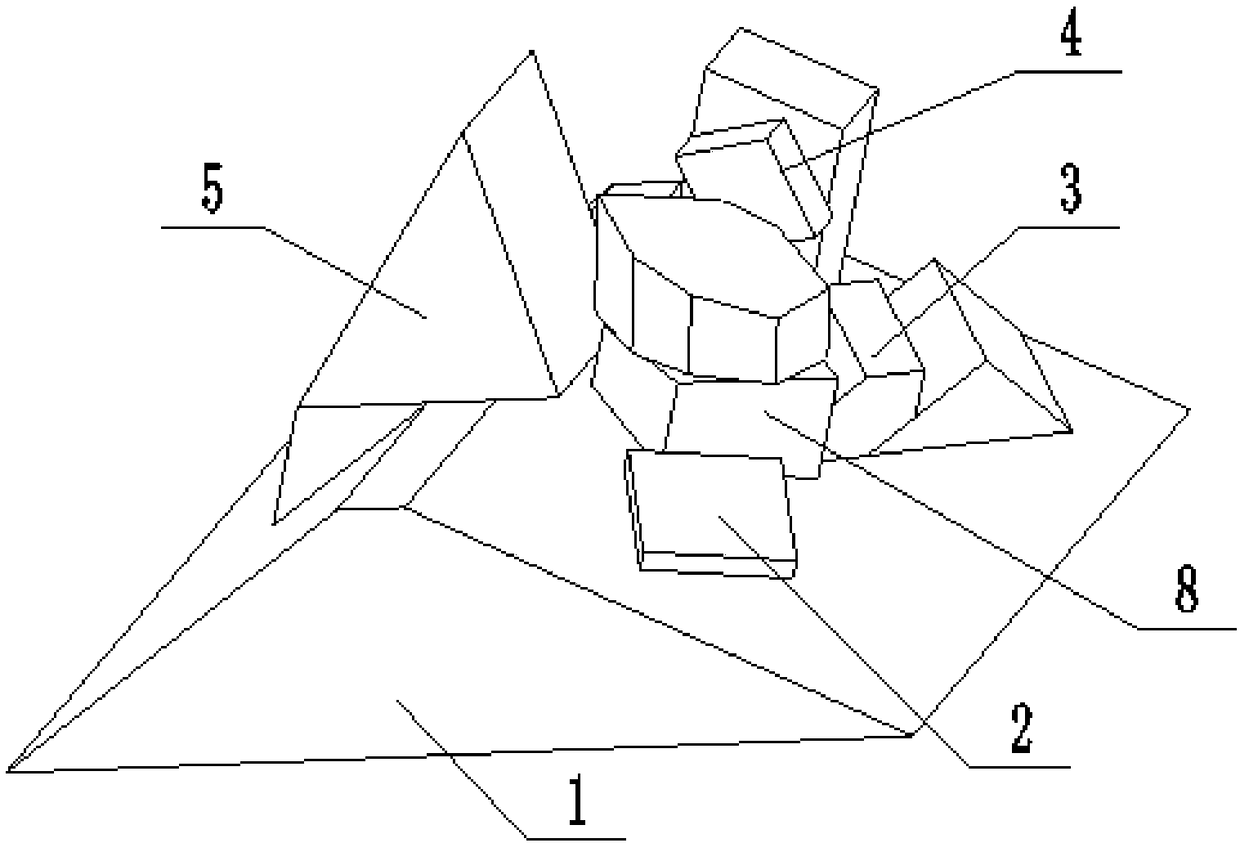

[0076] The present embodiment provides a kind of processing method of Schmidt roof prism, which is basically the same as embodiment 2, the difference is: in the B process of step 2, the side surface of the Schmitt roof prism blank processed through step 1 is used with 500 Purpose Wipe with polishing powder solution, and then use dust-free paper to dip in ether and ethanol according to a 3:1 mixture and wipe clean; the Schmitt roof prism and backing body 8 in step c are sent to the oven and heated at 100°C 8 hours;

[0077] In the process ③ of step 3, the grinding is divided into rough grinding and fine grinding. During rough grinding, the sand particle size is 330 mesh, the grinding speed is 80 rpm, and the feed rate is 9mm / min; the fine grinding sand particle size is 510 mesh, The grinding speed is 65 rpm, and the feed rate is 6.5 mm / min; polishing is divided into rough polishing and fine polishing. Kg pressure; during fine polishing, use a 530-mesh polishing powder solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com