Superhard material cutting tool and preparation method thereof

A cutting tool and superhard material technology, applied in the field of superhard material cutting tools, can solve the problem of difficult removal of floor coatings, and achieve the effect of ensuring smoothness, small friction coefficient and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

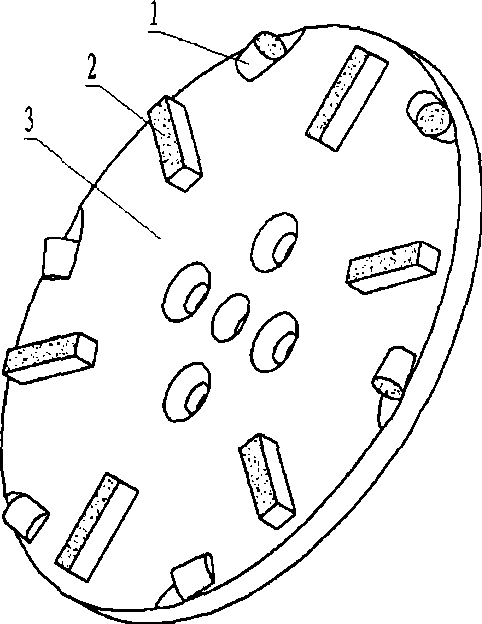

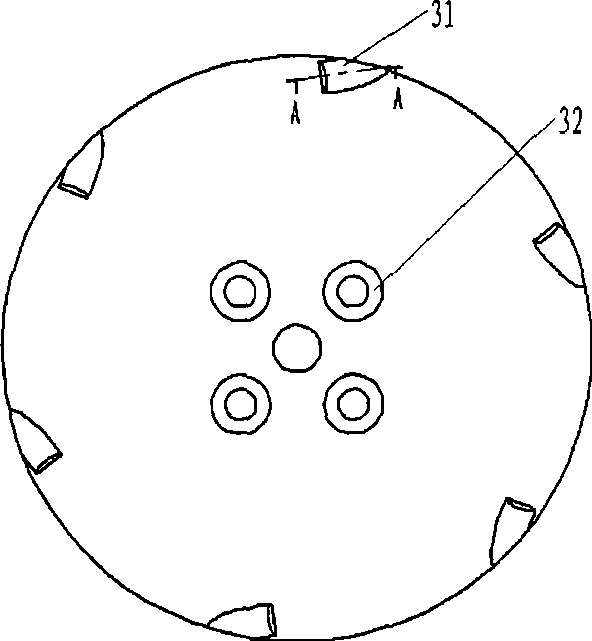

[0023] Figure 1 ~ Figure 3 It is a specific embodiment in the present invention.

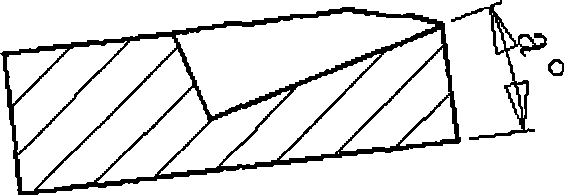

[0024] figure 1 It is a schematic diagram of the structure of the tool. The tool head is composed of two parts, polycrystalline diamond composite sheet 1, diamond pre-alloyed powder head 2, and steel matrix 3. The steel matrix is disc-shaped see figure 2 , equipment mounting holes 32 are distributed in the middle of the disk-shaped substrate, and oblique cylindrical grooves are punched on the periphery of the disk for welding polycrystalline diamond composite sheets. The A-A sectional view of the cylindrical groove is shown in image 3 As shown, the angle between the centerline of the cylindrical groove and the surface of the substrate (that is, the cutting surface) is a, and the value of a is (0-30)°.

[0025] In the design of the welded joint structure, the polycrystalline diamond composite sheet 1 is a cylinder, and the edge area of the composite sheet provides a cutting edge for the...

Embodiment 2

[0028] Figure 4 It is another superhard material cutting tool of the present invention. The steel matrix 3 of this cutting tool is disc-shaped, and an oblique cylindrical groove is cut on the outer edge of the disc matrix for welding polycrystalline diamond composite sheet 1. The cylindrical groove structure Same as Example 1; the diamond tip 2 used for grinding in this cutting tool is trapezoidal, and the production process of the cutting tool is as described in Example 1.

Embodiment 3

[0030] Figure 5 It is another superhard material cutting tool of the present invention. The steel matrix 3 of this cutting tool is disc-shaped, and an oblique cylindrical groove is cut on the outer edge of the disc matrix for welding polycrystalline diamond composite sheet 1. The structure of the cylindrical groove is the same as Example 1 is the same; the diamond bit 2 used for grinding in this cutting tool is in the form of a cylinder, and the production process of the tool is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com