Hardware workpiece surface treatment technology

A technology of workpiece surface and treatment process, applied in the direction of metal material coating process, surface pretreatment, device for coating liquid on the surface, etc. Combined with problems such as unreliability and poor workpiece quality, it can achieve the effects of small volume loss, low wear depth and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

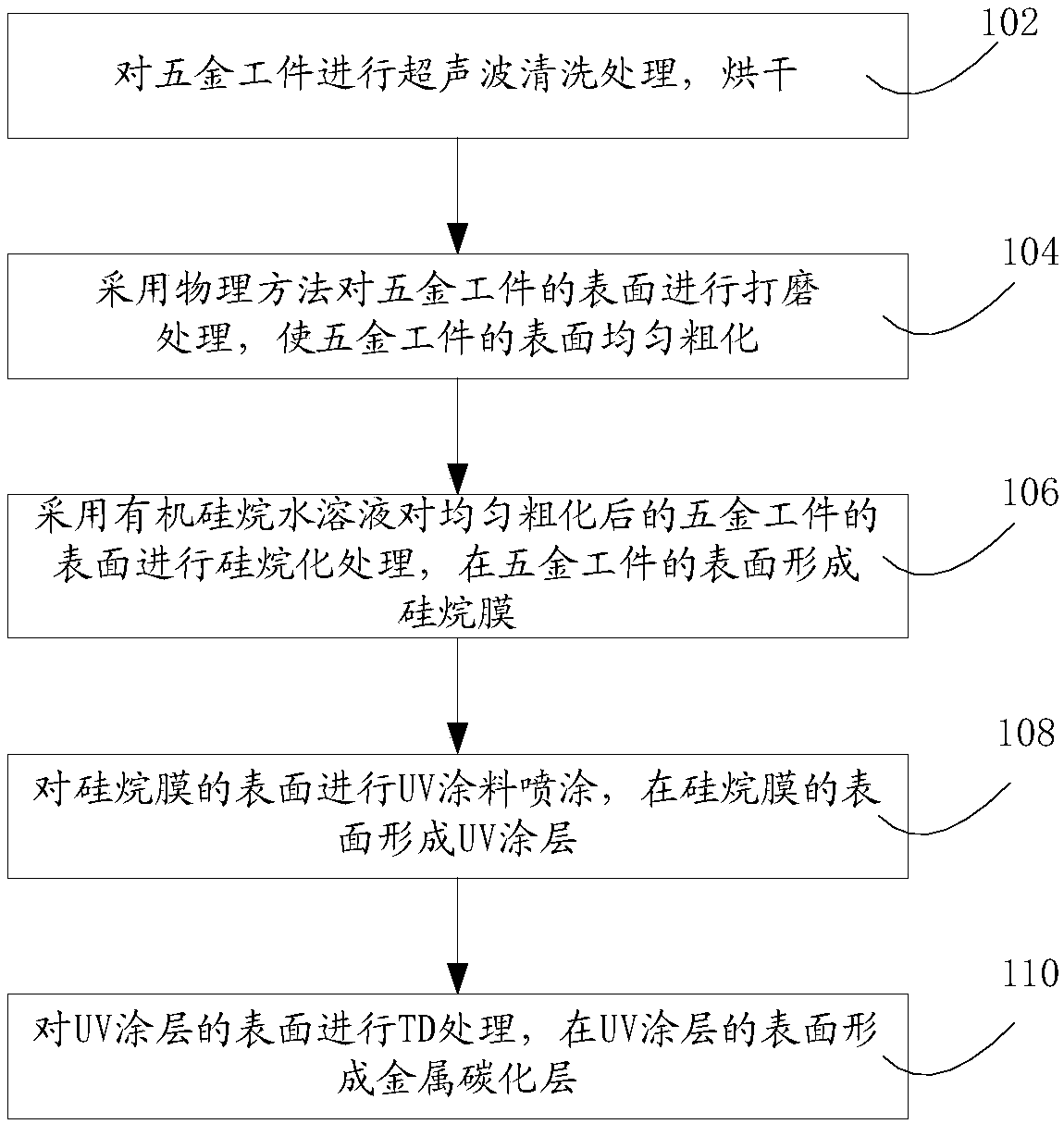

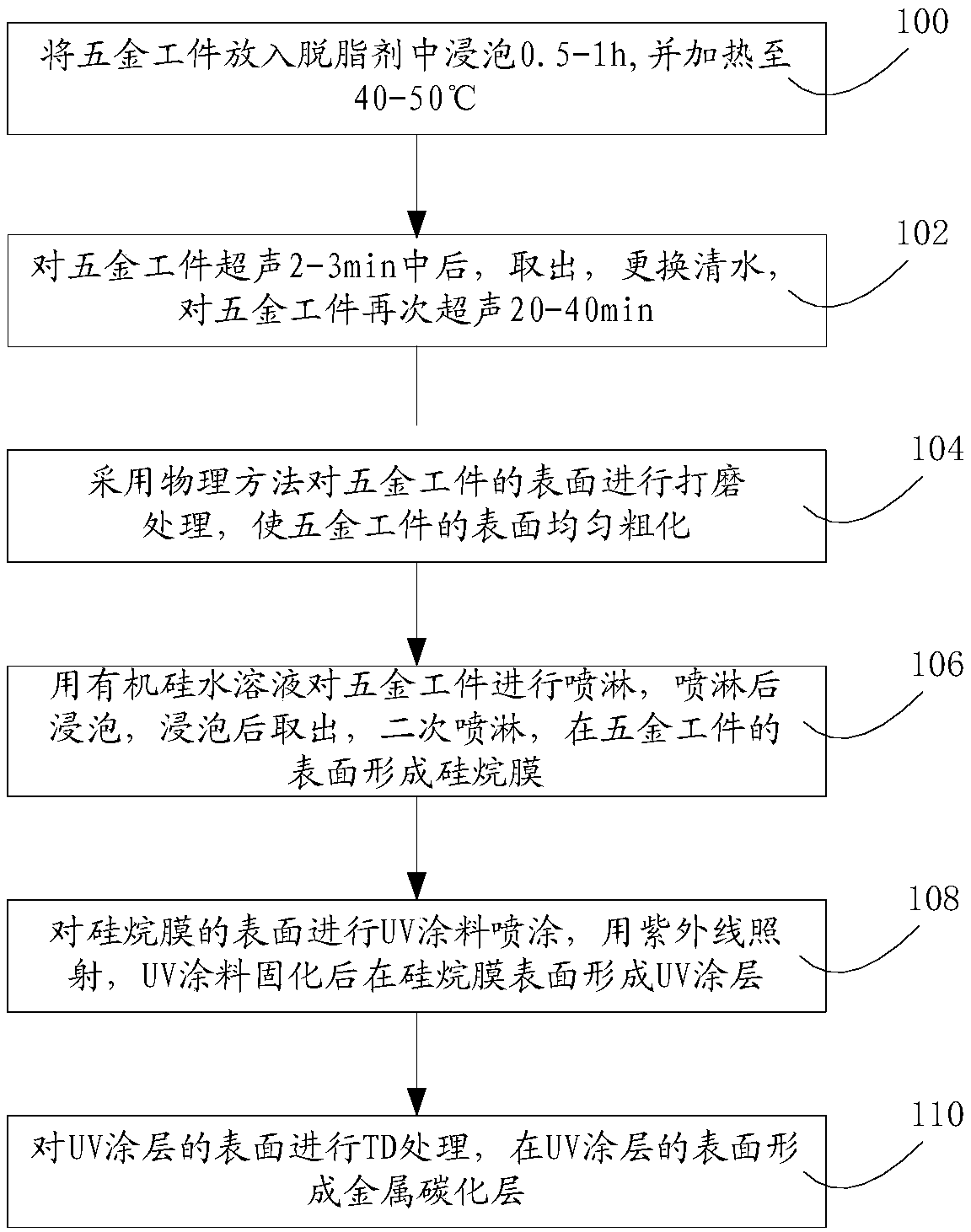

Method used

Image

Examples

Embodiment 1

[0044] A hardware workpiece is provided, and the hardware workpiece is soaked in a degreasing agent for 0.5 hours and then taken out;

[0045] Put the hardware workpiece into the cleaning tank of ultrasonic cleaning agent, inject clean water into the cleaning tank, after ultrasonic for 2 minutes, take out the hardware workpiece, replace the clean water in the cleaning tank, put the hardware workpiece into the cleaning tank again, and ultrasonic for 20 minutes Take it out and dry the hardware workpiece;

[0046] The surface of the hardware workpiece is treated by a dry sandblasting process, so that the surface of the hardware workpiece is textured and uniformly roughened;

[0047] Use organic silicon aqueous solution to spray the metal workpiece, put it into the tank for soaking after spraying, take it out after soaking, and then spray it again to form a silane film on the surface of the hardware workpiece;

[0048] The surface of the silane film is sprayed with UV paint, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com