Bearing lubricating oil composition and preparation method thereof

A technology of lubricating oil composition and bearing, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of unsuitable bearing lubricating oil use requirements, general anti-corrosion performance and anti-rust performance, low viscosity index of bearing oil, etc. Low temperature start-up and high temperature resistance, excellent corrosion and rust resistance, and the effect of reducing damage caused by friction and external erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

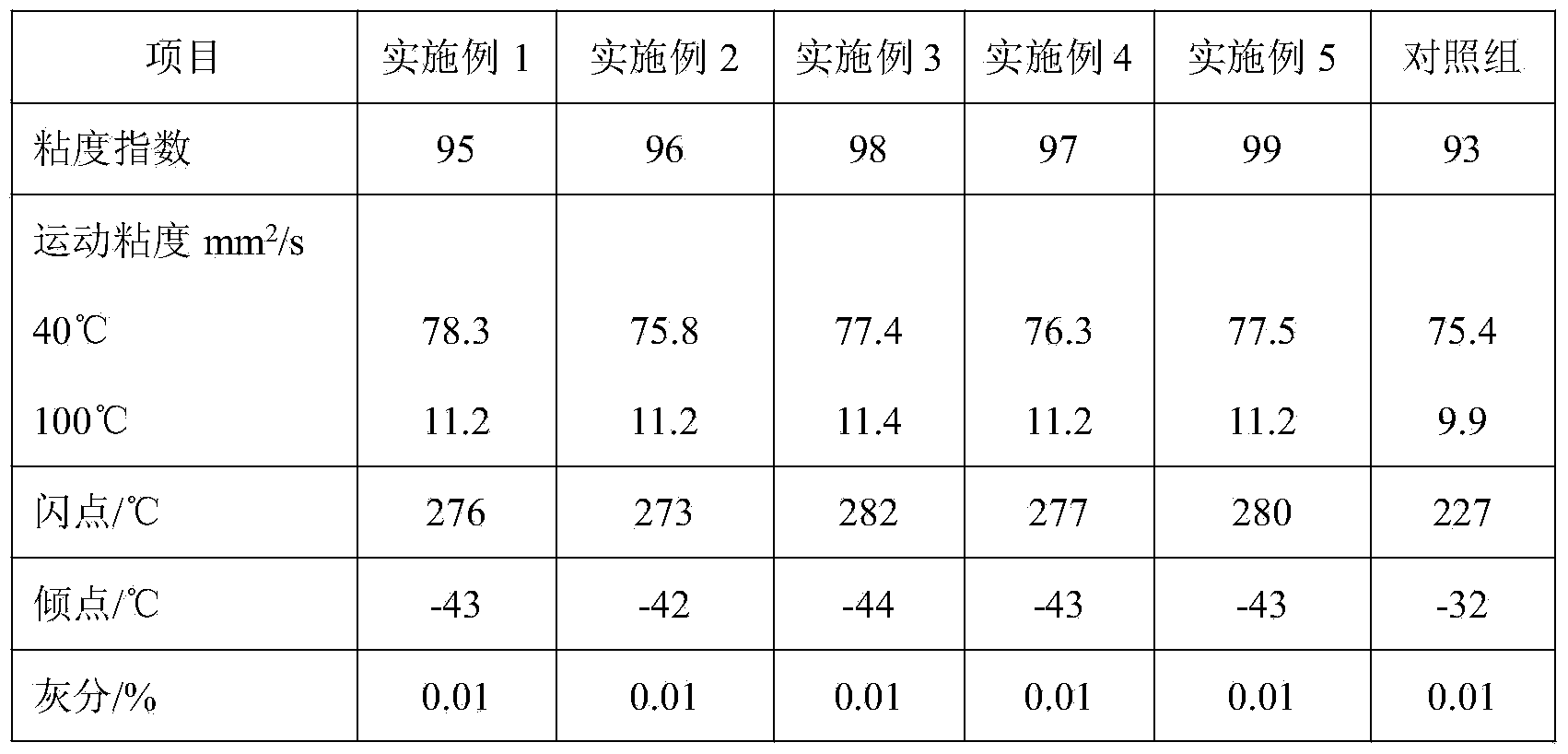

Examples

Embodiment 1

[0030] A kind of bearing lubricating oil composition, comprises each component of following mass parts:

[0031] Base oil is naphthenic base oil, 55 parts by mass;

[0032] The oily agent is oxidized rapeseed oil, 8 parts;

[0033] Extreme pressure antiwear agent, borated oleamide, 5-12 parts;

[0034] 5-10 parts of friction modifier, which is phosphoric acid ester;

[0035] Antirust agent is sulfonated castor oil, 3.5-6 parts;

[0036] 3.2-5.8 parts of viscosity index improver, which is polyacrylate;

[0037] 2.2-4.5 parts of anti-emulsifier is ethylene oxide.

[0038] According to the preparation method of the bearing lubricating oil composition provided by the present invention, the above-mentioned bearing lubricating oil composition is prepared, and the preparation steps are as follows:

[0039] (1) Weighing: accurately weigh each component of the bearing lubricating oil composition;

[0040] (2) Jet mixing method: the base oil and the liquid additive are mixed toget...

Embodiment 2

[0044] A kind of bearing lubricating oil composition, comprises each component of following mass parts:

[0045] 70 parts of base oil, which is naphthenic base oil;

[0046] 15 parts of oily agent is ethylene glycol oleate;

[0047] 12 parts of extreme pressure antiwear agent is sodium tetraborate;

[0048] 10 parts of friction modifier, which is phosphoric acid ester;

[0049] 6 parts of antirust agent, is castorate potassium;

[0050] 5.8 parts of viscosity index improvers are polyisobutylene;

[0051] 4.5 parts of anti-emulsifier is polyethylene oxide.

[0052] According to the preparation method of the bearing lubricating oil composition provided by the present invention, the above-mentioned bearing lubricating oil composition is prepared, and the preparation steps are as follows:

[0053] (1) Weighing: accurately weigh each component of the bearing lubricating oil composition;

[0054] (2) Jet mixing method: the base oil and the liquid additive are mixed together, a...

Embodiment 3

[0058] A kind of bearing lubricating oil composition, comprises each component of following mass parts:

[0059] 63 parts of base oil are naphthenic base oils;

[0060] 12 parts of oiliness agent is ethylene glycol oleate;

[0061] 10 parts of extreme pressure antiwear agent is borated oleamide;

[0062] 8 parts of friction modifier, which is phosphoric acid ester;

[0063] 5.5 parts of rust inhibitors are sulfonated castor oil;

[0064] 5 parts of viscosity index improvers are polyacrylates;

[0065] 2.2-4.5 parts of anti-emulsifier is polyethylene oxide-propylene oxide ether.

[0066] According to the preparation method of the bearing lubricating oil composition provided by the present invention, the above-mentioned bearing lubricating oil composition is prepared, and the preparation steps are as follows:

[0067] (1) Weighing: accurately weigh each component of the bearing lubricating oil composition;

[0068] (2) Jet mixing method: the base oil and the liquid additive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com