Anticorrosive coating used for flue gas desulfurization equipment and preparation method thereof

A technology for desulfurization equipment and anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as high cost and short protection time, improve dispersion stability, facilitate preparation, and improve high temperature resistance. and tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

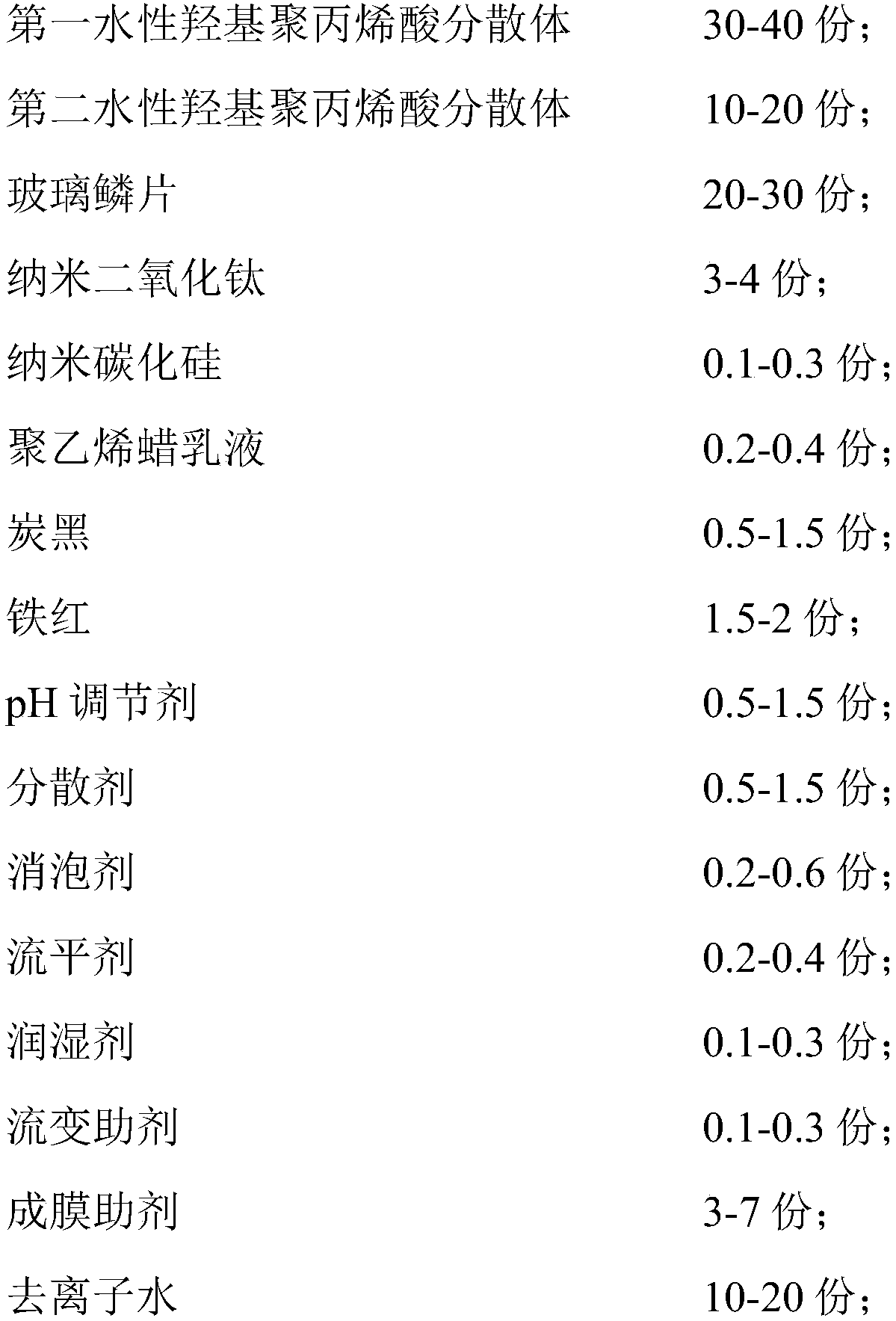

[0048] An embodiment of the present invention provides an anti-corrosion coating for flue gas desulfurization equipment, including A component and B component, and the A component includes the following raw material components in parts by weight:

[0049]

[0050]

[0051] The B component includes the following raw material components in parts by weight:

[0052] 82 parts of isocyanate curing agent;

[0053] Co-solvent 10 parts.

[0054] The above-mentioned first aqueous hydroxyl polyacrylic acid dispersion is Bayer's A2470; the second aqueous hydroxyl polyacrylic acid dispersion is Bayer's A2743; the glass flakes are glass flakes with a sheet diameter of 120 meshes produced by Huawei Glass Flake Factory in Wen'an County; nano titanium dioxide is DuPont's R-103; nano-silicon carbide is 409-21-2 produced by Shanghai Ziyi Reagent Factory; polyethylene wax emulsion is SX123A from Sanxing Chemical Co., Ltd.; carbon black is H200 produced by Shandong Lihua New Material Compa...

Embodiment 2

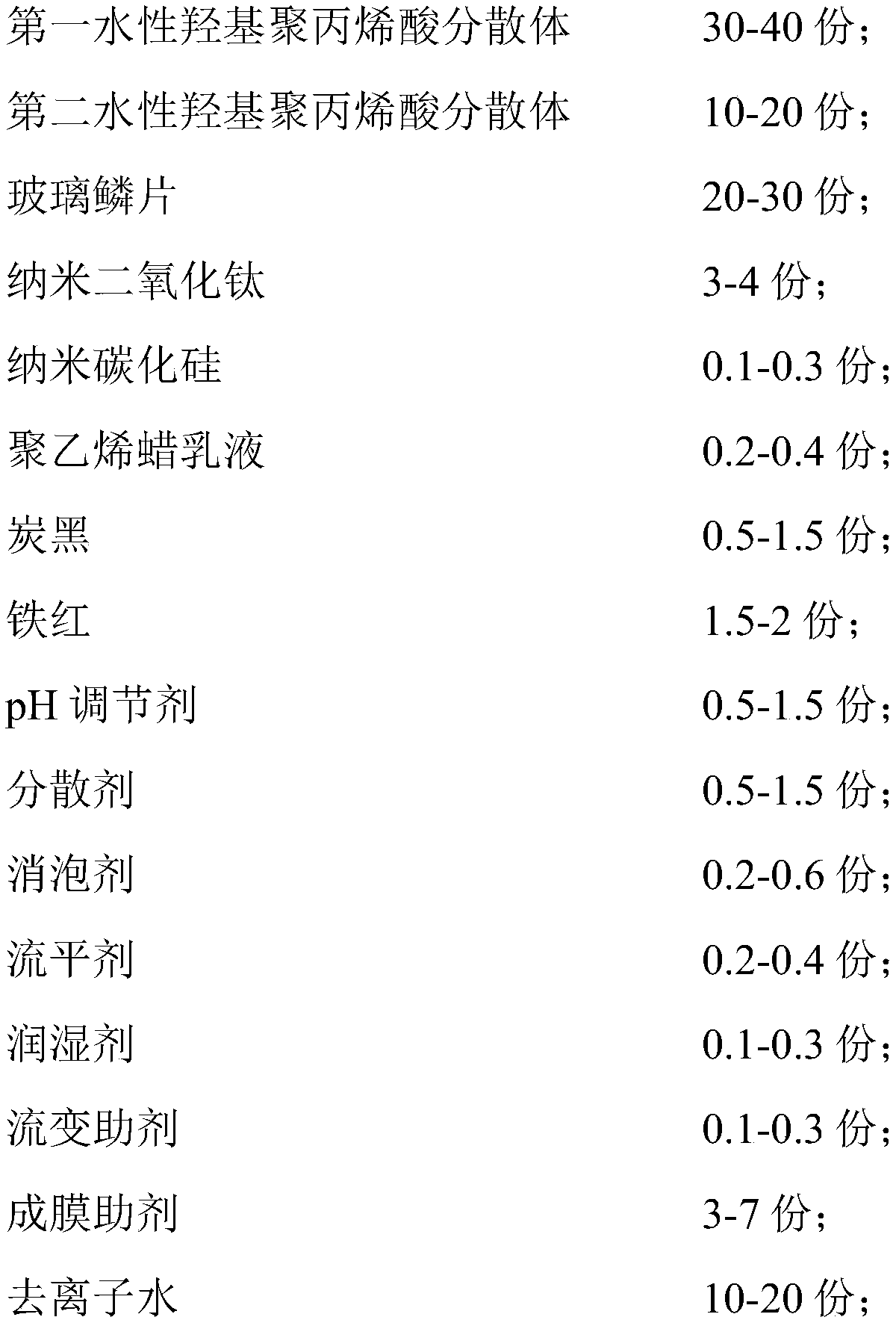

[0061] An embodiment of the present invention provides an anti-corrosion coating for flue gas desulfurization equipment, including A component and B component, and the A component includes the following raw material components in parts by weight:

[0062]

[0063]

[0064] The B component includes the following raw material components in parts by weight:

[0065] 80 parts of isocyanate curing agent;

[0066] 20 parts of co-solvent.

[0067] The above-mentioned first aqueous hydroxyl polyacrylic acid dispersion is Bayer's A2470; the second aqueous hydroxyl polyacrylic acid dispersion is Bayer's A2743; the glass flakes are glass flakes with a sheet diameter of 120 meshes produced by Huawei Glass Flake Factory in Wen'an County; nano titanium dioxide is DuPont's R-103; nano-silicon carbide is 409-21-2 produced by Shanghai Ziyi Reagent Factory; polyethylene wax emulsion is SX123A from Sanxing Chemical Co., Ltd.; carbon black is H200 produced by Shandong Lihua New Material Co...

Embodiment 3

[0074] An embodiment of the present invention provides an anti-corrosion coating for flue gas desulfurization equipment, including A component and B component, and the A component includes the following raw material components in parts by weight:

[0075]

[0076] The B component includes the following raw material components in parts by weight:

[0077] 74 parts of isocyanate curing agent;

[0078] Co-solvent 26 parts.

[0079] The above-mentioned first aqueous hydroxyl polyacrylic acid dispersion is Bayer's A2470; the second aqueous hydroxyl polyacrylic acid dispersion is Bayer's A2743; the glass flakes are glass flakes with a sheet diameter of 120 meshes produced by Huawei Glass Flake Factory in Wen'an County; nano titanium dioxide is DuPont's R-103; nano-silicon carbide is 409-21-2 produced by Shanghai Ziyi Reagent Factory; polyethylene wax emulsion is SX123A from Sanxing Chemical Co., Ltd.; carbon black is H200 produced by Shandong Lihua New Material Company; iron red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com