Grease composition for assembling standard sections of tower crane and preparation method of grease composition

A technology of tower crane and lubricating grease composition, which is applied in the field of lubricating grease, can solve problems such as difficult dismantling of pin shafts, and achieve the effects of improving anti-corrosion and anti-corrosion capabilities, beneficial protection performance, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

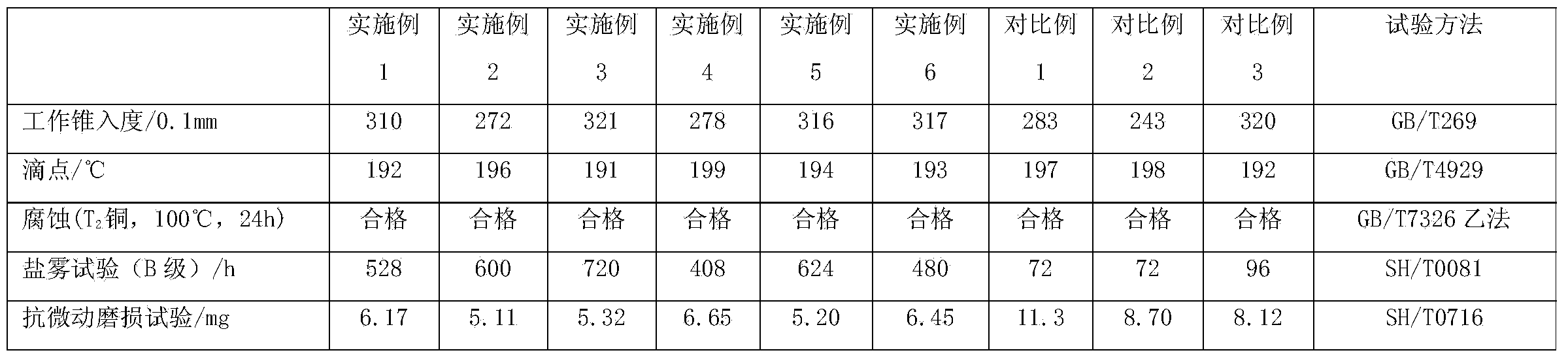

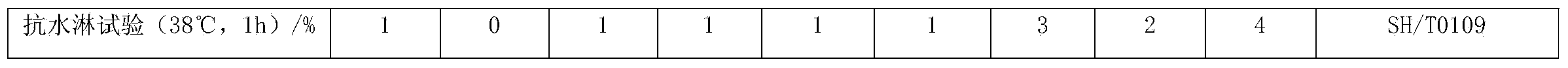

Examples

Embodiment 1

[0038] The special grease composition for the standard section assembly of tower cranes, the components and mass percentages are as follows:

[0039] (1) No. 2 general lithium grease 90.6%;

[0040] (2) Diphenylamine 0.4%;

[0041] (3) Flake graphite 1.3%;

[0042] (4) light calcium carbonate 2.7%;

[0043] (5) Sorbitan monooleate 1.2%

[0044] (6) Phenolic resin 1.0%

[0045] (7) Barium dinonyl naphthalene sulfonate 2.3%

[0046] (8) Polyisobutylene 0.5%

[0047]Put 906g of No. 2 general-purpose lithium-based grease (working penetration 287, unit 0.1mm) into the refining kettle, stir and heat up. When the temperature rose to 125°C, the heating was stopped. Add 10 g of phenolic resin and 23 g of barium dinonylnaphthalene sulfonate, and keep stirring at the temperature for 21 min. Cool the material. When the temperature reached 105°C, 4g of diphenylamine, 13g of flake graphite, 27g of light calcium carbonate (45μm sieve residue less than 0.4%), 12g of sorbitan monoolea...

Embodiment 2

[0049] The special grease composition for the standard section assembly of tower cranes, the components and mass percentages are as follows:

[0050] (1) No. 3 general lithium grease 85.5%;

[0051] (2) N-phenyl α-naphthylamine 0.3%;

[0052] (3) Colloidal graphite 2.7%;

[0053] (4) light calcium carbonate 3.6%;

[0054] (5) Sorbitan monooleate 1.5%

[0055] (6) Phenolic resin 1.9%

[0056] (7) Barium dinonyl naphthalene sulfonate 3.7%

[0057] (8) Polyisobutylene 0.8%

[0058] Put 855 g of No. 3 general-purpose lithium-based grease (working penetration 245, unit 0.1 mm) into the kettle, and stir to raise the temperature. When the temperature rose to 130°C, the heating was stopped. Add 19 g of phenolic resin and 37 g of barium dinonylnaphthalene sulfonate, and keep stirring at the temperature for 22 minutes. Cool the material. When the temperature reached 99°C, 3g of N-phenyl α-naphthylamine, 27g of colloidal graphite, 36g of light calcium carbonate (45μm sieve resid...

Embodiment 3

[0060] The special grease composition for the standard section assembly of tower cranes, the components and mass percentages are as follows:

[0061] (1) No. 2 general lithium grease 78.8%;

[0062] (2) N-phenyl α-naphthylamine 0.8%

[0063] (3) Colloidal graphite 3.2%;

[0064] (4) light calcium carbonate 4.5%;

[0065] (5) Sorbitan monooleate 3.0%

[0066] (6) Phenolic resin 2.2%

[0067] (7) Barium petroleum sulfonate 6.0%

[0068] (8) Polyisobutylene 1.5%

[0069] Put 788g of No. 2 general-purpose lithium-based grease (working penetration 287, unit 0.1mm) into the kettle, stir and heat up. When the temperature rose to 135°C, the heating was stopped. Add 22g of phenolic resin and 60g of barium petroleum sulfonate, keep the temperature and stir for 30min. Cool the material. When the temperature reaches 110°C, add 8 g of N-phenyl α-naphthylamine, 32 g of colloidal graphite (particle size less than 30 μm), 45 g of light calcium carbonate (45 μm sieve residue less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com