Cracking catalyst

A technology of catalyst and cracking activity, which is applied in the field of fluidized catalytic cracking catalysts to achieve the effects of increasing the conversion rate of crude oil, reducing the yield of heavy oil, and lowering the wear index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

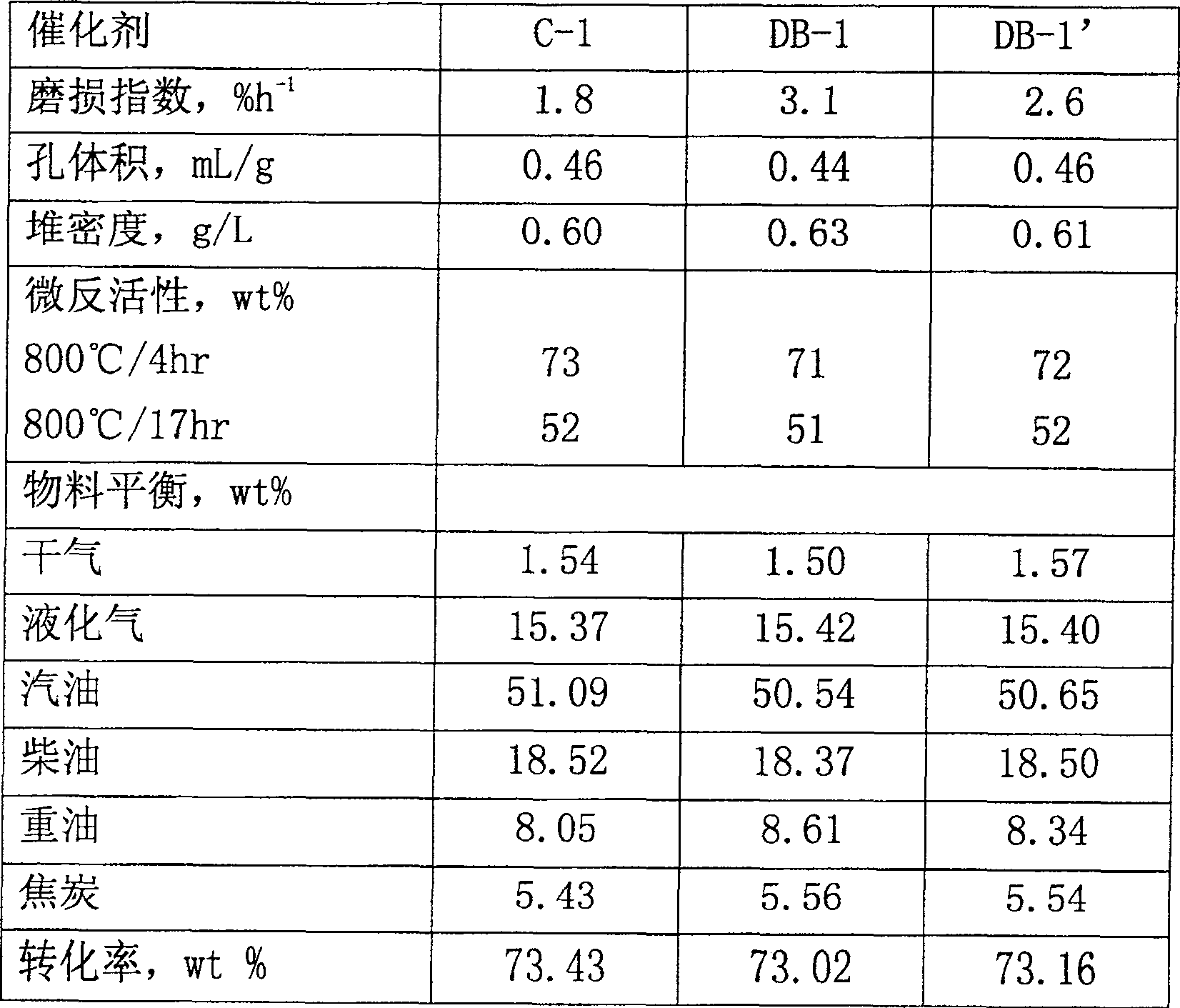

Embodiment 1

[0028] The mesoporous silicon-aluminum material adopts the mesoporous silicon-aluminum material SA-1 of Example 1 in CN1565733A, and the preparation process of SA-1 is as follows: get 100ml concentration to be 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 Put the solution in a beaker, add ammonia water drop by drop under stirring conditions until the system pH = 8, and the neutralization and gelling temperature is 55°C; add 50ml of SiO with a content of 60g under stirring conditions 2 / L of water glass, heated to 80°C for 4 hours; use NH 4 According to the weight ratio of the precipitate (dry basis): ammonium salt: H2O=1:0.8:15, the Cl solution was ion-exchanged at 60°C to remove the sodium ions in the silica-alumina precipitate, and the exchange was repeated twice, each Each exchange was carried out for 0.5 hours, washed with water and filtered after each exchange, then dried at 120° C. for 15 hours, and calcined at 600° C. for 3 hours. The chemical composition of SA-1 is 0.12Na 2 O·73...

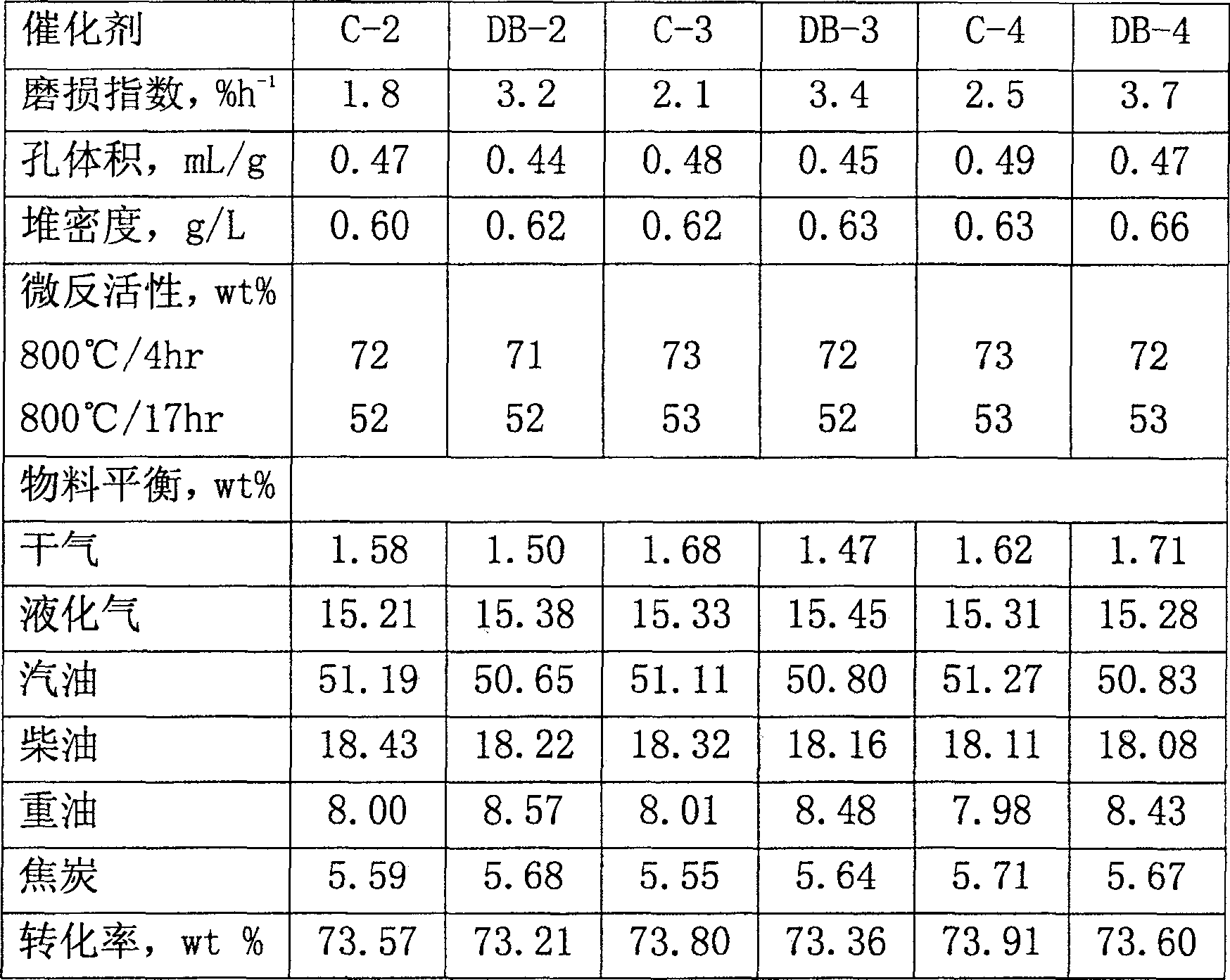

Embodiment 2~4

[0044] Examples 2-4 are used to illustrate the effects of different substitution amounts of acidified mesoporous silica-alumina materials on the physicochemical properties and cracking properties of catalysts.

[0045] After acidifying pseudo-boehmite, add kaolin slurry, aluminum sol and acidified mesoporous silica-alumina material SH-SA-1, stir for 20 minutes, then add REHY molecular sieve to the mixed slurry, stir for 20 minutes and then spray Form microsphere catalysts, and obtain catalysts C-2-4 after roasting, washing and drying, in which the acidified mesoporous silica-alumina material SH-SA-1 is used in amounts of 8%, 12% and 16% respectively.

[0046] The composition of catalyst C-2 is: REHY 35.0%, kaolin 28.0%, pseudoboehmite 22.0%, aluminum sol 7.0%, SH-SA-1 8.0%.

[0047] The composition of catalyst C-3 is: REHY 35.0%, kaolin 28.0%, pseudo-boehmite 18.0%, aluminum sol 7.0%, SH-SA-1 12.0%.

[0048] The composition of catalyst C-4 is: REHY 35.0%, kaolin 25.0%, pseudo...

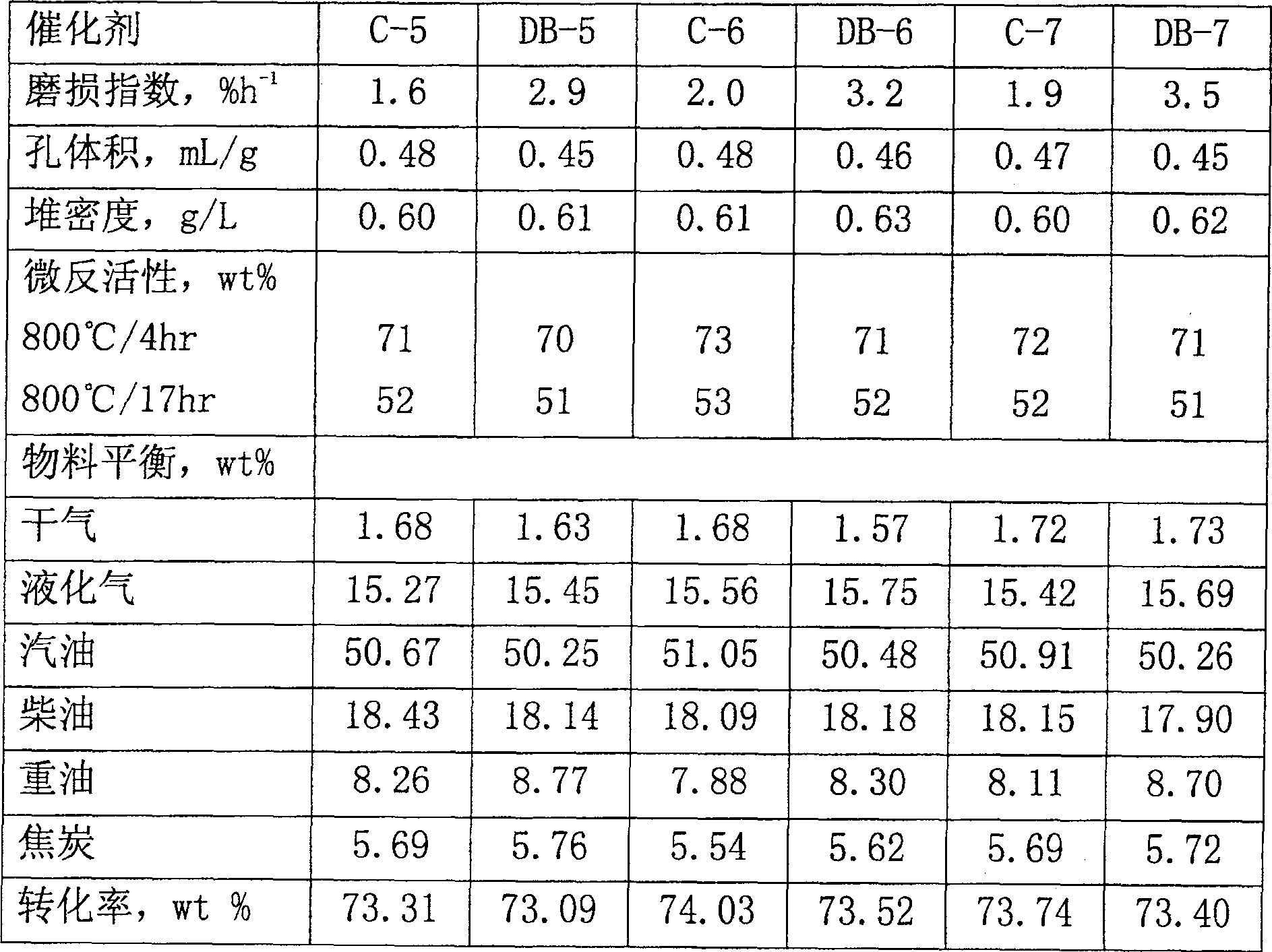

Embodiment 5~7

[0060] Examples 5-7 illustrate the effect of substituting the acidified mesoporous silica-alumina material SH-SA-1 for different components in the catalyst on the physical and chemical properties and cracking performance of the catalyst.

[0061] The specific process of spraying the catalyst is the same as in Example 1, but in the preparation process, the acidified mesoporous silica-alumina material SH-SA-1 is used to replace one or two or three of the active component molecular sieve, kaolin and binder. The mixture of catalysts C-5-7 was prepared.

[0062] The composition of catalyst C-5 is: 30.0% REHY, 28.0% kaolin, 25.0% pseudo-boehmite, 7.0% aluminum sol, and 10.0% acidified mesoporous silica-alumina material SH-SA-1.

[0063]The composition of catalyst C-6 is: 35.0% REHY, 23.0% kaolin, 25.0% pseudo-boehmite, 7.0% aluminum sol, and 10.0% acidified mesoporous silica-alumina material SH-SA-1.

[0064] The composition of catalyst C-7 is: REHY 30.0%, kaolin 26.0%, pseudoboehm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com