Zirconium sol, preparation method and applications thereof

A zirconium sol and weight technology, applied in sol preparation, chemical instruments and methods, zirconia, etc., can solve problems such as poor performance, no suitable method for providing zirconium sol, and failure to provide zirconium sol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] One embodiment, in the step (1), the zirconium-containing salt is first contacted with the alkali solution at a temperature of T1, and T1 is a value between 50-80°C, preferably 55-75°C; in the step (2), at The mixture after the first contact is contacted with the acid for the second time at a temperature of T2, and T2 is a value between 20 to 50° C., preferably 25 to 45° C.; The obtained mixture is contacted with an acid for the third time, and T3 is a value between 20-50°C, preferably 25-45°C. T1-T2 (the difference between T1 and T2) is 20-30°C, and T1-T3 (the difference between T1 and T3) is 20-30°C. The temperature of the reactor can be controlled by heating and / or cooling, and using a constant temperature water bath, so that the temperature of the reactor in each step can be controlled at T1, T2 and T3 respectively. Control the deviation of fluctuations in T1, T2 and T3 not to exceed 10°C.

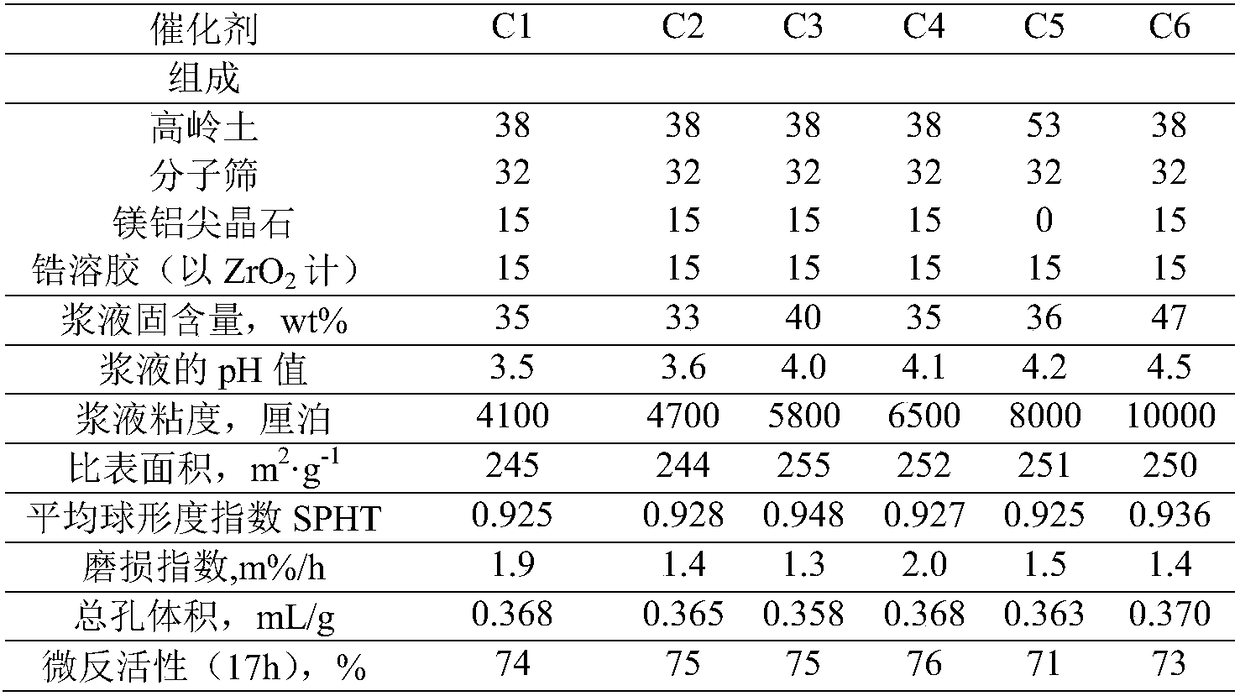

[0056] FCC catalyst (catalytic cracking catalyst) preparation method prov...

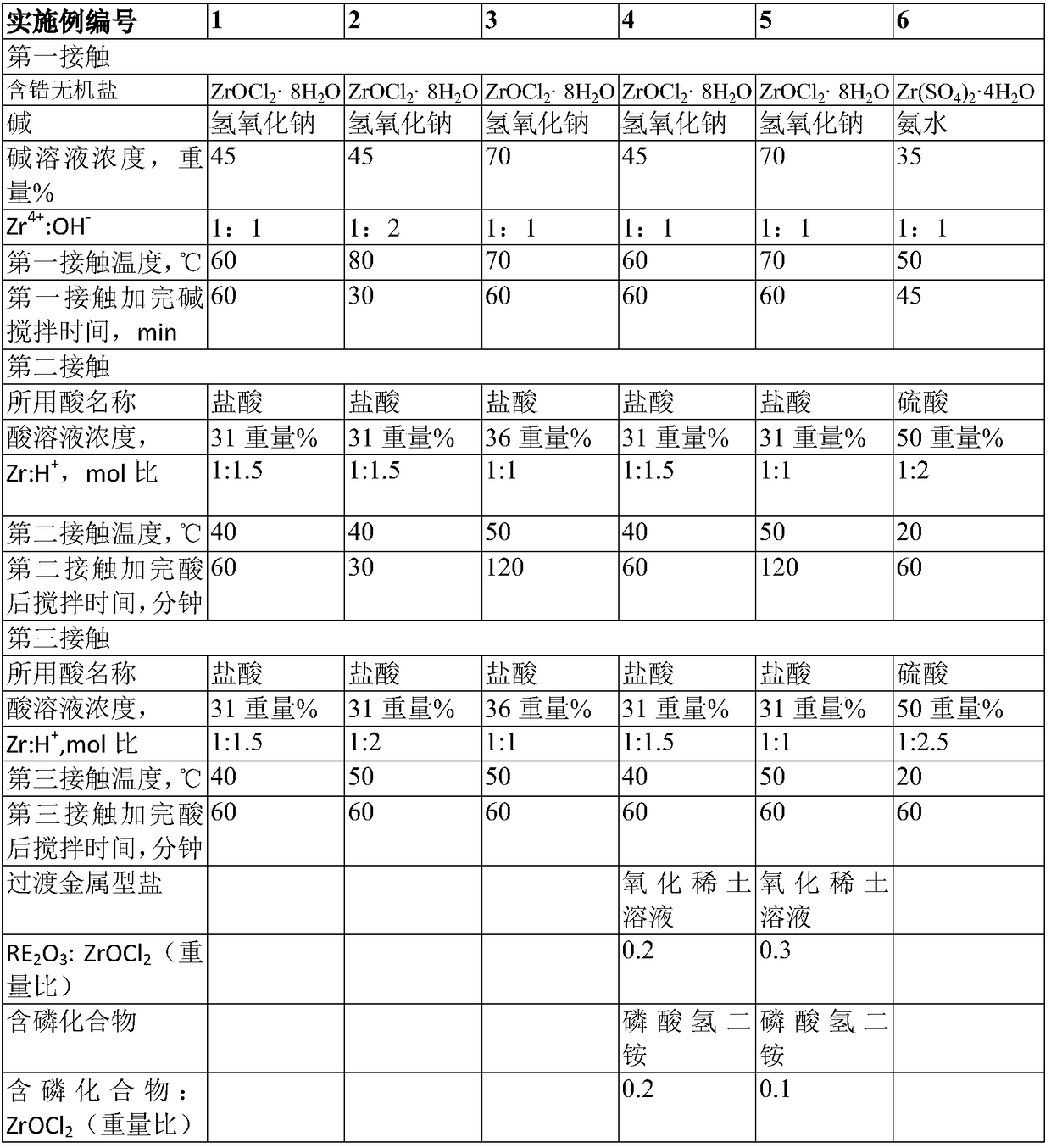

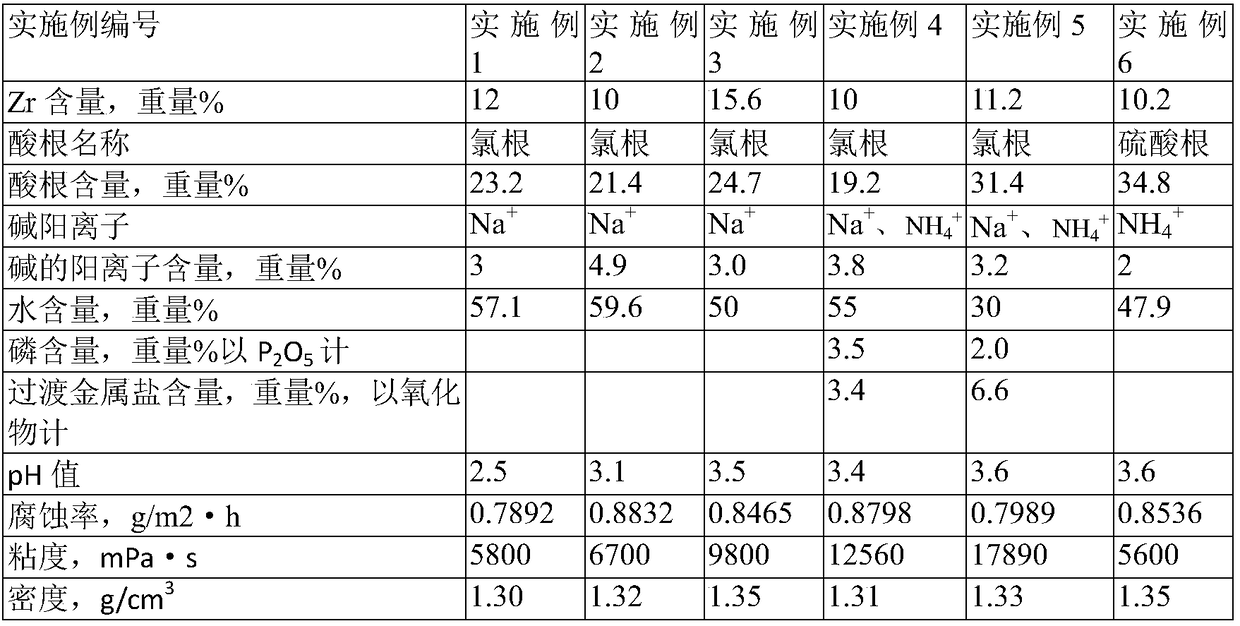

Embodiment 1

[0092] Add ZrOCl to the reaction kettle 2 ·8H 2 O 35.38Kg, then add concentration according to the ratio of Zr and sodium hydroxide molar ratio 1:1 under 60 ℃ of temperature and be the sodium hydroxide solution 9.77Kg of 45% by weight, then stir 60min at the temperature of 60 ℃, obtain after reaction The first contact object, and then at a temperature of 40 ° C according to Zr:H + =1:1.5 ratio, adding concentration is 19.41Kg of hydrochloric acid 31% by weight, then stirred at a temperature of 40°C for 60min to obtain the second contact, and then at a temperature of 40°C according to Zr:H + =1:1.5 ratio, adding 19.41Kg of hydrochloric acid with a concentration of 31wt% (wt% refers to weight%) to the second contact, and stirring at a temperature of 40°C for 60min to obtain the zirconium sol provided by the present invention. The preparation conditions and proportions are shown in Table 1, and the properties of the obtained zirconium sol are shown in Table 2.

Embodiment 2

[0094] With reference to the preparation method of Example 1, add ZrOCl in the reactor 2 ·8H 2 O, then add a sodium hydroxide solution with a concentration of 45wt%, stir, then add a concentration of 31wt% hydrochloric acid, stir, then add a concentration of 31wt% hydrochloric acid, stir, and obtain a zirconium sol. The preparation conditions and proportions are shown in Table 1, and the properties of the obtained zirconium sol are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com