Ferrosilicon block crushing device

A crushing device and iron block technology, applied in grain processing, etc., can solve the problems of high processing cost, low processing efficiency, high flour extraction rate, etc., and achieve the effect of low processing cost, good use effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

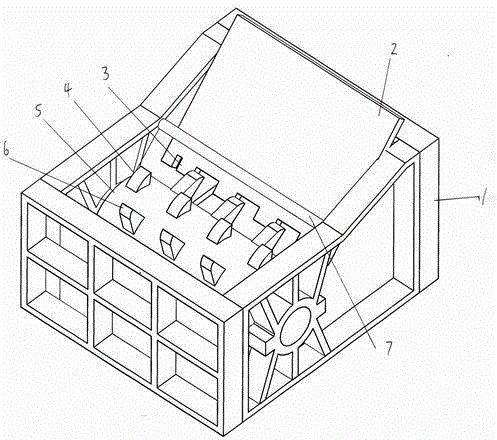

[0007] The embodiment is described in detail in conjunction with the accompanying drawings, a ferrosilicon block crushing device, which includes a frame 1, a fixed tooth plate 2 is provided at the feed port of the frame, and a grinding tooth 3 is provided at the bottom of the fixed tooth plate. There are toothed rollers 5 inside, and high wear-resistant teeth 6 and low wear-resistant teeth 4 are evenly distributed on the toothed rollers. The high wear-resistant teeth and low wear-resistant teeth are distributed at intervals. The distribution of high wear-resistant teeth is consistent with the grinding of fixed tooth plates The tooth distribution positions are staggered, the distribution of low wear-resistant teeth and the grinding teeth of high wear-resistant teeth are staggered, the tooth roller is driven by a motor, and a presser 7 is installed above the fixed tooth plate; The grinding teeth of the fixed tooth plate are made of high-strength material, and the high and low wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com