Patents

Literature

30results about How to "Good adhesion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

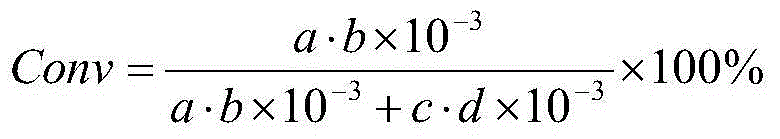

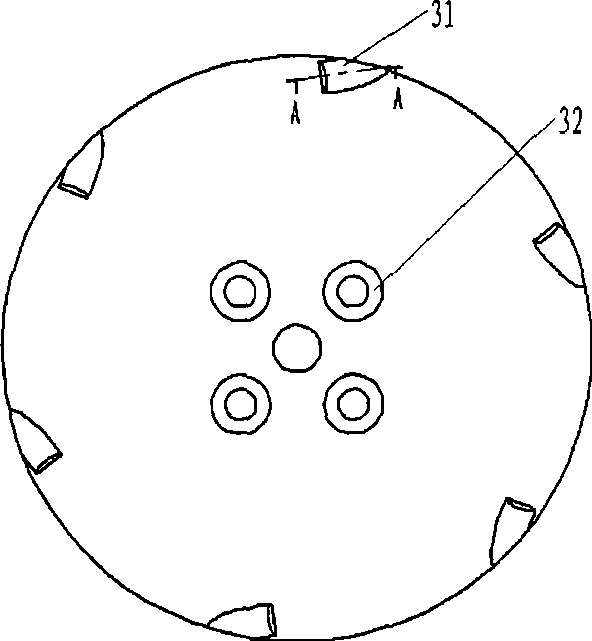

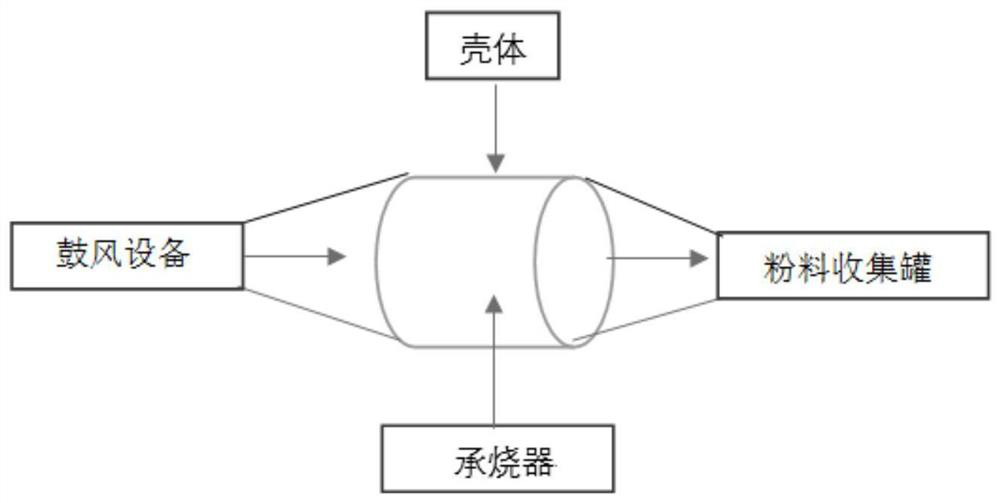

Preparation method of catalyst used for chlorine preparation, catalyst, and method used for preparing chlorine

ActiveCN104785271AImprove liquidityHigh activityHeterogenous catalyst chemical elementsCatalyst activation/preparationRare-earth elementPtru catalyst

The present invention relates to a method for preparing catalyst used for preparing chloride by oxidizing hydrogen chloride. The method is mixing a slurry mainly containing boron and chromium with a slurry mainly containing copper, boron, alkali-metal elements, rare-earth elements, aluminum sol, silica sol, carrier and optionally other metal elements, the mixing temperature being not more than 100℃, and the residence time being not more than 120 minutes, the mixed slurry is successively treated with spray drying, high temperature calcination and the like, so that catalyst particles is obtained. The present invention also relates to the catalyst prepared through the method, uses of the catalyst used in the process of preparing chloride by oxidizing hydrogen chloride and a method for preparing chlorine by using the catalyst. The catalyst is used for preparing chlorine by oxidizing hydrogen chloride with oxygen or air in fluidized bed reactor, and has an excellent activity and anti-caking property, a relatively good mechanical strength and a relatively long service life.

Owner:WANHUA CHEM GRP CO LTD

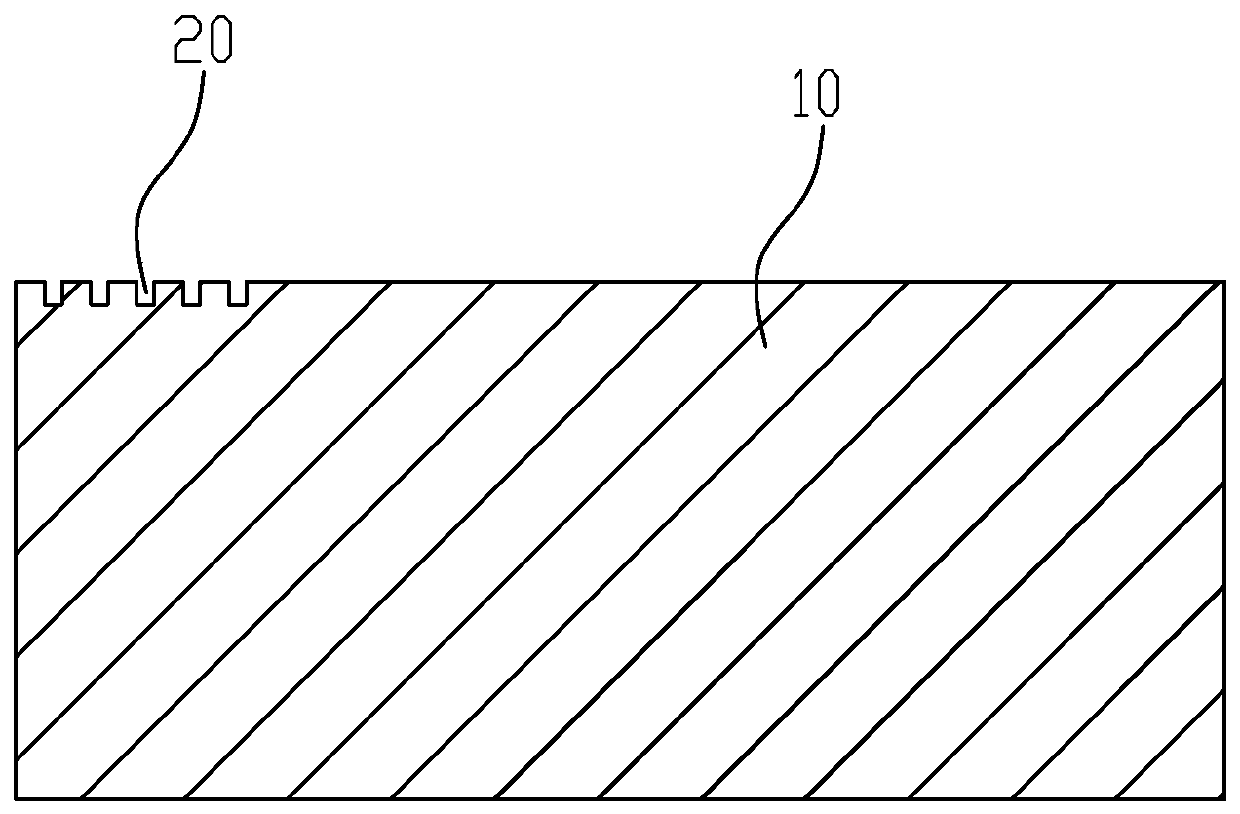

Fabrication process of stepped circuit board

InactiveUS20140304977A1Reduce gapSmall coefficientElectronic circuit testingPrinted circuit aspectsCopper platingSolder mask

A fabrication process of a stepped circuit board, comprises the following steps of: A) cutting a circuit board substrate, printing patterns on an inner layer thereof, performing etching, stepped groove grinding, washer milling, brownification and lamination processing on the inner layer, and then drilling holes on an outer layer thereof; B) depositing copper on the outer layer of the circuit board substrate with drilled holes, and then electroplating the entire circuit board substrate; C) performing pattern transfer; D) performing pattern copper plating on the circuit board substrate, and grinding the shape of a connecting piece (SET) on the circuit board substrate, and then etching the outer layer; E) printing a solder mask and texts in a silk-screen manner; F) depositing nickel immersion gold on the entire substrate, then printing characters in a silk-screen manner; and G) testing and inspecting the electrical performance and appearance of a finished board.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

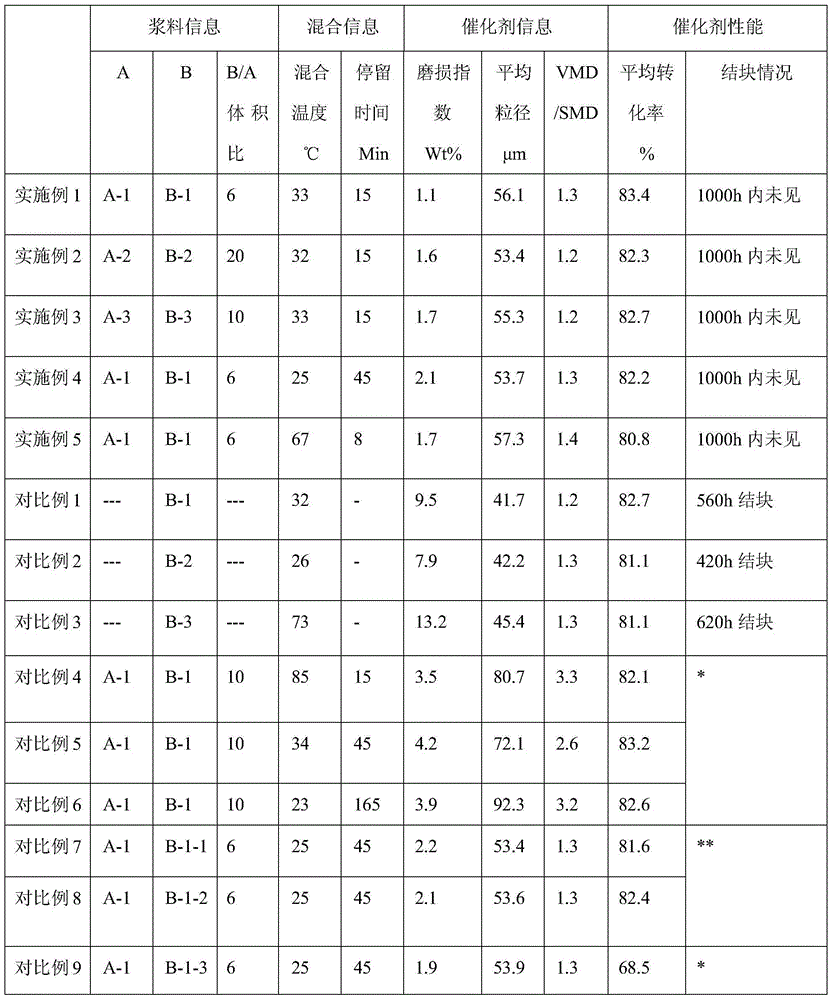

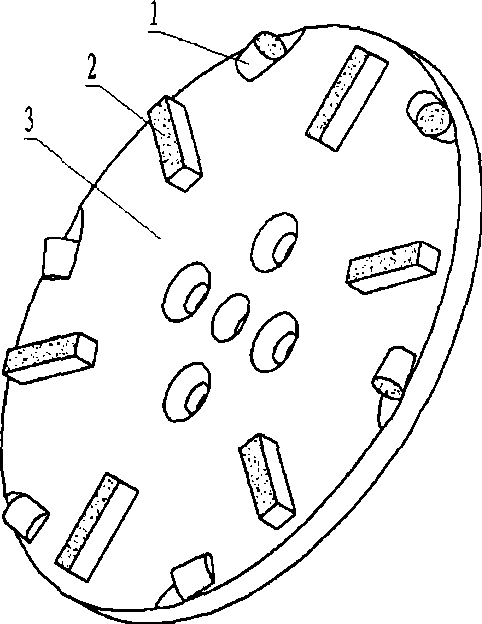

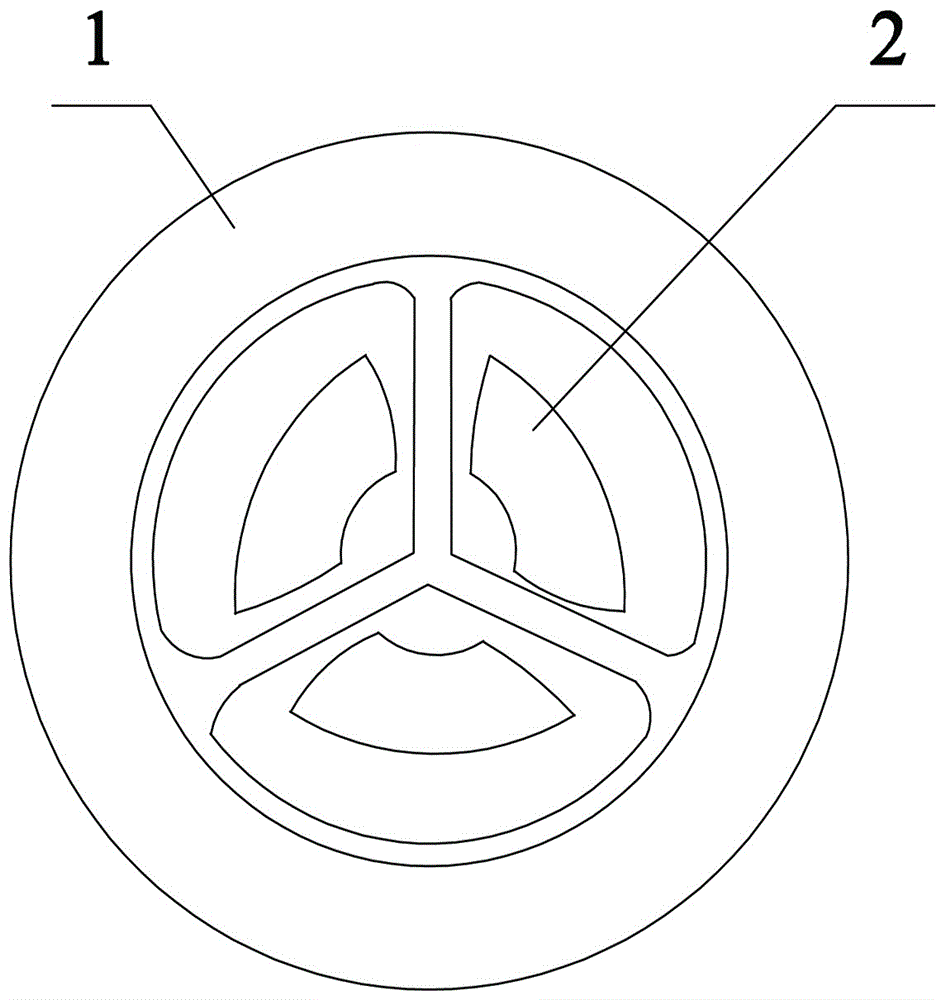

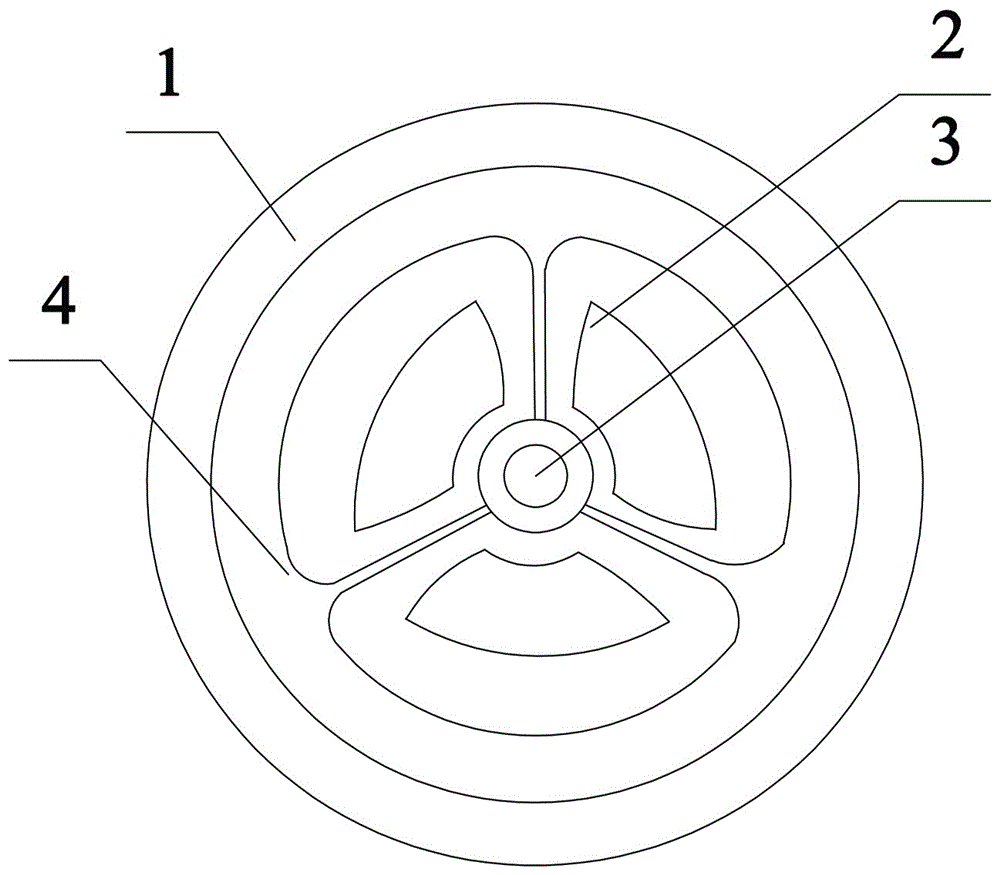

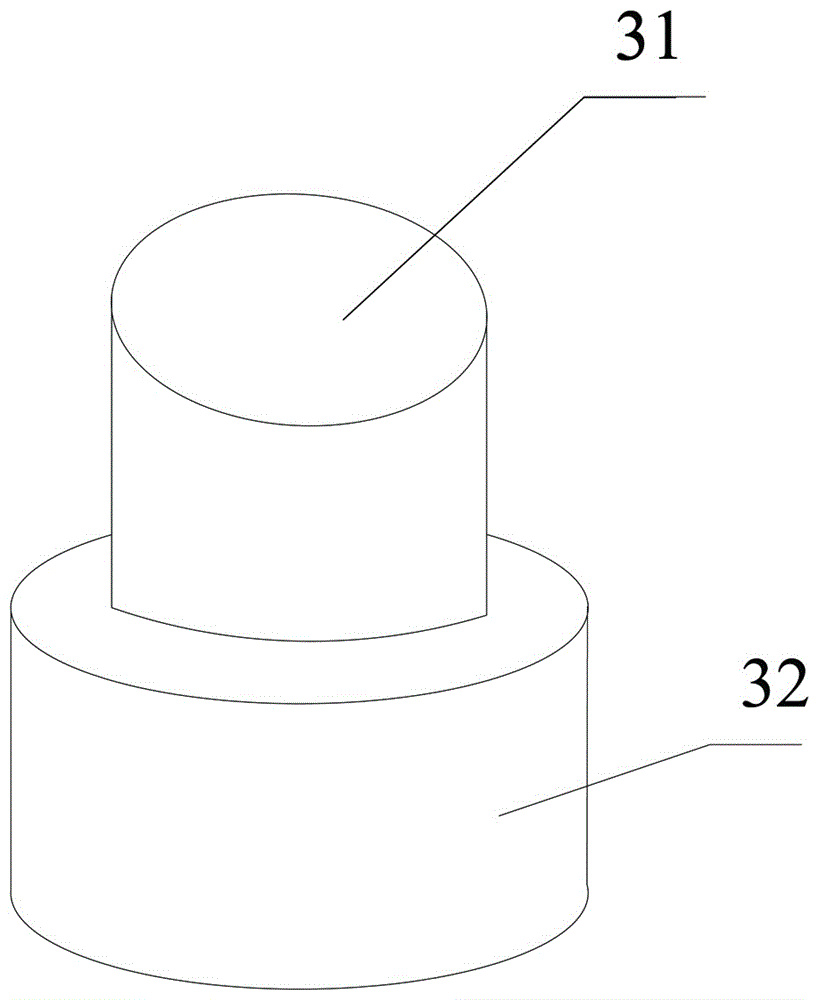

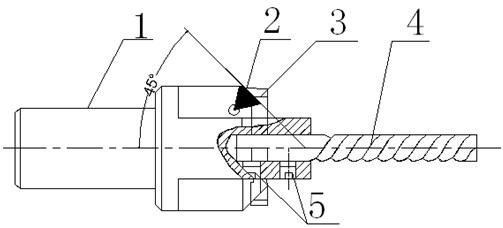

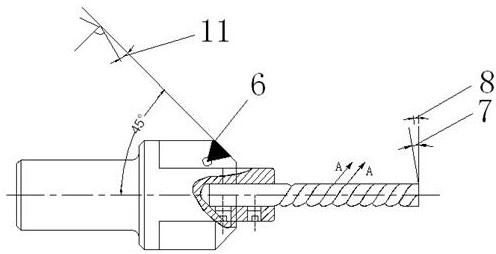

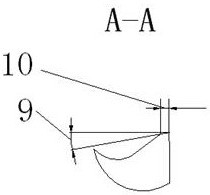

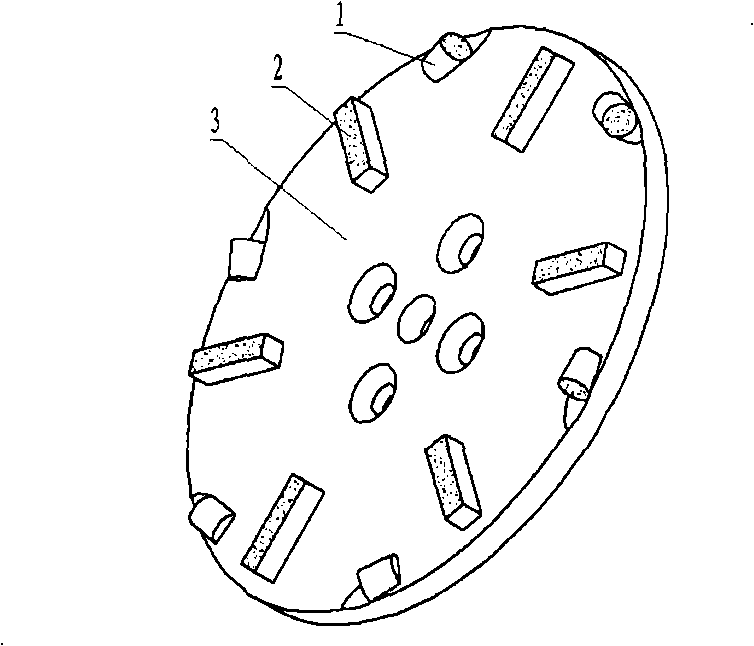

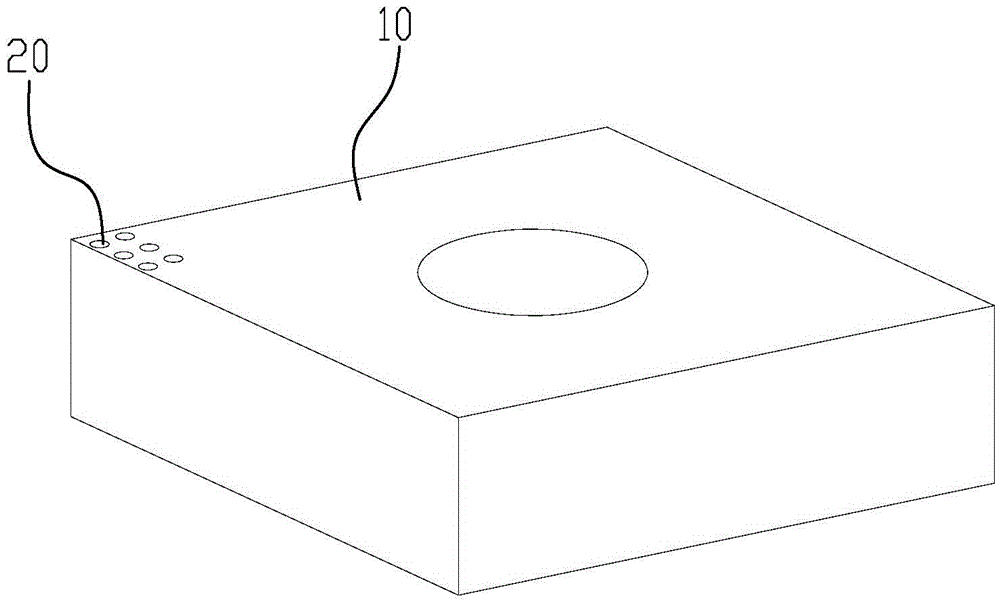

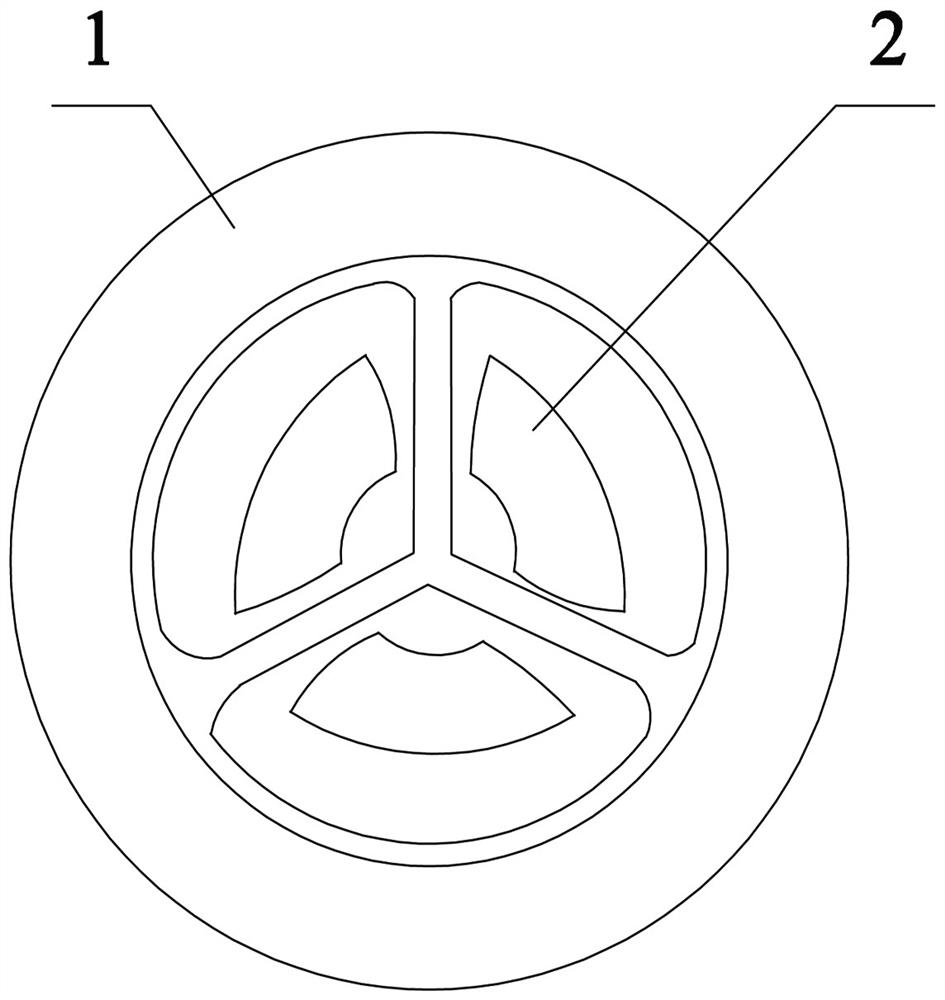

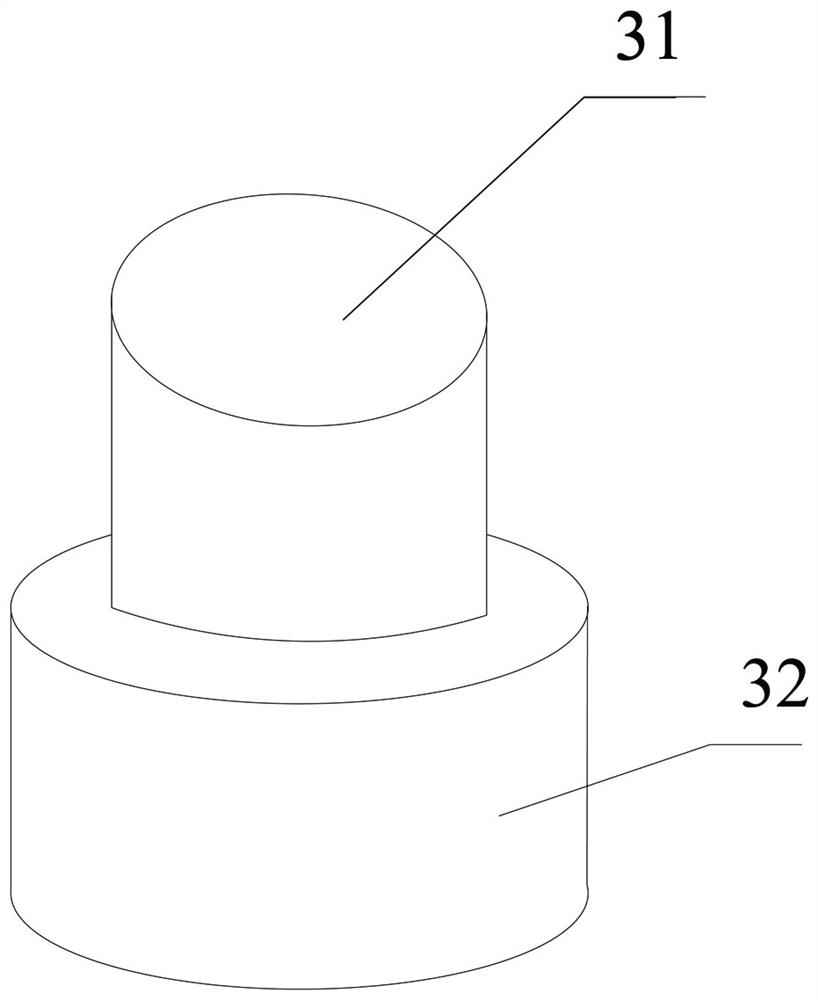

Superhard material cutting tool and preparation method thereof

ActiveCN101502926AGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

The invention relates to a superhard material cutting tool and a preparation method thereof, which belongs to the technical field of superhard material. The superhard material cutting tool comprises a steel matrix and a cutting tool bit. The cutting tool bit consists of a polycrystalline diamond compact (1) and a diamond tool bit (2); 1 to 12 inclined cylindrical tanks used for welding the diamond compact are distributed on the outer circle surface of the steel matrix, and the center line of the inclined cylindrical tank forms a cutting angle with the cutting face; the diamond tool bit is welded on the surface of the steel matrix. The polycrystalline diamond compact is combined by PCD and cemented carbide matrix and is sintered from the mixture of diamond and the metal powder after being compacted; the structure thereof is in the shape of cylinder, ladder or squareness; the fringe area of the clad compact is the cutting blade. The superhard material cutting tool solves the materials hard to be processed in the cutting field, and ensures the surface of the machined part free of burr, nick, spray and chatter mark; the cutting and grinding combination not only improves the cutting speed, but also ensures the cutting quality.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

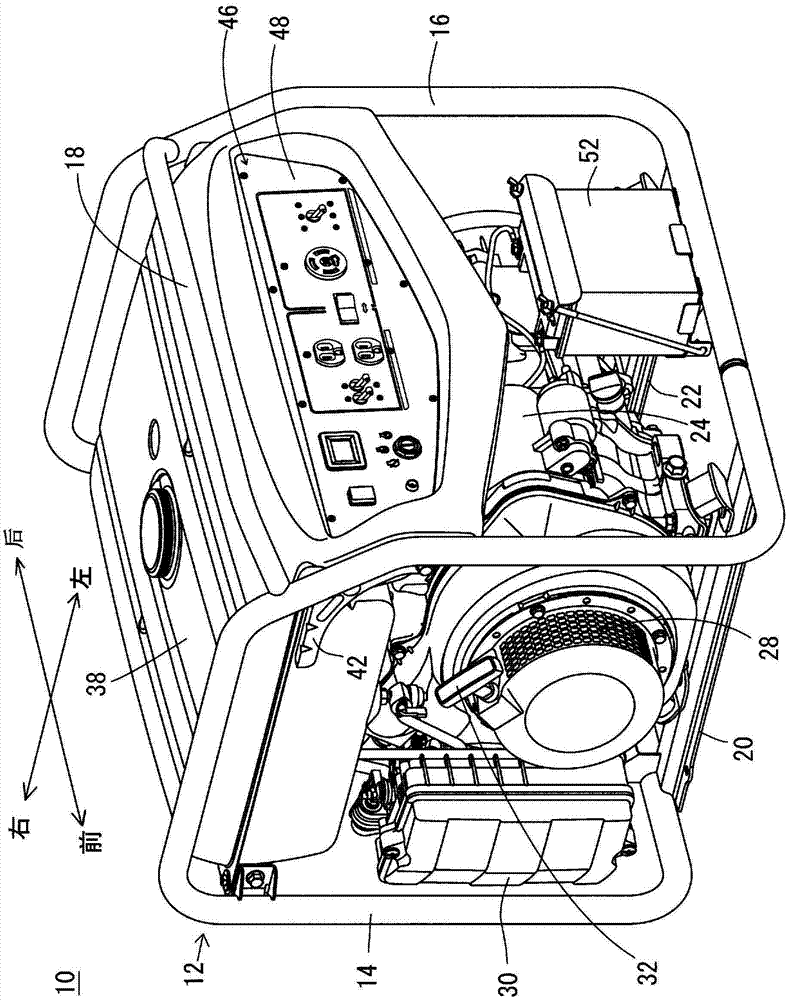

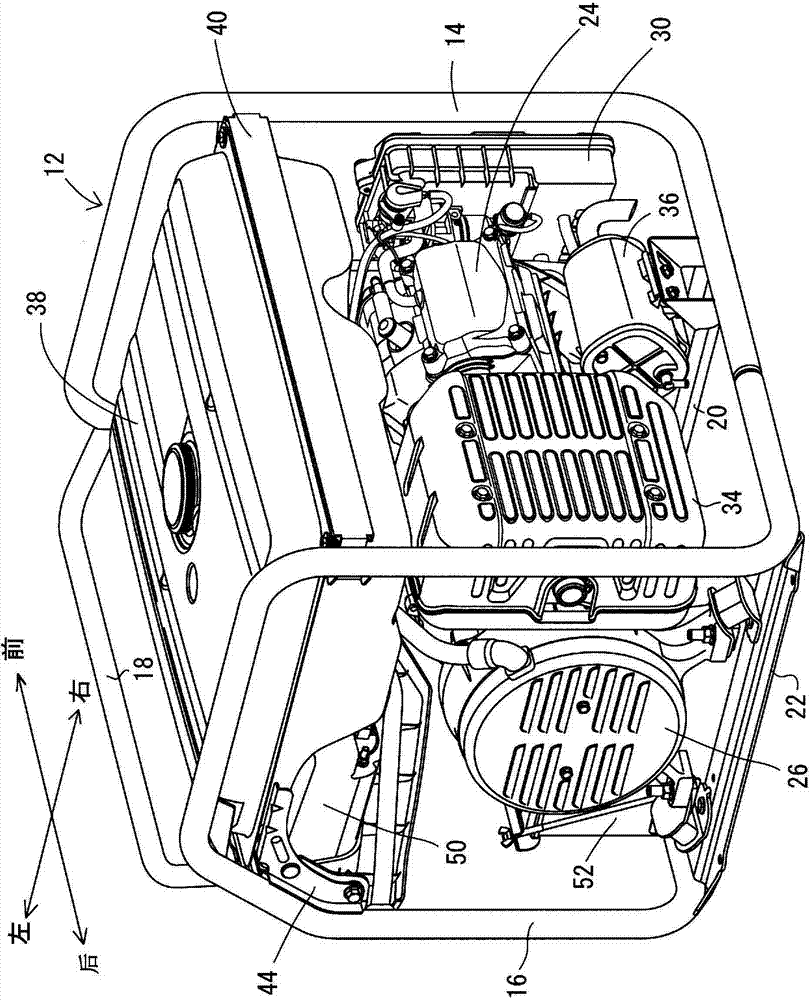

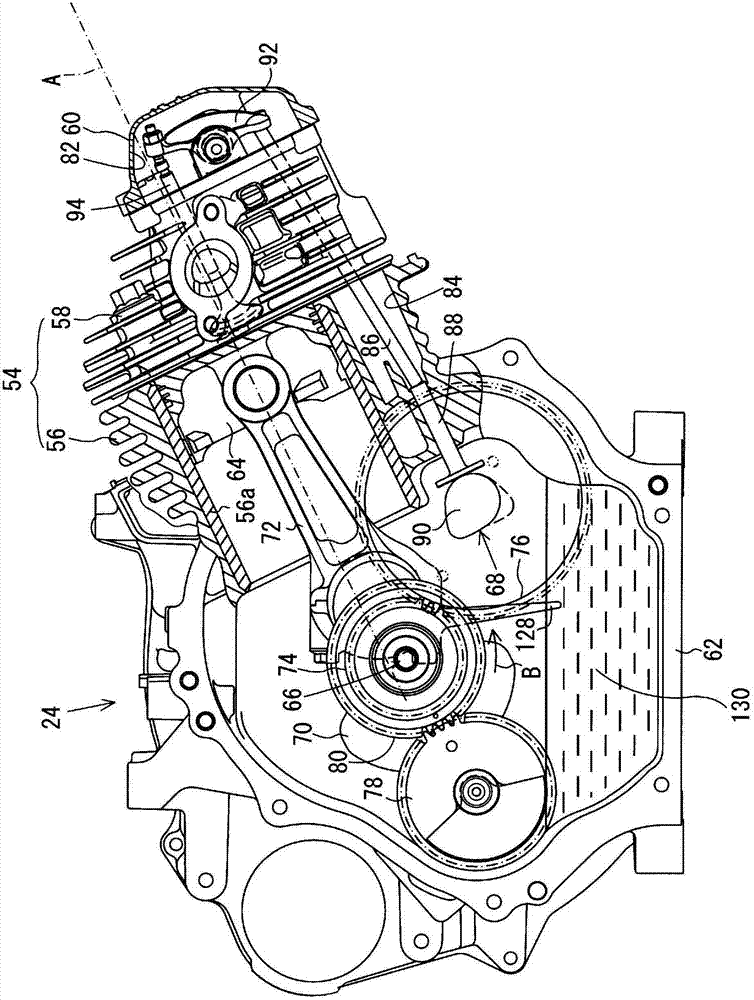

Engine

InactiveCN104514594AEasy to moveImprove cooling effectCasingsConnecting rodsCrankcaseMechanical engineering

An engine includes a piston inside a cylinder, a crank shaft, a connecting rod, an oil dipper provided in a big end portion of the connecting rod, and a piston pin which connects pin boss regions of the piston to a small end portion of the connecting rod, and a crank case. The piston pin is rotatably movable with respect to the pin boss regions and the connecting rod. There are counter regions between the small end portion and the piston pin, a first counter region on a side closer to a tip portion of the connecting rod and a second counter region on a side closer to the big end portion of the connecting rod. The first counter region includes two ends located farther inward than two ends of the second counter region in an axial direction of the piston pin.

Owner:YAMAHA MOTOR POWER PROD KK

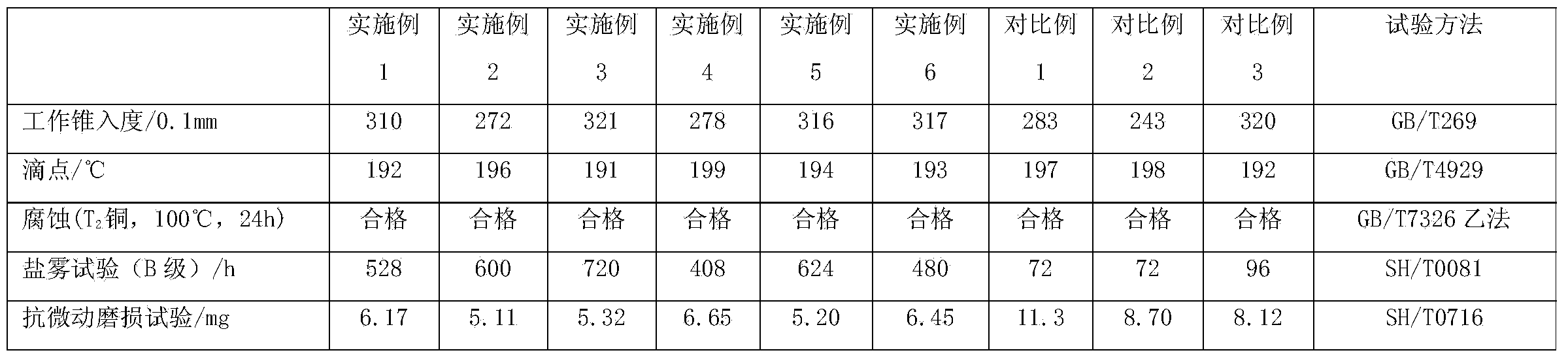

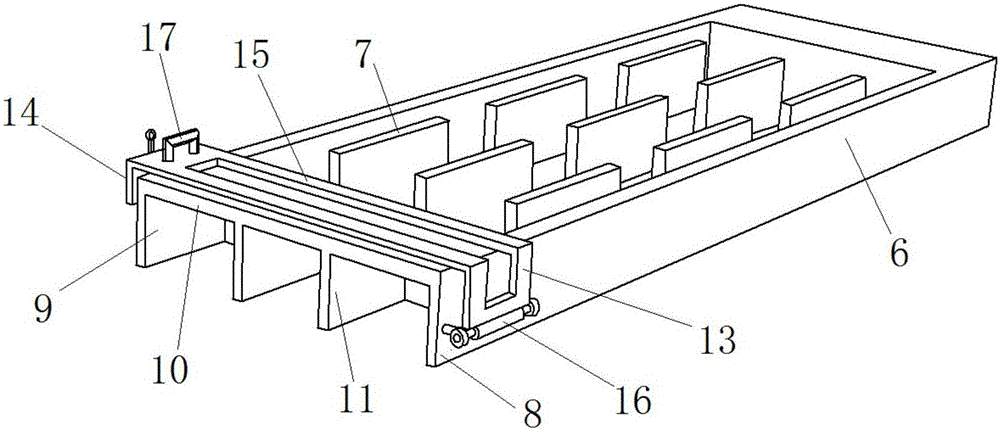

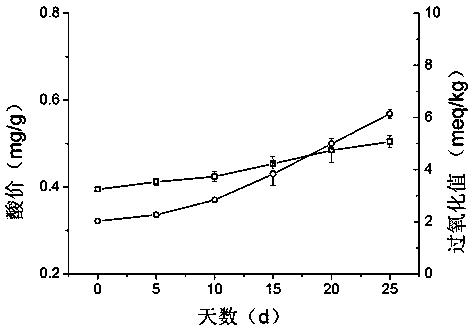

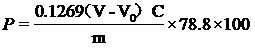

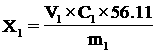

Grease composition for assembling standard sections of tower crane and preparation method of grease composition

ActiveCN104164289AImprove wear reduction performanceGood adhesion resistanceLubricant compositionLithiumSulfonate

The invention relates to a grease composition for assembling standard sections of a tower crane and a preparation method of the grease composition. The grease composition comprises the following components in percentage by weight: 78.8%-94.8% of common lithium-based grease, 0.2%-0.8% of antioxidant, 0.8%-3.2% of graphite powder, 1.0%-4.5% of light calcium carbonate, 0.5%-3.0% of sorbitan monooleate, 0.4%-2.2% of phenolic resin, 2.0%-6.0% of sulfonate and 0.3%-1.5% of polyisobutene. The special grease composition for assembling the standard sections of the tower crane is obtained by adding additives such as the antioxidant, an antifriction agent, an anti-locking and anti-occluding agent, an anti-rust agent, a tackifying agent and the like into the common lithium-based grease taken as a carrier. According to the grease composition, the corrosion speed of shaft pins of the tower crane can be slowed, the shaft pins are prevented from being corroded and bonded with a shaft sleeve during building construction, and the pin shafts of the standard sections of the tower crane can be smoothly assembled and disassembled. The service cycle of the grease composition is within 1-2 years.

Owner:CHINA PETROLEUM & CHEM CORP

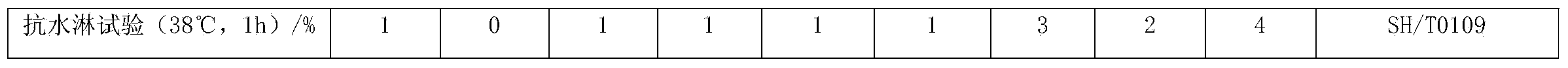

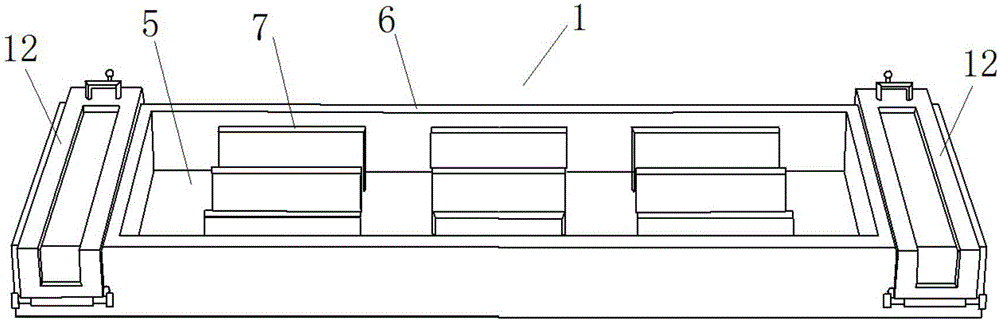

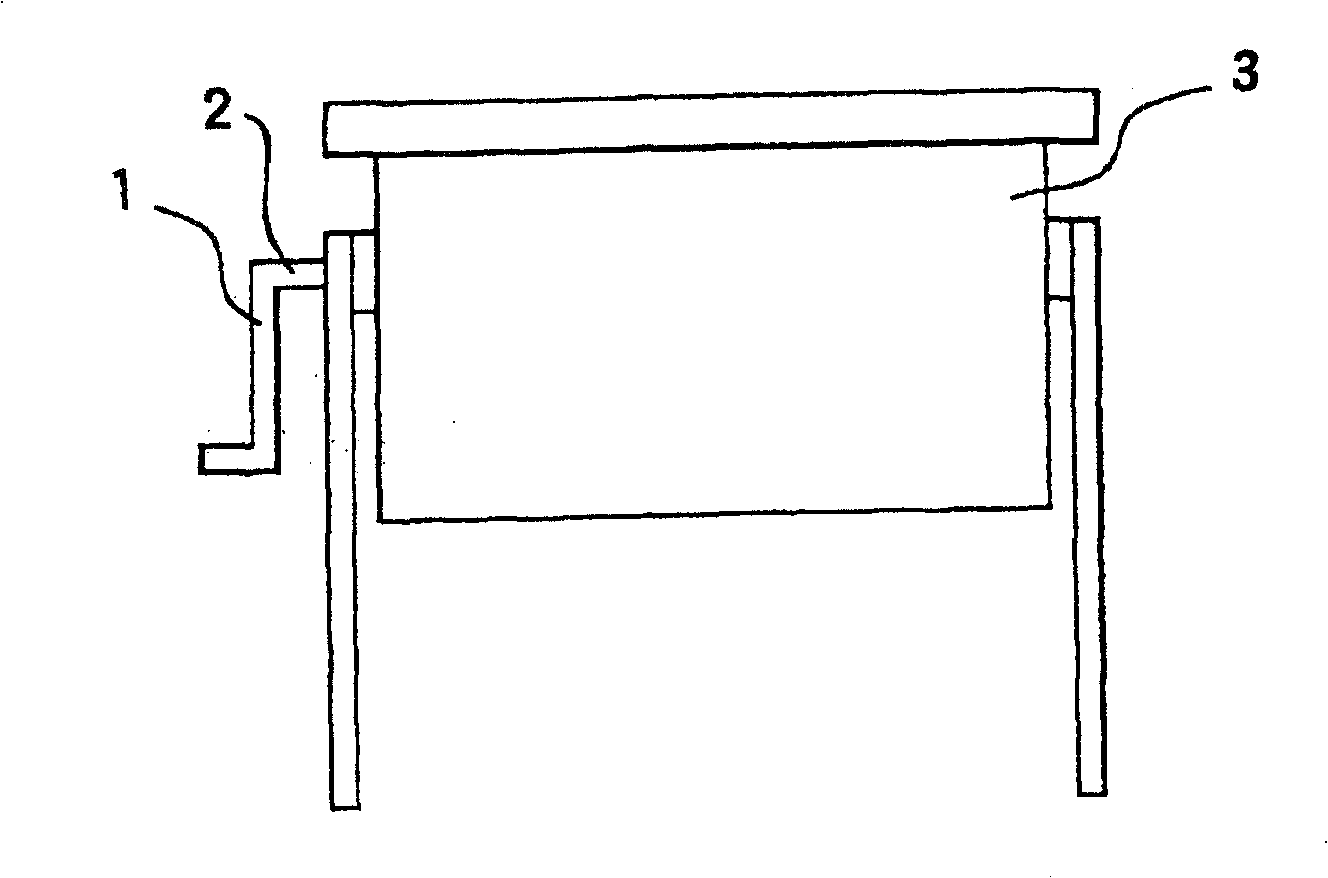

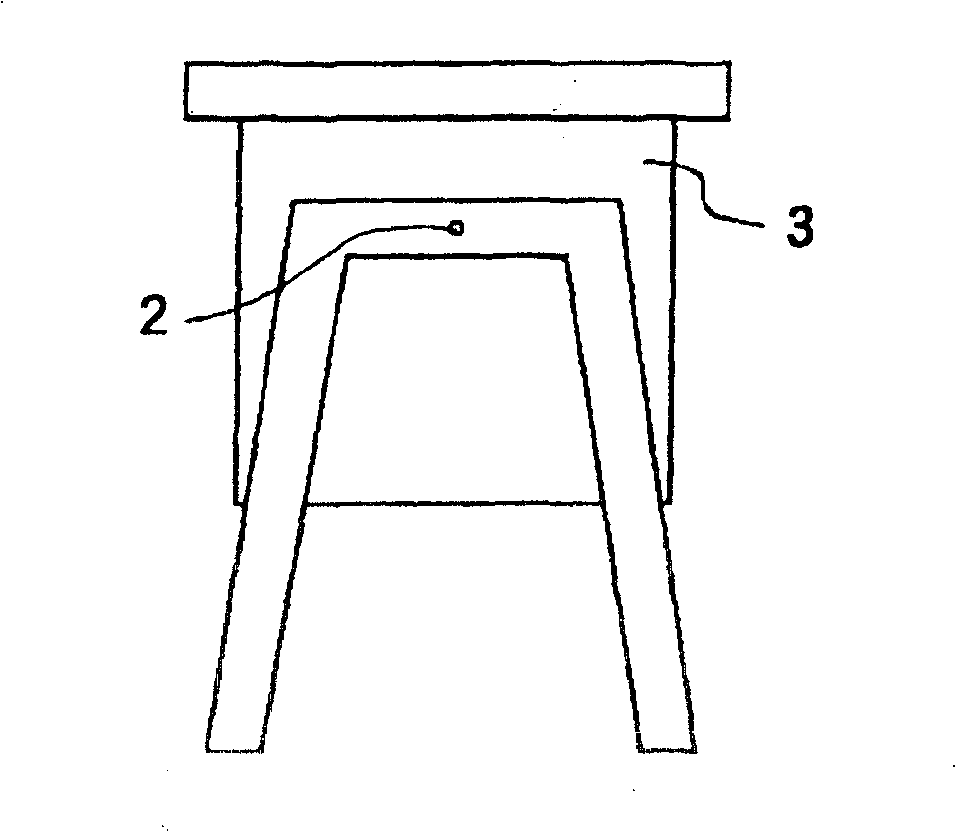

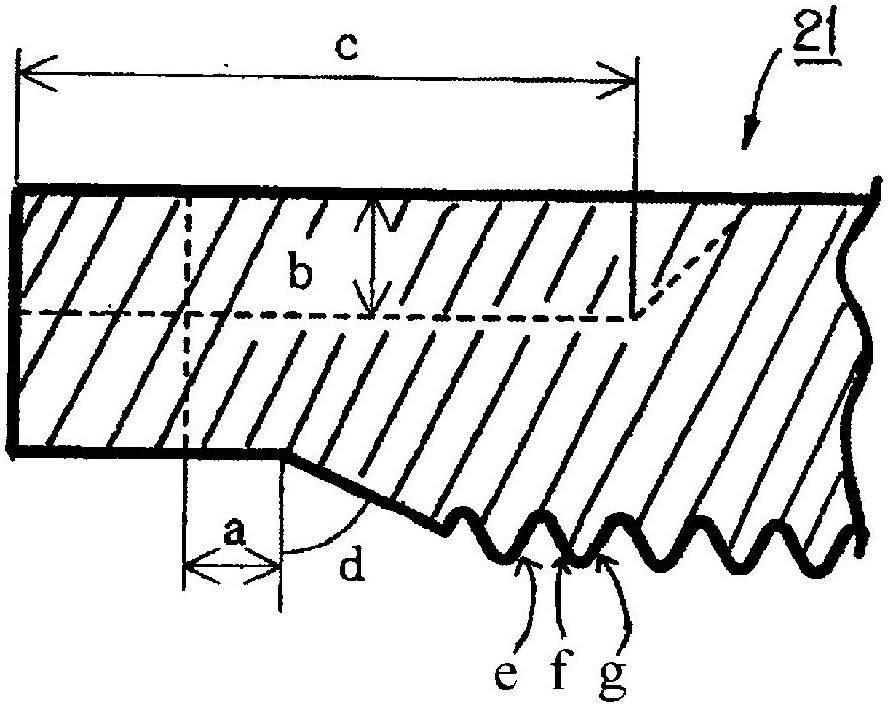

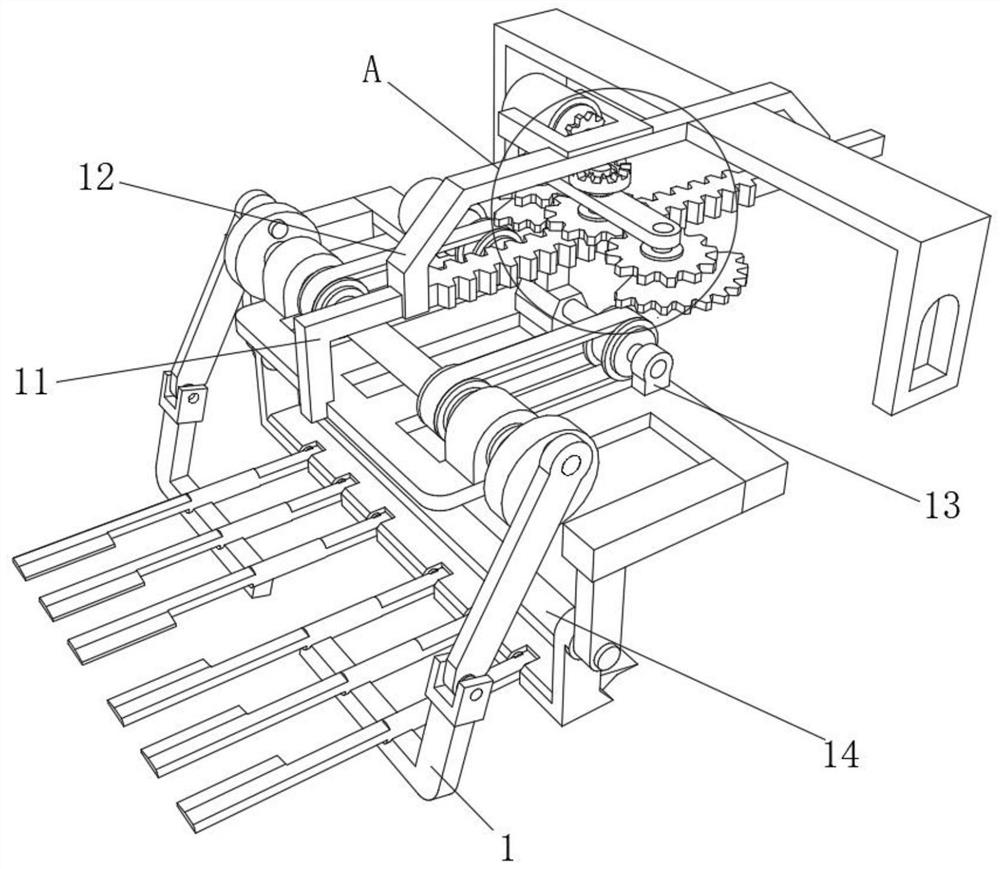

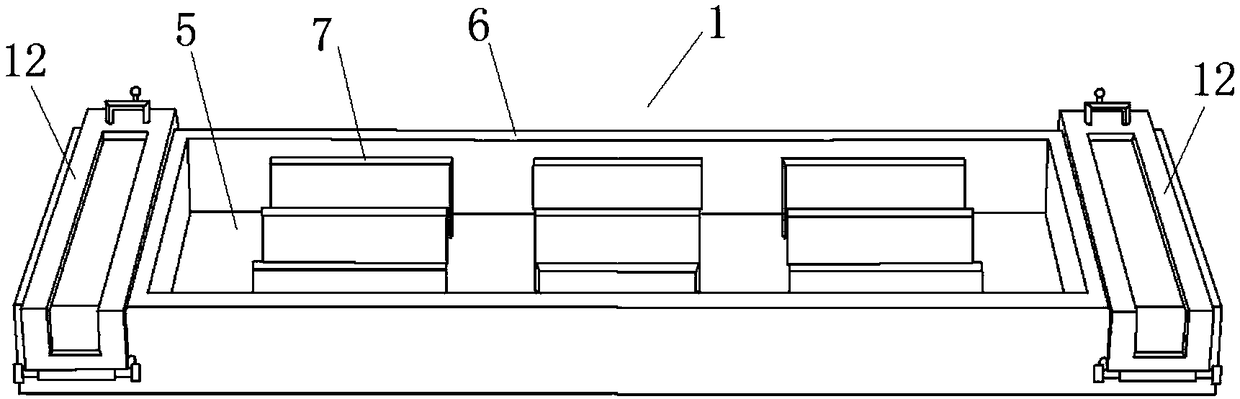

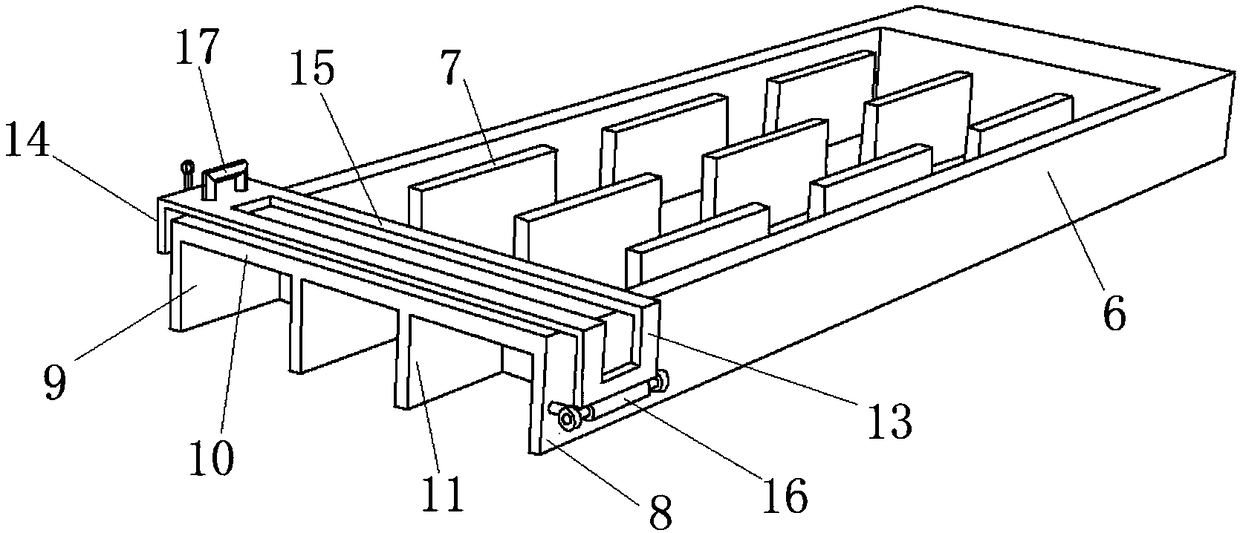

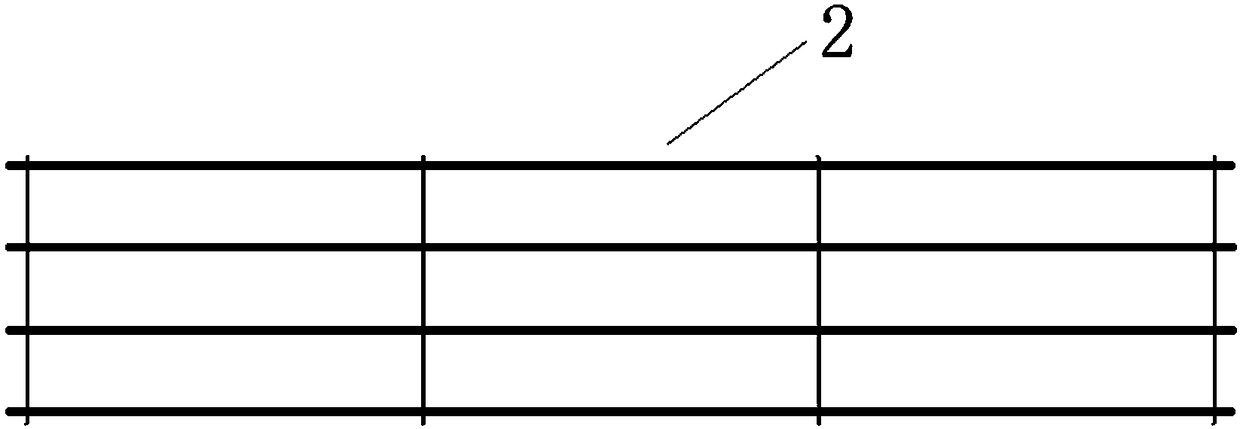

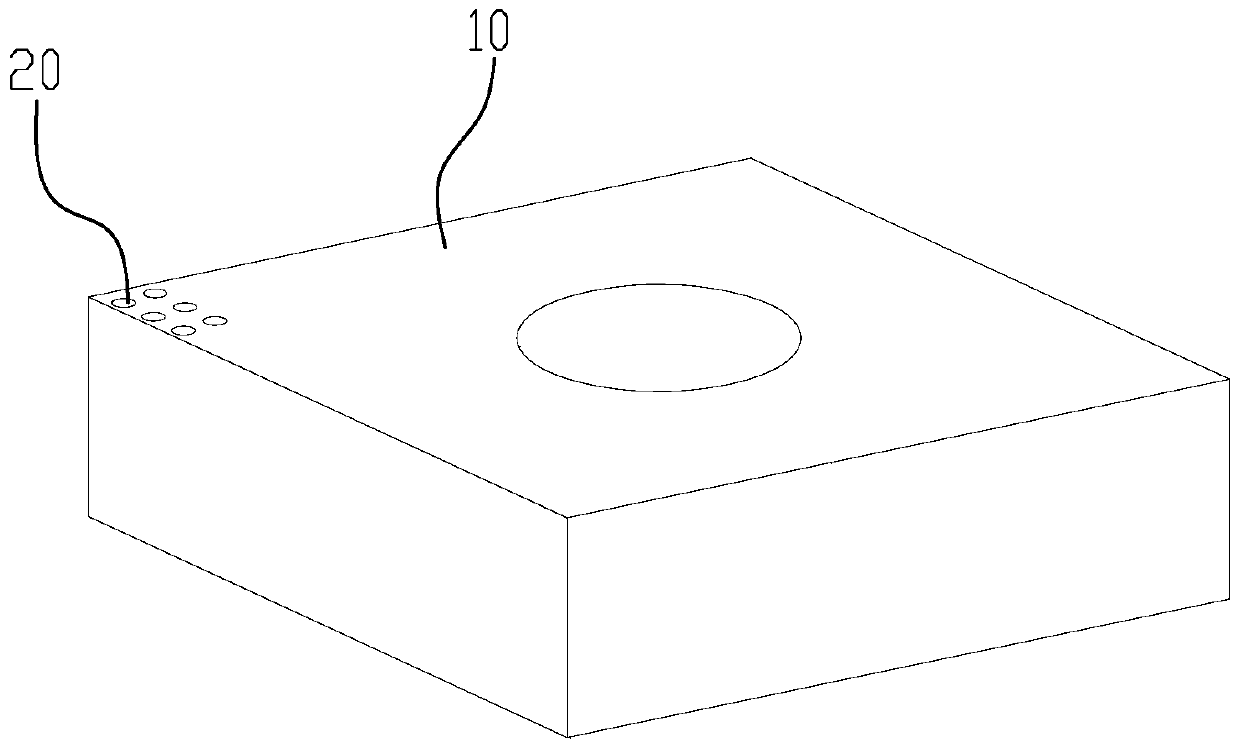

Mold assembly for manufacturing concrete narrow-gap slatted floor and application of mold assembly

ActiveCN106182362AStable structureNot easy to fall offMould auxillary partsFlooringIsolation layerThin layer

The invention belongs to the technical field of building materials and particularly relates to a mold assembly for manufacturing a concrete narrow-gap slatted floor and application of the mold assembly. The mold assembly comprises a mold and an isolating layer, wherein the mold comprises a base plate and a frame; the frame is formed by assembling four square side plates which are vertically arranged at the periphery of the base plate; a plurality of molding plates are vertically arranged on the base plate; and the isolating layer is attached to the base plate and the side plates. According to the mold assembly disclosed by the invention, the concrete narrow-gap slatted floor is produced by adopting the following method: firstly, uniformly spreading one thin layer of fine sands on the isolating layer, pouring a layer of concrete into the mold assembly and then starting a vibrating table for vibrating; secondly, putting the reinforcing mesh into the mold assembly, and continuously pouring concrete into the mold; when the concrete spills over the reinforcing mesh and is stacked to the top of the mold, plattening the top of the concrete and putting two reinforcing bars into the mold assembly; thirdly, uniformly spreading one layer of carborundum on the surface of the plattened concrete, and immediately turning over and demolding after plattening and forming, thus obtaining a finished product. According to the concrete narrow-gap slatted floor manufactured by adoption of the mold assembly, the pitted surface of the narrow-gap slatted floor surface can be effectively reduced, and surface quality of the floor is improved.

Owner:CHINA AGRI UNIV

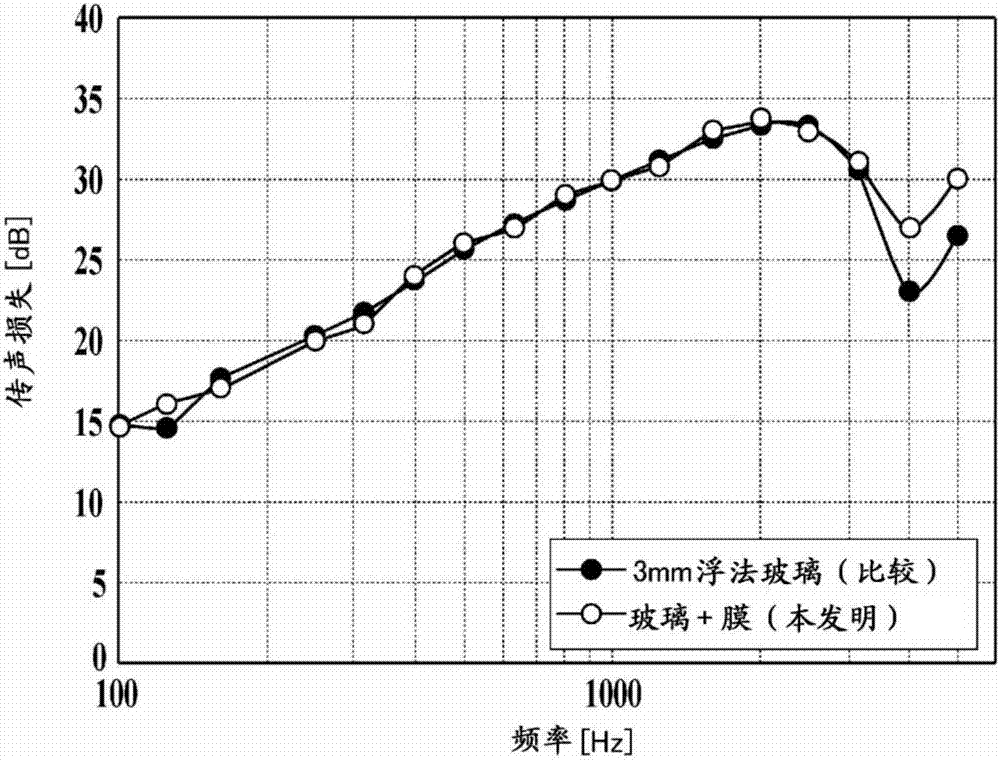

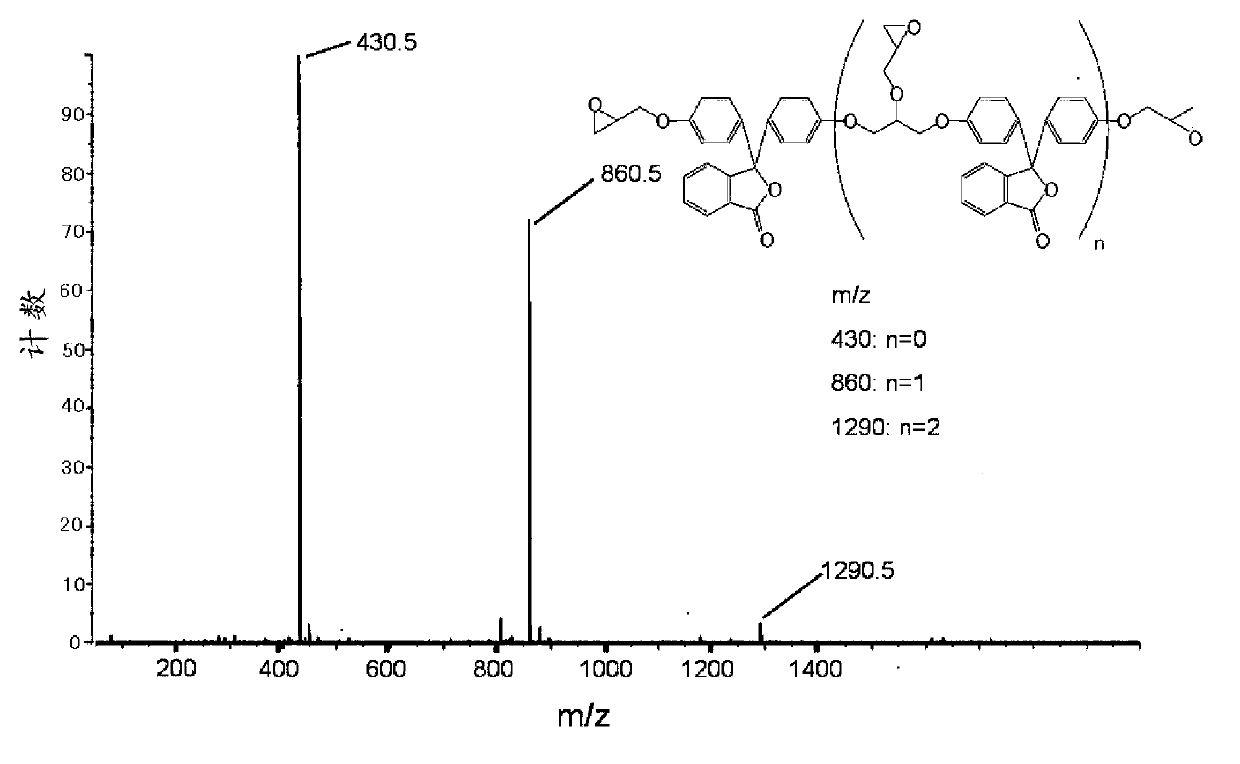

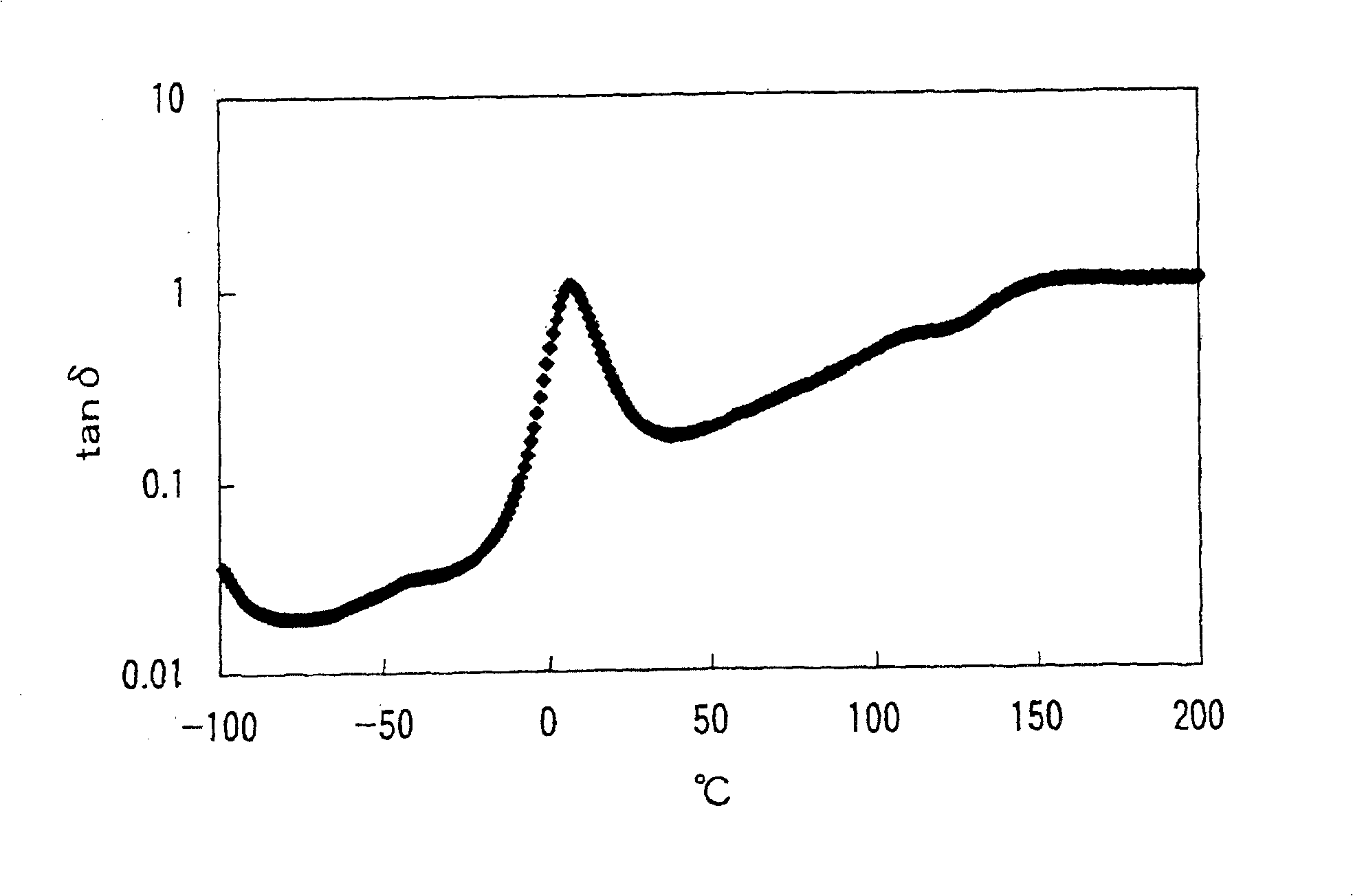

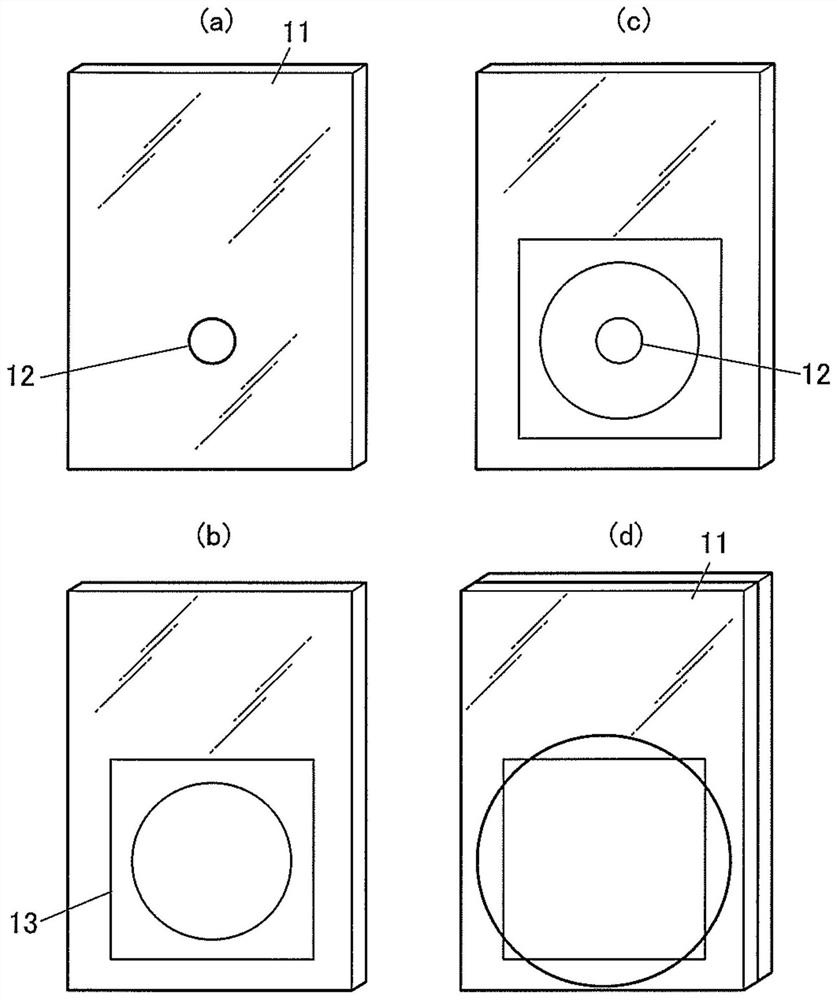

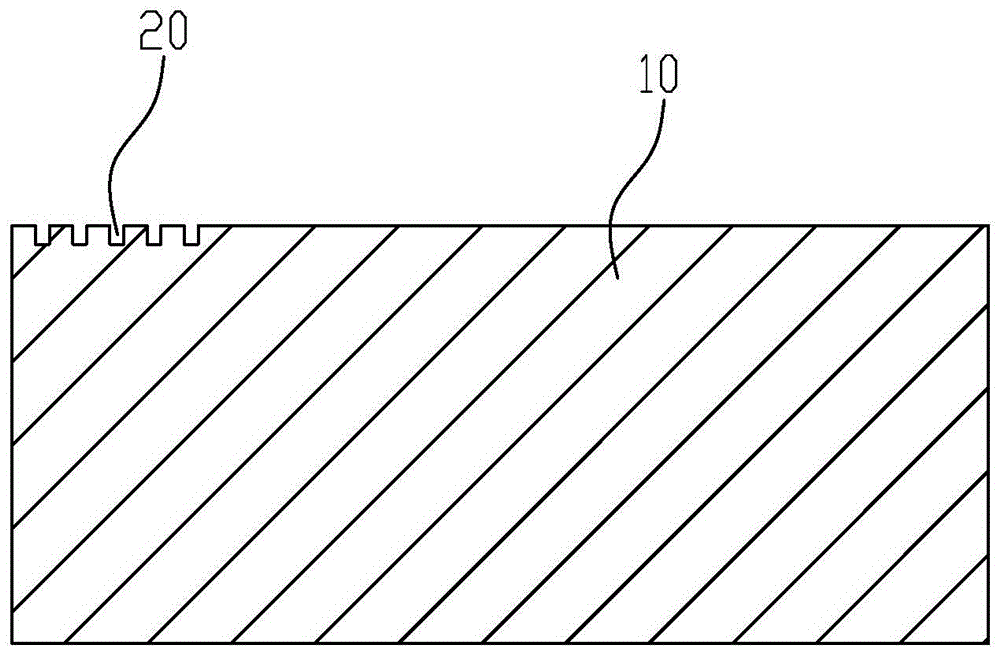

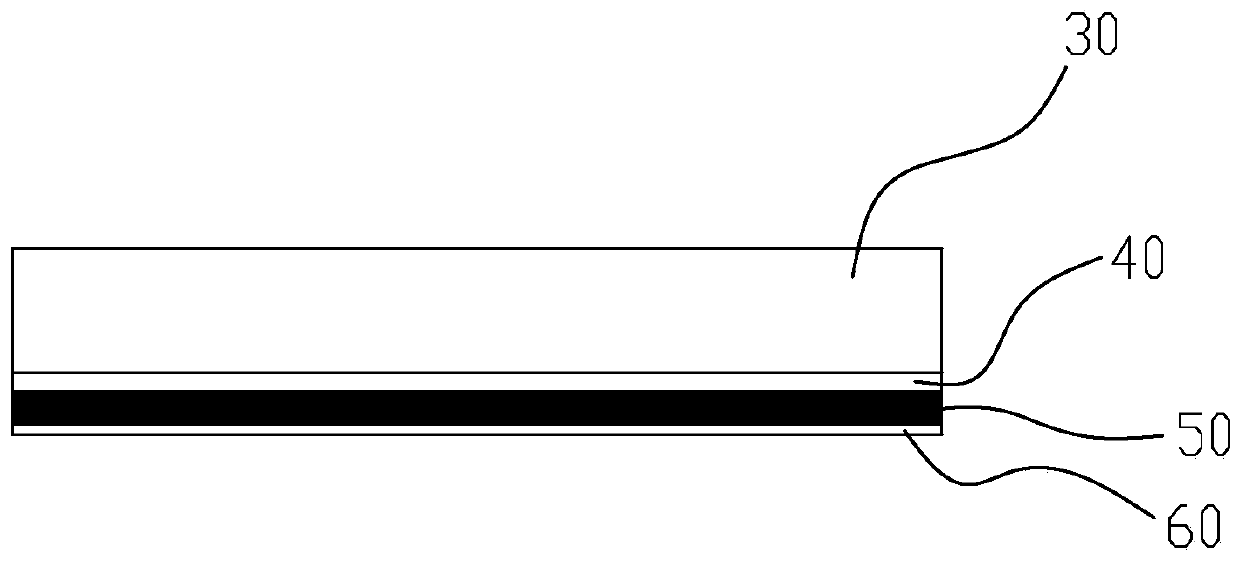

Functional film, sound-insulating glass comprising glass having said functional film bonded thereto, laminated glass, base member for decorative film, and method for producing functional film

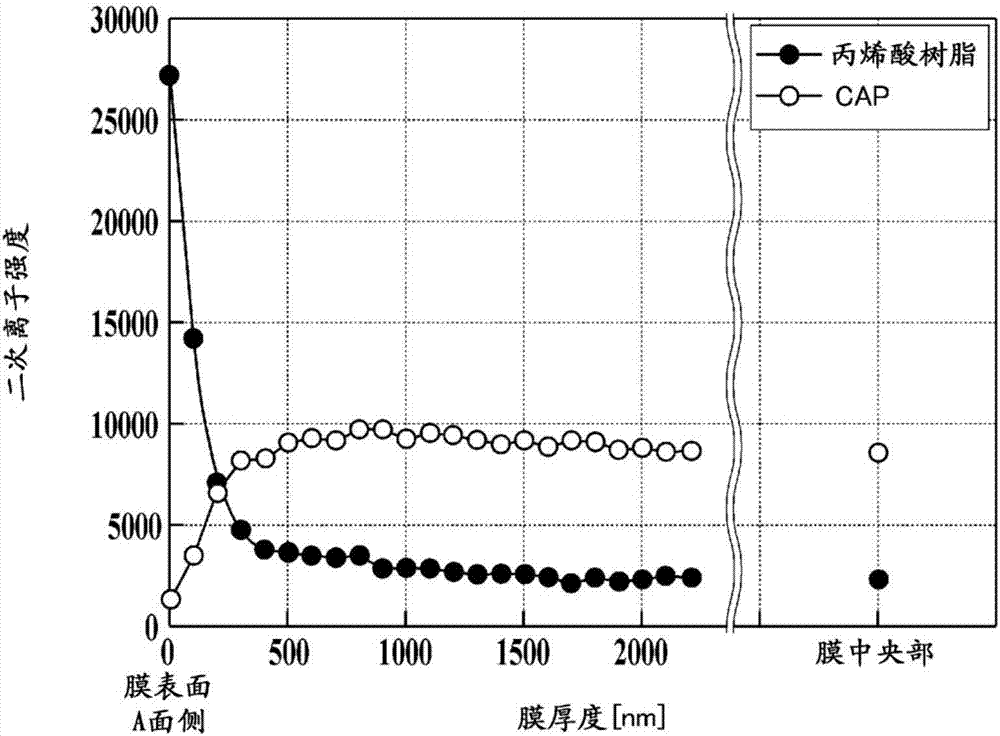

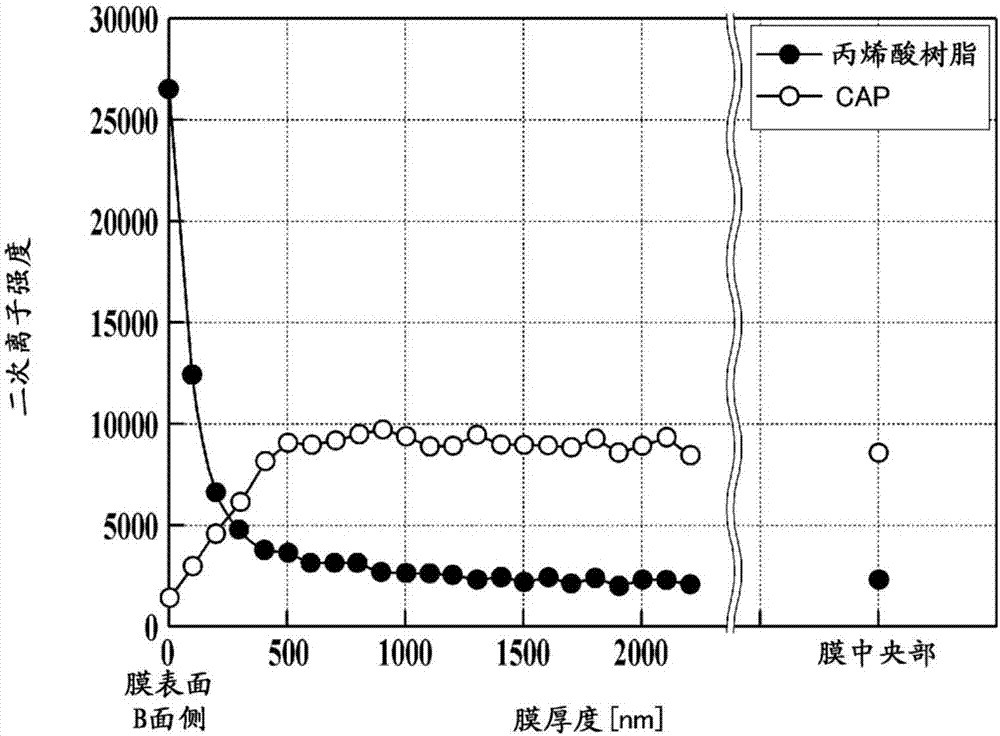

InactiveCN107108924AWrinkle freeExcellent adhesion resistanceGlass/slag layered productsFlat articlesPhysical propertyMonolayer

The present invention addresses the problem of providing: a functional film which consists of a single layer, and in which one of at least two resins contained therein is localized in surface areas, the physical properties on the both surfaces thereof are different from those in the inside part thereof, and which never undergoes the occurrence of wrinkling that is a problem in multi-layer films and has excellent sticking resistance; and others. The functional film according to the present invention contains at least a resin 1 and a resin 2, said functional film being characterized in that the ratio of the content of the resin 1 to the content of the resin 2 varies in the functional film as observed in the direction of thickness of the functional film, and the content ratio (% by mass) of the resin 1 meets the following relation: (the content ratio in a center part) < (the content ratio in surface B) <=(the content ratio in surface A), wherein the surface A refers to a zone lying from one outermost surface of the functional film to a depth of 200 nm as observed in the thickness direction of the functional film, the surface B refers to a zone lying from the other outermost surface of the functional film to a depth of 200 nm as observed in the thickness direction of the functional film, and the center part refers to a zone lying inside relative to the surface A and the surface B.

Owner:KONICA MINOLTA INC

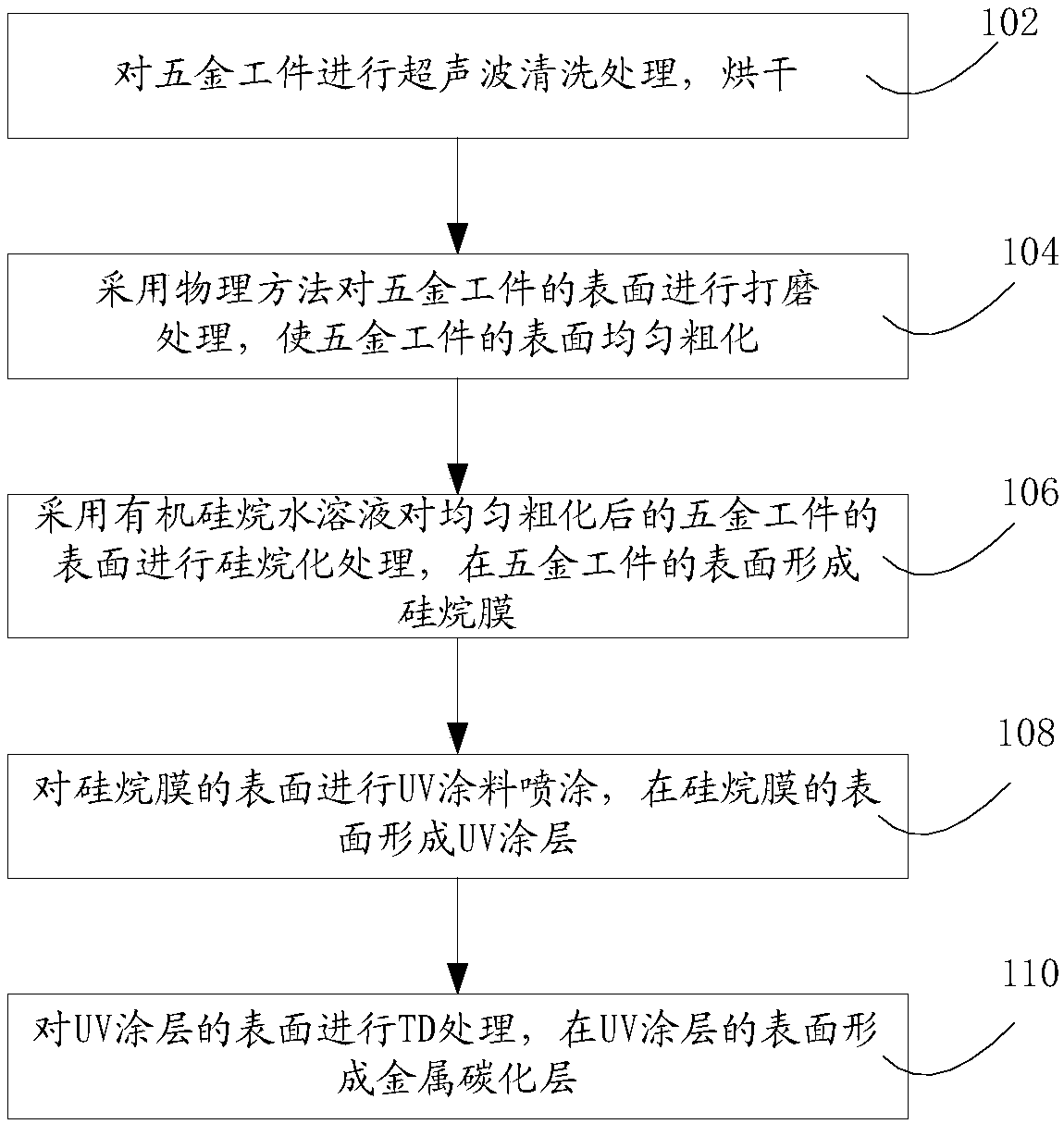

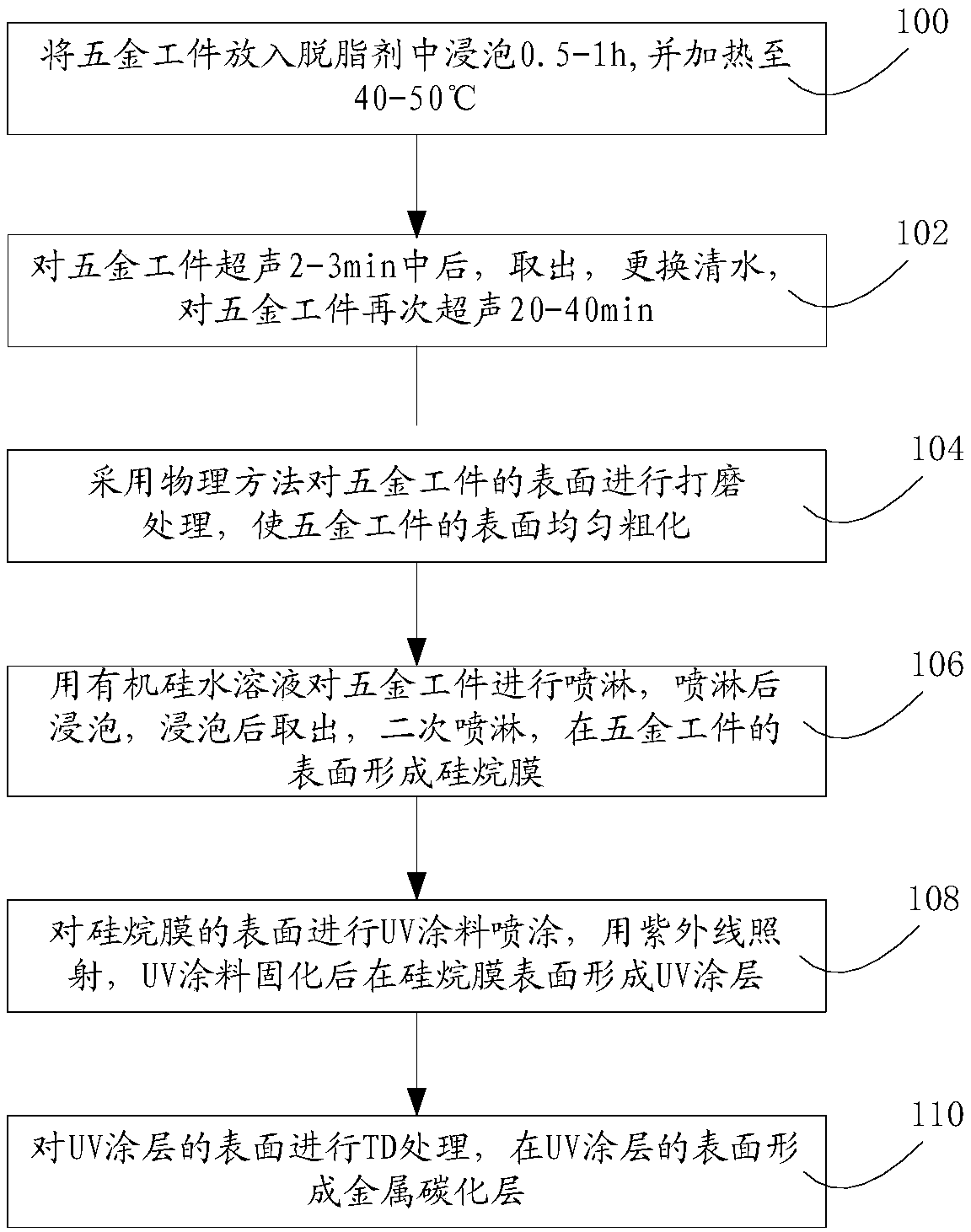

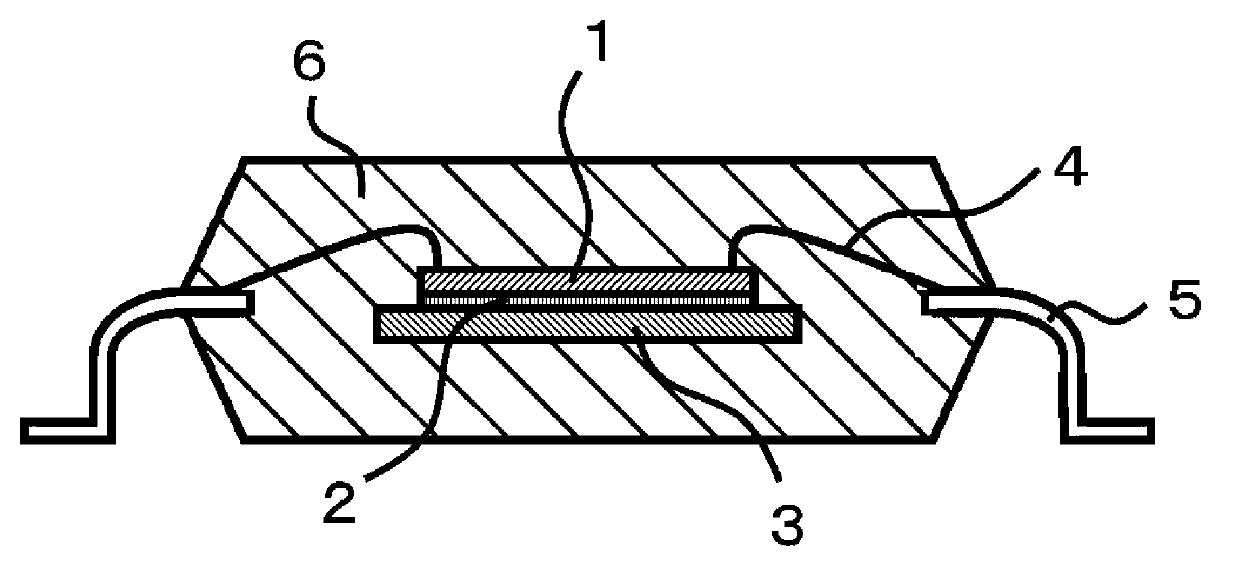

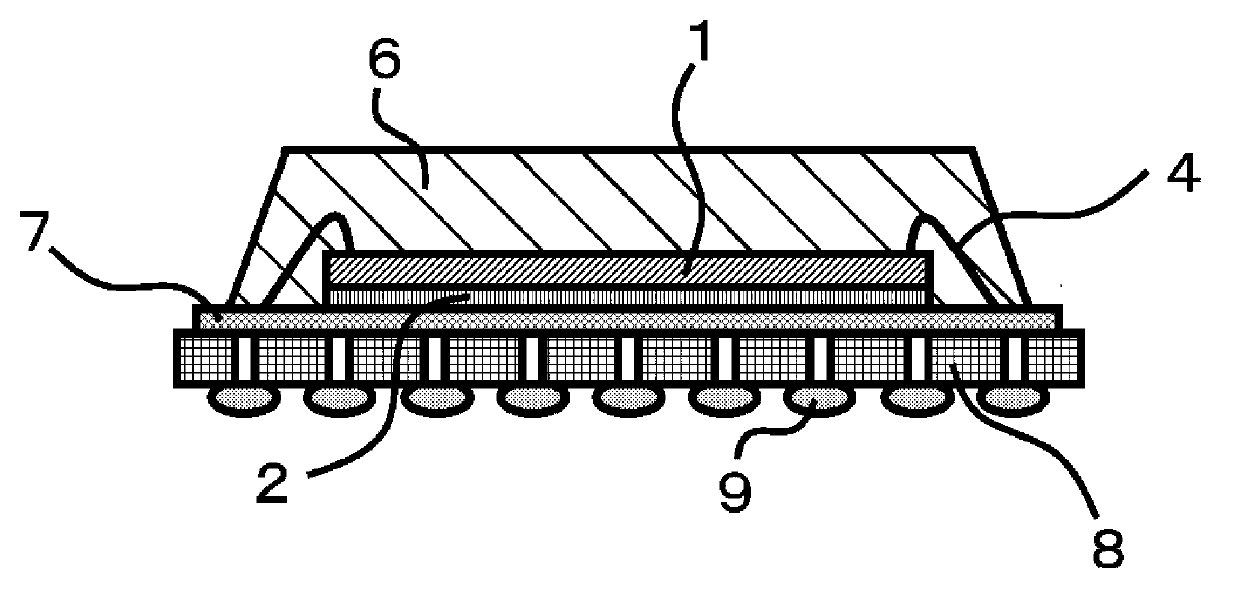

Hardware workpiece surface treatment technology

InactiveCN108690947ALong-term protectionReduce volume lossPretreated surfacesSolid state diffusion coatingCarbideMegasonic cleaning

The invention discloses ahardware workpiece surface treatment technology. The hardware workpiece surface treatment technology comprises the following steps thata base material pre-treated, specifically, a hardware workpiece is subjected to ultrasonic cleaning to remove impurities on the surface, and thehardware workpiece is dried; the base material ground, specifically, a physical method is used for grinding the surface of the hardware workpiece to uniformly roughen the surface of the hardware workpiece; silanization treatment is carried out, specifically, the uniformly roughened hardware workpiece is placed into an organosilane aqueous solution for silanization treatment, so that a silane film is formed on the surface of the hardware workpiece; middlecoating treatment is carried out, specifically, the surface of the silane film is subjected to UV coating spraying to form a UV coat on the surface of the silane film; and outeroverlaying layer treatment is carried out, specifically, thesurface of the UV coat is subjected to TD treatment to form a metal carbide layer on the surface of the UV coat. According to the hardware workpiece surface treatment technology, protection overlay layers with extreme high binding force are formed on the surface of the hardware workpiece, and the overlay layers are not liable to fall off from the surface of the hardware workpiece, so that the hardware workpiece can be protected for a long time; and the overlay layers have excellent performance of corrosion resistance and abrasion resistance.

Owner:惠州市国丰达五金制品有限公司

Resin composition for sealing semiconductors, and semiconductor device using same

InactiveCN102791796AExcellent continuous formabilityGood adhesion resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyFilling materials

Owner:SUMITOMO BAKELITE CO LTD

Hydrogenated copolymer

InactiveCN100451038CIncrease elasticityImprove scratch resistanceThin material handlingPolymer scienceDouble bond

Owner:ASAHI KASEI KK

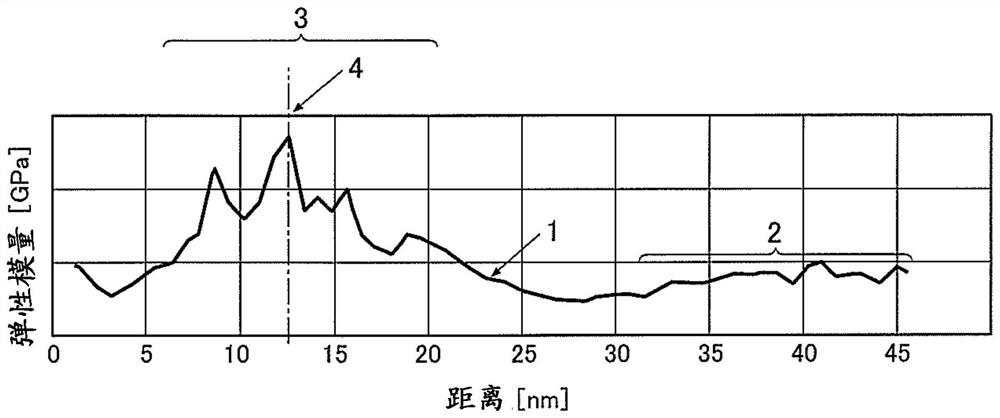

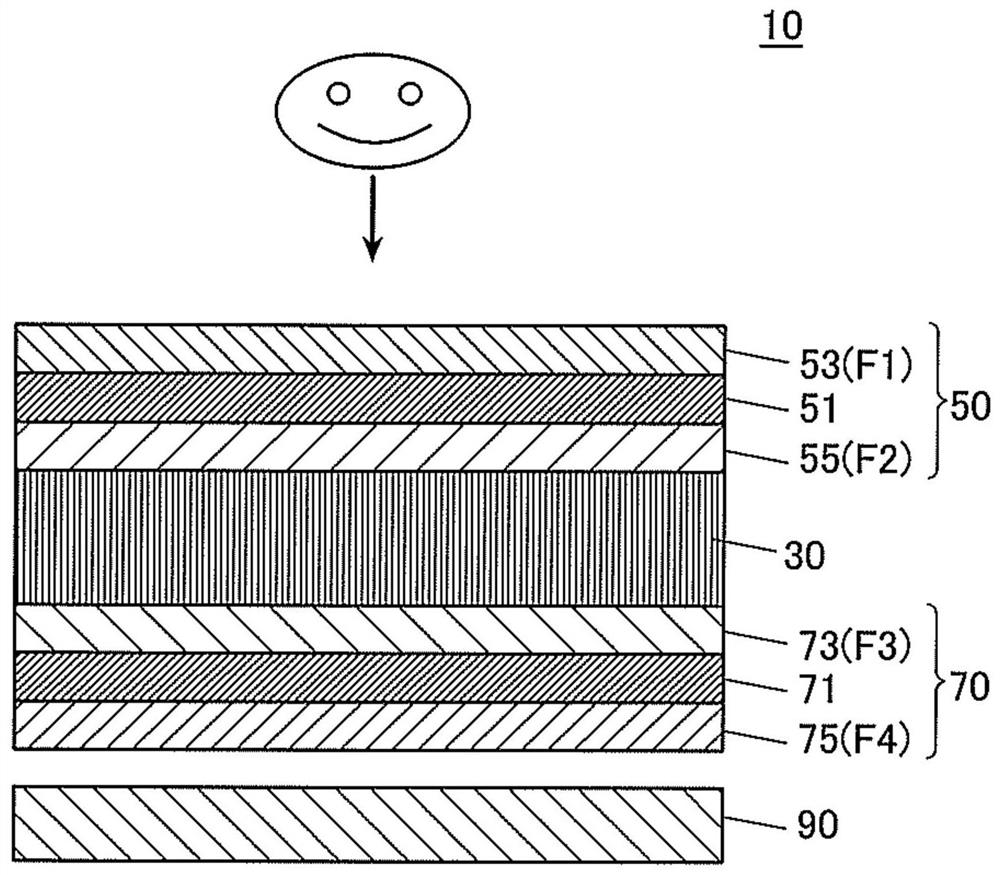

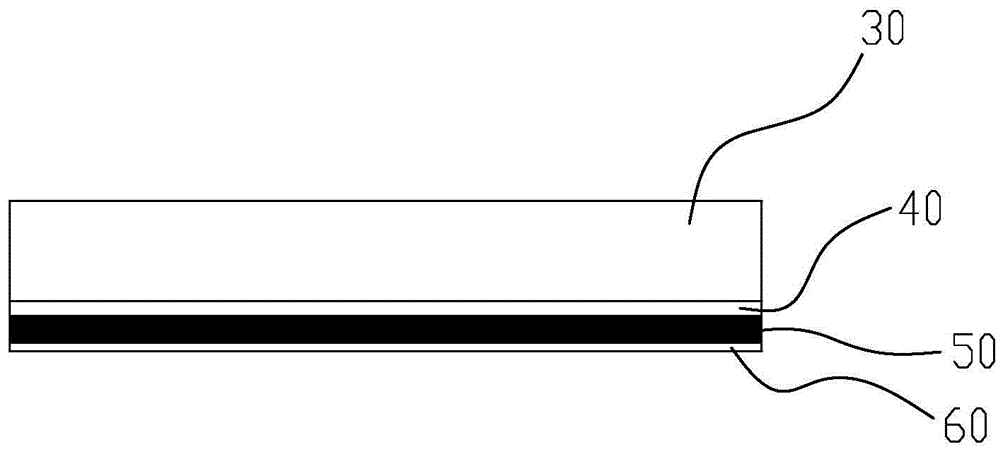

Optical film, polarizing plate, and liquid crystal display device

ActiveCN111983745AExcellent sticking resistanceGood transparencyPolarising elementsNon-linear opticsPolarizerChemistry

The present invention addresses the problem of providing an optical film having excellent adhesion resistance and transparency between films. Also provided are a polarizing plate and a liquid crystaldisplay device provided with the optical film. This optical film contains a resin and organic fine particles, and is characterized by satisfying the following requirements (I) and (II). (I) E1 represents the average modulus of elasticity of the resin portion that does not contain the organic fine particles, E2 represents the average modulus of elasticity of the organic fine particle portion, and the ratio (E2 / E1) of E1 to E2 satisfies formula (1): 1.0<E2 / E1<=4.0. (II) The resin contains at least one of a cycloolefin resin and a (meth) acrylic resin.

Owner:KONICA MINOLTA INC

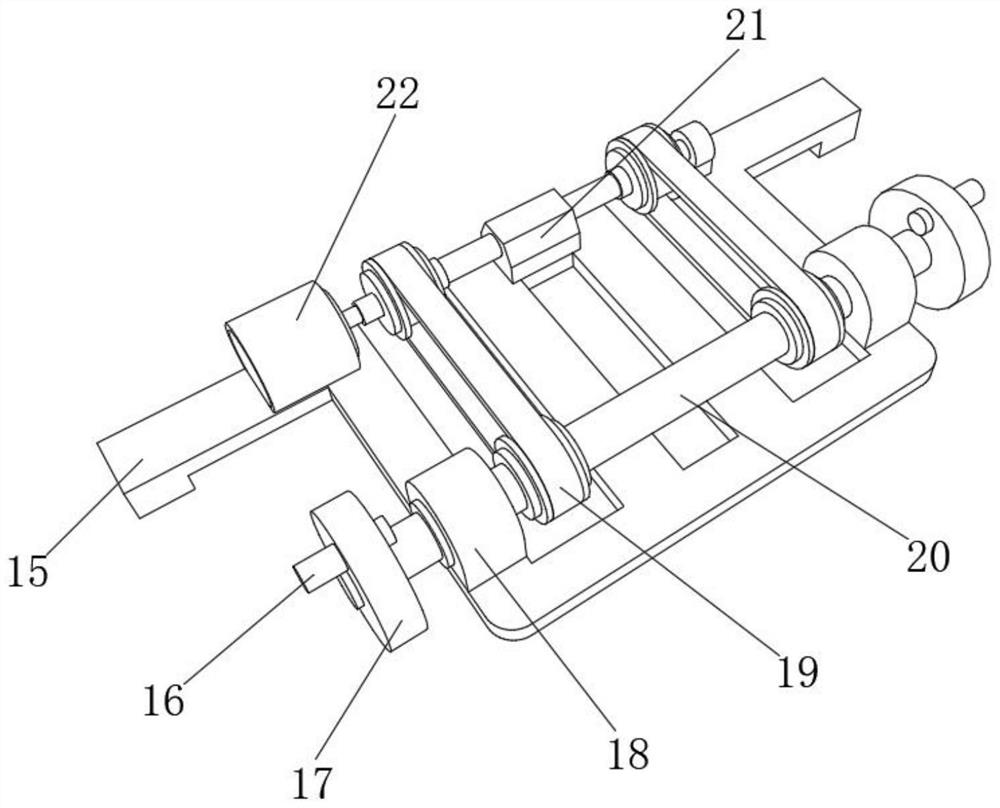

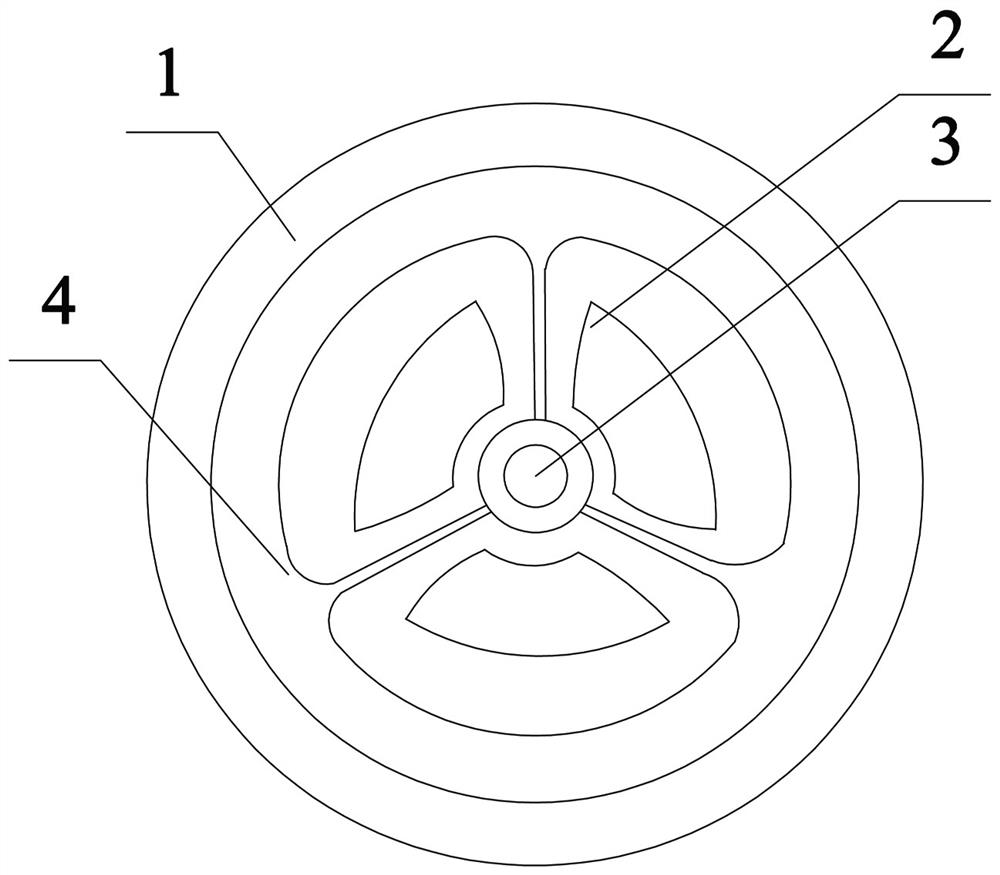

Continuous extrusion die for aluminum pipes

ActiveCN106735080AHigh temperature dimensional stabilityGuaranteed dimensional stabilityNiobiumTitanium nitride

The invention provides a continuous extrusion die for aluminum pipes. The continuous extrusion die comprises a male die, a female die and a forming mandrel arranged on the male die. The female die comprises a female die base body internally provided with an inverted frustum-shaped female die forming cavity, a forming gasket arranged on the inner side of the bottom of the female die base body, and a female die forming through hole penetrating the bottom of the female die and the forming gasket. Each of the forming mandrel and the forming gasket comprises a hard alloy base body and a nanometer titanium nitride layer or a nanometer titanium carbide layer or a nanometer carbon nitride titanium layer depositing on the hard alloy base body, wherein a hard alloy is a titanium carbide niobium molybdenum alloy or a titanium nitride niobium molybdenum alloy or a tungsten titanium alloy. The value of the surface roughness Ra of the hard alloy base body ranges from 0.01 to 0.1. The continuous extrusion die for the aluminum pipes has relatively high red hardness, surface gloss and high-temperature corrosion resistance, and the die has a relatively long service life.

Owner:河南明睿达机械制造有限公司

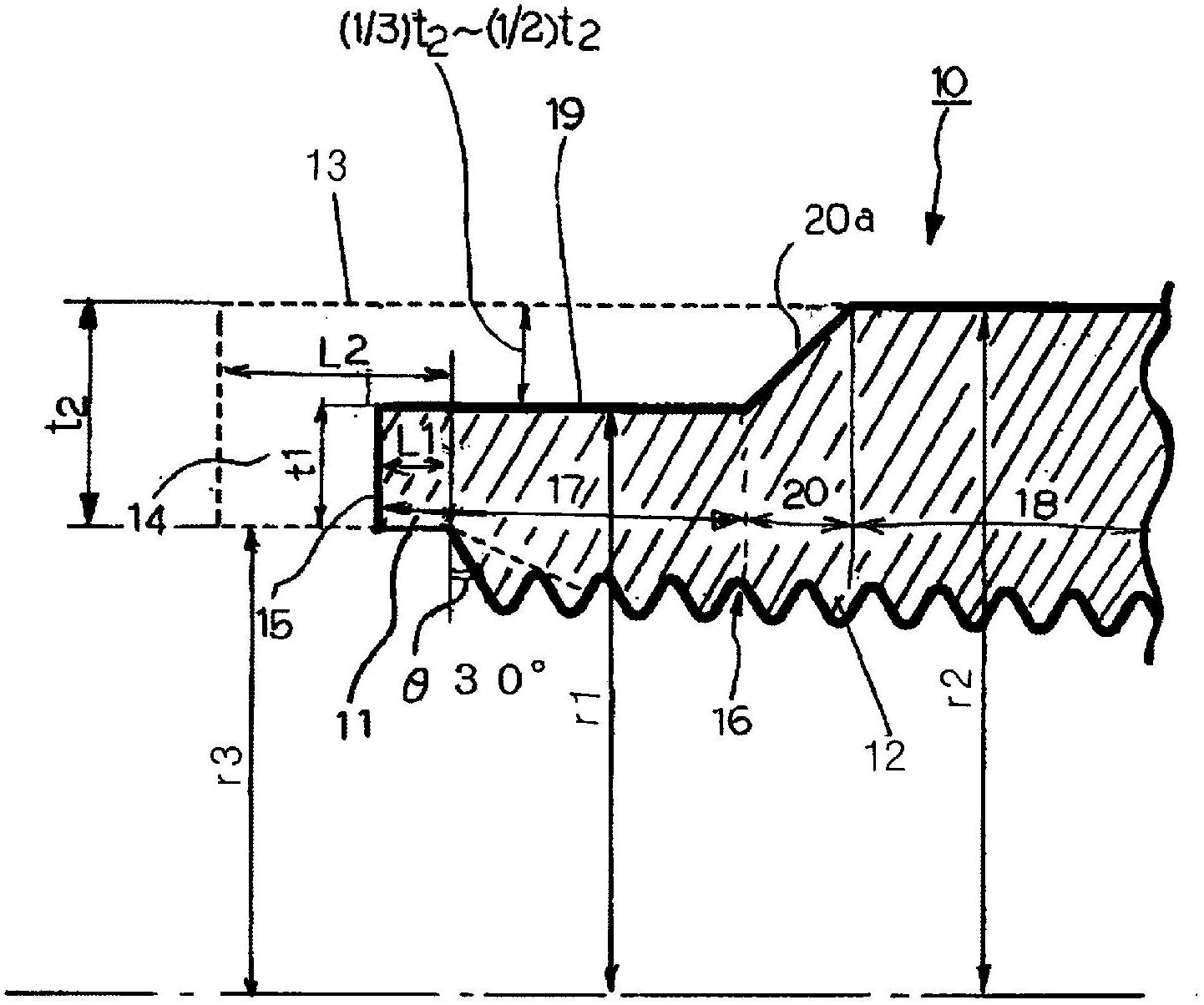

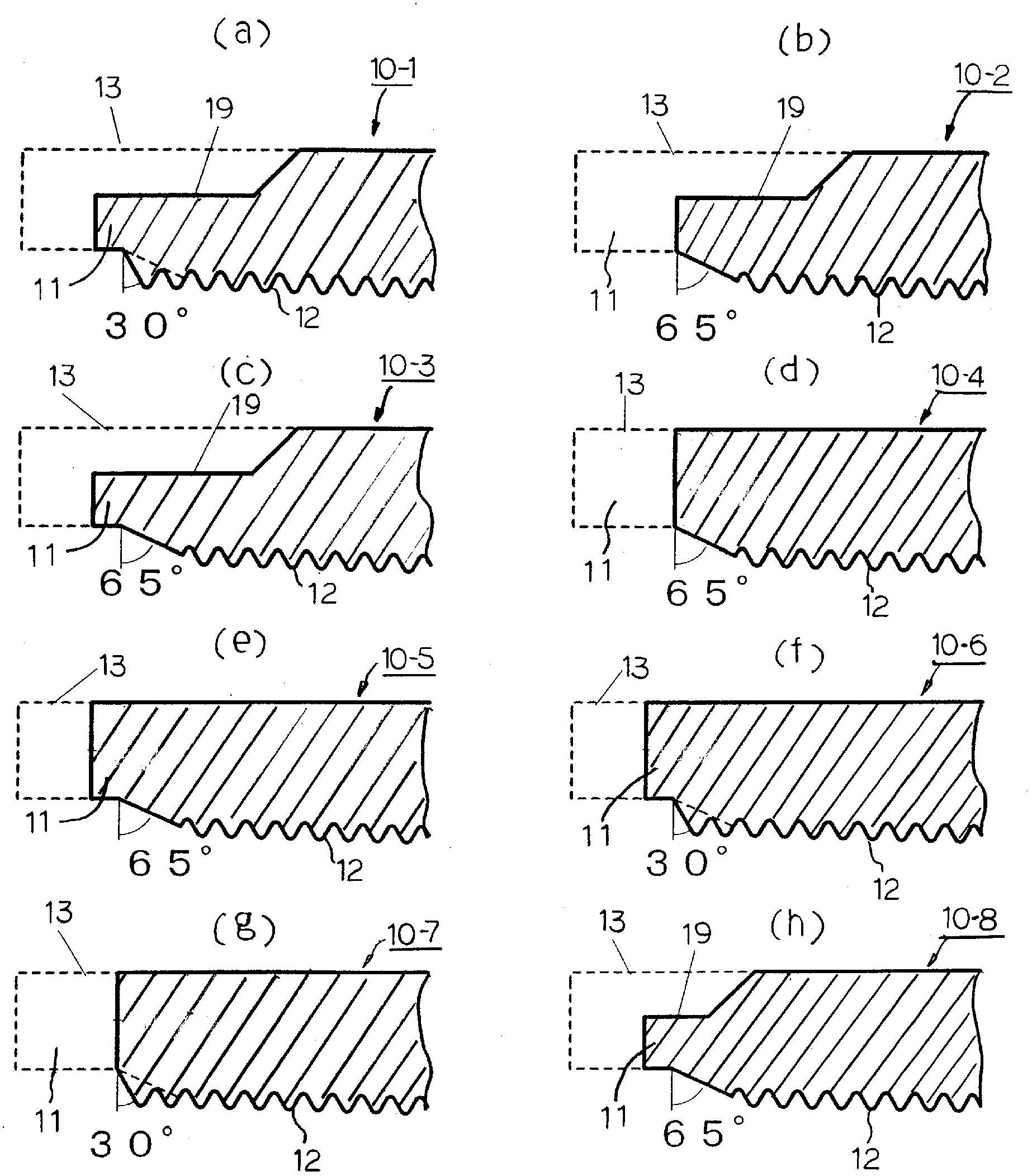

Screw joint for steel pipe

InactiveCN102667290AIncrease contact pressureGood adhesion resistanceDrilling rodsDrilling casingsSlope angleScrew thread

A screw joint for a steel pipe, having improved galling resistance, wherein the screw joint comprises: a pin which is provided with a male thread section having a triangular screw thread; and a box which is provided with a female thread section having a triangular screw thread and engaging with the male thread section, and also with a threadless sleeve section provided to the tip of the box, and wherein the screw joint satisfies the requirements of the standard for round screw joints set forth by the American Petroleum Institute. The threadless sleeve section of the box is reduced in length or eliminated so that the length of the threadless sleeve section in the axis direction of the box is less than or equal to 1 / 2 (including zero) the value defined in the standard. A swoosh section may be provided to the box end and / or the shape of the box which is defined in the standard may be changed so that the bevel angle at the end of the female thread section is within the range of +-15 DEG of the slope angle of the female thread.

Owner:NIPPON STEEL CORP

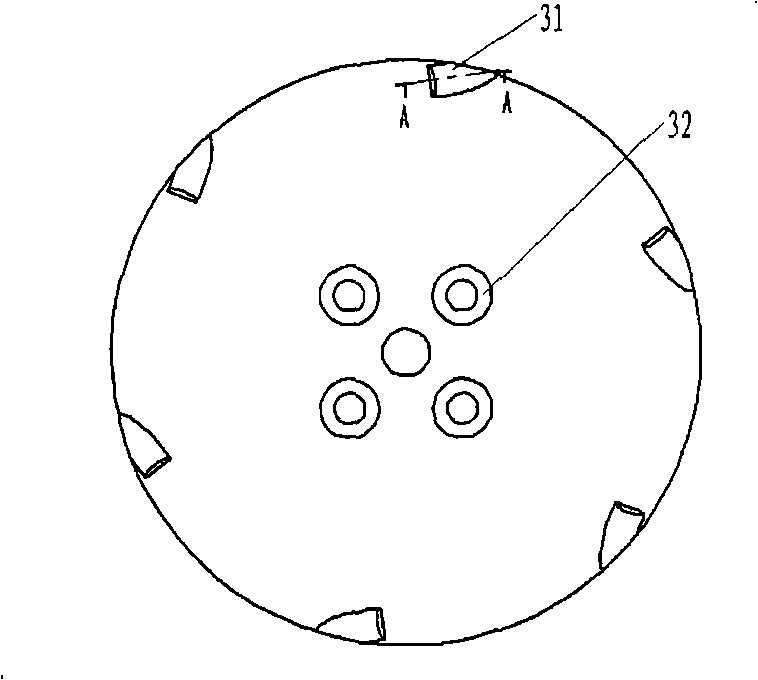

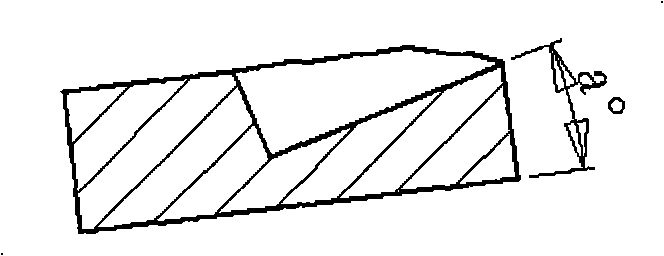

Reaming tool special for valve seat of cylinder cover of multi-cylinder diesel engine

The invention discloses a reaming tool special for a valve seat of a cylinder cover of a multi-cylinder diesel engine, which adopts mechanically-clamped single-blade cutting to replace boring, so that high shape precision and position precision can be achieved, and the surface roughness value is greatly reduced. A blade is a metal ceramic blade, has very high hardness, wear resistance and red hardness, has good adhesion resistance, chemical stability and low friction coefficient, and can meet the surface quality requirement of a sealing ring belt. A guide pipe inner hole reamer adopts a push reaming mode, the straightness requirement and the surface roughness requirement of a guide pipe inner hole are met, and the coaxiality requirement of the sealing ring belt relative to the guide pipe inner hole is met. The tool solves the problems that the sealing ring belt has poor surface roughness, large shape error and large coaxiality error relative to the guide pipe inner hole, improves the percent of pass of the machined cylinder cover of the multi-cylinder diesel engine, saves labor and machining cost, and is advanced in technology and high in practicability.

Owner:江苏恒悦机械有限公司

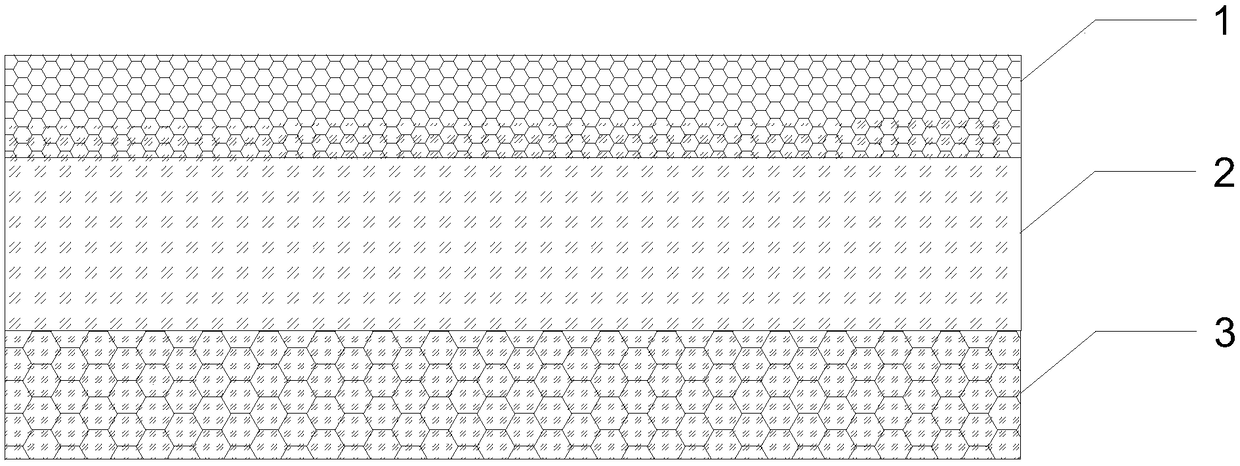

Integrated composite multilayer anti-adhesion hemostatic sponge and preparation method thereof

InactiveCN109223307AHemostasis, sterilization and anti-infection effect lastsGuaranteed moisturizing and anti-adhesion effectSurgical adhesivesPlastersFiberBletilla striata

The invention discloses an integrated composite multilayer anti-adhesion hemostatic sponge. The sponge specifically comprises an upper surface weaving protective layer, a middle porous hemostatic gellayer and a lower surface porous hemostatic gel weaving composite layer which are sequentially bonded and crosslinked to form an integrated composite multi-layer structure. The upper surface weaving protective layer comprises a middle porous hemostatic gel layer and a lower surface porous hemostatic gel composite layer, wherein the upper surface weaving protective layer is a mesh fabric woven by chitosan fiber and / or bletilla striata polysaccharide fiber. The intermediate porous hemostatic gel layer is chitosan. Polyethylene glycol modified porous gel layer. A low surface porous hemostatic gelwoven composite lay is composed of bletilla striata polysaccharide modified fiber woven cloth and chitosan, wherein that lower surface porou hemostatic gel woven composite layer is composed of bletilla striata polysaccharide modified fiber and chitosan. Polyethylene glycol modified porous gel composite. The whole sponge product has the advantages of high molding degree, quick blood suction and hemostasis, good air permeability, persistent hemostasis and bactericidal resistance to infection, good anti-adhesive effect without additional additives, high biocompatibility, and effectively avoidingthe negative influence of the use and release of other additives in the sponge product on the secondary infection of the wound and the like.

Owner:SICHUAN LIZHI JIUCHUANG INTPROP OPERATION CO LTD

Crystal lamp glass production technology

InactiveCN107365970AThe production process is simple and easy to controlReduce energy consumptionVacuum evaporation coatingSputtering coatingChromium nitrideTitanium oxide

The invention discloses a production process of crystal lamp glass. The production process includes the following steps: (1) cleaning and drying the formed crystal lamp ornaments, and sending them to a vacuum coating machine for coating; (2) coating the crystal lamp ornaments Magnetron sputtering a TiOx layer on top; (3) Magnetron sputtering a chromium nitride film layer on the TiOx layer; (4) Magnetron sputtering a zinc tin oxide layer on the chromium nitride film layer; (5) A titanium oxide layer is magnetron sputtered on the zinc tin oxide layer. The process of the invention is simple and controllable, saves energy consumption, and the produced crystal lamp glass is wear-resistant and corrosion-resistant. The multi-layer coating film can use the photocatalytic effect to achieve the effect of self-cleaning, has good light transmission, and has certain economic benefits.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Superhard material cutting tool and preparation method thereof

ActiveCN101502926BGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

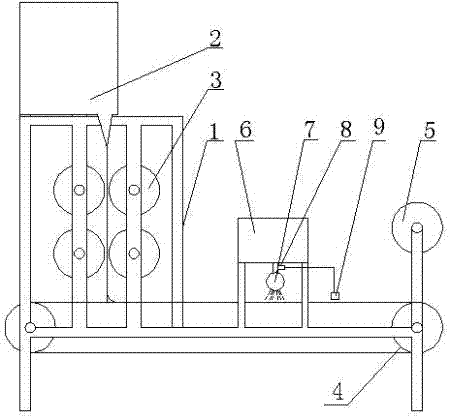

Waterproof coiled material forming machine

The present invention relates to the technical field of waterproof coiled material production, in particular to a waterproof coiled material forming machine, the name of which is an anti-bonding waterproof coiled material forming machine, including a forming machine body, which has a frame, and a hopper is arranged on the frame , forming roller, conveying device and coiling device, it is characterized in that: a water tank is also installed on the frame between the forming roller and the coiling device, the water tank is connected with a spray pipe, the spray pipe has a plurality of water spray ports, and the water spray The mouth is facing the edge of one side of the conveying device to the edge of the other side. There is a stirring device in the water tank, and a valve is arranged between the water tank and the spray pipe. The valve is a solenoid valve, and there is an induction device on the conveying device. The sensing device is connected to the solenoid valve. Such an anti-adhesion and waterproof coil forming machine has the advantages of less pollution, uniform spraying, and good anti-adhesion effect of the waterproof coil.

Owner:湖北永阳材料股份有限公司

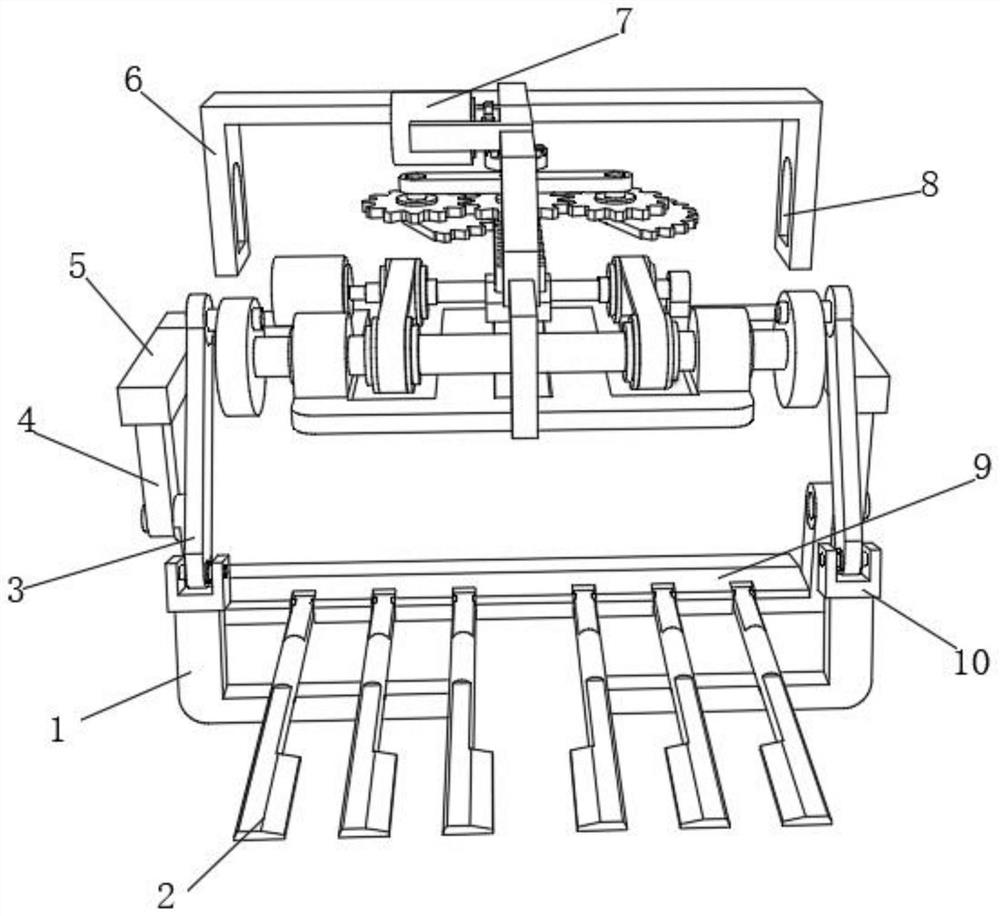

Anti-bonding conveying device for frozen food processing

ActiveCN113895916AImprove integrityAnti-adhesive GuaranteeConveyorsClimate change adaptationEngineeringStructural engineering

The invention discloses an anti-bonding conveying device for frozen food processing, and relates to the technical field of frozen food processing. The anti-bonding conveying device for frozen food processing aims to solve the problem of anti-bonding efficiency. The anti-bonding conveying device specifically comprises a driving mechanism, two L-shaped guide plates and two guide rods, a U-shaped connecting base is welded to the top end of each L-shaped guide plate, the top end of each U-shaped connecting base is rotationally connected with the ends of the two guide rods through rotating shafts, the two ends of the driving mechanism are connected with the top ends of the two guide rods respectively, connecting plates are arranged at the two ends of the driving mechanism respectively, a connecting rod is welded to the bottom of each connecting plate, a U-shaped plate is arranged at the bottom of each connecting rod, guide grooves distributed at equal intervals are formed in one side of the top of each U-shaped plate, a swing plate is connected into each guide groove through a guide shaft, and every three swing plates are fixed to the L end of each L-shaped guide plate through bolts. According to the anti-bonding conveying device for frozen food processing, anti-bonding during conveying of large frozen food is guaranteed, and the integrity of the frozen food is promoted.

Owner:安徽靖童科技农业发展有限公司

Plasma texturing cutter and preparing method thereof

ActiveCN105543802AGood adhesion resistanceImprove anti-adhesionVacuum evaporation coatingSputtering coatingChromium sesquioxidePre treatment

The invention discloses a plasma texturing cutter and a preparing method thereof. The method comprises the steps that firstly, a mask plate is prepared, a chromium nitride layer is sputtered and deposited on the surface of a glass substrate through a sputtering method, a chromium film layer is sputtered on the surface of the chromium nitride layer, a chromium sesquioxide layer is sputtered on the surface of the chromium film layer, and then a nanoscale texture array is machined on the chromium film layer through the electron beam lithography; secondly, pre-treatment of the cutter is carried out; thirdly, photoetching pattern transferring is carried out, a cutter-cuttings contact area of a front cutter face of the cutter is evenly coated with photoresist, exposure is carried out on the photoresist, the photoresist is dissolved through a developing solution, and a nanoscale texture array pattern is formed on the photoresist; and fourthly, plasma etching is carried out, and by means of plasma etching, the nanoscale texture array is formed on the cutter in an etching manner. The cutter-cuttings contact length in the cutting process is reduced through the nanoscale texture array, accordingly, the cutting force and the cutting temperature are reduced, and bonding of cuttings is reduced; and the anti-bonding performance of the cutter is improved, and the service life of the cutter is prolonged.

Owner:XIAMEN UNIV

A mold component for making concrete micro-slit floor and its application

ActiveCN106182362BReduce pockmarksQuality improvementMould auxillary partsFlooringThin layerEngineering

The invention belongs to the technical field of building materials and particularly relates to a mold assembly for manufacturing a concrete narrow-gap slatted floor and application of the mold assembly. The mold assembly comprises a mold and an isolating layer, wherein the mold comprises a base plate and a frame; the frame is formed by assembling four square side plates which are vertically arranged at the periphery of the base plate; a plurality of molding plates are vertically arranged on the base plate; and the isolating layer is attached to the base plate and the side plates. According to the mold assembly disclosed by the invention, the concrete narrow-gap slatted floor is produced by adopting the following method: firstly, uniformly spreading one thin layer of fine sands on the isolating layer, pouring a layer of concrete into the mold assembly and then starting a vibrating table for vibrating; secondly, putting the reinforcing mesh into the mold assembly, and continuously pouring concrete into the mold; when the concrete spills over the reinforcing mesh and is stacked to the top of the mold, plattening the top of the concrete and putting two reinforcing bars into the mold assembly; thirdly, uniformly spreading one layer of carborundum on the surface of the plattened concrete, and immediately turning over and demolding after plattening and forming, thus obtaining a finished product. According to the concrete narrow-gap slatted floor manufactured by adoption of the mold assembly, the pitted surface of the narrow-gap slatted floor surface can be effectively reduced, and surface quality of the floor is improved.

Owner:CHINA AGRI UNIV

Anti-annealing bonding cold-rolled strip cleaning agent

The invention discloses a cold-roll strip steel cleaning agent capable of preventing bonding during annealing and an application thereof. The cleaning agent comprises the components in percentage by weight: 25-35 percent of NaOH, 15-25 percent of Na2CO3, 15-25 percent of Na3PO4, 20-30 percent of NaSiO3, and 5-7 percent of disodium EDTA. When the cleaning agent is in use, by weight percent, 3-5 percent of the cleaning agent is added into water to form a cleaning solution, and cold-roll steel plate can be cleaned in the cleaning solution at the temperature of 70-85 DEG C before annealing. The cleaning agent has no strong pungent odor, can be directly added into the frequently-used cleaning water before recrystallization annealing, is convenient to use and has a good cleaning effect; and the cleaning efficiency is higher than 99 percent, and the residue on strip steel plate surface is smaller than 6 mg / m<2>, and the bonding of the steel plate is also avoided.

Owner:武汉钢铁有限公司

Composite electrically contacting silver-conducting ceramic material

InactiveCN1124621CSimple production processLow costOxide conductorsMetal/alloy conductorsFusion weldingContact resistance

The silver-conductive ceramics composite contact material belongs to the field of new material technology, and its main composition contains 60%-90% of silver and 40%-10% of conductive ceramics. Said invention possesses good arc-suppressing property, fusion welding resistance, loss resistance, antisticking property and silver mobility resistance, also has the low and stable contact resistance and small temp. rise.

Owner:SHANDONG UNIV

Multiple M genus cemented carbide

The utility model discloses a multi-component M-type hard alloy which relates to a hard alloy cutting tool material. To solve the problem that the prior hard alloy tool has low stainless steel cuttingefficiency and short service life, the multi-component M-type hard alloy of the invention is processed with the following components: 4 weight percent to 10 weight percent of hard-phase Tic, 5 weightpercent to 12 weight percent of hard-phase TaC, 0.5 weight percent to 4 weight percent of hard-phase TiN, 7 weight percent to 12 weight percent of binding-phase Co, and the rest is hard-phase WC. Compared with the prior M-type products, the product of the invention has three characteristics: first, the service strength is enough, which avoids tool breakage in cutting, second, the anti-galling property in cutting is very good, and third,red hardness is excellent.

Owner:牡丹江工具有限责任公司

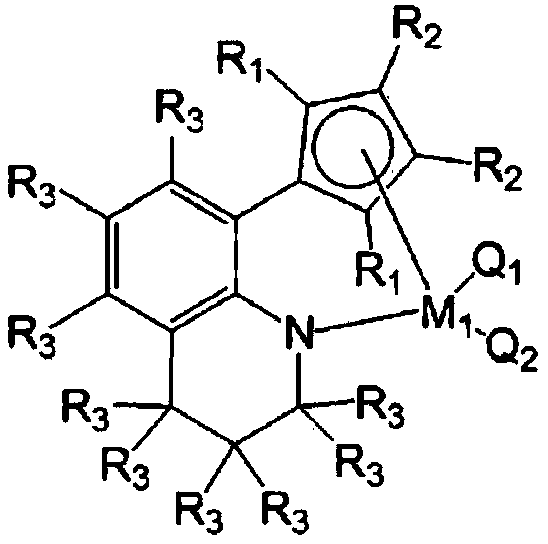

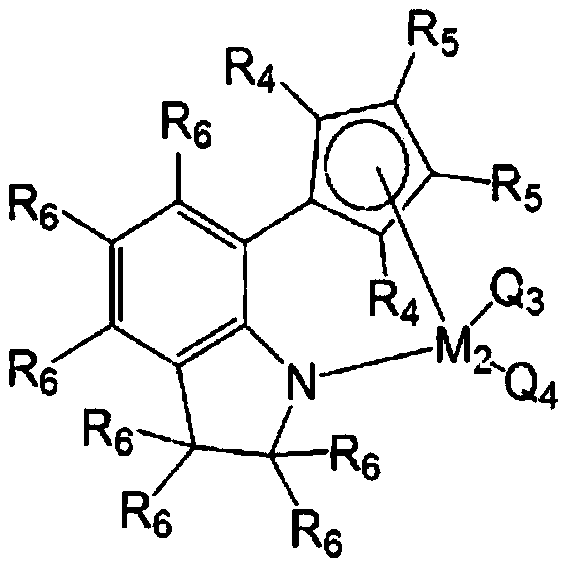

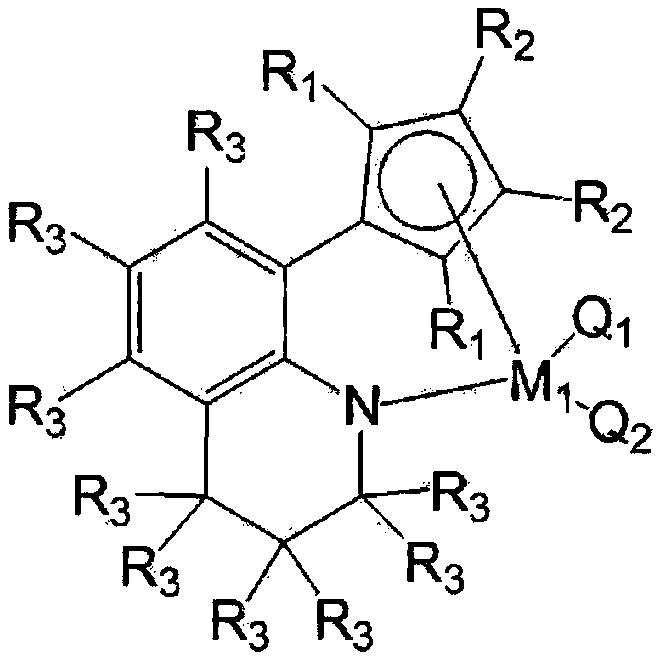

Olefin-based polymer

The present invention relates to an olefin-based polymer having (1) a density of 0.85 to 0.865 g / cc, (2) a melt index (MI) of 0.1 g / 10 min. to 3.0 g / 10 min. at 190 DEG C under a load condition of 2.16kg, (3) a soluble fraction (SF) of 10% or more at -20 DEG C in cross-fractionation chromatography (CFC), and a weight average molecular weight (MW) for corresponding fraction of 50,000 g / mol to 500,000 g / mol. The olefin-based polymer according to the present invention exhibits improved anti-blocking properties as a low-density olefin-based polymer.

Owner:LG CHEM LTD

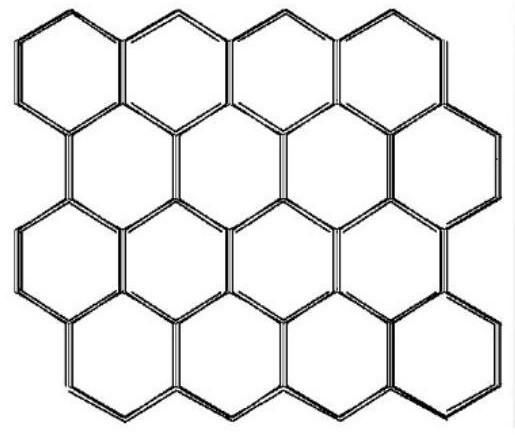

An anti-bonding high temperature resistant setter and its preparation method

ActiveCN113321520BGood adhesion resistanceImprove high temperature resistanceCharge supportsElectrical batteryCeramic capacitor

The invention discloses an anti-adhesive and high-temperature-resistant setter and a preparation method thereof. The slurry is evenly sprayed on the surface of a substrate and sintered to form a coating; wherein, the slurry is composed of yttrium oxide, zirconium oxide, oxide It is obtained by uniformly mixing tungsten and binder; the matrix is obtained by processing zirconia into a honeycomb structure. In the invention, the coating is processed on the surface of the honeycomb matrix, so that the setter has better performances of anti-bonding and high temperature resistance. The setter can be used for sintering easily sintered powders and materials with high chemical activity and easy reaction with crucible materials, and has good promotion and application value in the fields of battery materials, ceramic capacitor firing, high-temperature sintering and other fields.

Owner:湖南洛兰新材料有限公司

Plasma textured cutting tool and its preparation method

ActiveCN105543802BGood adhesion resistanceImprove anti-adhesionVacuum evaporation coatingSputtering coatingChromium sesquioxideChromium nitride

Owner:XIAMEN UNIV

Aluminum Tube Continuous Extrusion Die

ActiveCN106735080BHigh temperature dimensional stabilityGuaranteed dimensional stabilityTitanium nitrideTitanium carbonitride

The invention provides an aluminum tube continuous extrusion die, which comprises a punch, a die and a forming mandrel arranged on the punch, and the die includes a die base with an inverted frustum-shaped die forming cavity inside. , a forming gasket arranged on the inner side of the bottom of the die matrix and a die forming through hole passing through the bottom of the die and the forming gasket, the forming mandrel and the forming gasket both include cemented carbide The substrate and the nano-titanium nitride layer, nano-titanium carbide layer or nano-titanium carbonitride layer deposited on the hard alloy substrate, the hard alloy is titanium carbide niobium molybdenum alloy, titanium nitride niobium molybdenum alloy or tungsten Titanium alloys. The surface roughness Ra value of the cemented carbide substrate is 0.01-0.1. The aluminum tube continuous extrusion die has higher red hardness, higher surface gloss and better high temperature corrosion resistance, so that the die has a longer service life.

Owner:河南明睿达机械制造有限公司

A kind of preparation method of Nanchang fried noodles

The invention discloses a preparation method of Nanchang stir-fried rice noodles. A double-screw extrusion technology is utilized, liquid seasonings and solid seasonings are added to rice noodles after online aging and repeated steaming, the mixture is stir-fired and the Nanchang stir-fried rice noodles are prepared, wherein the liquid seasonings comprise olive oil, sesame oil, chive oil, light soy sauce, dark soy sauce, pork fillets and green vegetables; the solid seasonings comprise star anise, five spices, monosodium glutamate, chicken essence, dried shallots, chilies, fresh ginger, garlic, white granulated sugar, starch, dextrin, fennel, pepper, ginger powder, food additives and the like. A preparation process is simple, the rice noodles subjected to extrusion and repeated steaming are directly used to be stir-fried, the taste is better, time is saved due to use of the seasonings, the taste is guaranteed, and the industrial standard can be met. The prepared Nanchang stir-fried rice noodles have better caking resisting performance, and the oxidation rancidification is slow.

Owner:NANCHANG UNIV

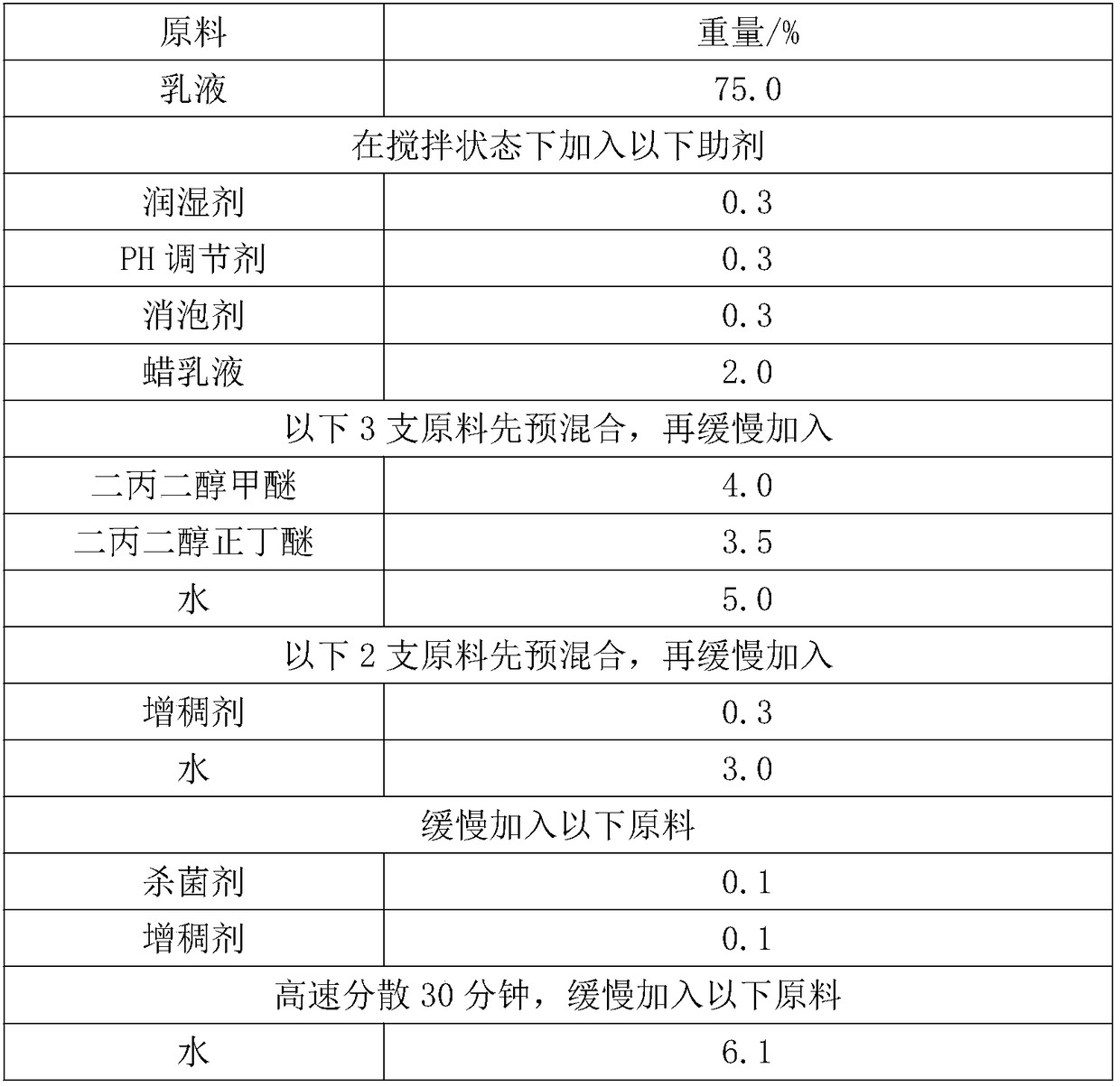

A kind of aqueous wood lacquer aqueous acrylate emulsion and preparation method thereof

The invention discloses water-based acrylate emulsion for water-based woodware paint and a preparation method thereof. The water-based acrylate emulsion is prepared from the following materials in parts by weight: 0.1-5 parts of butyl acrylate, 10-30 parts of methyl methacrylate, 5-15 parts of iso-octyl acrylate, 3-15 parts of oligomer, 0.1-3 parts of an emulsifying agent, 0.1-5 parts of crosslinking monomer, 0.05-0.2 part of a chain transferring agent, 0.1-5 parts of carboxylic monomer, 0.1-0.3 part of persulfate, 1.4-3 parts of ammonia water, 0.1-5 parts of adipic acid dihydrazide and 43-67 parts of water. The preparation process comprises the steps of emulsifying, polymerizing and discharging. The preparation method disclosed by the invention has the advantages of simple equipment, convenience in operation, low cost and short period. The prepared emulsion has the characteristics of low film-forming temperature, high paint-film fullness and good cohesion resistance and has good application prospect in the field of the water-based woodware paint.

Owner:中山市巴德富化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com