Anti-bonding conveying device for frozen food processing

A frozen food and conveying device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of uneven anti-adhesion and inability to remove food, so as to avoid uneven anti-adhesion and promote integrity , to ensure the effect of anti-adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

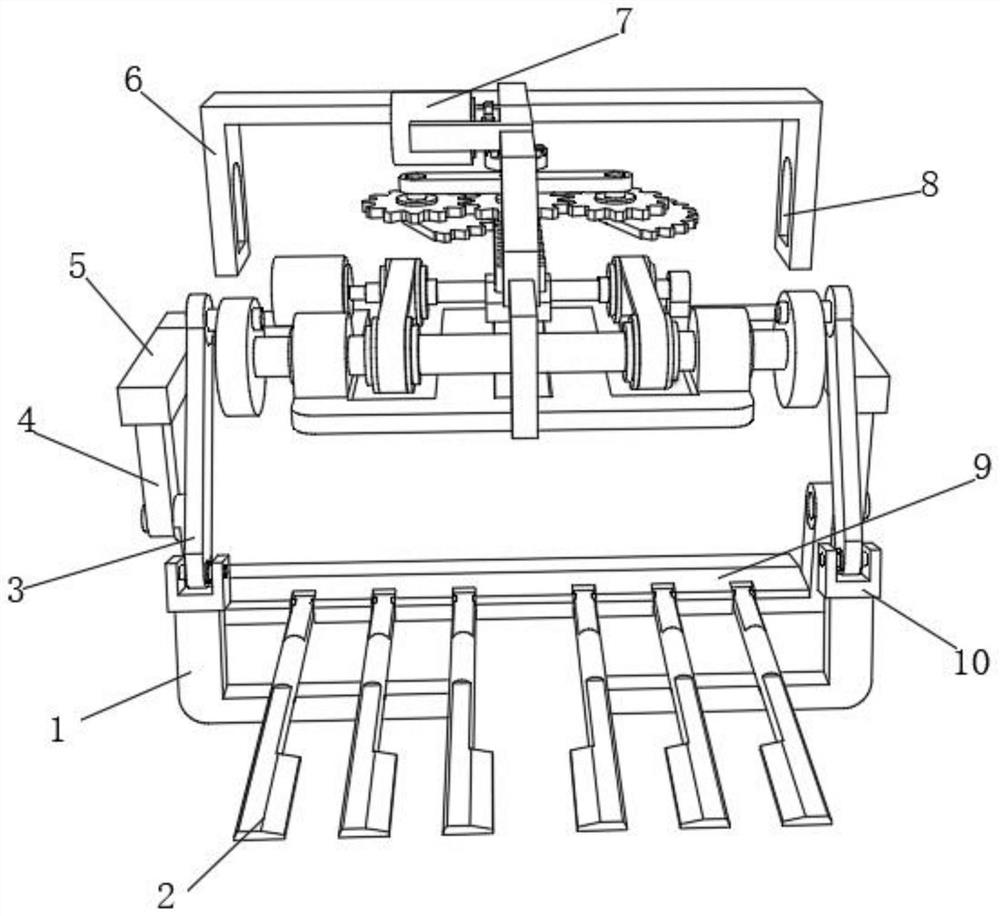

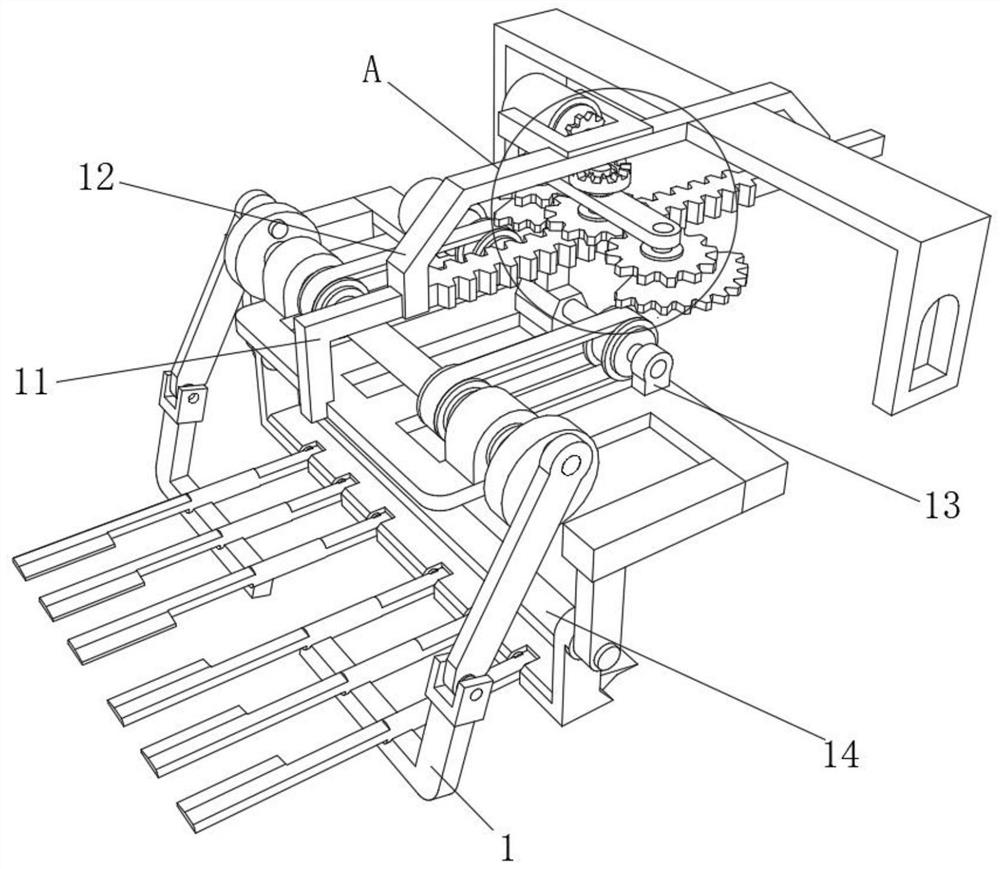

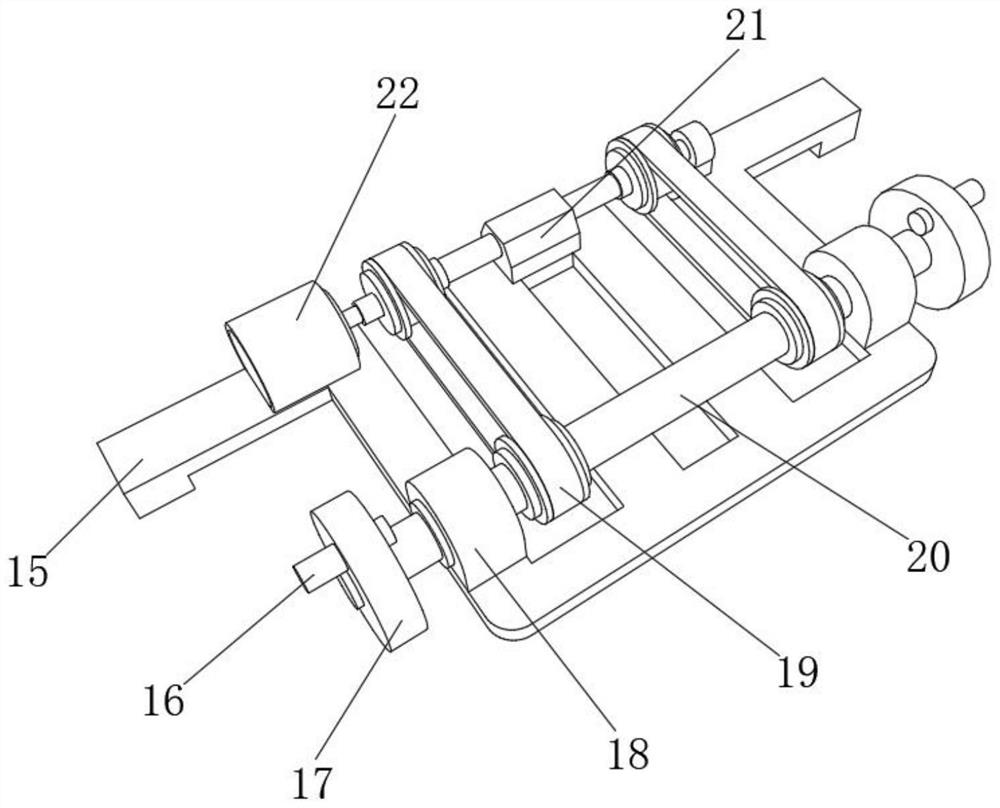

[0033] A stick-resistant conveying device for frozen food processing, such as Figure 1-5 As shown, it includes a drive mechanism, two L-shaped guide plates 1 and two guide rods 3, the top of each L-shaped guide plate 1 is welded with a U-shaped connecting seat 10, and the top of each U-shaped connecting seat 10 is connected to the The ends of the two guide rods 3 are connected by rotating shafts, the two ends of the driving mechanism are respectively connected with the tops of the two guide rods 3, the two ends of the driving mechanism are respectively fixed with connecting plates 5 by bolts, and each connecting plate 5 The bottom of each connecting rod 4 is welded with a connecting rod 4, and the bottom of each connecting rod 4 is threadedly connected with a U-shaped plate 9, and the top side of the U-shaped plate 9 is provided with guide grooves distributed equidistantly, and each guide groove is passed through a guide groove respectively. The shaft 31 is connected with a s...

Embodiment 2

[0041] A stick-resistant conveying device for frozen food processing, such as Figure 5 As shown, in order to avoid the problem that the swinging plate 2 shakes the food out of the conveyor belt when swinging; this embodiment makes the following improvements on the basis of Embodiment 1: one side of the swinging plate 2 is bonded with a raised strip 30; When the frozen food is separated by the shovel plate 14, the raised strip 30 can effectively buffer the frozen food to a certain extent, avoiding the problem that the swing plate 2 shakes the food out of the conveyor belt when it swings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com