Aluminum alloy surface micro-arc oxidation coating and preparing method thereof

A technology of micro-arc oxidation on the surface of aluminum alloy, applied in the field of electrochemistry, can solve the problems of complex film forming process, reducing the wear resistance of the film layer, affecting the wear resistance of the film layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Preparation and pretreatment of matrix materials

[0058] The substrate is made of 6061 aluminum alloy, and its main components are shown in Table 1. Cut the aluminum alloy sheet into small cuboid pieces of 20mm×20mm×12mm by wire cutting, and wash off the oil stain remaining on the surface of the sample during the wire cutting process with gasoline. Use a drill press to drill a hole on the surface of 20 mm × 12 mm, and then use a tap to tap for easy clamping in the micro-arc oxidation experiment. Before the experiment started, the samples were polished on 400#, 600#, and 1000# sandpaper respectively, and then the samples were removed with acetone to remove the surface grease. After taking it out, wipe off the surface grease, then ultrasonically cleaned in alcohol, and then Rinse with deionized water and dry before use.

[0059] Table 1 Chemical composition of 6061 aluminum alloy (mass fraction, %)

[0060] Mg Si Cu Cr Fe Zn mn Ti Al 0.8...

Embodiment 2

[0072] 1. Preparation and pretreatment of matrix materials

[0073] Operate with embodiment 1.

[0074] 2. Electrolyte preparation

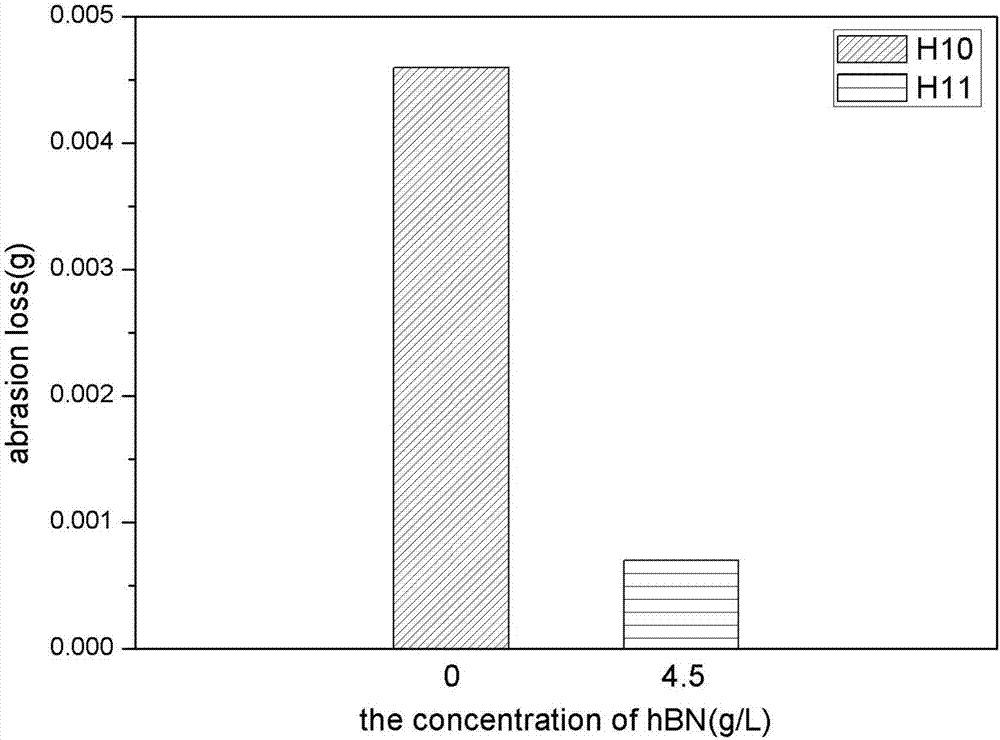

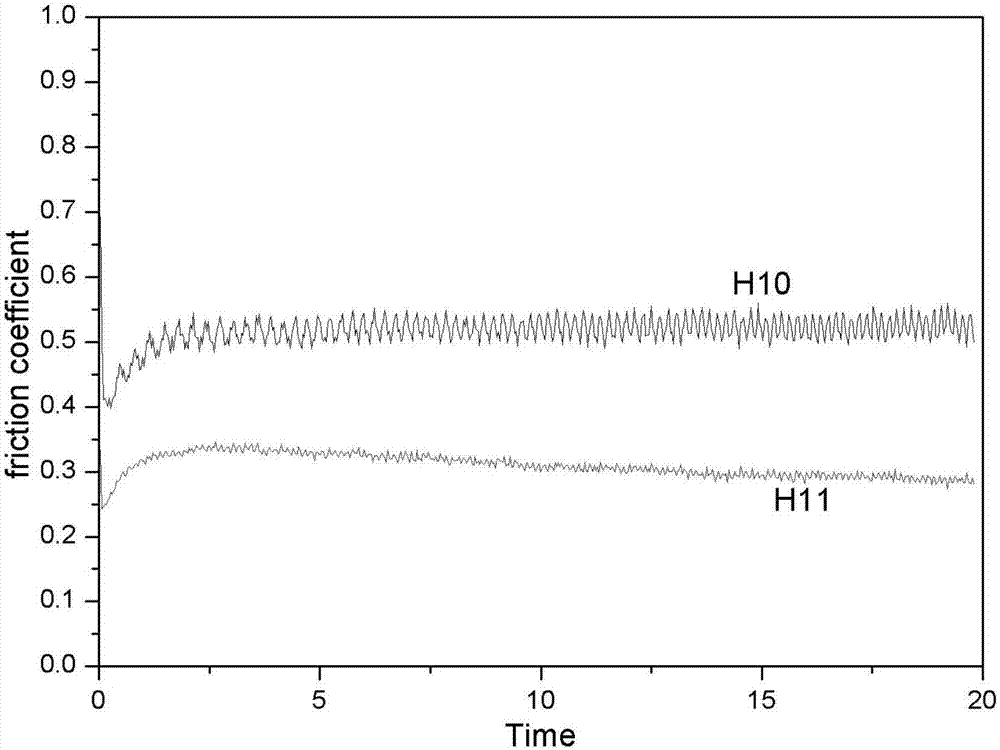

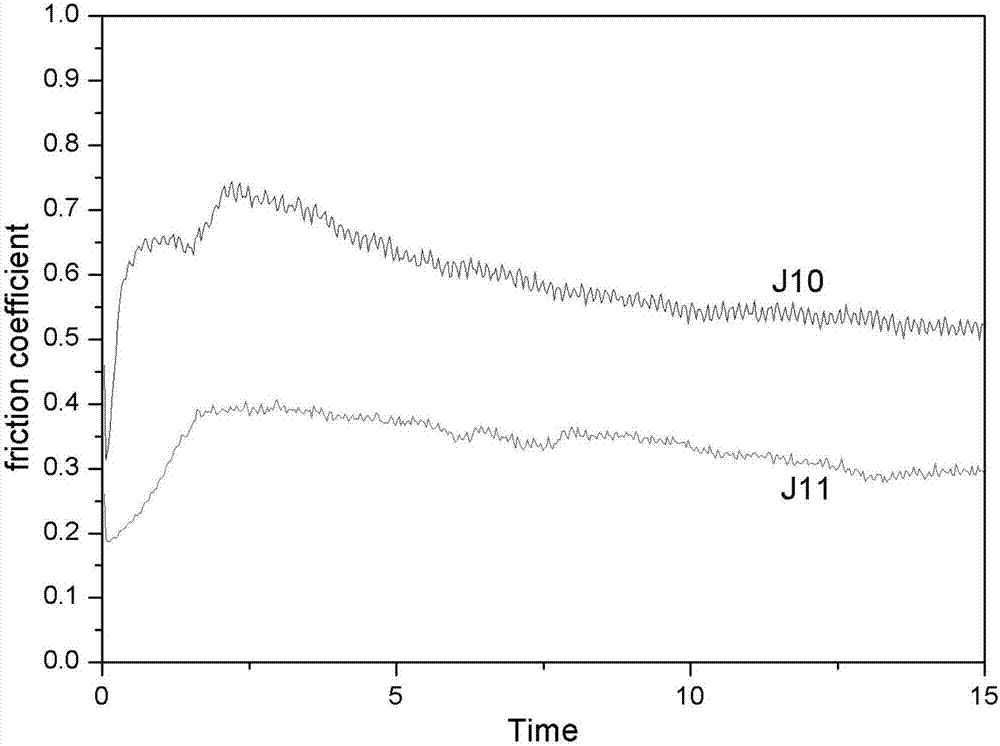

[0075] AcNa+(NaPO 3 ) 6 +Na 2 WO 4 The micro-arc oxidation experiment was carried out, and the specific composition of the electrolyte is shown in Table 3. Among them, the median particle size of micron-sized HBN is 0.7 μm, and the particle size range is 0.1-0.9 μm.

[0076] Table 3 Electrolyte formula of J11 acetate system

[0077] Sample No AcNa(g / L) (NaPO 3 ) 6 (g / L)

Na 2 WO 4 (g / L)

EDTA-2Na(g / L) HBN (g / L) J11 12 6 3 0.5 4.5

[0078] 3. Micro-arc oxidation treatment in coating preparation process

[0079] Operate with embodiment 1.

[0080] 4. Experiment and film formation process

[0081] Operate with embodiment 1.

Embodiment 3

[0083] 1. Preparation and pretreatment of matrix materials

[0084] Operate with embodiment 1.

[0085] 2. Electrolyte preparation

[0086] AcNa+(NaPO 3 ) 6 +Na 2 WO 4 The micro-arc oxidation experiment was carried out, and the specific composition of the electrolyte is shown in Table 4. Among them, the median particle size of micron-sized HBN is 0.7 μm, and the particle size range is 0.1-0.9 μm.

[0087] Table 4 Electrolyte formula of J21 acetate system

[0088] Sample No AcNa(g / L) (NaPO 3 ) 6 (g / L)

Na 2 WO 4 (g / L)

EDTA-2Na(g / L) HBN (g / L) J21 12 4 3 0.5 4.5

[0089] 3. Micro-arc oxidation treatment in coating preparation process

[0090] Operate with embodiment 1.

[0091] 4. Experiment and film formation process

[0092] Operate with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com