Multifunctional liquid efficient fuel-coal sulfur-fixing agent and preparation method thereof

A multi-functional, sulfur-fixing agent technology, applied in fuel additives, fuels, solid fuels, etc., can solve the problems of reducing soil fertilizer efficiency, high operating costs, and high costs, and achieves excellent application prospects, wide application range, and guaranteed service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

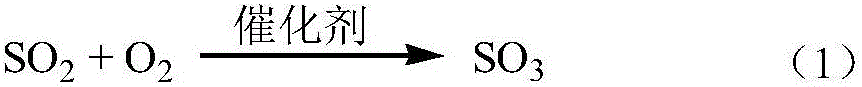

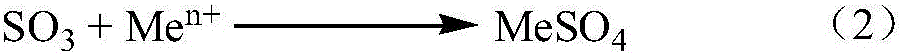

Method used

Image

Examples

Embodiment 1

[0027] A liquid multifunctional high-efficiency coal-burning sulfur-fixing agent, comprising the following substances in weight percentages: 1% of lanthanum oxide, 0.7% of cerium oxide, 0.6% of vanadium pentoxide, 1% of nanometer titanium oxide, 0.5% of nanometer zinc oxide, 0.5% of nanometer Nickel oxide 0.3%, nano calcium carbonate 1.5%, nonylphenol polyoxyethylene ether 2%, octylphenol polyoxyethylene ether 3%, fatty alcohol polyoxyethylene ether 1%, oily penetrant 12%, polyethylene glycol Alcohol monooleate 7%, glycerol 8%, polymeric polyol 10%, propylene glycol polyoxyethylene polyoxypropylene ether 9%, dimethylpolysiloxane polyether 6%, sorbitan monooleate 7%, the balance is diethylene glycol.

[0028]The preparation process of the liquid multifunctional high-efficiency coal-burning sulfur-fixing agent of the present invention is as follows:

[0029] Lanthanum oxide, cerium oxide, diethylene glycol, nano-titanium oxide and nano-nickel oxide, vanadium pentoxide, nano-cal...

Embodiment 2

[0033] A liquid multifunctional high-efficiency coal-burning sulfur-fixing agent, comprising the following substances by weight: 1.2% of lanthanum oxide, 0.5% of cerium oxide, 0.6% of vanadium pentoxide, 0.9% of nanometer titanium oxide, 0.6% of nanometer zinc oxide, 0.6% of nanometer Nickel oxide 0.2%, nano calcium carbonate 1.8%, nonylphenol polyoxyethylene ether 2.5%, octylphenol polyoxyethylene ether 3.2%, fatty alcohol polyoxyethylene ether 1%, oil penetrant 11%, polyethylene glycol Alcohol monooleate 7%, glycerol 8%, polymeric polyol 9%, propylene glycol polyoxyethylene polyoxypropylene ether 8%, dimethylpolysiloxane polyether 6%, sorbitan monooleate 6%, the balance is diethylene glycol.

[0034] The preparation process is the same as that in Example 1.

[0035] The following tests are carried out to the coal-fired sulfur-fixing agent product prepared by the present embodiment:

[0036] Take 50kg of pulverized coal, 50kg of pulverized coal + 50g of sulfur-fixing agent ...

Embodiment 3

[0038] A liquid multifunctional high-efficiency coal-burning sulfur-fixing agent is composed of the following weight percentages: lanthanum oxide 0.5%, cerium oxide 0.2%, vanadium pentoxide 0.1%, nano-titanium oxide 0.2%, nano-zinc oxide 0.5%, nano- Nickel oxide 0.2%, nano calcium carbonate 0.6%, nonylphenol polyoxyethylene ether 1%, octylphenol polyoxyethylene ether 1%, fatty alcohol polyoxyethylene ether 0.5%, oil penetrant 10%, polyethylene glycol Alcohol monooleate 5%, glycerol 7%, polymeric polyol 7%, propylene glycol polyoxyethylene polyoxypropylene ether 8%, dimethylpolysiloxane polyether 5%, sorbitan monooleate 6%, the balance is diethylene glycol.

[0039] The preparation method is the same as in Example 1.

[0040] The following tests are carried out to the coal-fired sulfur-fixing agent product prepared by the present embodiment:

[0041] Take 50kg of pulverized coal, 50kg of pulverized coal + 50g of sulfur-fixing agent respectively, mix the sulfur-fixing agent an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com