Mold assembly for manufacturing concrete narrow-gap slatted floor and application of mold assembly

A concrete and floor technology, applied in the directions of mold auxiliary parts, manufacturing tools, ceramic molding machines, etc., can solve the problems affecting the durability of concrete micro-slit floors, reducing the effective thickness of the steel protective layer, and accelerating the carbonization process of the concrete surface. Anti-adhesion, improved quality, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

[0038] In the description of the present invention, unless otherwise specified, the meaning of "plurality" is two or more; in addition, the terms "first", "second", "third" and so on are only used for descriptive purposes, It should not be construed as indicating or implying relative importance.

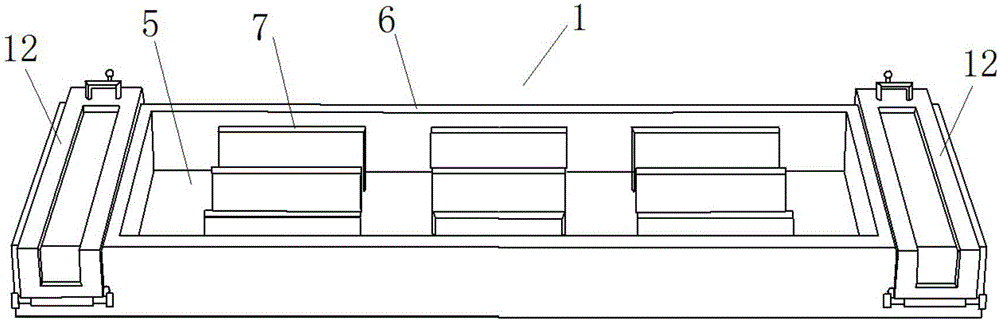

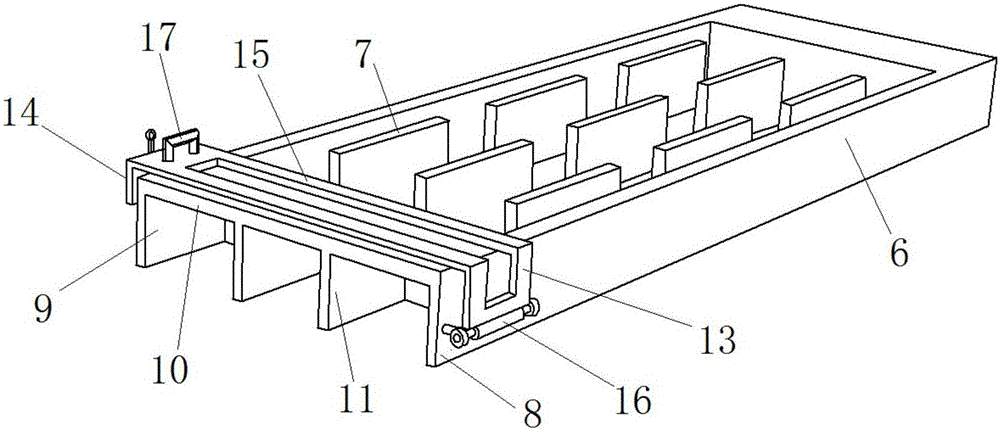

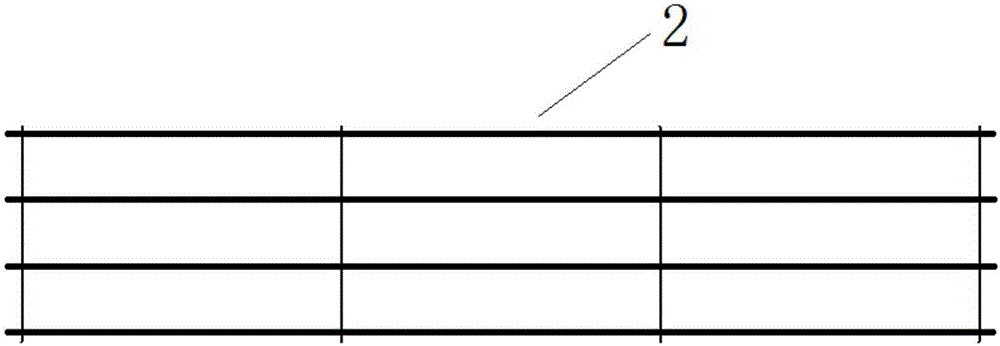

[0039] like Figure 1~5 As shown, a mold assembly for making concrete micro-slit floors provided in this embodiment includes a steel mold 1 for pouring concrete into the floor, an isolation layer (not shown in the figure), and 8 A reinforcement mesh 2 welded by root reinforcement, 4 reinforcement positioning cards 3 and a vibrating table 4 positioned below the mold 1.

[0040] The mold 1 includes a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com