Patents

Literature

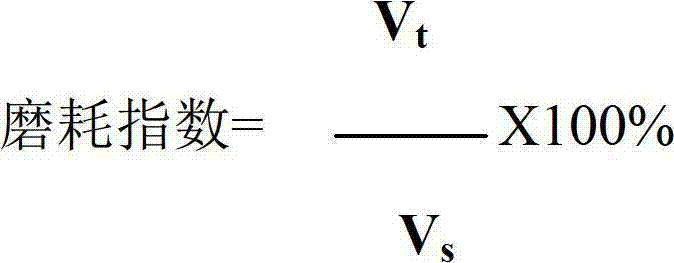

40results about How to "Reduced wear index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

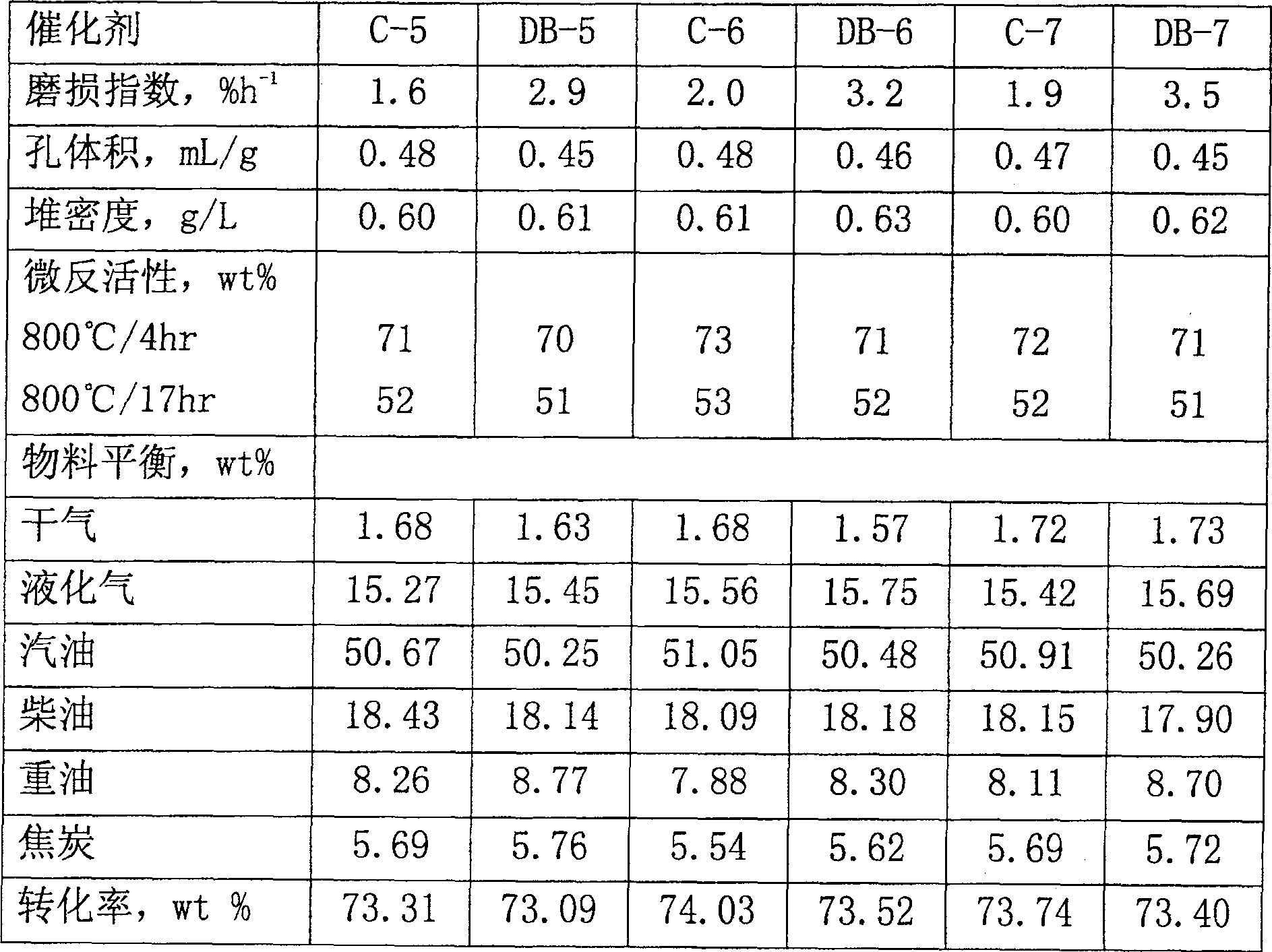

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalyst used for chlorine preparation, catalyst, and method used for preparing chlorine

ActiveCN104785271AImprove liquidityHigh activityHeterogenous catalyst chemical elementsCatalyst activation/preparationRare-earth elementPtru catalyst

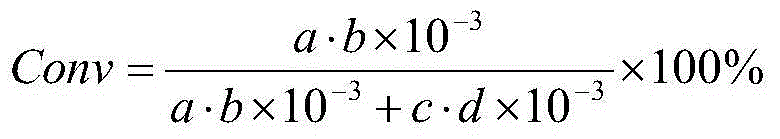

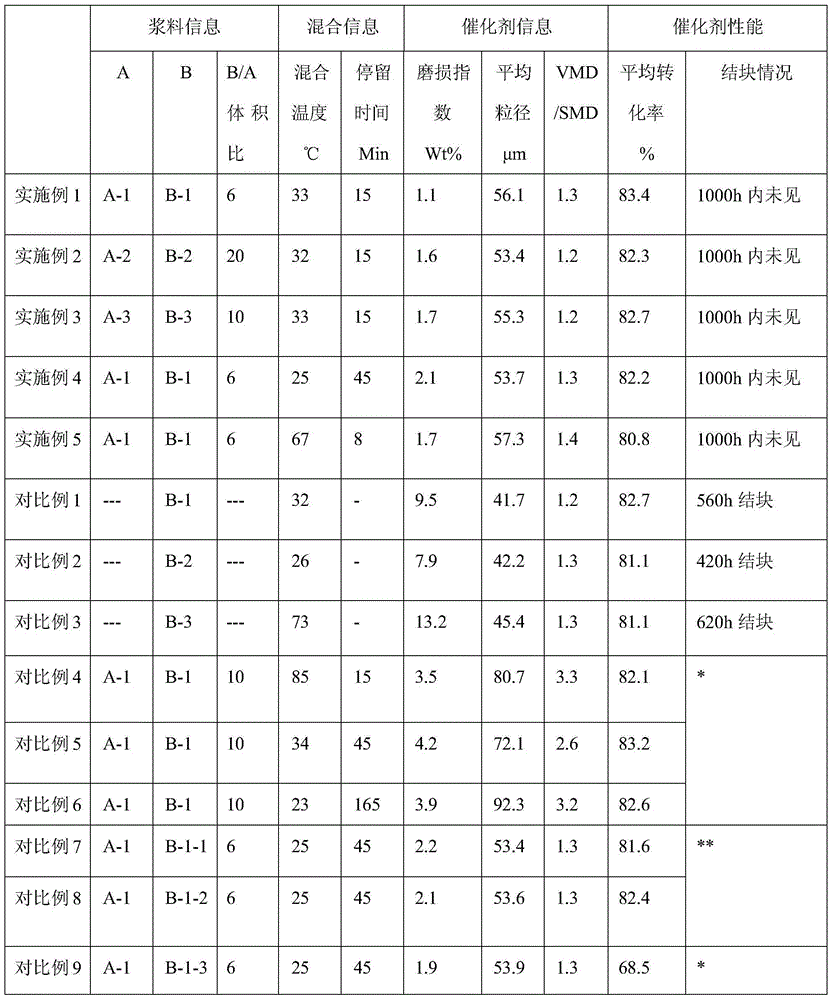

The present invention relates to a method for preparing catalyst used for preparing chloride by oxidizing hydrogen chloride. The method is mixing a slurry mainly containing boron and chromium with a slurry mainly containing copper, boron, alkali-metal elements, rare-earth elements, aluminum sol, silica sol, carrier and optionally other metal elements, the mixing temperature being not more than 100℃, and the residence time being not more than 120 minutes, the mixed slurry is successively treated with spray drying, high temperature calcination and the like, so that catalyst particles is obtained. The present invention also relates to the catalyst prepared through the method, uses of the catalyst used in the process of preparing chloride by oxidizing hydrogen chloride and a method for preparing chlorine by using the catalyst. The catalyst is used for preparing chlorine by oxidizing hydrogen chloride with oxygen or air in fluidized bed reactor, and has an excellent activity and anti-caking property, a relatively good mechanical strength and a relatively long service life.

Owner:WANHUA CHEM GRP CO LTD

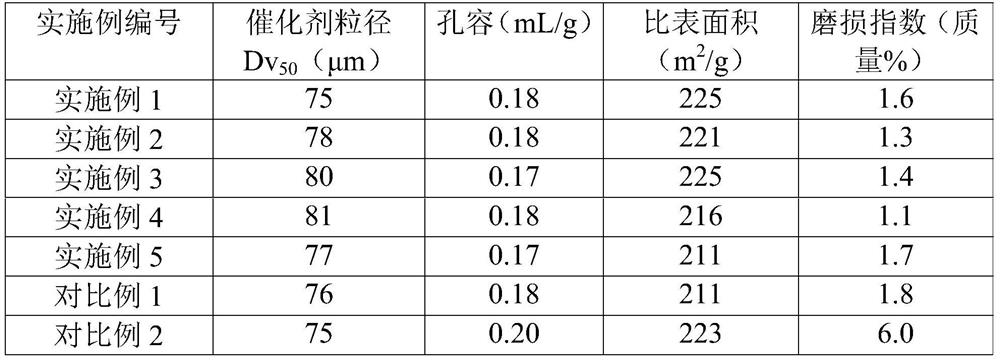

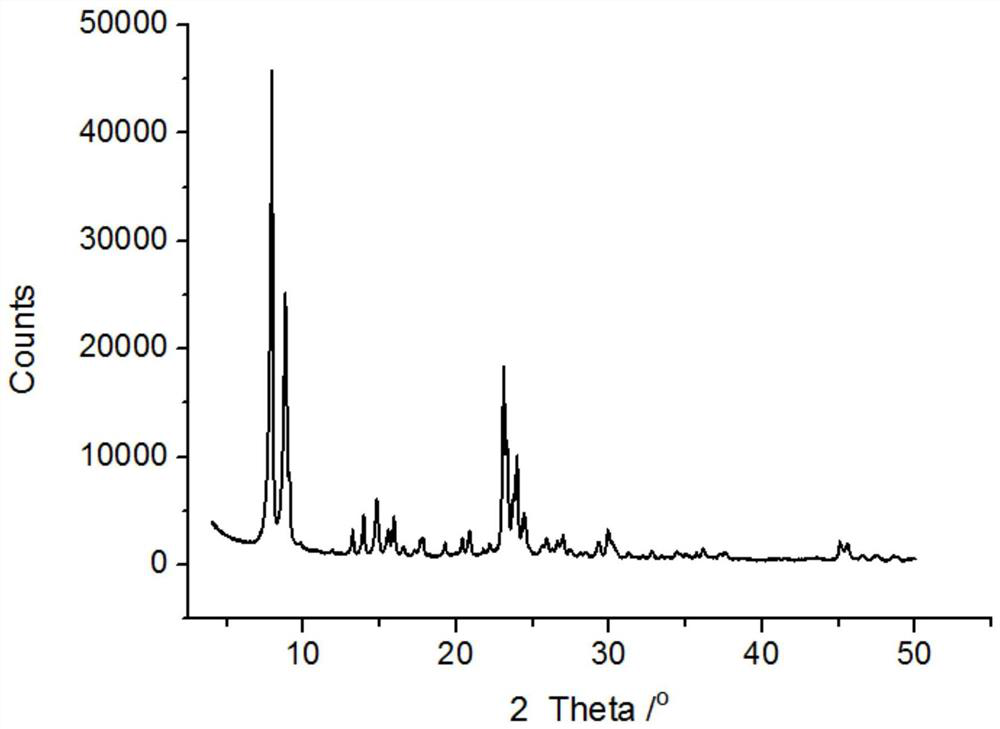

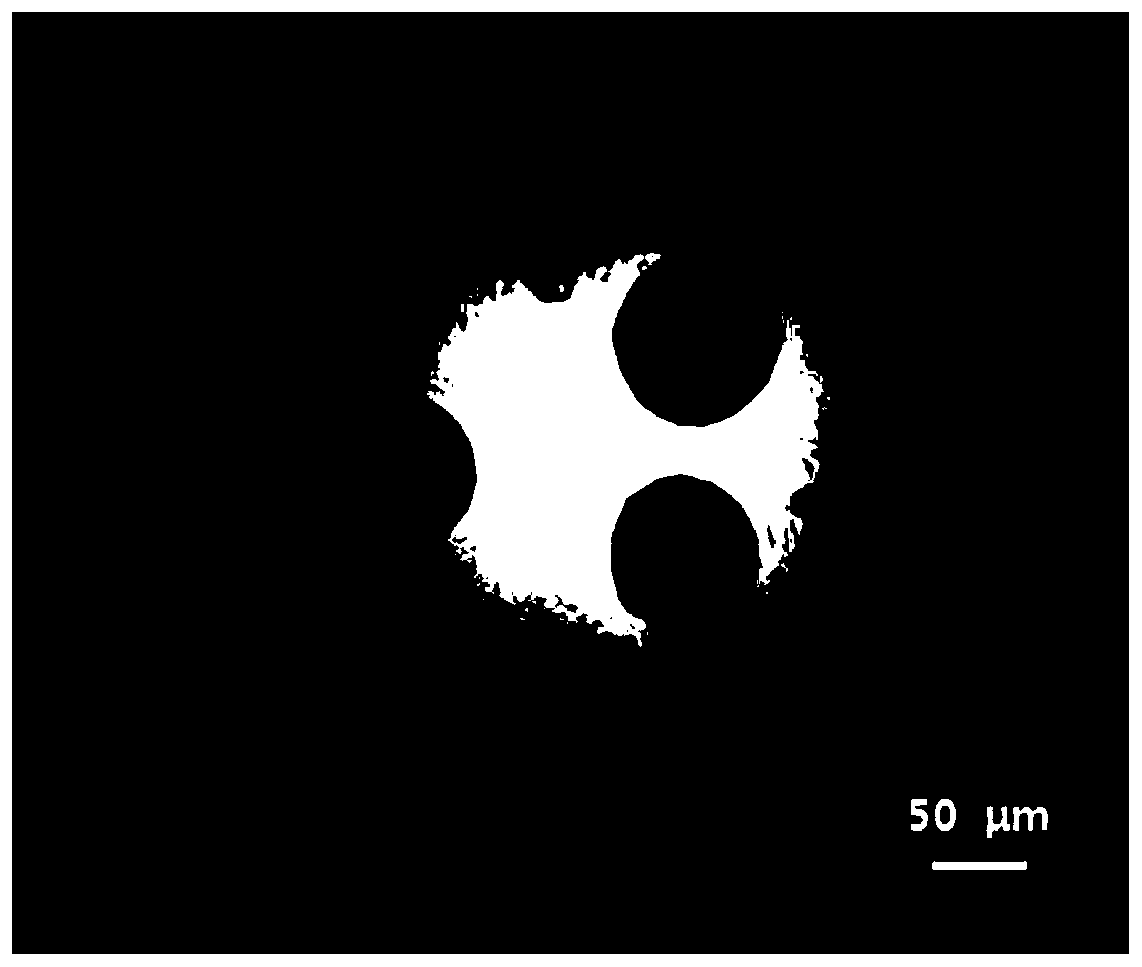

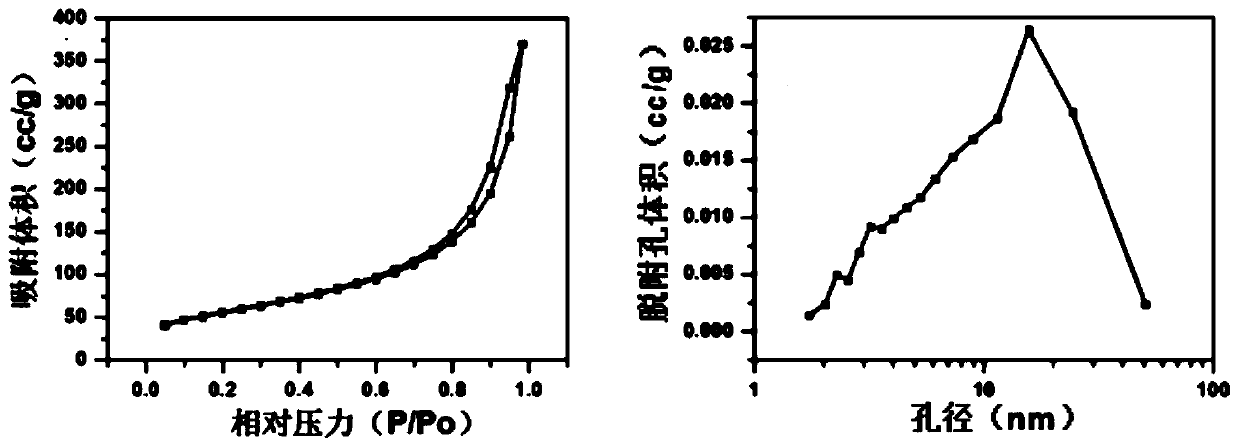

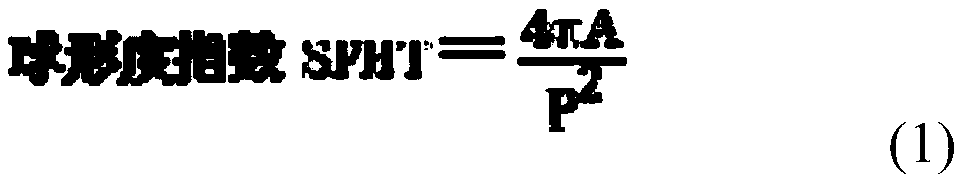

Micro-spherical silicon oxide/aluminum oxide based noble metal catalyst and preparation method thereof

ActiveCN107233881ALarger than surfaceLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsDispersityPetrochemical

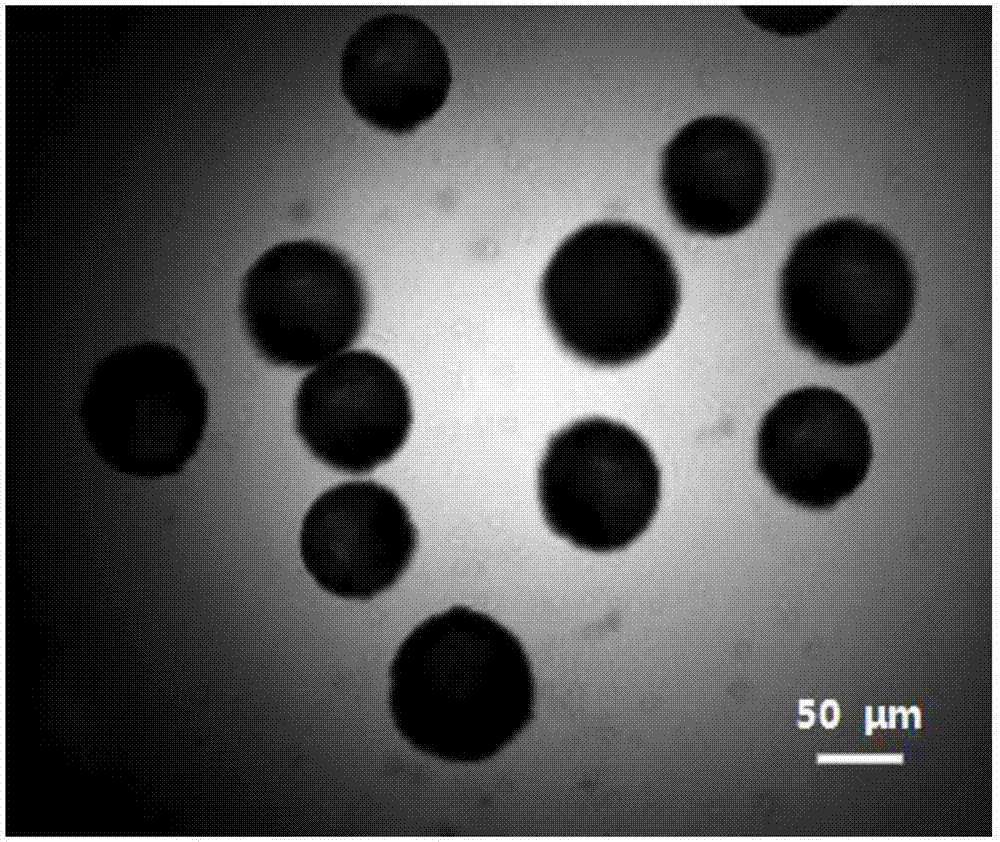

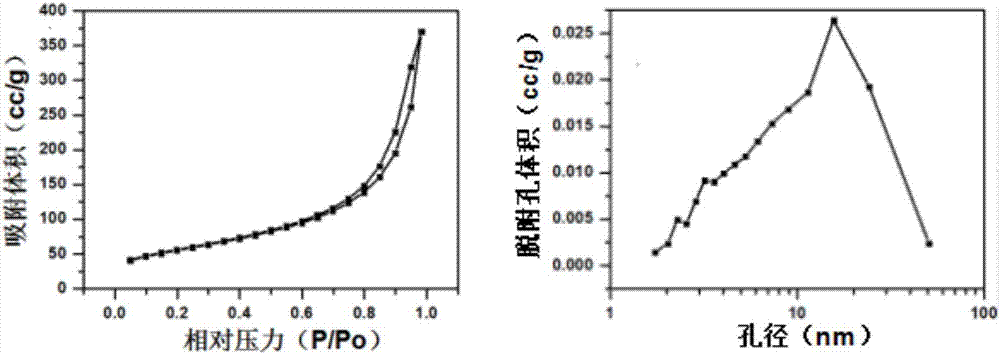

The invention provides a micro-spherical SiO2-Al2O3 based noble metal catalyst and a preparation method thereof. The preparation method comprises the following steps: dispersing silica sol into a silica sol system, so that silica sol is mixed with alumina sol and a coagulant to form formed sol, forming the sol by virtue of an atomizing dispersion-oil column formation method, and carrying out aging, washing, drying and roasting to obtain micro-spherical SiO2-Al2O3; and loading noble metal active components with the micro-spherical SiO2-Al2O3 as a carrier, obtain the micro-spherical SiO2-Al2O3 based noble metal catalyst. The catalyst has the characteristics that the specific surface area and the pore volume are large, the dispersity of active components is high, the abrasion index is relatively low, and the wear resistance is high. The catalyst is mainly applied to a hydrogenation process of preparing hydrogen peroxide by using a fluidized bed anthraquinone method and has relatively high catalytic activity, selectivity and stability. The catalyst can be also applied to reaction processes such as hydrorefining, selective hydrogenation and selective oxidation in petrochemical engineering and fine chemical engineering production.

Owner:BEIJING UNIV OF CHEM TECH

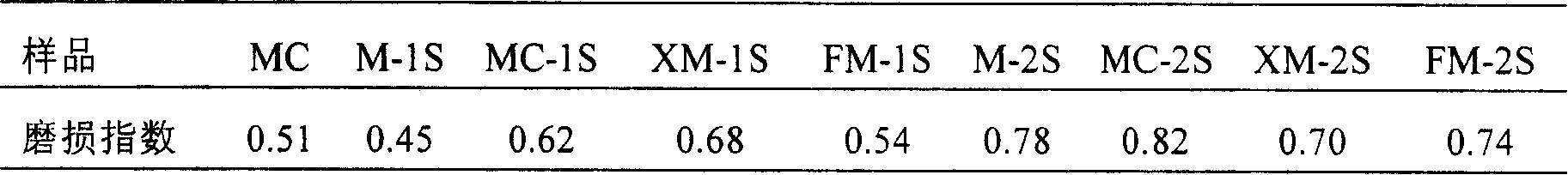

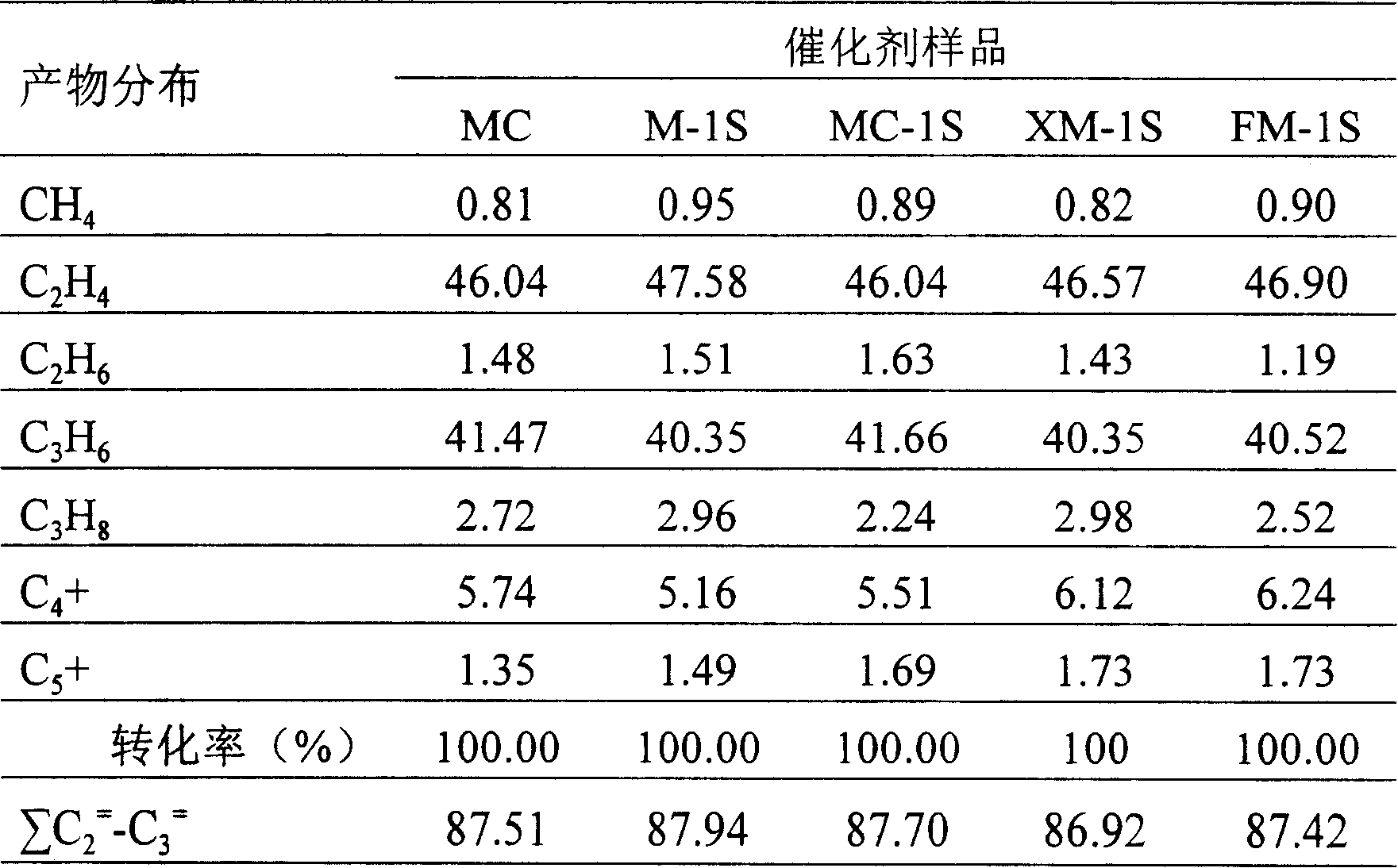

Recovery method of microspherical catalyst of fluid bed

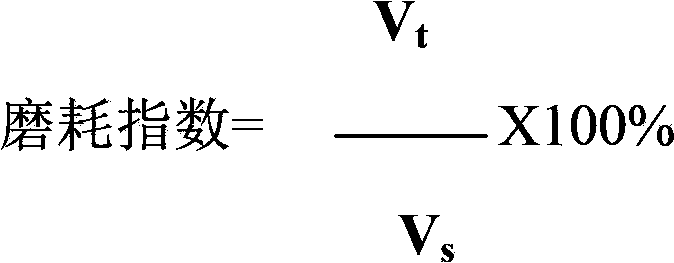

ActiveCN101157051AReduced wear indexSuitable particle size distributionMolecular sieve catalystsCatalyst activation/preparationRecovery methodMicrosphere

The invention relates to a recovery method of microspherical catalyst for a fluidized bed. The invention provides the method that catalyst to be recovered is mixed with each raw material preparing the fresh microspherical catalyst in certain proportion, the spray drying and the high temperature roasting are performed after the colloid milling of feed pulp, and the microspherical catalyst having the low abrasion index and the suitable particle size distribution can be obtained. The invention has the preparation processes that: firstly, according to the stoichiometric ratio of oxide dry basis, the catalyst to be recovered, molecular sieve initial powder, binding agent, auxiliary agent, pore forming agent, and deionized water are mixed and pulped, and the weight content of the oxide dry basis of recovered catalyst is not more than 80 percent in total blending; secondly, the colloid milling of the feed pulp through a colloid mill is performed, thereby the solid particle diameter contained in the feed pulp is smaller than 20 micron, 90 percent of the particle diameter is small than 10 micron, and 70 percent of the particle diameter is small than 5 micron; thirdly, the spray drying is performed, thereby producing a microspherical sample; fourthly, the microspherical sample is roasted in oxygen-containing atmosphere at 500 to 800 DEG C, thereby obtaining the microspherical catalyst for the fluidized bed. The recovered and prepared microspherical catalyst can be used for the reaction of producing alkene by converting an oxygen compound.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalytic cracking catalyst and preparation method thereof

InactiveCN103301889ALarge mesopore volumeHigh strengthCatalytic crackingMolecular sieve catalystsOrganic filmMolecular sieve

The invention provides a preparation method of a catalytic cracking catalyst. The method comprises the steps of: (1) mixing a porous material and a molecular sieve with a water solution of an organic film forming matter at a first temperature, and then drying; and (2) mixing clay and binders with the mixture prepared in the step (1) at a second temperature, pulping the mixture, and then carrying out spray drying, washing and drying in sequence, wherein washing is carried out at the first temperature; the organic film forming matter is a film forming matter with solubility in water at the first temperature higher than that at the second temperature; and the porous material is porous alumina and / a porous silicon-aluminum material. The invention also provides the catalytic cracking catalyst prepared by the method. The catalytic cracking catalyst not only has bigger mesopore volume but also maintains higher strength.

Owner:山西腾茂科技股份有限公司 +1

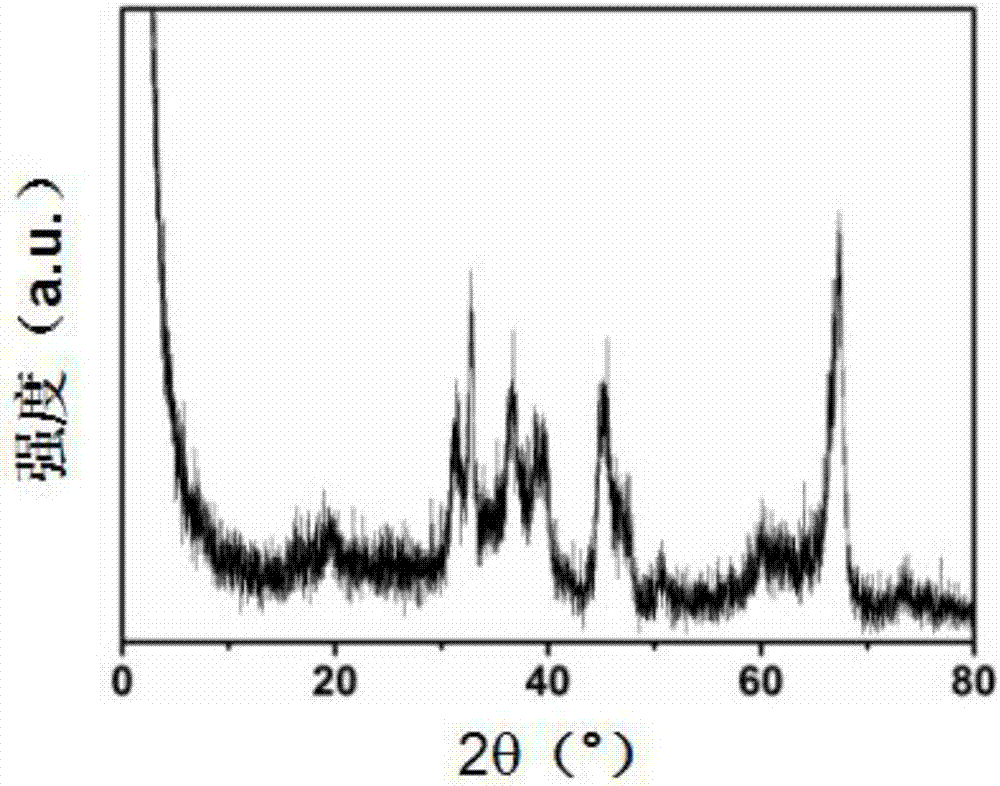

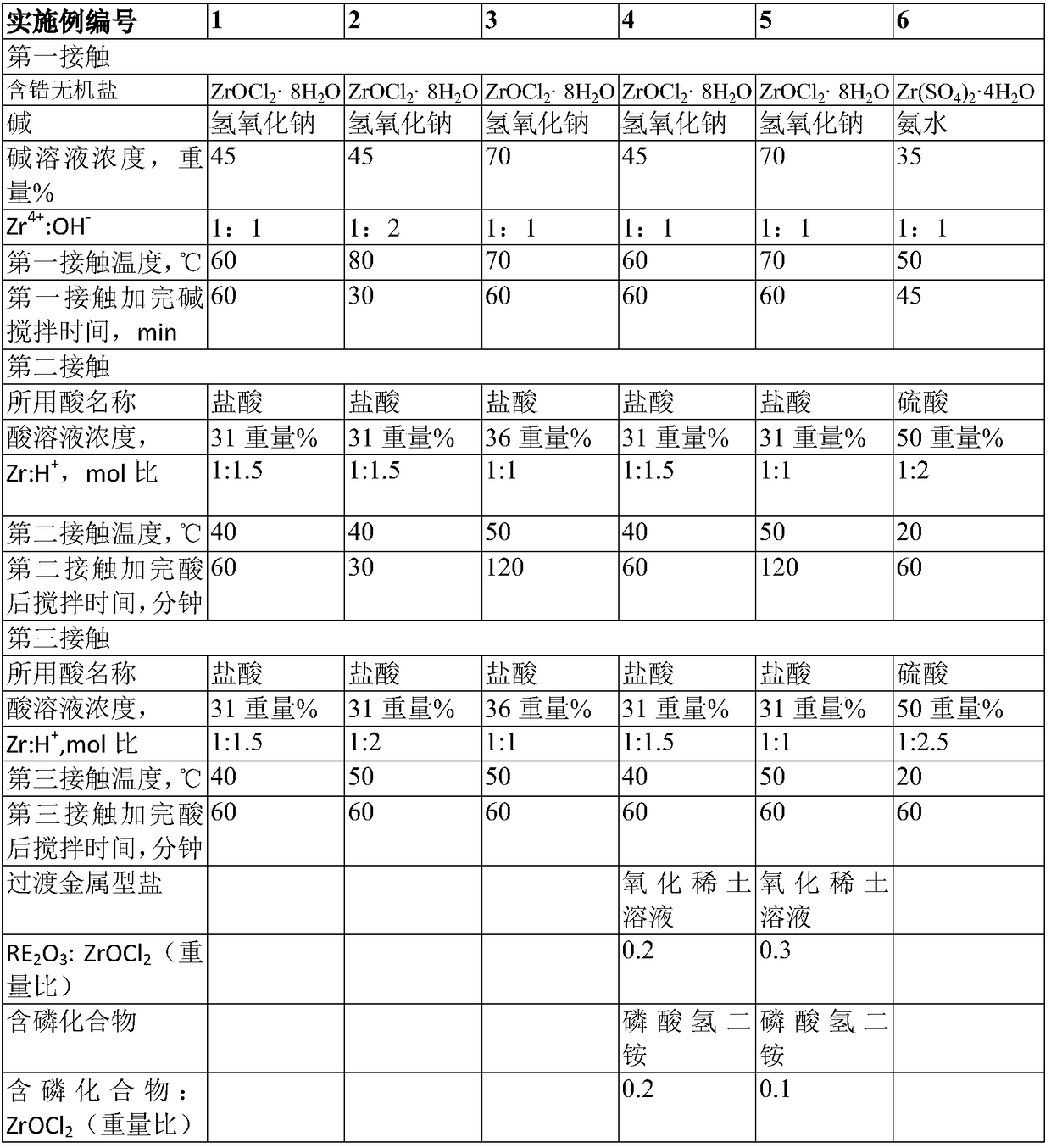

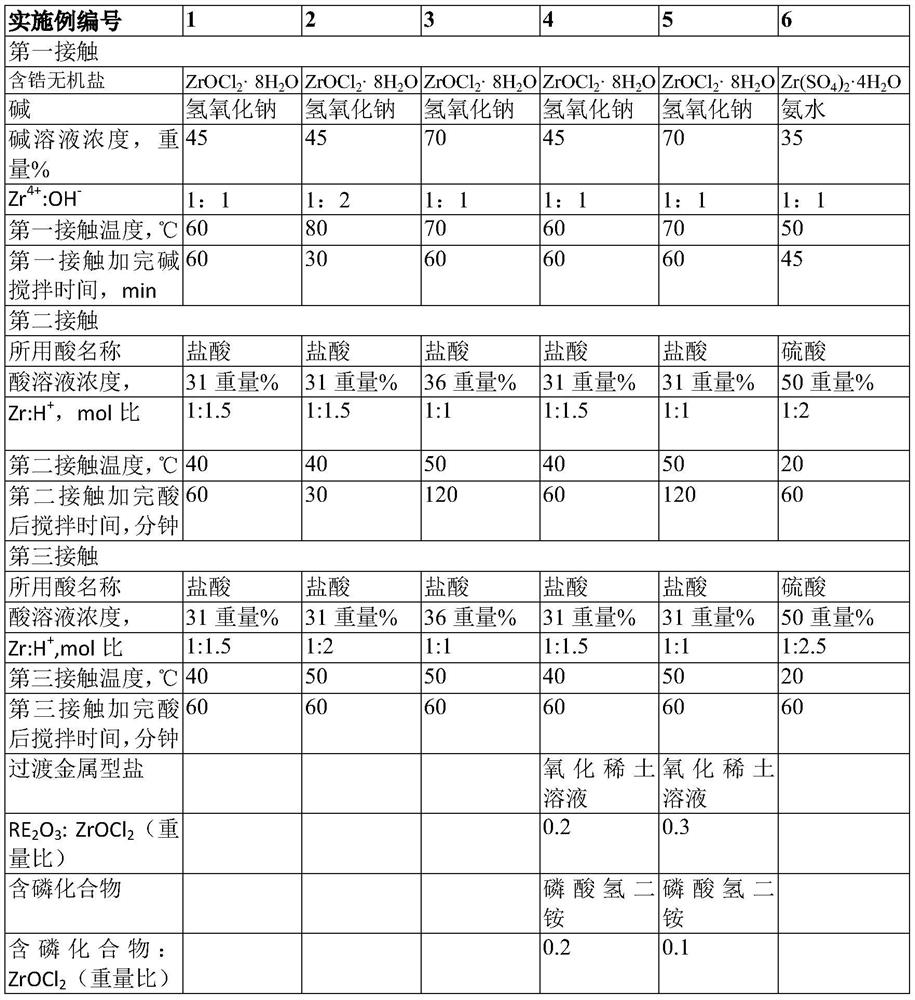

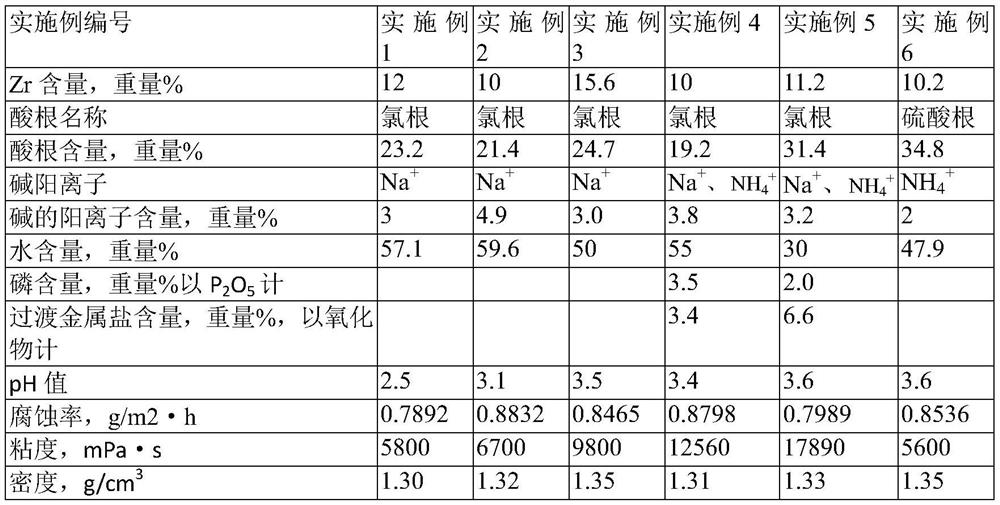

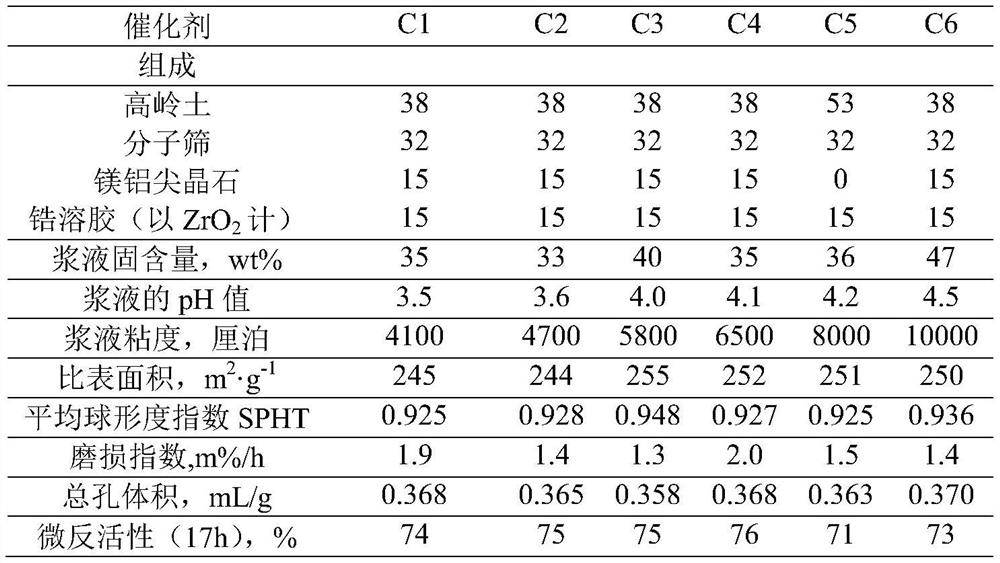

Zirconium sol, preparation method and applications thereof

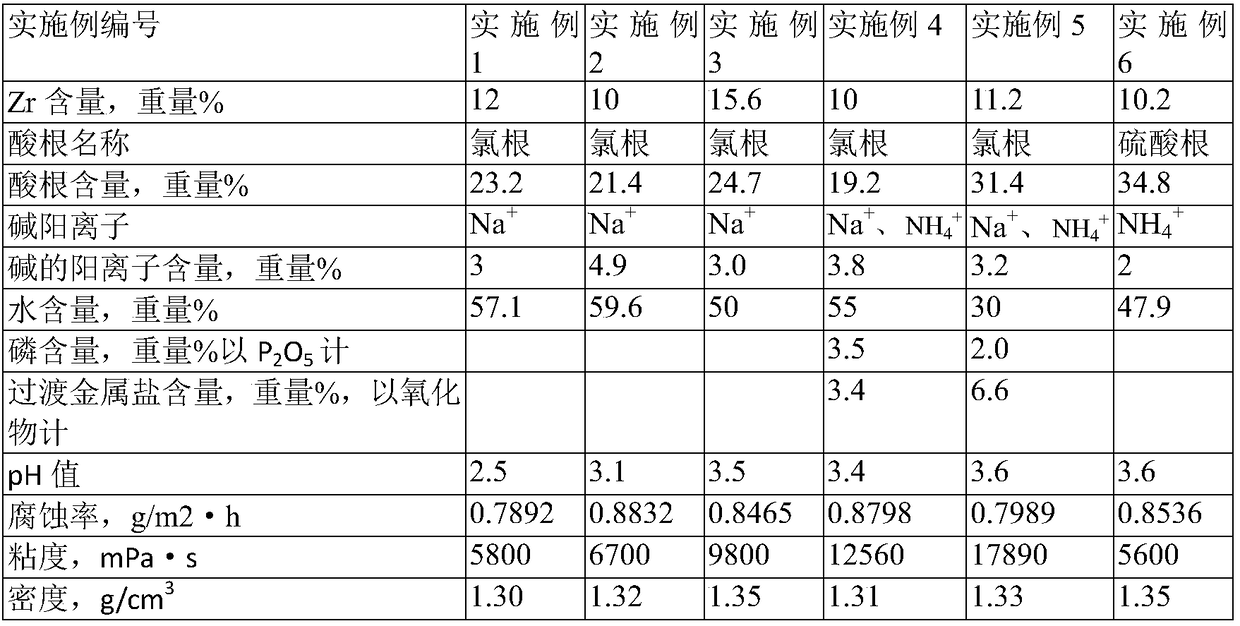

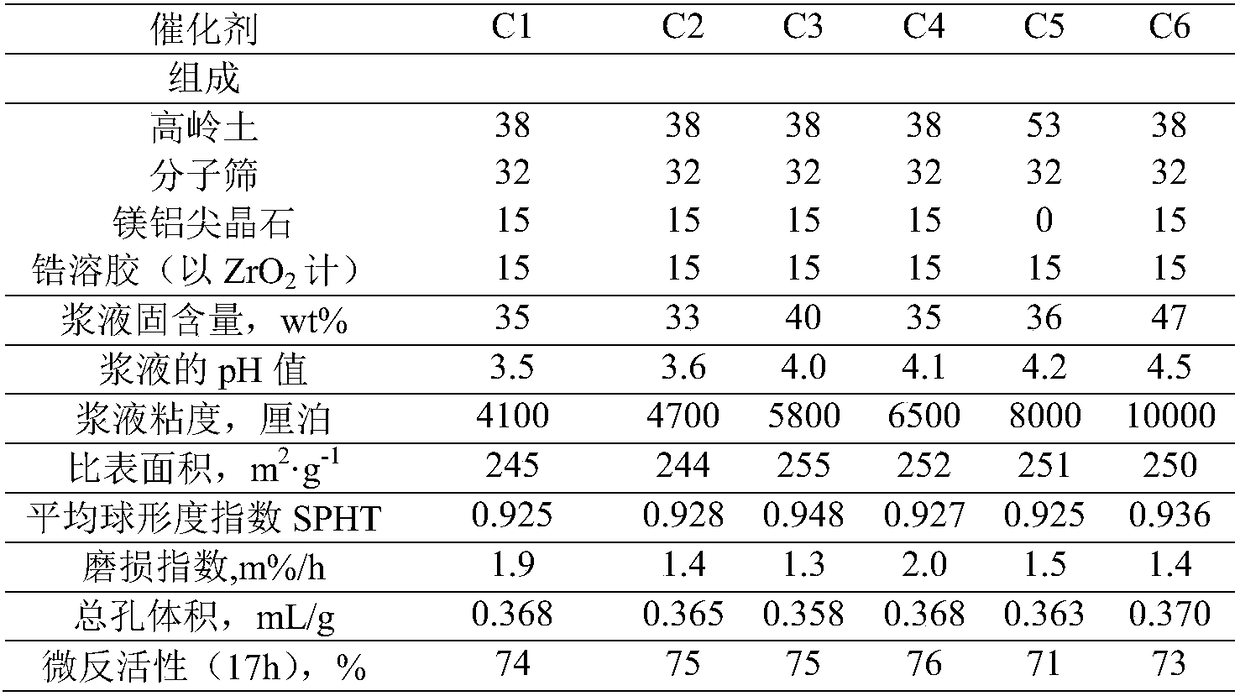

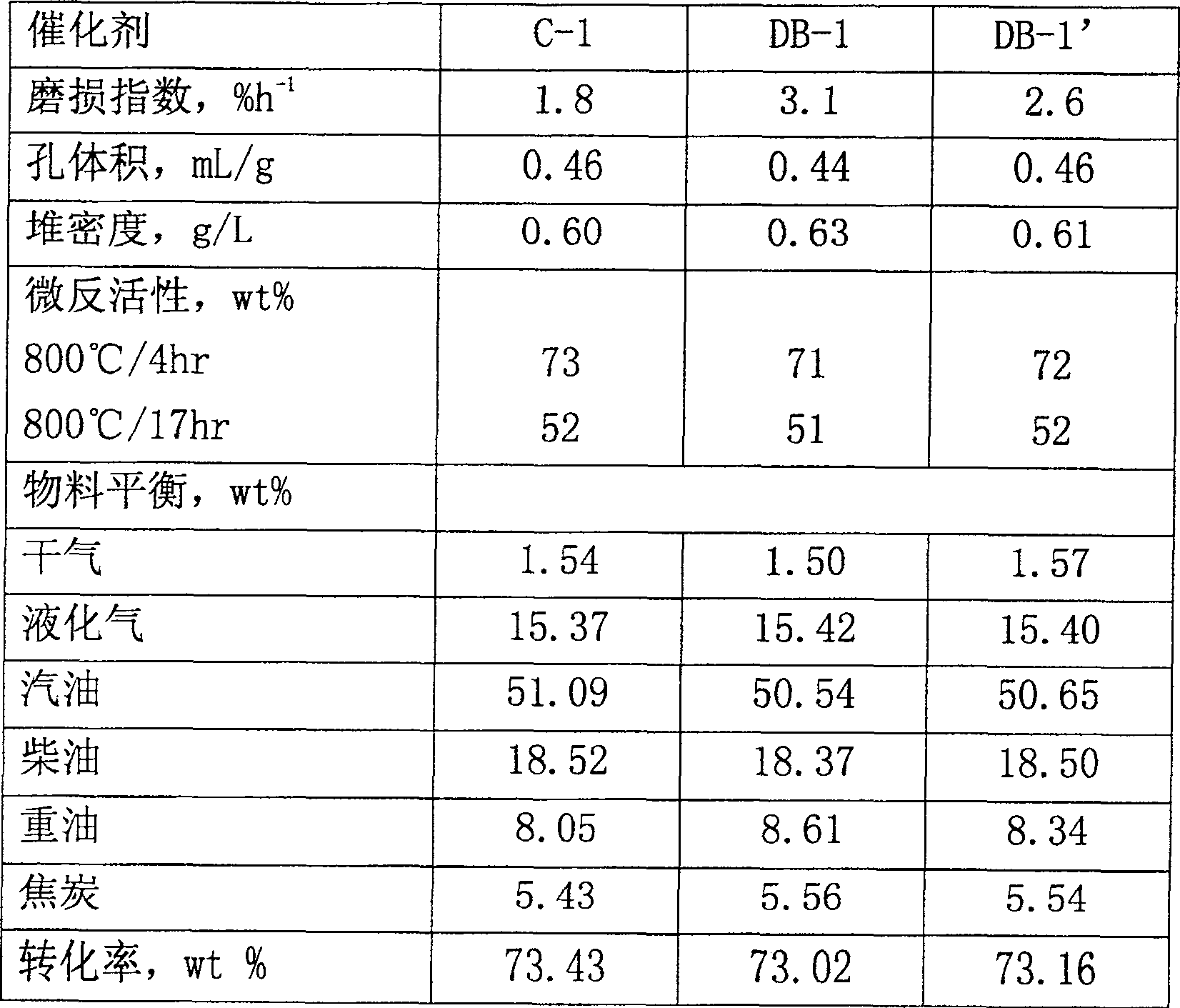

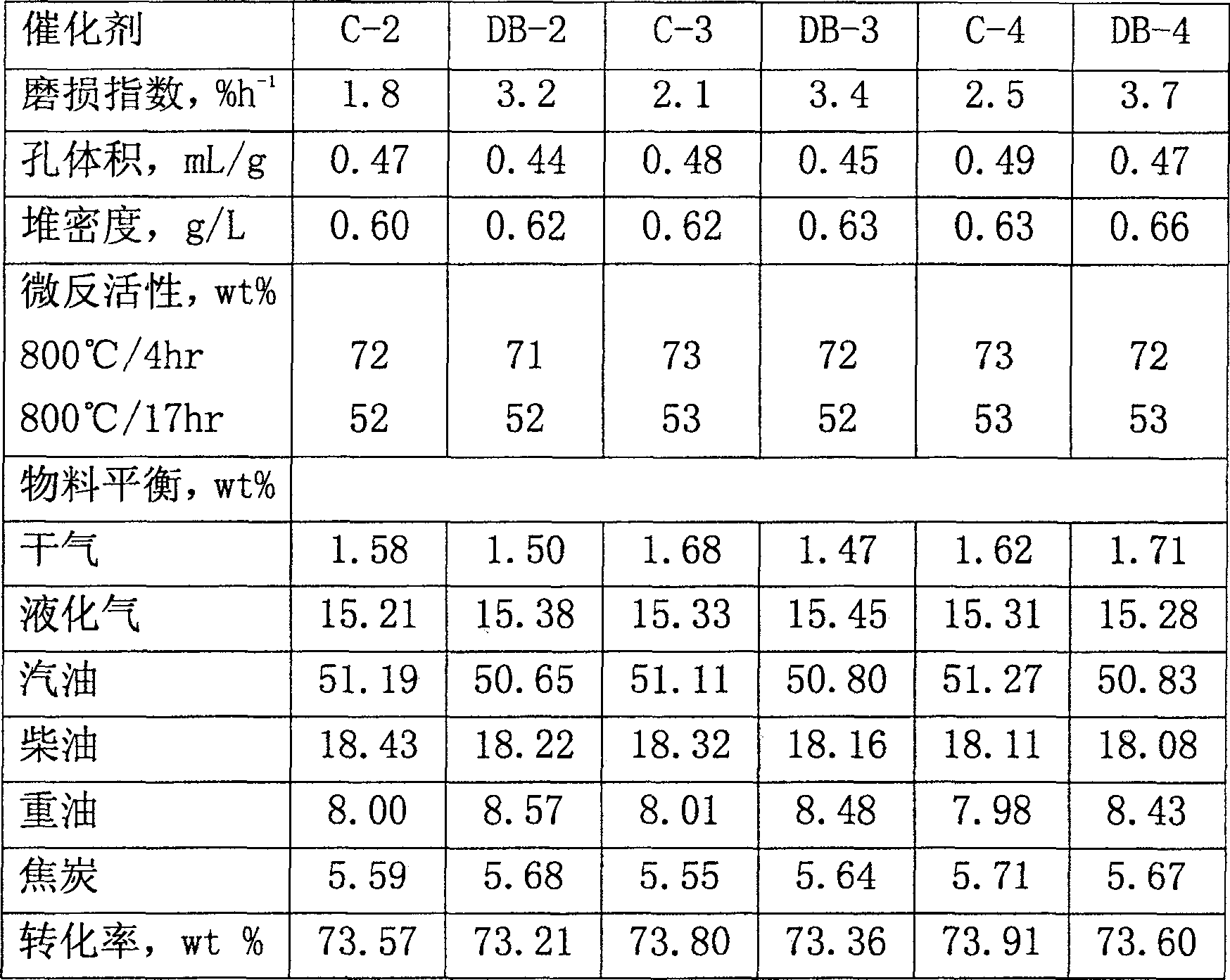

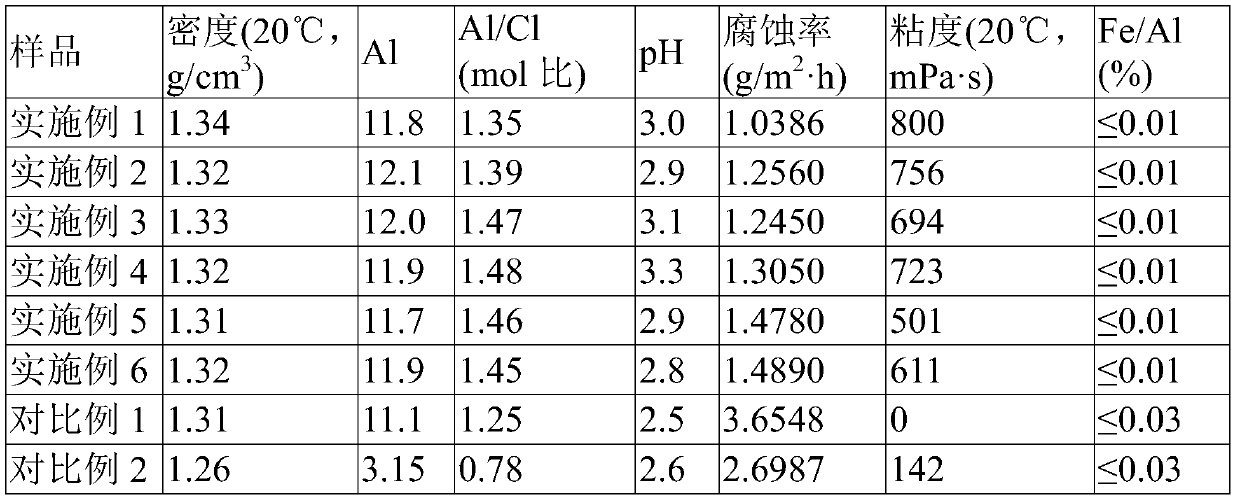

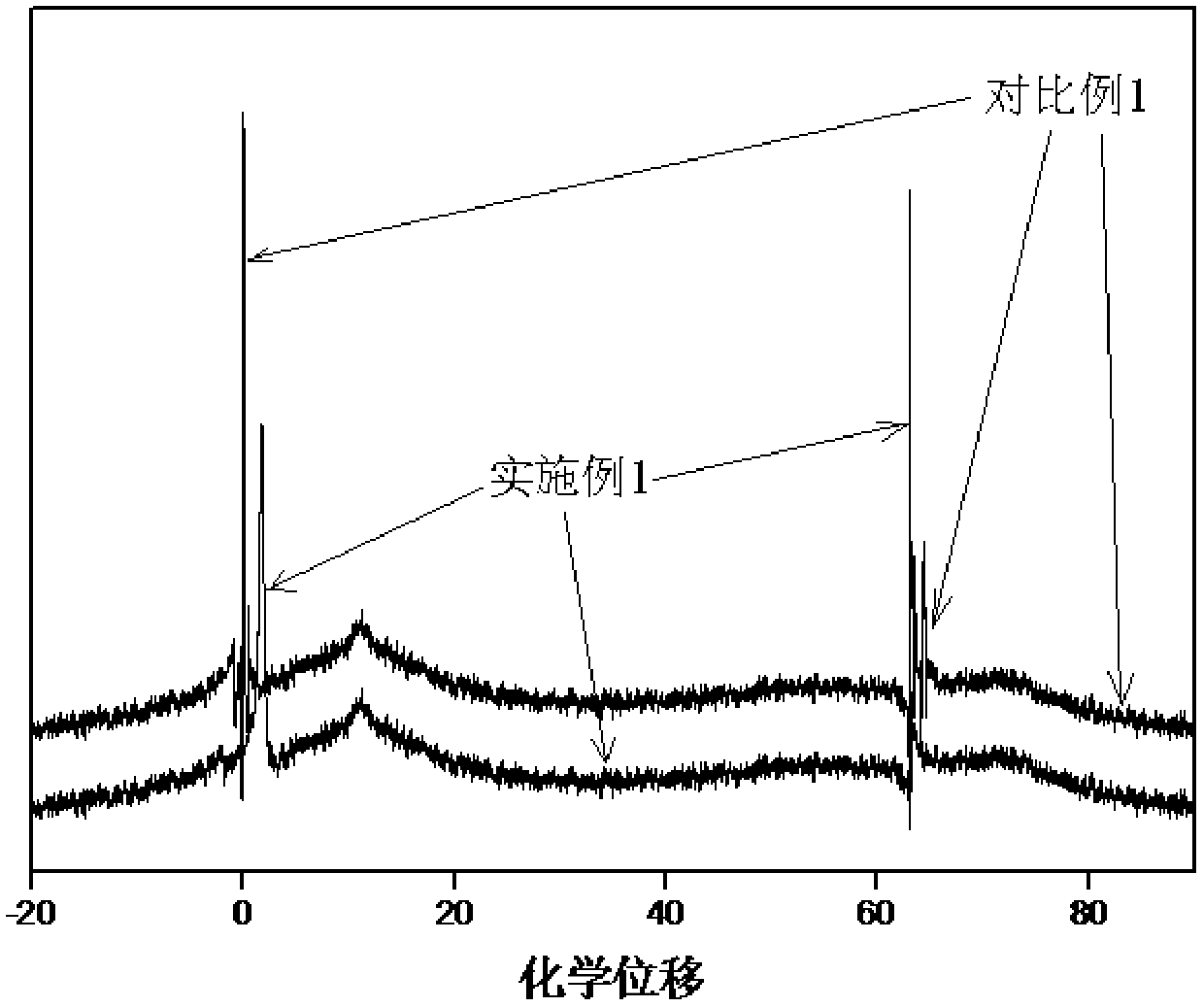

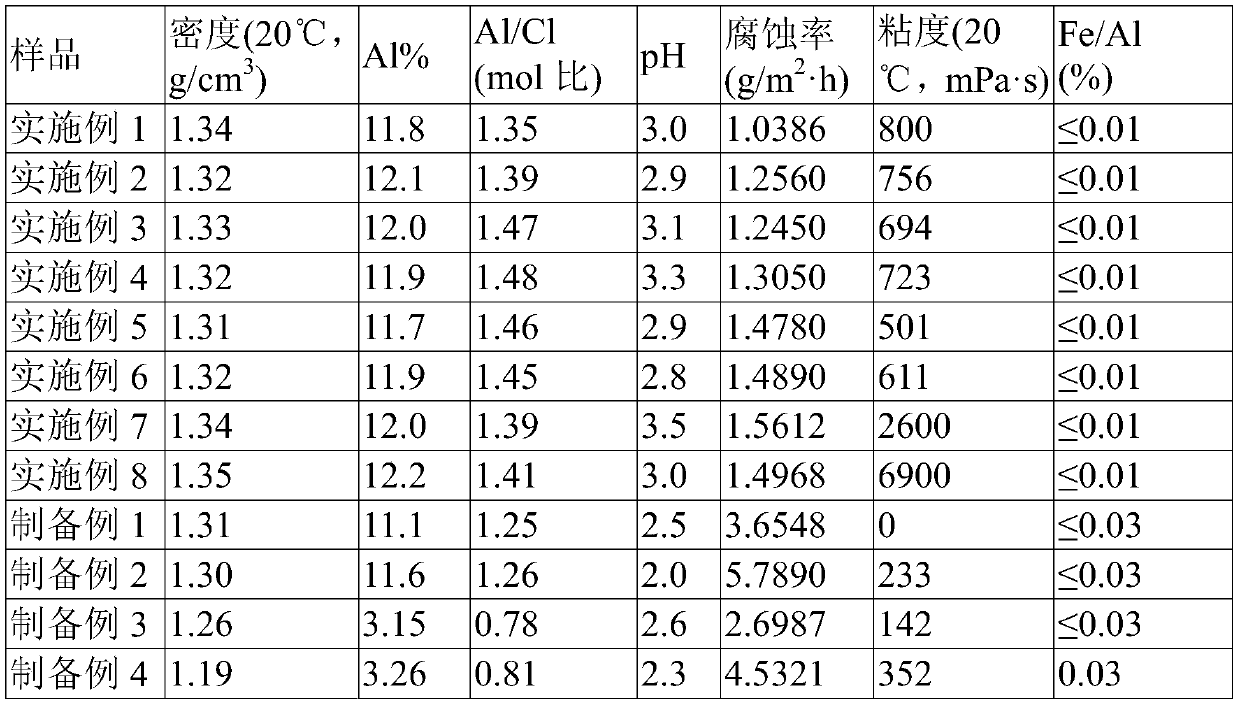

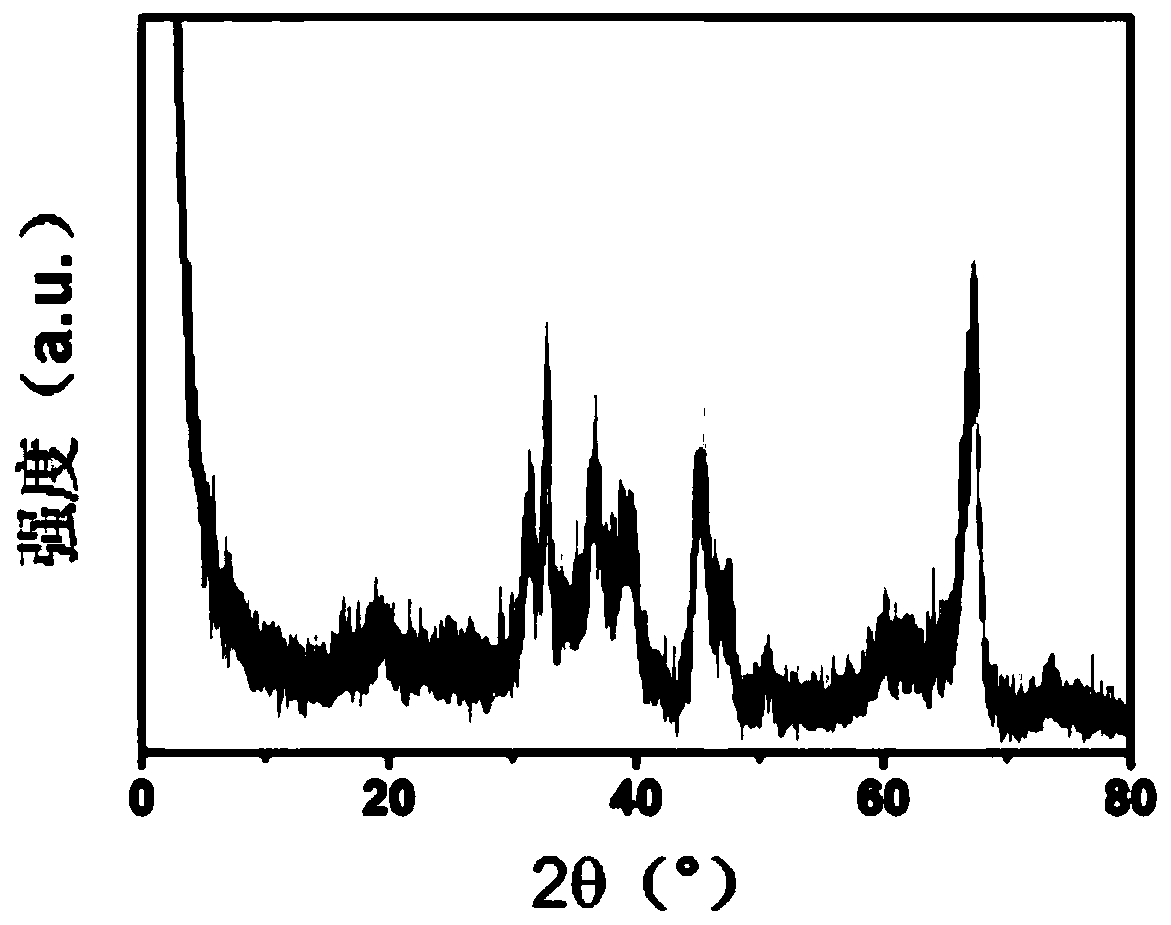

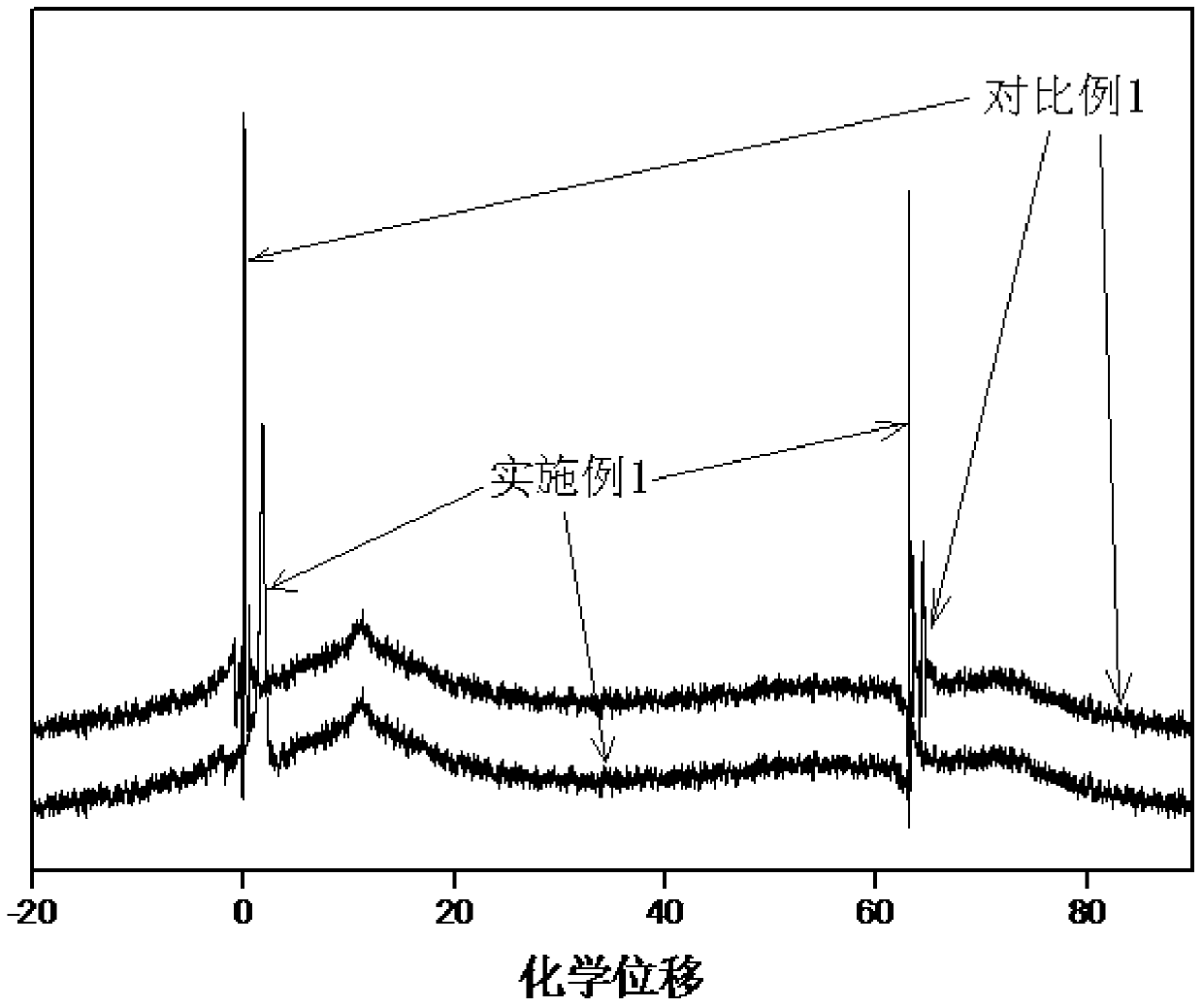

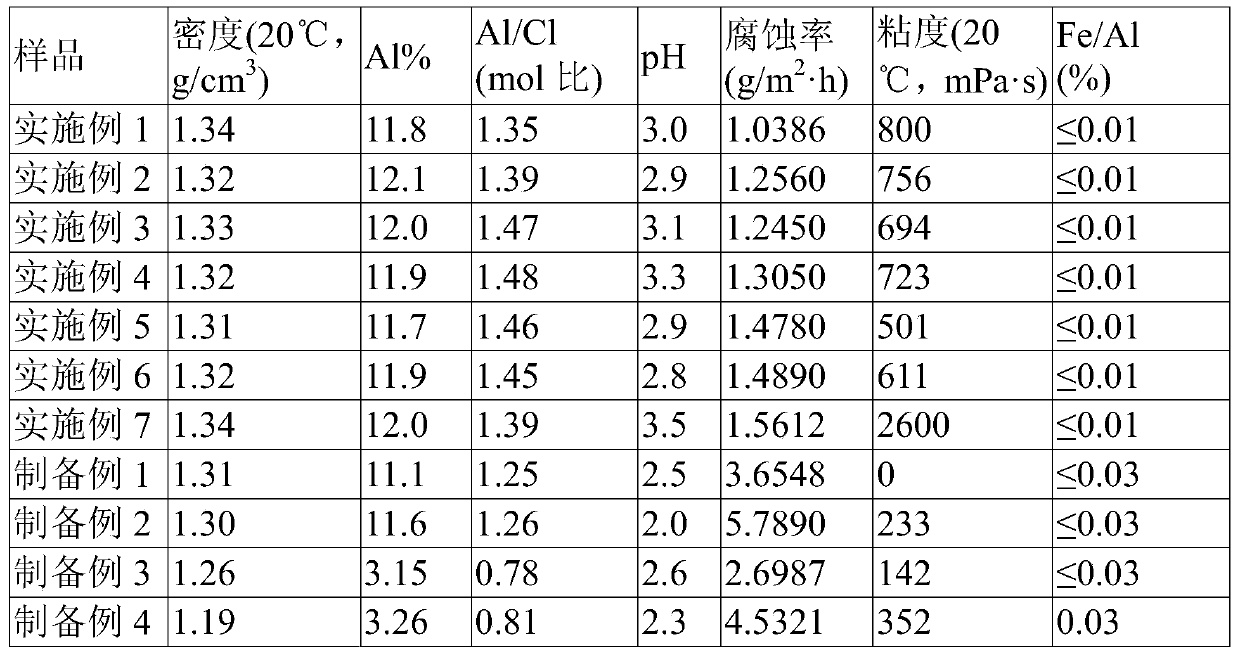

ActiveCN109110808AImprove adhesionLess corrosiveCatalytic crackingMolecular sieve catalystsCracking reactionViscosity

The invention relates to a zirconium sol, a preparation method and applications thereof, wherein the zirconium sol has a corrosion rate of not more than 1 g / m<2>.h, the pH value of 2.5-4, and the viscosity of more than 1000 mPa.s. The preparation method comprises: carrying out first contact on a zirconium-containing salt and an alkali solution, wherein a molar ratio of Zr to OH<-> is 1:1-2; carrying out second contact on the first contact mixture and an acid, wherein a molar ratio of Zr to H<+> is 1:1-3, and preferably the temperature of the first contact is 20-30 DEG C higher than the temperature of the second contact; and carrying out third contact on the second contact mixture and an acid, wherein a molar ratio of Zr to H<+> is 1:1-3. According to the present invention, the zirconium sol is used for preparing catalytic cracking catalysts, can improve the sphericity of the catalyst, and can improve the hydrocarbon oil cracking reaction effect of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for molecular sieve fluidized-bed catalyst

InactiveCN101274284AGood wear resistanceReduced wear indexMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveDimethyl ether

The invention relates to a preparation method of a fluid molecular sieve catalyst, which mainly solves the problem that the fluid molecular sieve catalysts have lower abrasion resistance in the prior art, and adopts the technical proposal which comprises the following steps: (1) a liquid medium, a molecular sieve, a caking agent and a carrier material are evenly mixed to form a suspension, wherein, pH value of the suspension is controlled to be lower than the pH value above 5.0 of the isoelectric points of the caking agent; (2) the suspension is spray dried to obtain a preformed catalyst; (3) the preformed catalyst is roasted to obtain a finished catalyst product; consequently the preparation method of the fluid molecular sieve catalyst preferably solves the problem in the prior art and can be applied in the reaction procedure for producing low-carbon olefin with the raw materials of methanol or dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst

This invention published a fluidization cracking catalyst. The main components of the catalyst are 5~70% (w / w) cracked active component, 5~80%clay and 10~60%agglomerant. Y-type of molecular sieve and 3~20% sialic material which based on catalyst and had been acidized within the cracked active component is the characteristic of the catalyst. The sialic material has a phase structure as thin diaspore. Its formula (calculated by weight of oxidants) is (0-0.3) Na2O . (40-90) Al2O3 . (10-60) SiO2. It has specific area 200~400m2 / g, average aperture 8~20nm, most probable aperture 5~15nm.The acidification treatment mentioned was inorganic acid and sialic material (ratio of the tow: 0.1~0.3) kept contacting for 0.5~3h under room-temperature ~80DEG C.This catalyst has well intensity, high stability of activity, low yield of heavy oil and strong capability of conversion for crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high intensity alumina from two extractive liquids in different consistencies

ActiveCN1915826AHigh strengthReduced wear indexAluminium oxides/hydroxidesHigh concentrationDecomposition

This invention relates to a method for producing high-strength sand-like aluminum oxide with diasporite bauxite as the raw material. In this invention, a low-concentration refined solution and slurry prepared from aluminum hydroxide fine crystal seeds are efficiently agglomerated in the front part pool of the decomposition flow, and introduced into the back part of the decomposition flow together with a high-concentration refined solution and coarse crystal seeds. The concentrations of the two kinds of refined solution are 110-150 g / L and 170-220 g / l, respectively. The causticity ratios of the two kinds of refined solution are both 1.4-1.6. the volume ratio of the low-concentration and the high-concentration solution is (0.25) : 1. The method can guarantee the balance of the system grain sizes as well as improve the strength of the aluminum oxide product by controlling the concentration of the refined solution and the grain sizes of the fine crystal seeds.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Catalyst used in process of preparing dimethyl ether from methanol on fluidized bed and preparation method thereof

ActiveCN102029184ASpeed up the flowImprove liquidityMolecular sieve catalystsEther preparation by compound dehydrationMolecular sieveMicrosphere

The invention discloses a catalyst used in the process of preparing dimethyl ether from methanol on a fluidized bed, which is prepared by a method comprising the following steps of: uniformly mixing desalted water and a silicon-containing material, adding an aluminum-containing material and silicon aluminum phosphorus molecular sieves, uniformly mixing, adding a base material, uniformly mixing toobtain slurry, adjusting a pH value to ensure that the slurry forms a gel state, continuously stirring, pelleting by spraying so as to obtain solid microspheres, roasting, acid-washing, drying and roasting to obtain the catalyst which has the abrasion index of 0.5 to 2.0 and is used in the process of preparing the dimethyl ether from the methanol on the fluidized bed. The hollow degree of the solid microspheres can be lowered by the catalyst prepared by the method, while the catalytic activity is met, the wear-resisting property of the catalyst is obviously improved, and the abrasion index ofthe catalyst is below 2.0 and can be below 1.5 by optimizing preparation parameters; and the catalyst has high stability and long service life and is characterized by low reaction temperature, high methanol conversion ratio, high selectivity of the dimethyl ether and low cost, and the large-scale production of the dimethyl ether can be realized by the catalyst.

Owner:CHINA TIANCHEN ENG +1

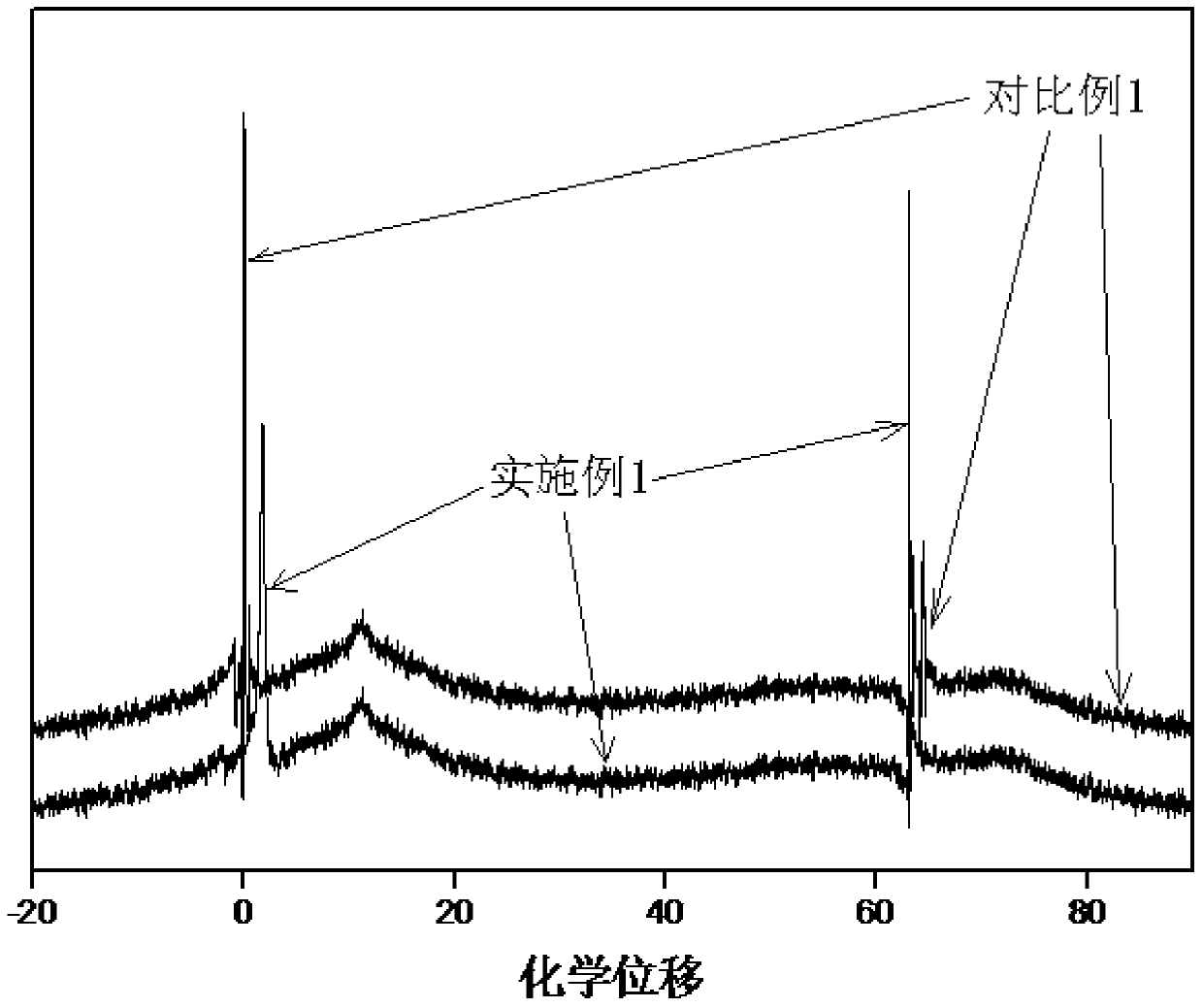

Semi-synthesized olefins conversion catalyst containing modified nano aluminium oxide

InactiveCN1438297AHigh activityImprove wear resistanceCatalytic crackingMolecular sieve catalystsSlurryAluminium silicate

The invention is a conversion catalyzer of half-synthetical hydrocarbon, containing denaturing nano alumina. It disperses synthetic molecular screen and denaturing nano alumina containing Ce, Zr and Mg to inorganic oxide clay and natural aluminium silicate clay, mixes into serum, and makes jet-drying shaping, washing and drying to get the conversion catalyzer. It is especially applied to process heavy raw materials with Ni and V.

Owner:吉林省嘉孚化学工业股份有限公司

Modified rubber master batch and preparation method thereof, oil-extended solution-polymerized styrene-butadiene rubber composition, and preparation method and vulcanized rubber thereof

ActiveCN103524813ALarge room for adjustmentWear index improvementRolling resistance optimizationComposite materialPolymer chemistry

The invention provides a modified rubber master batch and a preparation method thereof, an oil-extended solution-polymerized styrene-butadiene rubber composition, and a preparation method and a vulcanized rubber thereof. The modified rubber master batch comprises an uncrosslinked rubber and crosslinked-structure nitrile-butadiene rubber particles dispersed in the uncrosslinked rubber, wherein the average particle size of the nitrile-butadiene rubber particles is 50-200 nm; the gel content is 60 wt% or higher; the uncrosslinked rubber is styrene-butadiene rubber; and the weight ratio of the crosslinked nitrile-butadiene rubber particles to the uncrosslinked rubber is more than 20:80 and less than or equal to 80:20. The oil-extended solution-polymerized styrene-butadiene rubber composition comprises 100 parts by weight of modified rubber master batch and 1-70 parts by weight of oil-extended solution-polymerized styrene-butadiene rubber which are blended. The vulcanized rubber of the oil-extended solution-polymerized styrene-butadiene rubber composition has the advantages of higher slippery resistance, higher abrasion resistance and lower rolling resistance, and can be used for preparing a high-performance car tread rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN104549421ANo need to increase dosageReduced wear indexMolecular sieve catalystsActive componentChemistry

The invention provides a preparation method of a catalytic cracking catalyst. The method comprises the following steps: premixing a cracking active component, clay and a binder into a gel; performing homogenous dispersion to the gel; acidifying the obtained dispersion materials, and then forming. The catalytic cracking catalyst is prepared by adopting the method. According to the method, the homogenous dispersion step is added, so that the catalytic cracking catalyst with low wear index can be obtained without addition of the amount of the binder; and the method is simple in technological process, and very suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst used for preparing chlorine, catalyst and method for preparing chlorine

ActiveUS10226758B2High activityHigh mechanical strengthHeterogenous catalyst chemical elementsCatalyst activation/preparationRare-earth elementSlurry

The present invention relates to a method for preparing catalyst used for preparing chlorine by oxidizing hydrogen chloride. The method is mixing a slurry mainly containing boron and chromium with a slurry mainly containing copper, boron, alkali-metal elements, rare-earth elements, aluminum sol, silica sol, carrier and optionally other metal elements, the mixing temperature being not more than 100° C., and the residence time being not more than 120 minutes, the mixed slurry is successively treated with spray drying, high temperature calcination, so that the catalyst is obtained. The present invention also relates to the catalyst prepared through the method, use of the catalyst used in the process of preparing chlorine by oxidizing hydrogen chloride and a method for preparing chlorine by using the catalyst. The catalyst is used for preparing chlorine by oxidizing hydrogen chloride with oxygen or air in fluidized bed reactor.

Owner:WANHUA CHEM GRP CO LTD

Method for improving strength of catalytic cracking propylene assistant and application

PendingCN113262813AReduced wear indexEasy to prepareMolecular sieve catalystsMolecular sieve catalystMolecular sievePolymer chemistry

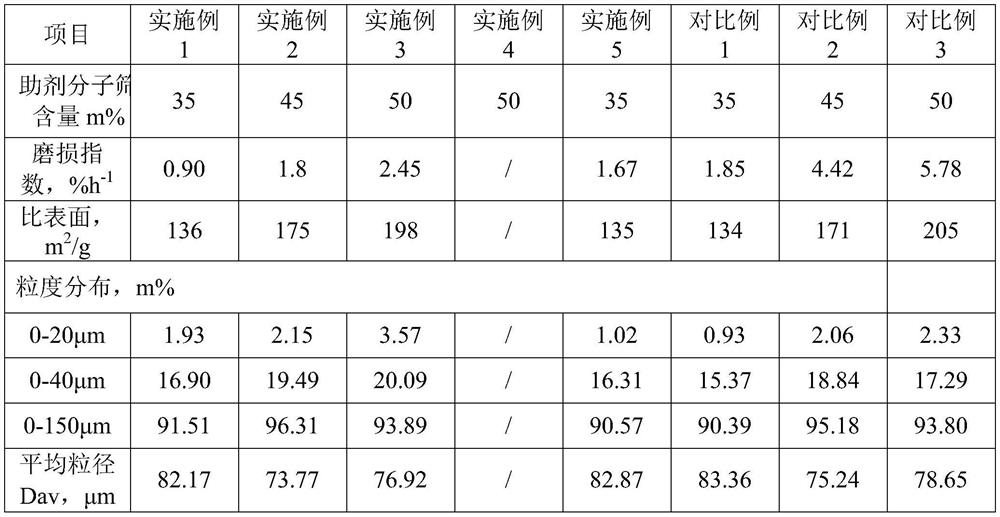

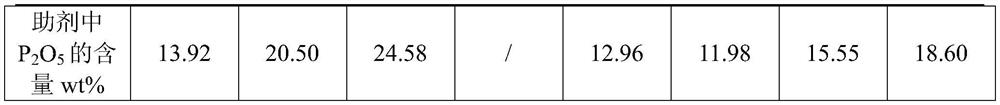

The invention discloses a method for improving the strength of a catalytic cracking propylene assistant and application of the method. Propylene assistant microspheres and a strength improver are mixed, filtered, roasted, washed and dried to obtain a modified propylene assistant; the content of the propylene assistantZSM-5 molecular sieve is 35-50 wt%, the main particle size after modification is 20-150 [mu] m, and the wear index is greatly reduced. The wear index of the propylene assistant improved by the method is reduced by about 50% compared with that before modification, so that a product with better wear resistance and higher intrinsic activity can be obtained on the premise that the content of the molecular sieve in the propylene assistant is high, and the product can be better applied to industrial production and exert catalytic activity.

Owner:湖北赛因斯科技开发有限公司

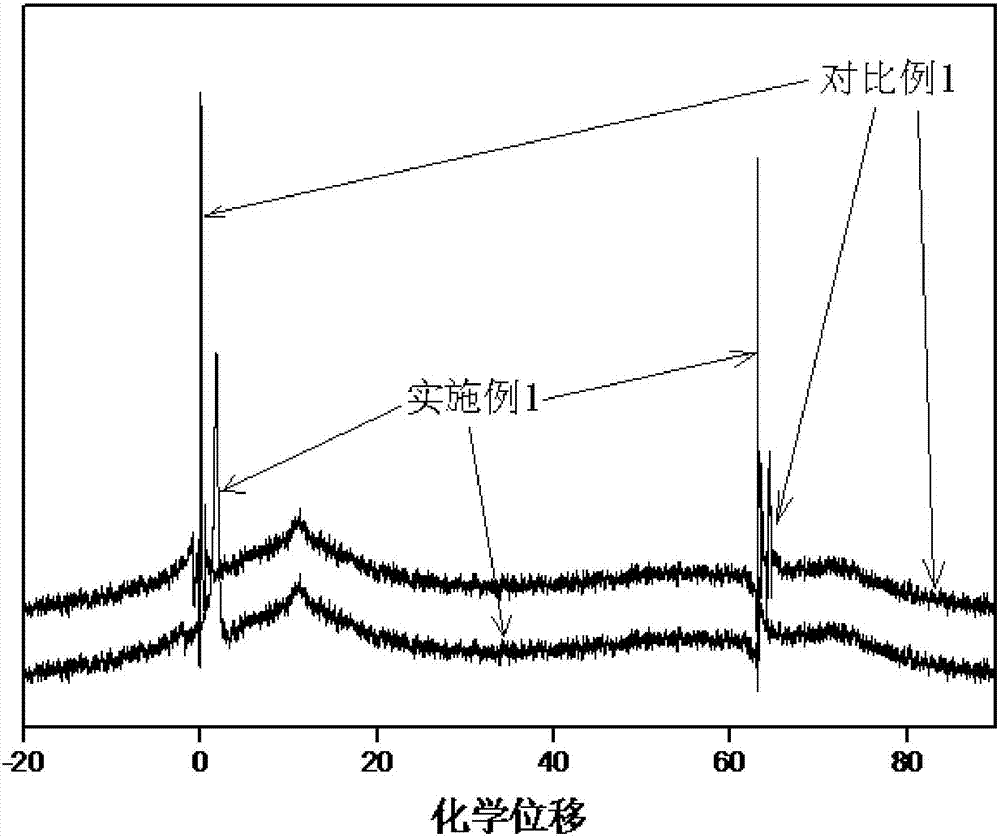

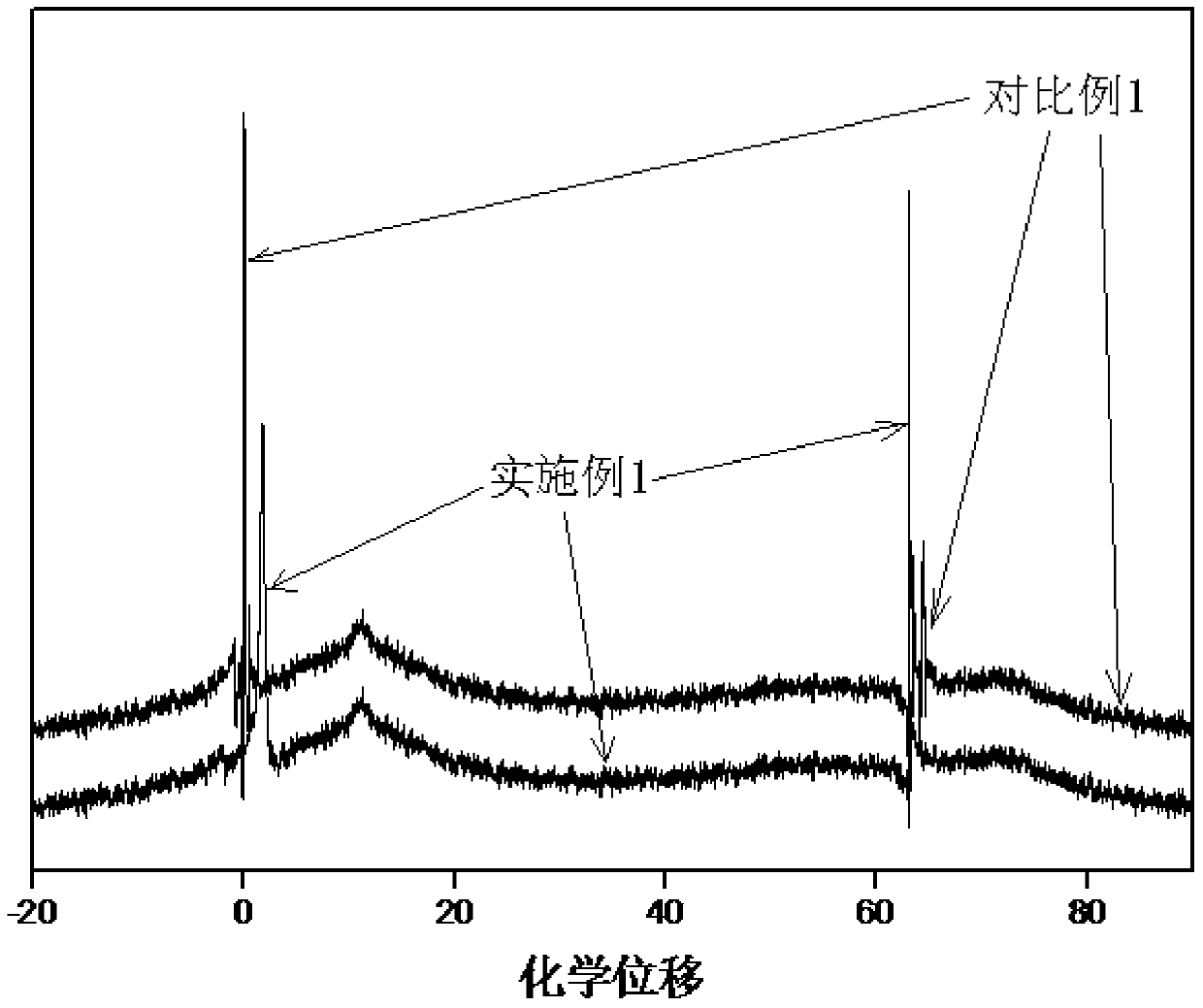

Phosphorus-aluminum sol, preparation method and application thereof, catalytic cracking catalyst and preparation method thereof

ActiveCN107303479ALess free chloride ionsSimple structureCatalytic crackingMolecular sieve catalystsMolecular sieveO-Phosphoric Acid

The invention relates to the field of phosphorus-aluminum sol and discloses phosphorus-aluminum sol, a preparation method and application thereof, a catalytic cracking catalyst and a preparation method thereof. The phosphorus-aluminum sol is obtained through contact between aluminum sol and phosphoric acid, wherein the molar ratio of aluminum to chlorine in the aluminum sol is (1-1.5) to 1, the corrosion rate of the aluminum sol is not more than 1.5g / m<2>.h, the pH value of the aluminum sol is 2.8 or above, and the viscosity of the aluminum sol is 500mPa.s or above. The aluminum sol of the phosphorus-aluminum sol has the advantages of few free chloride ions, optimal structure, large viscosity, low corrosion rate, high pH value and the like, so that the particle structure of the phosphorus-aluminum sol can be enhanced, the adhesive property of the phosphorus-aluminum sol is improved, meanwhile, the blockage caused by the phosphorus-aluminum sol to molecular sieve structures of active components in the catalyst is reduced, the contribute of the phosphorus-aluminum sol to the cracking activity of the catalyst is increased, the use amount of molecular sieves can be reduced, and the cost of the catalyst is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for baking industrial iron base catalyzer through Fischer-Tropsch synthesis from plasma phase

ActiveCN1260006CReduced wear indexGuaranteed sphericityHydrocarbon from carbon oxidesCatalyst activation/preparationResidenceSynthesis methods

A slurry phase Fischer-Tropsch synthesis industrial iron-based catalyst roasting method is to combine the continuous co-precipitation and spray drying method to prepare the industrial large-particle spherical iron-based catalyst with a thickness of 20-100 mm, which is tiled on the swirling airflow belt drying method. On the material conveyor belt of the dryer, adjust the inlet temperature of the heating section of the dryer to 200-300°C, and stay for 5-10 hours; After 4 to 8 hours, a catalyst that has been roasted and can be directly used for industrial slurry phase Fischer-Tropsch synthesis without sieving is obtained. The attrition index of the catalyst after calcination of the present invention is less than 0.5%. The invention has the advantages of continuous drying of large batches of materials, easy operation, less failure and less equipment investment.

Owner:SYNFUELS CHINA TECH CO LTD

A kind of phospho-alumina sol and preparation method and application thereof, catalytic cracking catalyst and preparation method thereof

ActiveCN107303479BLess free chloride ionsSimple structureCatalytic crackingMolecular sieve catalystsMolecular sieveActive component

The invention relates to the field of phosphorus-aluminum sol and discloses phosphorus-aluminum sol, a preparation method and application thereof, a catalytic cracking catalyst and a preparation method thereof. The phosphorus-aluminum sol is obtained through contact between aluminum sol and phosphoric acid, wherein the molar ratio of aluminum to chlorine in the aluminum sol is (1-1.5) to 1, the corrosion rate of the aluminum sol is not more than 1.5g / m<2>.h, the pH value of the aluminum sol is 2.8 or above, and the viscosity of the aluminum sol is 500mPa.s or above. The aluminum sol of the phosphorus-aluminum sol has the advantages of few free chloride ions, optimal structure, large viscosity, low corrosion rate, high pH value and the like, so that the particle structure of the phosphorus-aluminum sol can be enhanced, the adhesive property of the phosphorus-aluminum sol is improved, meanwhile, the blockage caused by the phosphorus-aluminum sol to molecular sieve structures of active components in the catalyst is reduced, the contribute of the phosphorus-aluminum sol to the cracking activity of the catalyst is increased, the use amount of molecular sieves can be reduced, and the cost of the catalyst is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high intensity alumina from two extractive liquids in different consistencies

ActiveCN100398445CHigh strengthReduced wear indexAluminium oxides/hydroxidesHigh concentrationDecomposition

This invention relates to a method for producing high-strength sand-like aluminum oxide with diasporite bauxite as the raw material. In this invention, a low-concentration refined solution and slurry prepared from aluminum hydroxide fine crystal seeds are efficiently agglomerated in the front part pool of the decomposition flow, and introduced into the back part of the decomposition flow together with a high-concentration refined solution and coarse crystal seeds. The concentrations of the two kinds of refined solution are 110-150 g / L and 170-220 g / l, respectively. The causticity ratios of the two kinds of refined solution are both 1.4-1.6. the volume ratio of the low-concentration and the high-concentration solution is (0.25) : 1. The method can guarantee the balance of the system grain sizes as well as improve the strength of the aluminum oxide product by controlling the concentration of the refined solution and the grain sizes of the fine crystal seeds.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Catalytic cracking catalyst and preparation method thereof

ActiveCN103301871BLarge mesopore volumeHigh strengthCatalytic crackingMolecular sieve catalystsMolecular sieveSolubility

Owner:山西腾茂科技股份有限公司 +1

Catalytic cracking catalyst and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of catalyst

PendingCN114433247AFast preparationReduced wear indexMolecular sieve catalystsCatalyst activation/preparationPtru catalystPeptization

The invention relates to the field of catalysts, and discloses a preparation method and application of a catalyst, and the method comprises the following steps: 1) preparing an alumina suspension from a pseudo-boehmite sample to be detected and water; (2) mixing the aluminum oxide suspension obtained in the step (1) with acid to obtain a glue solution; (3) measuring the granularity of the mixed solution obtained in the step (2); wherein when the particle size Dv90 measured in the step (3) is less than or equal to 15 microns, the pseudo-boehmite is peptized for preparing the catalyst. The method has the advantages of simplicity in operation and high speed, and the catalyst prepared by the method is low in wear index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst containing MFI topological structure silicon molecular sieve, preparation method and application thereof, and gas phase Beckmann rearrangement reaction method

PendingCN111790434AReduced wear indexImprove catalytic performanceLactams preparationMolecular sieve catalystsMolecular sieveBeckmann rearrangement

The invention relates to the field of preparation of catalysts, and discloses a catalyst containing an MFI topological structure silicon molecular sieve, and a preparation method and application of the catalyst. The catalyst includes the molecular sieve and a binder; based on the dry basis weight of the catalyst, the content of the molecular sieve in the catalyst is 50-95 wt%, and the content of the binder is 5-50 wt% based on the dry basis weight; the molecular sieve contains metal elements, and ions of the metal elements have Lewis acid characteristics; and based on the total amount of the molecular sieve, the content of the metal elements in the molecular sieve is 5-100 [mu]g / g. The catalyst has the characteristics of low wear index, high cyclohexanone-oxime conversion rate and high caprolactam selectivity.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

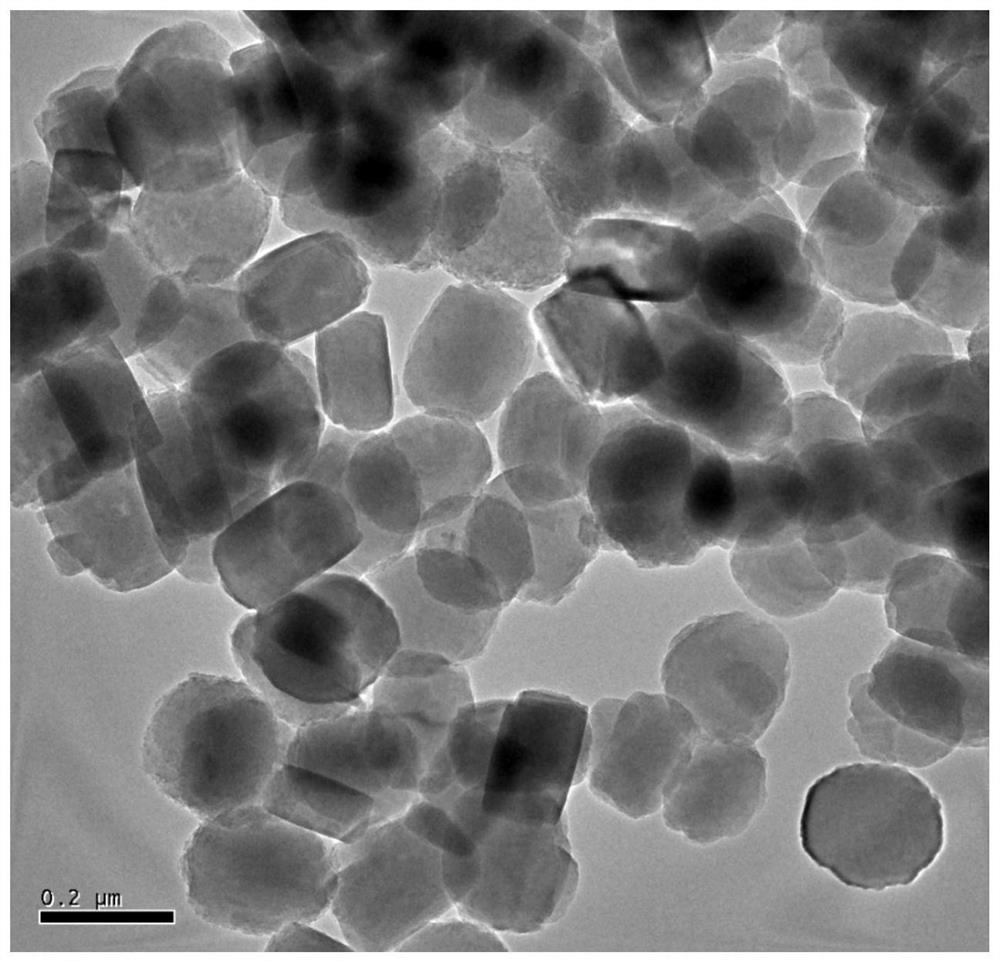

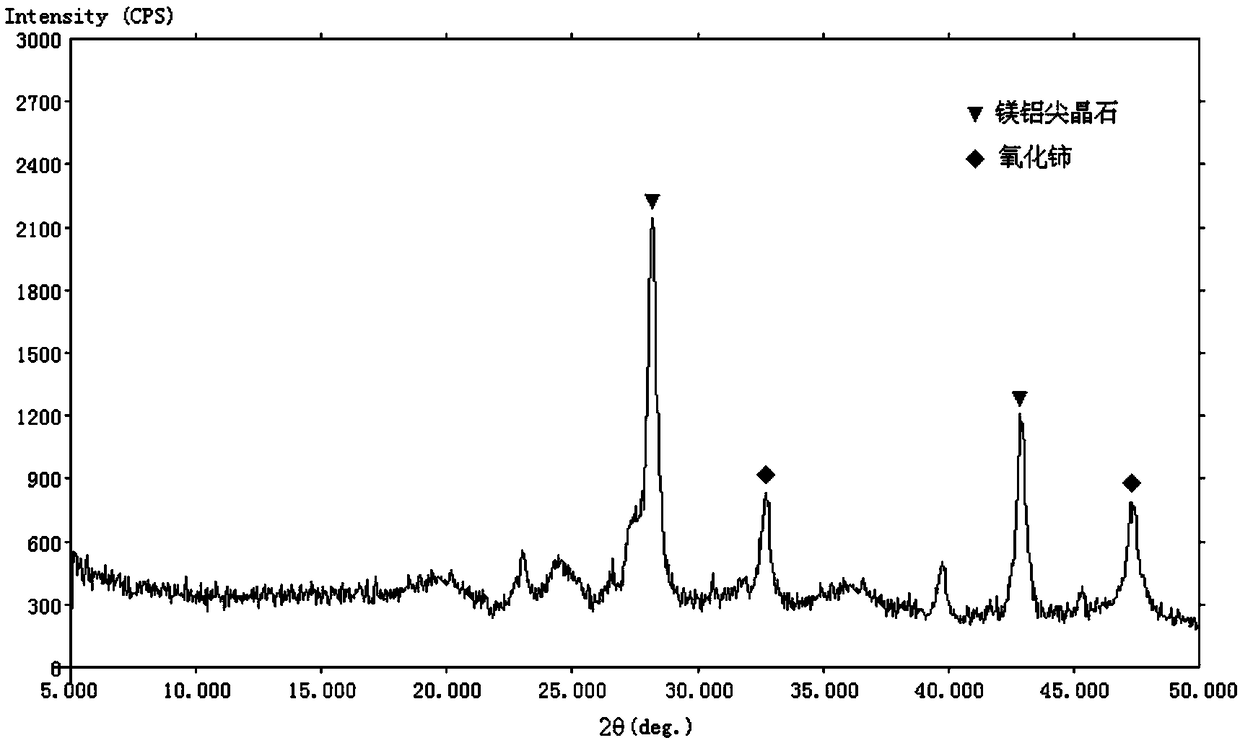

A kind of denitrification catalyst and preparation method thereof

ActiveCN106311276BHigh mechanical strengthReduce concentrationGas treatmentHeterogenous catalyst chemical elementsRare-earth elementCerium

The invention provides a denitration catalyst and a preparation method thereof. The denitration catalyst comprises a carrier and active components, wherein the carrier is magnesia-alumina spinel modified with the first rare earth elements, and the active components comprise palladium oxide and iron oxide; in terms of the total weight of the denitration catalyst, palladium oxide accounts for 1wt%-8wt%, iron oxide accounts for 2wt%-5wt%, oxide of the first rare earth elements accounts for 5wt%-15wt%, magnesia accounts for 20wt%-40wt%, and alumina accounts for 18wt%-67wt% ; the first rare earth elements are one or more of lanthanum, cerium, praseodymium, samarium, europium, terbium and dysprosium. The denitration catalyst has quite high denitration capacity under the specific material composition and ratio, the NO conversion rate of the denitration catalyst can be as high as 92%, and the denitration catalyst can resist poisoning of SO2 at the high temperature and has good SO2 poisoning resistant capacity.

Owner:SHENYANG SANJUKAITE CATALYST

Silica sol, silica-alumina sol, preparation method and application, catalytic cracking catalyst and preparation method

ActiveCN107376887BRaise the pHReduced molecular sieve contentCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to the field of silica-alumina sol for catalytic cracking catalysts, and discloses a silica sol, silica-alumina sol and their preparation methods and applications, as well as a catalytic cracking catalyst and their preparation method. SiO in this silica sol 2 The content is 25~40% by weight, Na 2 The content of O is less than 0.15% by weight; the pH value of the silica sol is 2 to 10, and the density is 1.1g / cm 3 ~1.3g / cm 3 , the viscosity is above 200mPa·s. The silicon-aluminum sol further provided by the present invention contains aluminum sol with the advantages of less free chloride ions, optimized structure, high viscosity, low corrosion rate, high pH value, etc., which can strengthen the binder particle structure and increase the bonding performance of the binder. , reduce the blocking of the molecular sieve structure of the active component in the catalyst by the binder, reduce the impact of the binder on the activity of the catalyst, reduce the use of molecular sieves in the catalyst, and reduce the cost of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microspherical silica/alumina-based noble metal catalyst and preparation method thereof

ActiveCN107233881BLarger than surfaceLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsDispersityPetrochemical

The invention provides a microspherical SiO 2 ‑Al 2 O 3 Based noble metal catalyst and its preparation method. The preparation method used in the present invention is to disperse silica sol into the aluminum sol system, mix the silica sol with the aluminum sol and the coagulant to form a molded sol, and adopt the spray dispersion-oil column molding method. Shaping it, and then aging, washing, drying and baking to obtain microspherical SiO 2 ‑Al 2 O 3 . With this microspherical SiO 2 ‑Al 2 O 3 The carrier is loaded with precious metal active components to obtain microspherical SiO 2 ‑Al 2 O 3 Based precious metal catalyst. The catalyst has the characteristics of large specific surface and pore volume, high dispersion of active components, small wear index, and high wear resistance. The catalyst is mainly used in the hydrogenation process of preparing hydrogen peroxide by the fluidized bed anthraquinone method, and has high catalytic activity, selectivity and stability. The catalyst can also be used in reaction processes such as hydrorefining, selective hydrogenation and selective oxidation in petrochemical and fine chemical production.

Owner:BEIJING UNIV OF CHEM TECH

Magnesium-aluminum sol and its preparation method and application, catalytic cracking catalyst and its preparation method

ActiveCN107433170BRaise the pHReduced wear indexCatalytic crackingMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to the field of magnesium-aluminium sol for a catalytic cracking catalyst and discloses magnesium-aluminium sol, a preparation method and application thereof, a catalytic cracking catalyst and a preparation method thereof. Molar ratio of Mg: Al in the magnesium-aluminium sol is (1.5-6): (1-2), preferably (4-6): 1. Molar ratio of Al: Cl in the magnesium-aluminium sol is (1-1.5): 1. When the magnesium-aluminium sol provided by the invention is used as a binder for a catalytic cracking catalyst, particle structure of the binder can be enhanced, bonding performance of the binder can be improved, blocking of the molecular sieve structure of an active ingredient in the catalyst by the binder is reduced, influence of the binder on activity of the catalyst is decreased, application amount of a molecular sieve in the catalyst can be reduced, and cost of the catalyst is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used in process of preparing dimethyl ether from methanol on fluidized bed and preparation method thereof

ActiveCN102029184BSpeed up the flowImprove liquidityMolecular sieve catalystsEther preparation by compound dehydrationMolecular sieveMicrosphere

The invention discloses a catalyst used in the process of preparing dimethyl ether from methanol on a fluidized bed, which is prepared by a method comprising the following steps of: uniformly mixing desalted water and a silicon-containing material, adding an aluminum-containing material and silicon aluminum phosphorus molecular sieves, uniformly mixing, adding a base material, uniformly mixing toobtain slurry, adjusting a pH value to ensure that the slurry forms a gel state, continuously stirring, pelleting by spraying so as to obtain solid microspheres, roasting, acid-washing, drying and roasting to obtain the catalyst which has the abrasion index of 0.5 to 2.0 and is used in the process of preparing the dimethyl ether from the methanol on the fluidized bed. The hollow degree of the solid microspheres can be lowered by the catalyst prepared by the method, while the catalytic activity is met, the wear-resisting property of the catalyst is obviously improved, and the abrasion index ofthe catalyst is below 2.0 and can be below 1.5 by optimizing preparation parameters; and the catalyst has high stability and long service life and is characterized by low reaction temperature, high methanol conversion ratio, high selectivity of the dimethyl ether and low cost, and the large-scale production of the dimethyl ether can be realized by the catalyst.

Owner:CHINA TIANCHEN ENG +1

A kind of zirconium sol and its preparation method and application

ActiveCN109110808BImprove adhesionLess corrosiveCatalytic crackingMolecular sieve catalystsPtru catalystCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

A modified rubber masterbatch and its preparation method, an oil-extended solution polystyrene-butadiene rubber composition, its preparation method and its vulcanizate

ActiveCN103524813BLarge room for adjustmentWear index improvementRolling resistance optimizationPolymer scienceNitrile rubber

The invention provides a modified rubber masterbatch and its preparation method, an oil-extended solution-polymerized styrene-butadiene rubber composition, its preparation method and its vulcanized rubber. The modified rubber masterbatch includes uncrosslinked rubber and nitrile rubber particles with a cross-linked structure dispersed therein; the nitrile rubber particles have an average particle size of 50 to 200 nm and a gel content of 60% by weight or Higher; the uncrosslinked rubber is styrene-butadiene rubber; the weight ratio of the crosslinked nitrile rubber particles to the uncrosslinked rubber is greater than 20:80 and less than or equal to 80:20. The oil-extended styrene-butadiene rubber composition includes the blended modified rubber masterbatch and oil-extended styrene-butadiene rubber; based on 100 parts by weight of the oil-extended styrene-butadiene rubber, the modified rubber The components are divided into 1 to 70 parts. The oil-extended solution-polymerized styrene-butadiene rubber composition can simultaneously improve the wet slip performance and wear resistance of the vulcanized rubber, and has lower rolling resistance, and can be used to prepare high-performance automobile tread rubber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com