Reaming tool special for valve seat of cylinder cover of multi-cylinder diesel engine

A technology for reaming tools and valve seats, which is used in reamers, manufacturing tools, metal processing equipment, etc., can solve the problems of large coaxiality error of the inner hole of the guide tube, poor surface roughness of the sealing ring, and large shape error, etc. Achieve high hardness, ensure coaxiality requirements, and reduce the surface roughness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

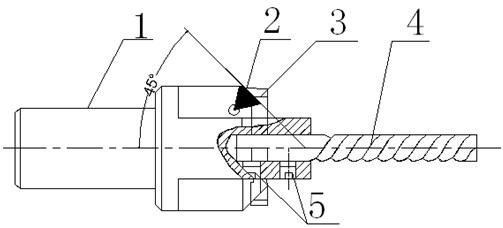

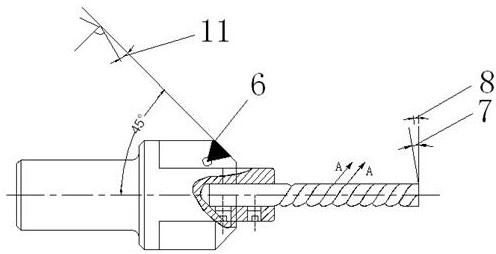

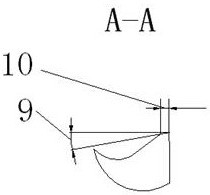

[0023] see figure 1 , 2 , 3. The present invention provides the following technical solutions: a multi-cylinder diesel engine cylinder head valve seat special reaming cutter, the cutter includes: cutter body 1, blade 2, valve seat valve 3, conduit inner hole push reamer 4, locking Bolt 5, chip breaker 6, end face cutting edge relief angle 7, radial cutting edge relief angle 8, radial cutting edge rake angle 9, radial cutting edge land width 10, seat ring Verville line reamer relief angle 11 , the cutter body 1 is a cylindrical shape, made of 38CrMoAl alloy modulation steel, the cutter body 1 is provided with a chip breaker 6, and the blade 2 is a machine-clamped cermet blade, which is set on the cutter body 1, and the central axis of the cutter body 1 At an angle of 45 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com