Degumming method of waste rubber skeleton material

A skeleton material and degumming method technology, which is applied in the degumming field of waste rubber skeleton materials, can solve problems such as difficulty in recycling and poor separation effect, achieve low cost, improve degumming efficiency, and improve the effect of degumming solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

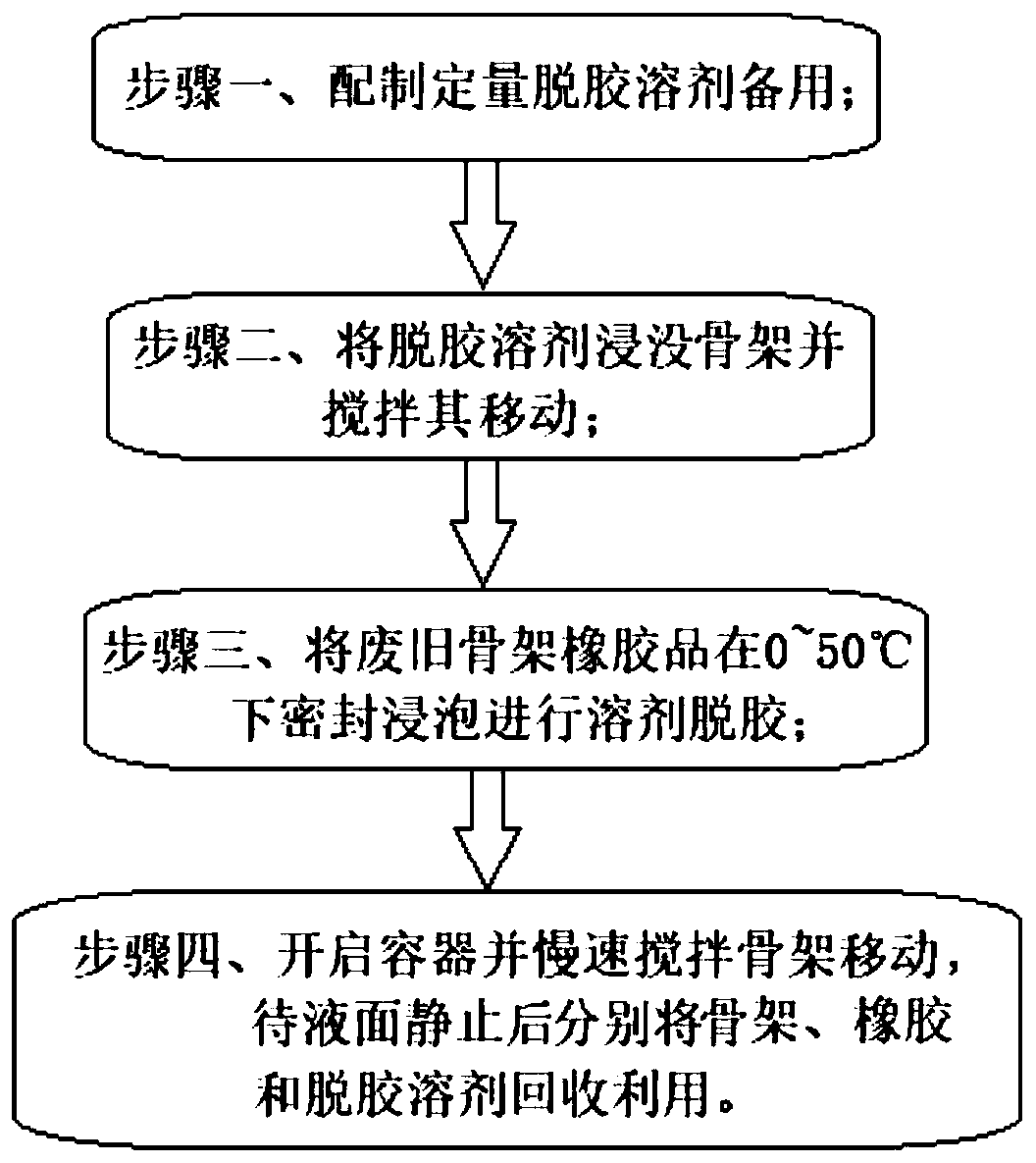

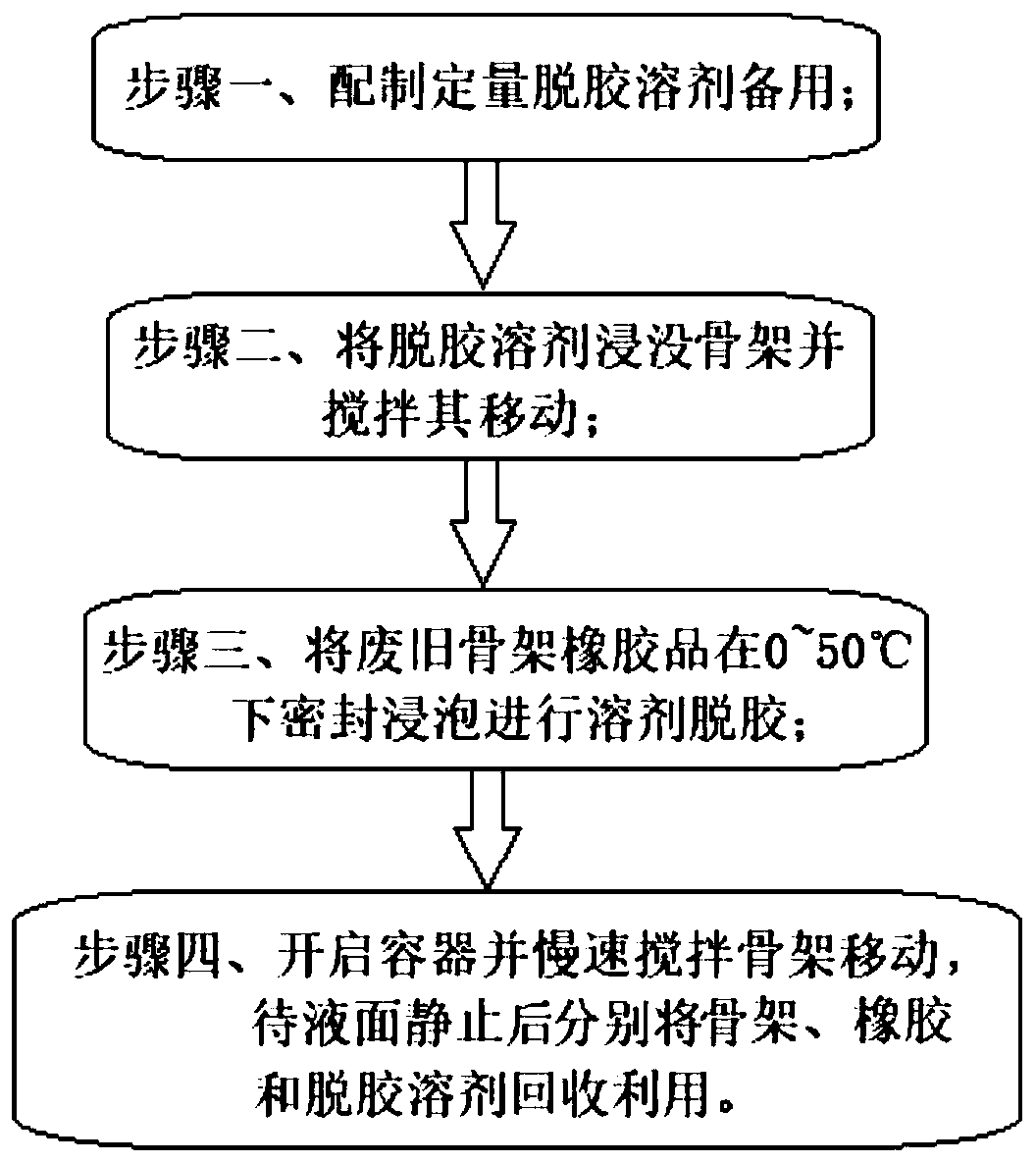

[0035] A kind of degumming method of waste rubber framework material of the present embodiment, comprises the following steps:

[0036] Step 1, prepare quantitative degumming solvent for standby;

[0037] Step 2. Put the waste skeleton rubber product into a sealed container, add degumming solvent until all the skeleton is submerged, and slowly stir the skeleton to move;

[0038] Step 3, seal and soak the waste skeleton rubber product at 0-50°C for a certain period of time, and perform solvent degumming;

[0039] Step 4: Open the container and slowly stir the skeleton to move, and recycle the degumming solvent after the liquid level is still.

[0040] In this embodiment, at first prepare a sealable container, a filter screen, a waste rubber recovery bucket and a skeleton recovery box, and the degumming solvent described in step 1 adopts a mixture of ethyl acetate and xylene, specifically, the degumming solvent includes 85 Parts by weight of ethyl acetate and 15 parts by weigh...

Embodiment 2

[0047] The degumming method of a kind of waste rubber skeleton material of this embodiment, its steps are basically the same as embodiment 1, the difference is: the degumming solvent described in step 1 of this embodiment adopts the mixture of ethyl acetate and xylene, specifically , the degumming solvent includes 80 parts by weight of ethyl acetate and 16 parts by weight of xylene, each raw material is measured according to the above mass percentage to prepare the degumming solvent for subsequent use, and then the standard waste skeleton rubber product is ready to be pulled off and peeled off. This implementation In the example, the waste skeleton rubber product is ethylene propylene rubber, the thickness of the rubber on the bonding surface of the waste skeleton rubber product is 10mm, and the size of the rubber bonding surface is a circular plane of φ30mm.

[0048] According to the above steps, place the waste skeleton rubber product in a large enough container, and then add...

Embodiment 3

[0054] The degumming method of a kind of waste rubber framework material of this embodiment, its steps are basically the same as embodiment 2, the difference is: the degumming solvent described in step 1 of this embodiment adopts the mixture of ethyl acetate and xylene, specifically , the degumming solvent includes 75 parts by weight of ethyl acetate and 25 parts by weight of xylene, the raw materials are measured according to the above mass percentages to prepare the degumming solvent for subsequent use, and then the standard waste skeleton rubber product is ready to be pulled off and peeled off. This implementation In the example, the waste skeleton rubber product is natural rubber, the thickness of the rubber on the bonding surface of the waste skeleton rubber product is 15mm, and the size of the rubber bonding surface is a semicircular plane of φ40mm.

[0055] According to the above steps, place the waste skeleton rubber product in a large enough container, and then add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com