Patents

Literature

56results about How to "Guaranteed sphericity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal powder preparation method and device based on plasma atomization technology

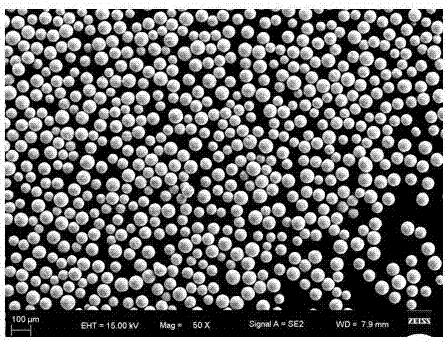

InactiveCN107175337AGuaranteed sphericityGuaranteed Particle SizeAdditive manufacturing apparatusPlasma torchMelting point

The invention discloses a method for preparing metal powder based on plasma atomization technology and a device thereof. The device includes a feeding chamber, an induction heating melting chamber, a plasma torch chamber, an atomization chamber and a powder collection chamber, and an induction heating device and a magnetic restraint device are arranged in the induction heating melting chamber. Frequency smelting technology, magnetic levitation technology and plasma atomization preparation technology are combined to maximize the effect of plasma atomization technology to prepare high-sphericity and high-quality metal particles. Compared with traditional plasma atomization preparation technology, it is guaranteed Under the premise of the sphericity and particle size of metal particles, the production volume of high melting point metal powder can be increased exponentially.

Owner:加拿大艾浦莱斯有限公司 +1

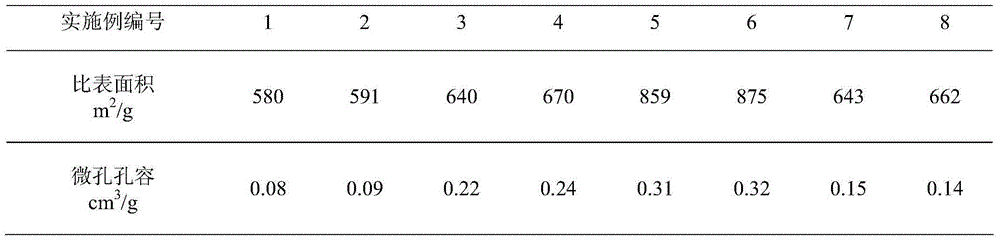

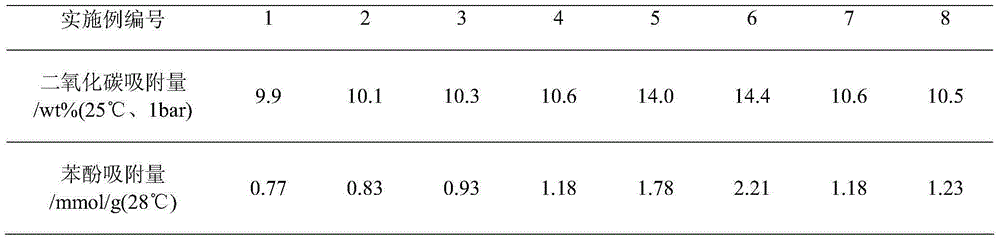

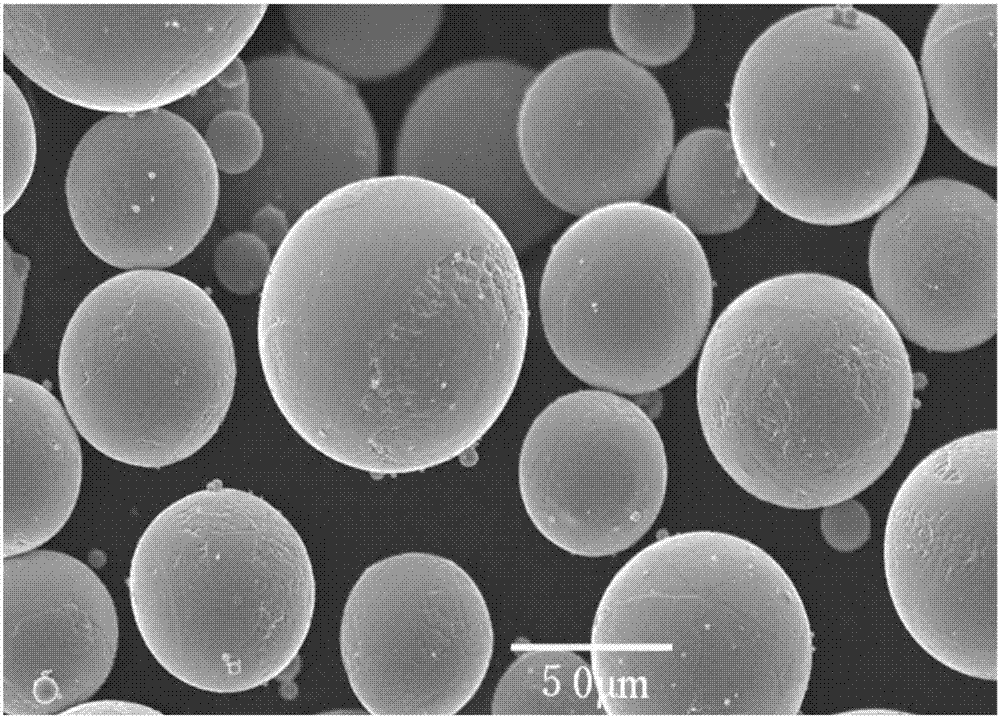

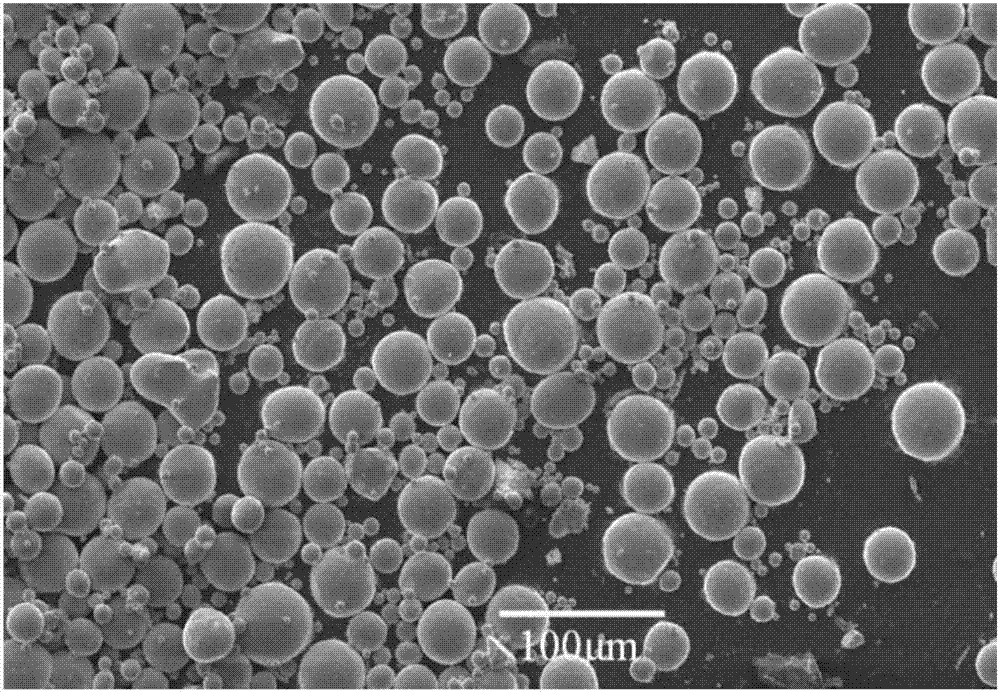

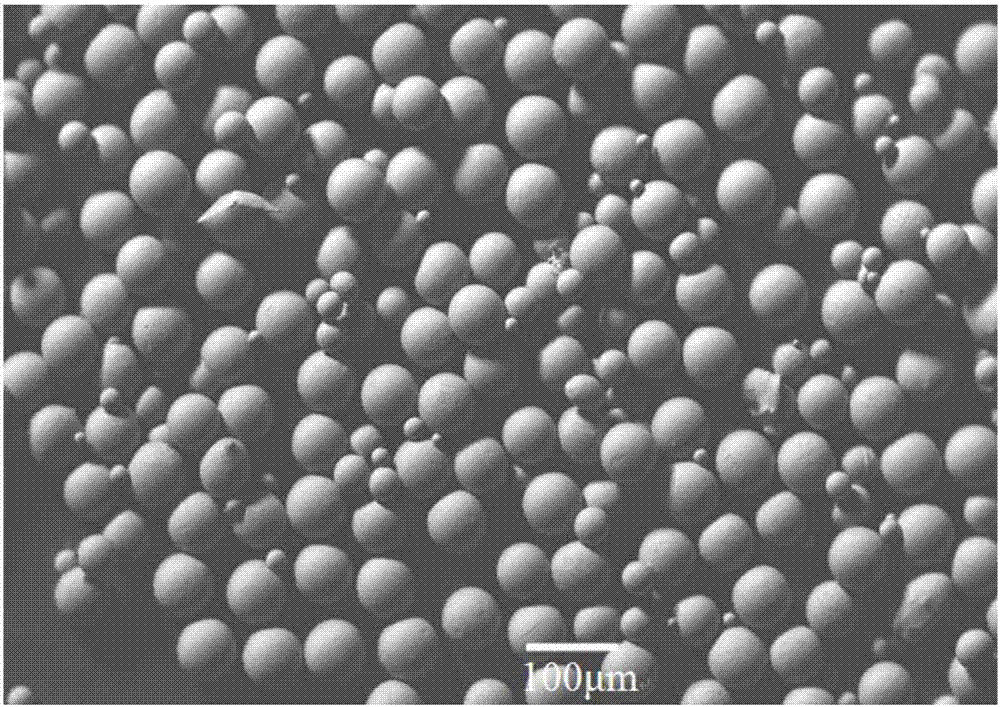

Preparation method for activated carbon material and application thereof

The invention provides a preparation method for an activated carbon material. The preparation method comprises the following steps: 1) taking an activator aqueous solution, adding ion exchange resin and stirring and mixing the mixture for ion exchange; 2) washing, filtering and drying the obtained mixture to obtain the required resin; 3) optional one step: a, carbonizing the obtained resin in an N2 atmosphere; b, after pre-oxidizing the obtained resin in air, carbonizing the resin in the N2 atmosphere; and 4) washing and drying the obtained carbon material to obtain the required activated carbon material. The invention further discloses an activated carbon material by adopting the method and application thereof. According to the activated carbon material and the application thereof provided by the invention, the activator can be uniformly dispersed and the carbon material is activated by alkali metal ions at a high temperature. The prepared activated carbon material has good application potential in adsorbing carbon dioxide and phenol.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Method for deoxidizing iron base catalyst of Fisher-Tropsch synthesis in slurry bed

ActiveCN1562484AHigh activityGood stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationSyngasBoiling point

A process for reducing the Fe-base catalyst used for slurry-bed Fischer-Tropsch synthesis includes such steps as adding the liquid-phase hydrocarbon compound whose boiling point is higher than 34 deg.C and proper Fe-base catalyst to slurry-bed reactor, displacing the air in the reactor system by inertial gas or synthetic gas, raising pressure, program-controlled raising temp, in-situ reducing for 15-94 hrs, and direct Fischer-Tropsch synthesizing.

Owner:SYNFUELS CHINA TECH CO LTD

Titanium and aluminum based alloy powder material for additive manufacturing and preparation method thereof

ActiveCN107400802AImprove oxidation resistanceImproves strength and ductilityAdditive manufacturing apparatusTitaniumSystems design

The invention provides a titanium and aluminum based alloy powder material for additive manufacturing. The titanium and aluminum based alloy powder material is prepared from the following raw materials in percentage by atom: 47 to 56 percent of Al, 1.6 to 2.3 percent of Cr, 1.6 to 2.0 percent of Mo, 0.6 to 1.2 percent of TiB2 and the balance of Ti and unavoidable impurity. In addition, the invention also provides a method for preparing the alloy powder material. The method comprises the following steps of I, protecting the inner wall of a graphite flow guiding pipe by adopting a ceramic flow guiding inner core; II, preparing high-temperature-preventing carbonized coatings at the end surfaces of the graphite flow guiding pipe and then loading the graphite flow guiding pipe into a smelting chamber; III, preparing an ingot blank by adopting vacuum self-consuming arc smelting; IV, smelting to prepare an alloy melt by adopting a water-cooled copper crucible; V, carrying out atomization treatment, so that the titanium and aluminum based alloy powder material for the additive manufacturing is obtained. The alloy powder material is an alloy system designed for the additive manufacturing process and various properties of a product manufactured through the additive manufacturing technique by adopting the alloy powder material can reach expected effects.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

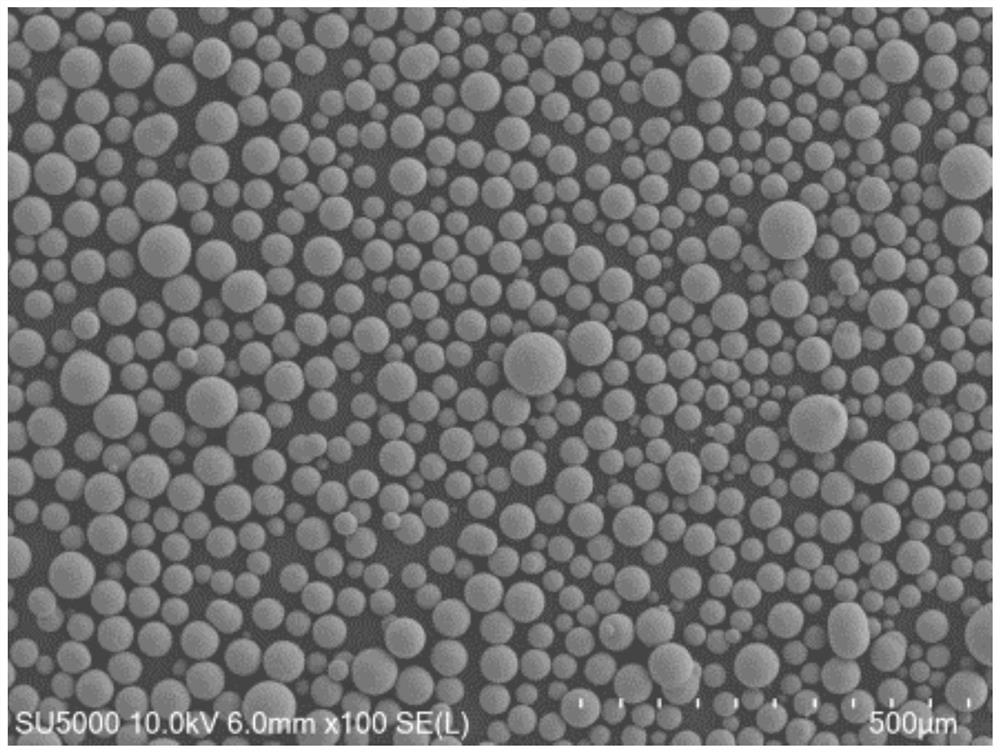

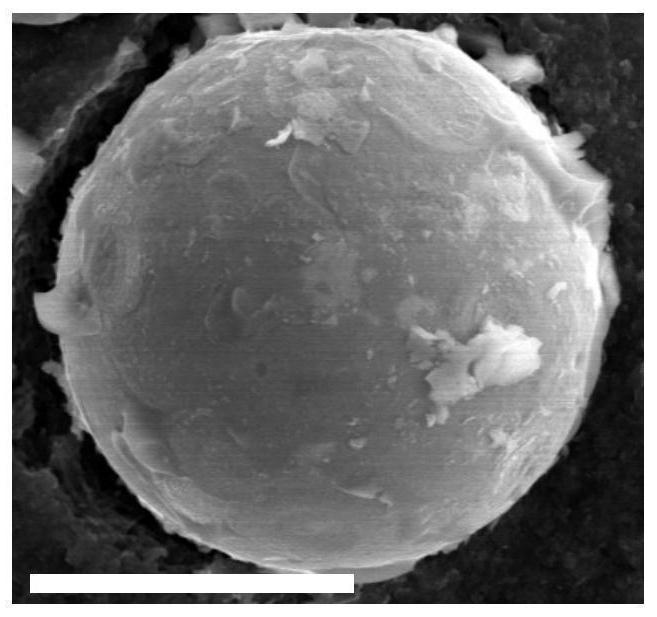

Method for preparing Mo powder and Mo alloy spherical powder for additive production

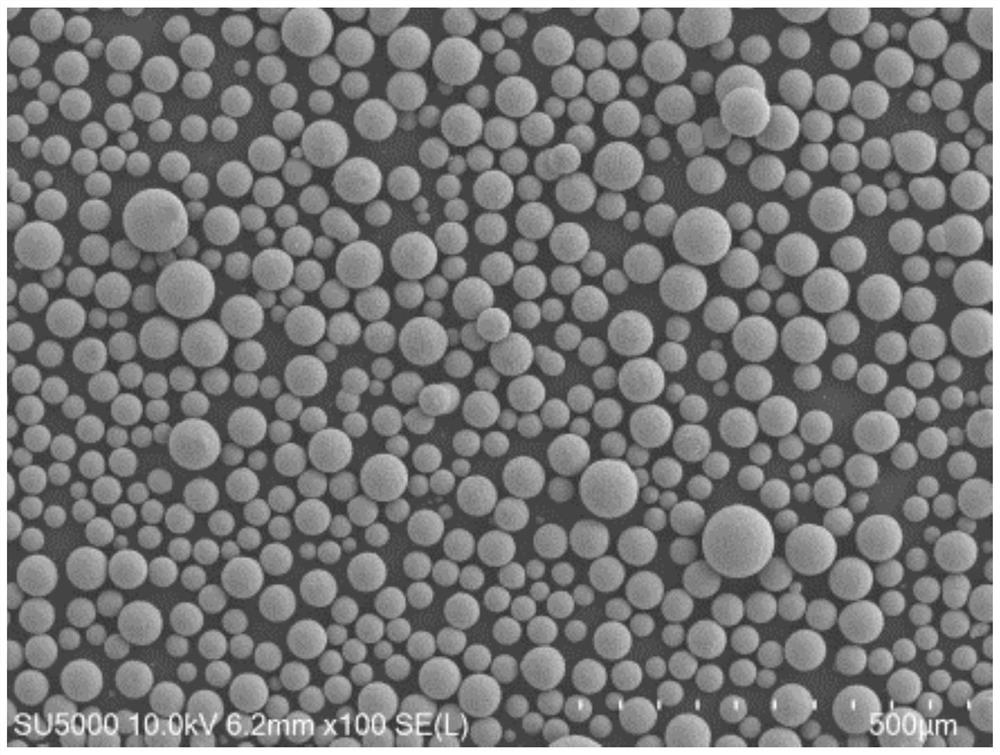

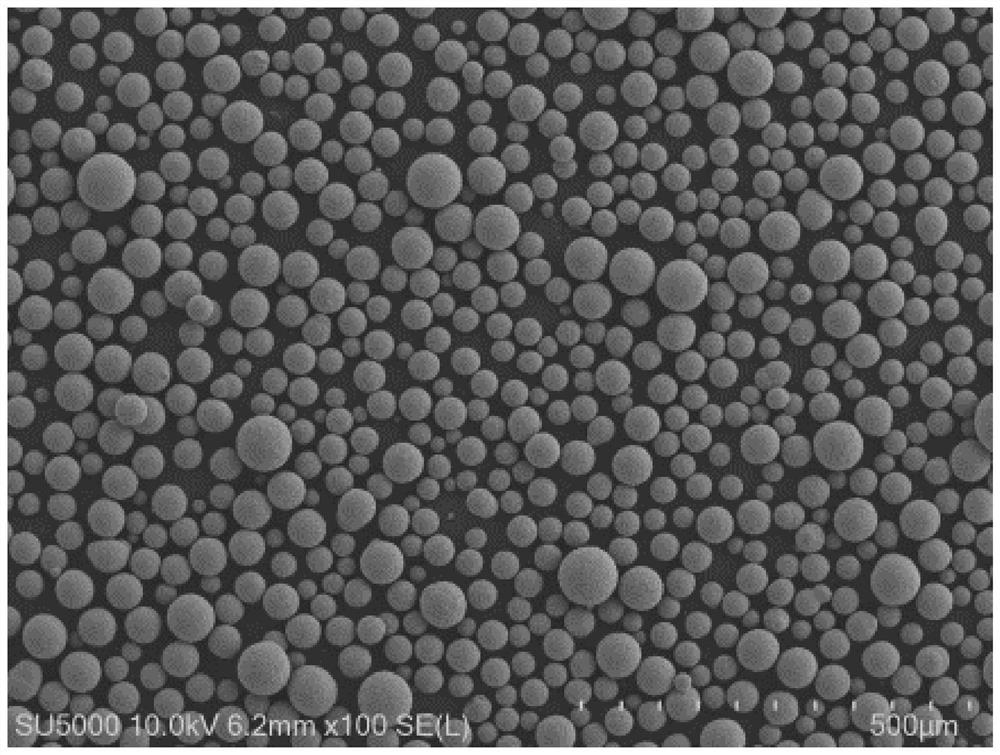

InactiveCN107876794AImprove qualityHigh sphericityAdditive manufacturing apparatusTransportation and packagingUltra fineAlloy

The method for preparing Mo powder and Mo alloy spherical powder for additive production includes the following steps that 1), smelted Mo rods and Mo alloy rods are finish-machined into Mo electrode rods and Mo alloy electrode rods; 2), the Mo electrode rods and the Mo alloy electrode rods are loaded to a reaction chamber, the reaction chamber is vacuumized, and inert gas is introduced into the reaction chamber according to a certain proportion; 3), a plasma gun contains a tungsten cathode and a copper anode, the Mo electrode rods and the Mo alloy electrode rods are not used as the electrode,the ends of the Mo electrode rods and the ends of the Mo alloy electrode rods are heated and uniformly melted, atomized droplets are thrown away from the ends of the Mo electrode rods and the ends ofthe Mo alloy electrode rods, and the droplets are rapidly cooled into spherical particles in an inert gas environment and fall into a collector; and 4), the obtained Mo powder and Mo alloy powder aresieved and packaged under the inert gas protection environment. The Mo powder and Mo alloy powder prepared through the method have the ultra-fine, high-purity, high-grade spherical, free-of-hollow-powder and free-of-satellite-powder characteristics.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

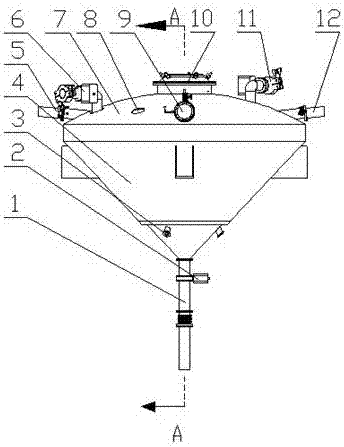

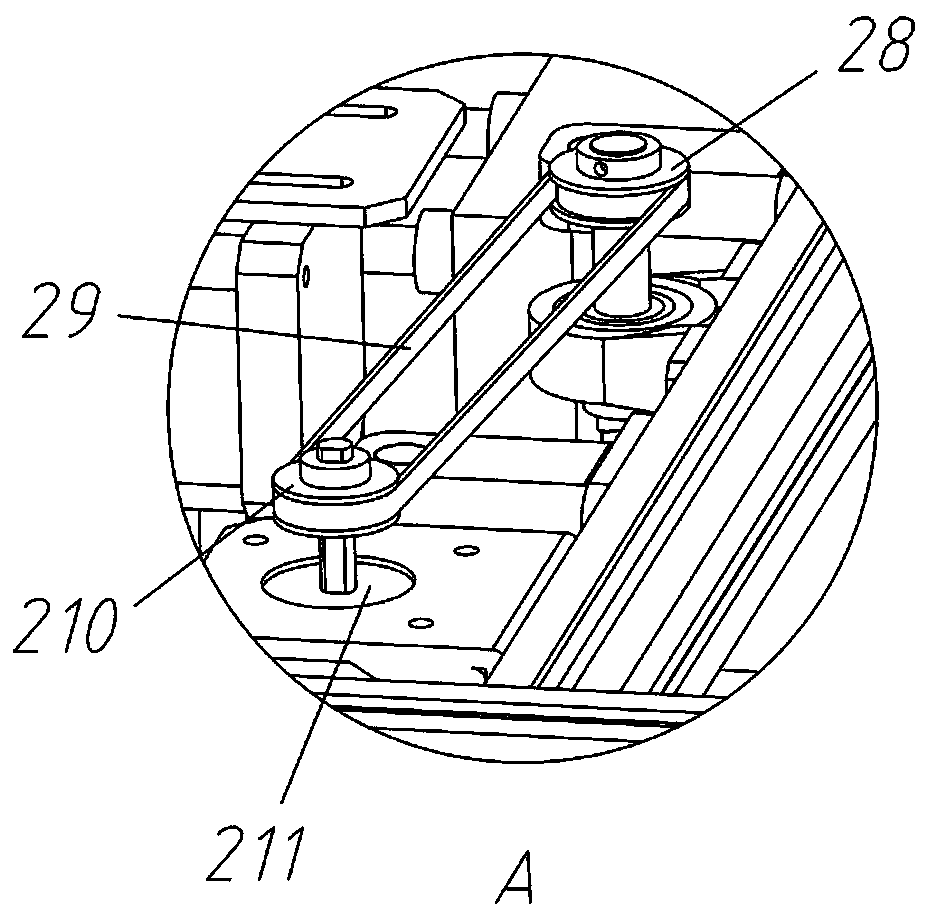

High speed centrifugal atomization device used for metal centrifugal atomization powder preparation

A high speed centrifugal atomization device used for metal centrifugal atomization powder preparation comprises an atomization tank, a rotary disc and a gas driven rotary shaft. The center of the top of the atomization tank is provided with a metal smelting leakage ladle. The lower end of the side wall of the atomization tank is provided with a gas conveying pipe conveying driving gas to the gas driven rotary shaft. The bottom of the atomization tank is provided with a power outlet pipe. The gas conveying pipe communicates with a high pressure gas source. The rotary disc is located under the metal smelting leakage ladle, connected with the top end of the gas driven rotary shaft and driven by the gas driven rotary shaft to rotate at a high speed. The rotating speed of the gas driven rotary shaft is 50000 r / min or above. The high speed centrifugal atomization device adopts the gas drive rotary shaft, is convenient to mount and is 50000 r / min or above in rotating speed, metal powder prepared through the device is uniform in particle size, and the service life of the device can be up to 10 years or above.

Owner:HUNAN JUTA TECH

LED fluorescent glue and packaging method for improving luminescence uniformity, and LED

InactiveCN105845812AGood dispersionLarge specific surface areaSolid-state devicesSemiconductor devicesFluorescenceWavelength

The invention discloses an LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 0.01-1 part of fluorescent powder, 0.01-0.1 part of silica-based inorganic nanoparticles, 0.01 part of ‑1 part silicone granules. Inorganic nanomaterials and silicone particles are mixed in the encapsulation glue, which reduces the sedimentation rate of the phosphor in the encapsulation glue, improves the uniformity of the phosphor distribution in the colloid, makes the white light spot more uniform, and improves the light diffusivity and transmittance. The light rate is maximized, and by changing the propagation path of the light, the light of various wavelengths is more fully mixed, and the spatial color uniformity of the light is further improved. It also provides an LED packaging method and LED that improve the uniformity of light emission, which improves the consistency of products, reduces the probability of uneven color distribution in space due to uneven distribution of phosphor powder, and improves product yield and product production. efficiency.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

Method for reducing iron base catalyst of Fisher-Tropsch synthesis in slurry bed

ActiveCN1247305CSimple methodSimple and fast operationHydrocarbon from carbon oxidesCatalyst activation/preparationSyngasReactor system

Owner:SYNFUELS CHINA TECH CO LTD

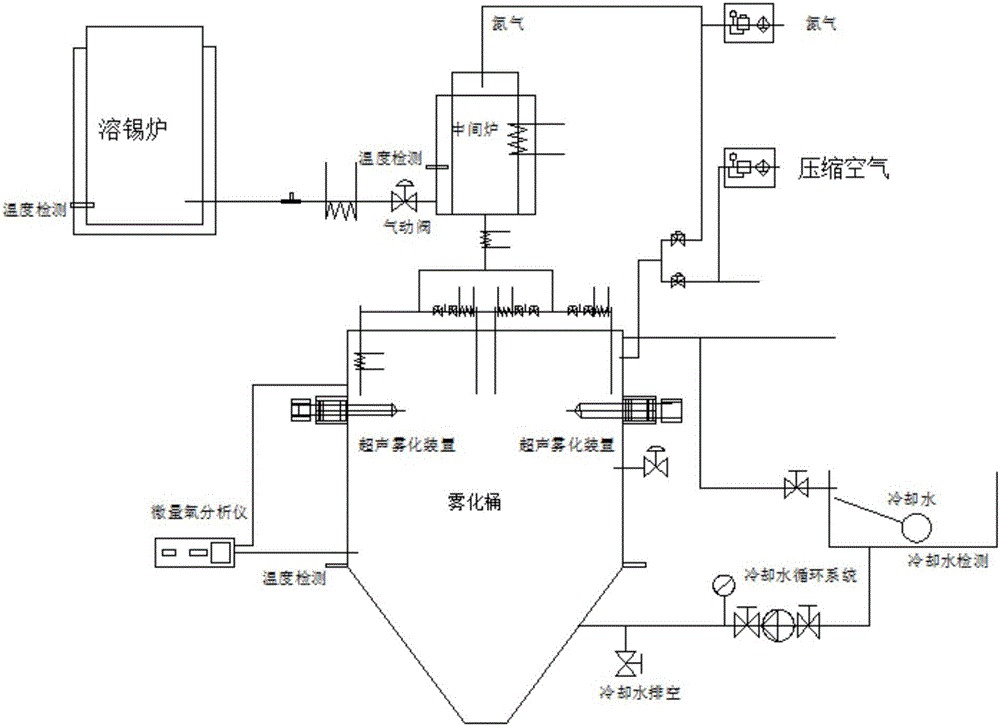

Tin-powder ultrasonic atomization device and atomization process thereof

The invention discloses a tin-powder ultrasonic atomization device. The tin-powder ultrasonic atomization device comprises a tool head, wherein an amplitude varying pole is arranged on one side of the tool head, a cooling device is arranged on one side of the amplitude varying pole, a transducer front cover is arranged at the part, in the cooling device and located at one end of the amplitude varying pole, a transducer rear cover is arranged on one side of the transducer front cover, a piezoelectric ceramic stack is arranged between the transducer front cover and the transducer rear cover, an electrode lead electrically connected to the piezoelectric ceramic stack is arranged on one side of the cooling device, and a signal generator is arranged at one end of the electrode lead. Ultrasonic atomization of tin powder researched and developed by the invention can fundamentally solve the defects, ultrasonic is formed according to liquid surface tension waves to generate atomization, namely liquid metal forms a liquid film on the surface of an atomization head under ultrasonic vibration, and then the liquid film is broken by the effect of the vibration, uniform spheres are separated from the liquid film and formed, so that the sphericity of the generated powder is higher.

Owner:GUANGDONG TIANGAO TECH CO LTD

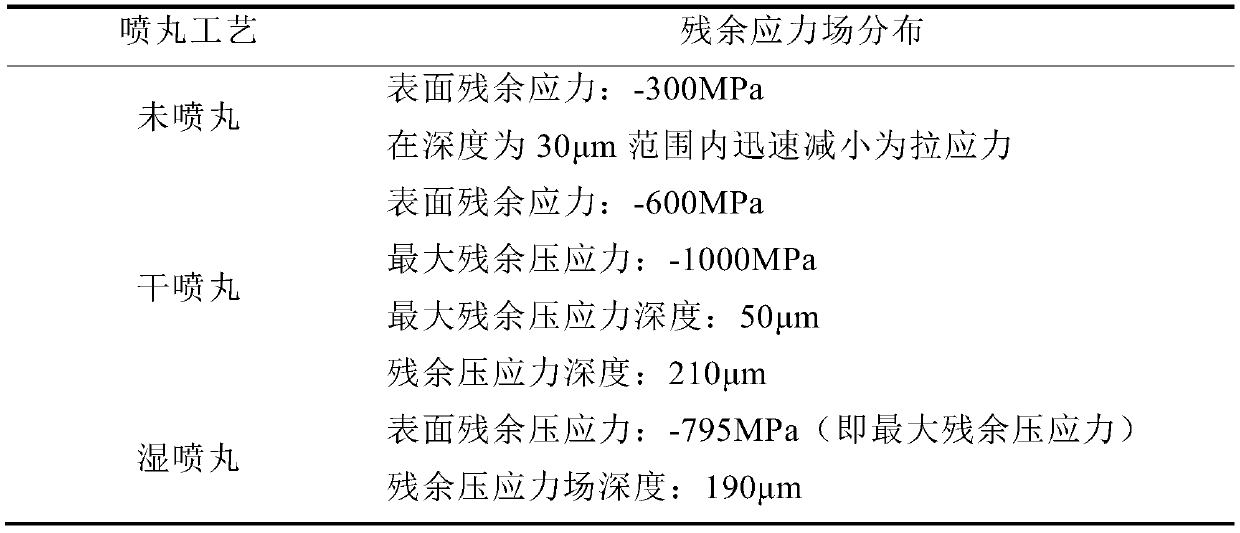

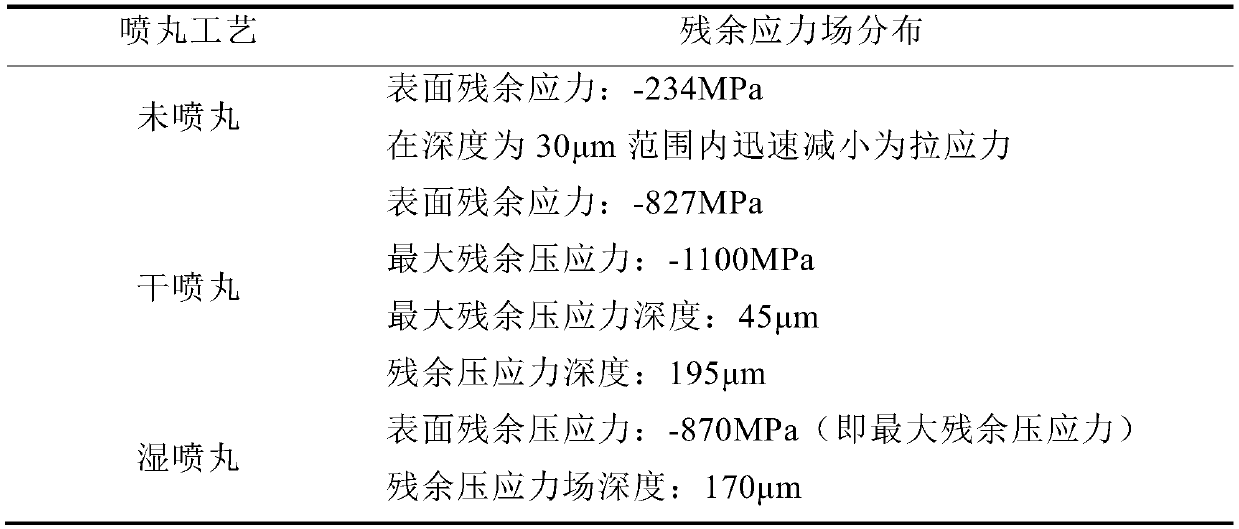

Wet shot peening surface modification treatment method suitable for nickel-based high-temperature alloy

The invention relates to a wet shot peening surface modification treatment method suitable for a nickel-based high-temperature alloy. The method comprises the following treatment methods of pre-treatment before shot peening, wherein the surface cleaning is carried out on nickel-based high-temperature alloy parts, no pollutants exist on the surface of the parts, and the parts which cannot be shot-peened are wrapped and plugged; wet shot peening treatment, wherein the wet shot peening treatment is carried out on the nickel-based high-temperature alloy parts by using ceramic shots and water, andthe water to ceramic shots is 4:1 by mass ratio; and post-treatment of shot peening, the nickel-based high-temperature alloy parts after conducting wet shot peening are dried at room temperature to finish surface modification treatment. According to the wet shot peening surface modification treatment method, the structure of materials is adjusted and controlled through the optimization of technological parameters, thus improving the universality of the method, and by utilizing the lubricating and buffering effects of water, the strain rate of plastic deformation during the process of shot peening can be reduced, the surface defects such as microcracks and peeling on the surface of the nickel-based high-temperature alloy are avoided, thus enhancing the surface integrity level of the materials and perfecting the fatigue performance of the materials.

Owner:TONGJI UNIV

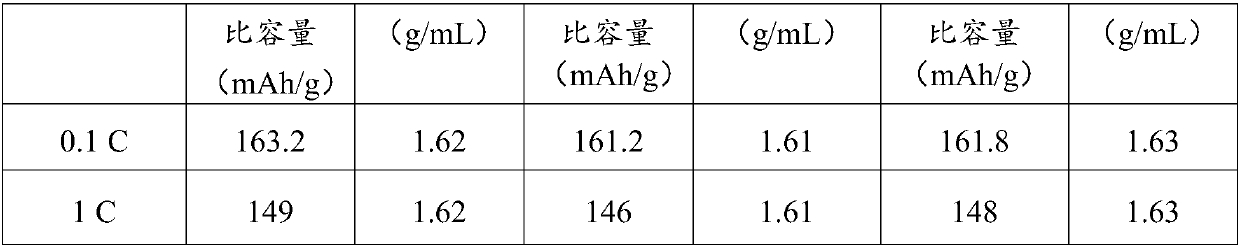

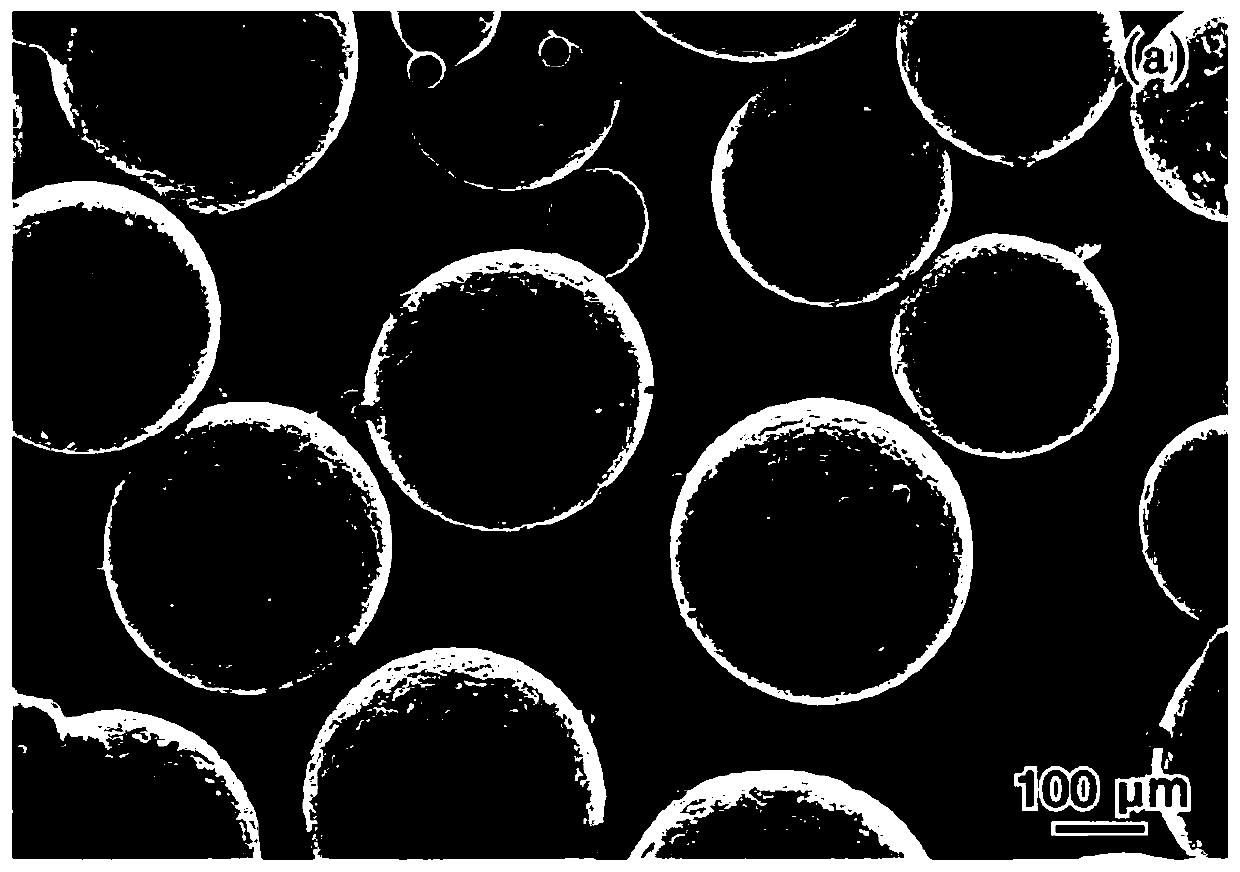

Preparation method of titanium-doped lithium iron phosphate cathode material

ActiveCN107611413AIncrease the kinetic energy of the reactionRapid responseCell electrodesSecondary cellsCarbon coatingElectron

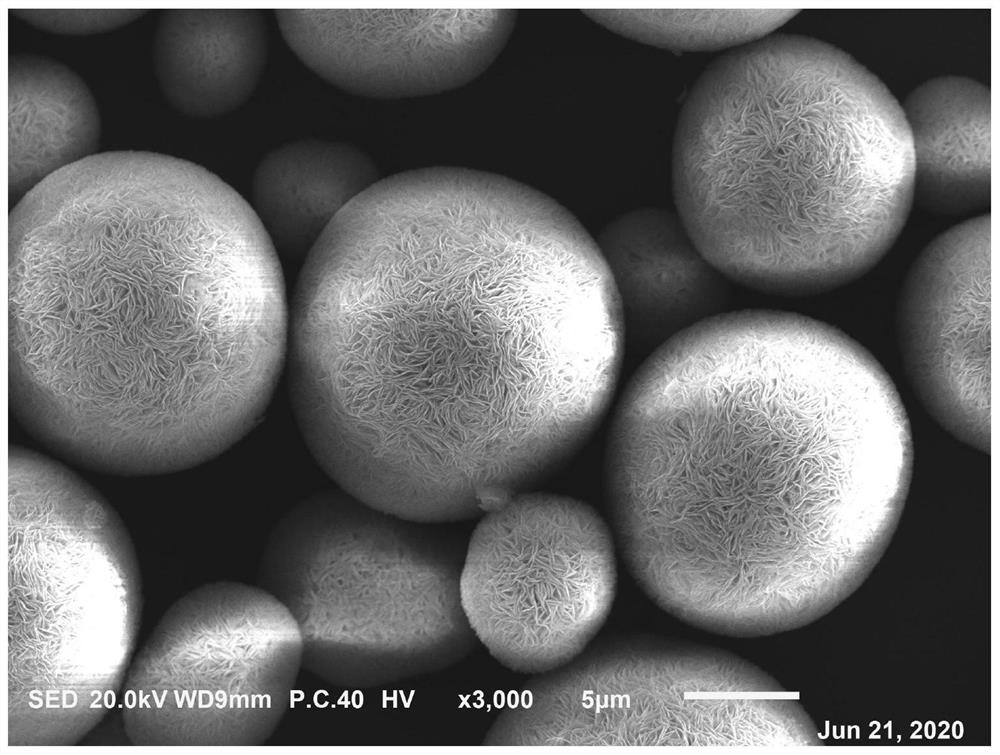

The invention discloses a preparation method of a titanium-doped lithium iron phosphate cathode material. The preparation method comprises the following steps: by using a lithium source compound, a phosphorus source compound, an iron source compound and metallic titanium as raw materials, evenly mixing the raw materials and melting the mixture in a melting furnace at high temperature to obtain a mixture; performing water quenching on the mixture into particles; grinding and dispersing the particles and a carbon source compound together to ensure that the particle size reaches the Fineness index of D90 being less than or equal to 0.2 micron; making powder in a spray drying method, and calcining the powder for 40 to 300 minutes in an atmosphere furnace of 600 to 800 DEG C; performing coolingto obtain the lithium iron phosphate cathode material. By adopting a high-temperature melting method, the uniformity of the lithium iron phosphate cathode material is improved; by introducing metallic titanium powder, Fe<3+> in a melt solution is reduced into Fe<2+> at high-temperature melting state, and generated Ti<4+> is doped into a lithium iron phosphate structure, and the electron conductivity of the lithium iron phosphate cathode material is improved through formation of vacant positions; the specific surface area is reduced by means of grinding and dispersion as well as carbon coating, and the tapping density of the lithium iron phosphate cathode material is improved. According to the preparation method disclosed by the invention, crushing and integration are not needed, so that the original sphericity can be maintained and technological processes are also simplified.

Owner:威远县大禾陶瓷原料有限公司

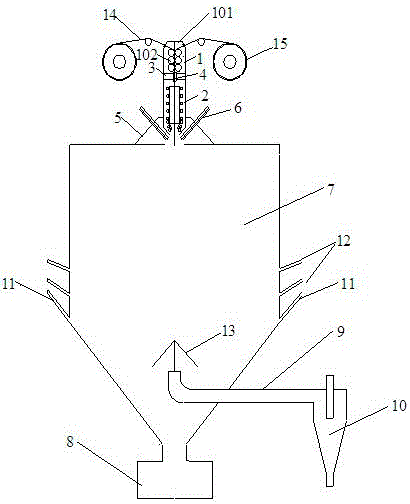

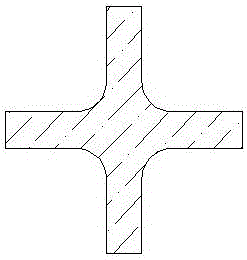

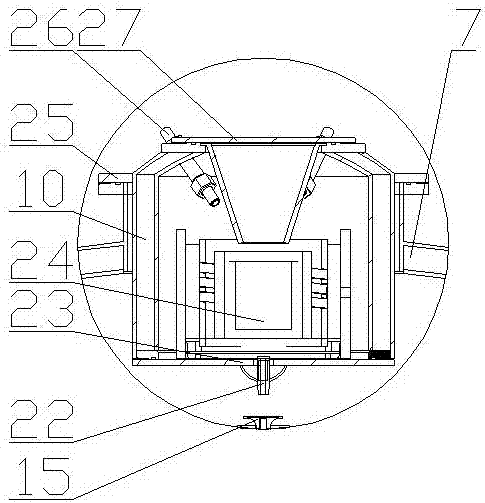

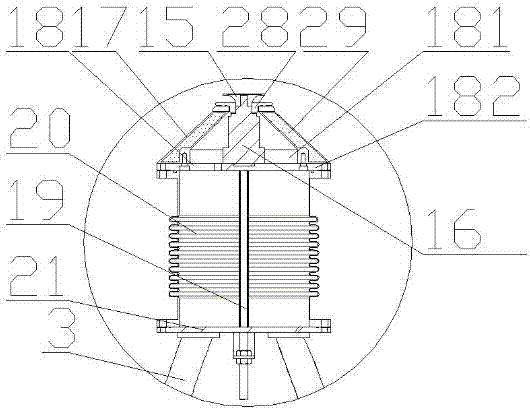

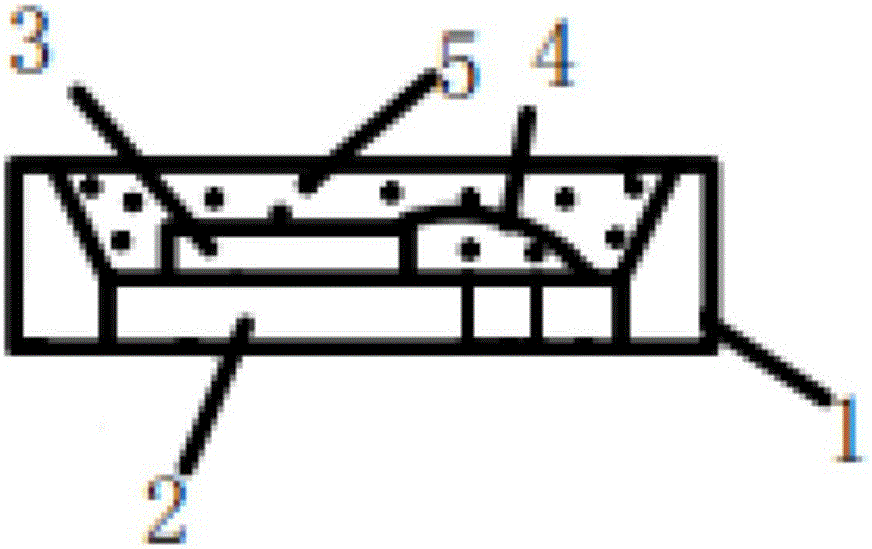

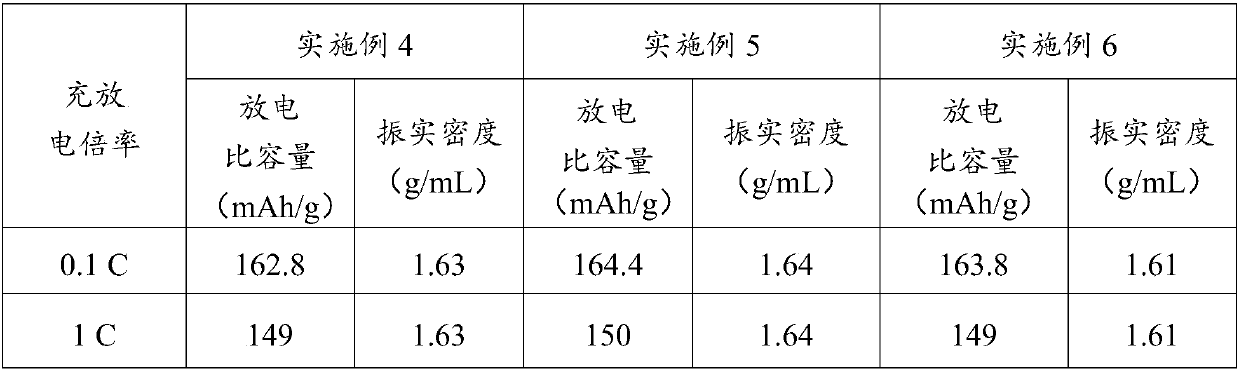

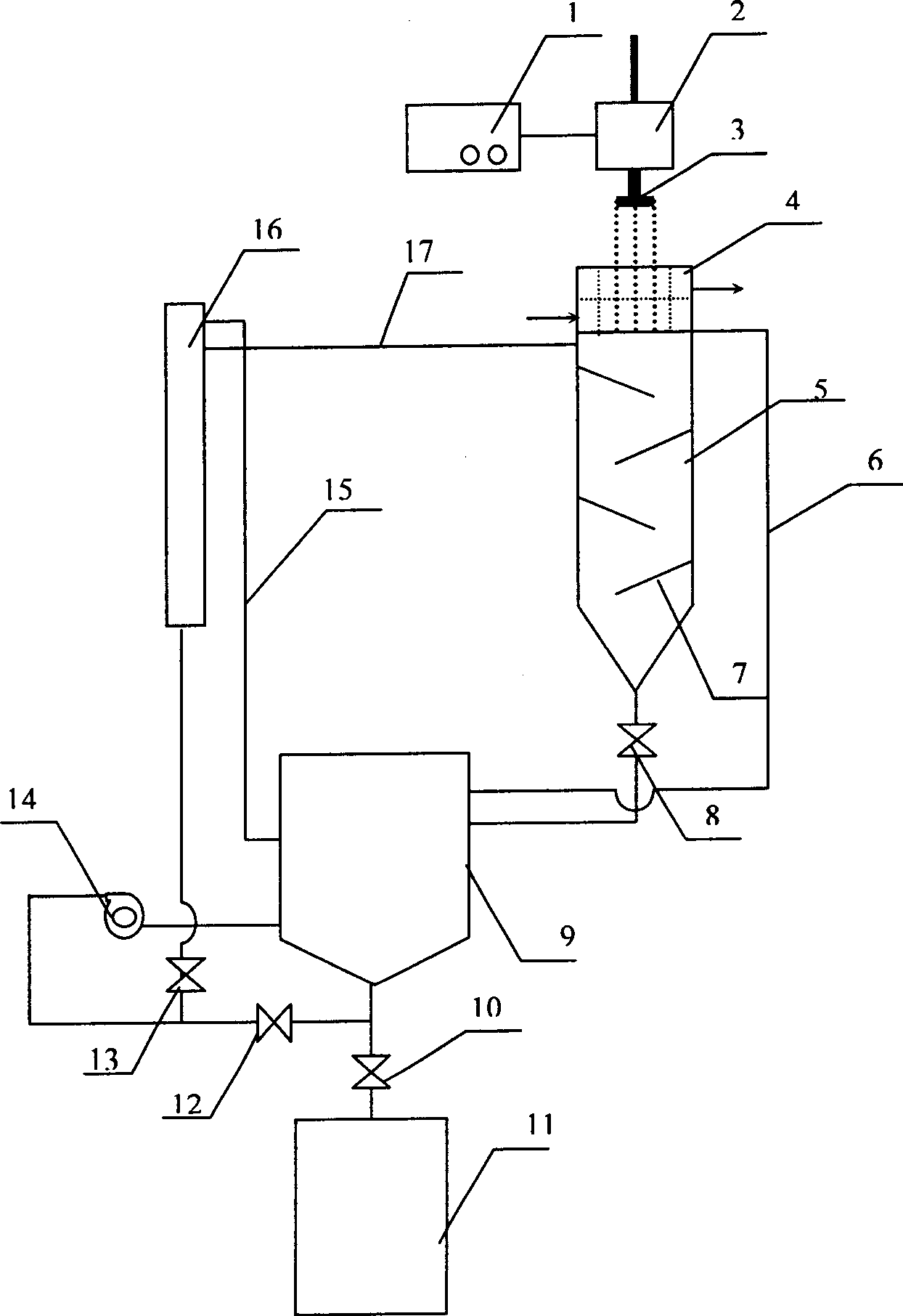

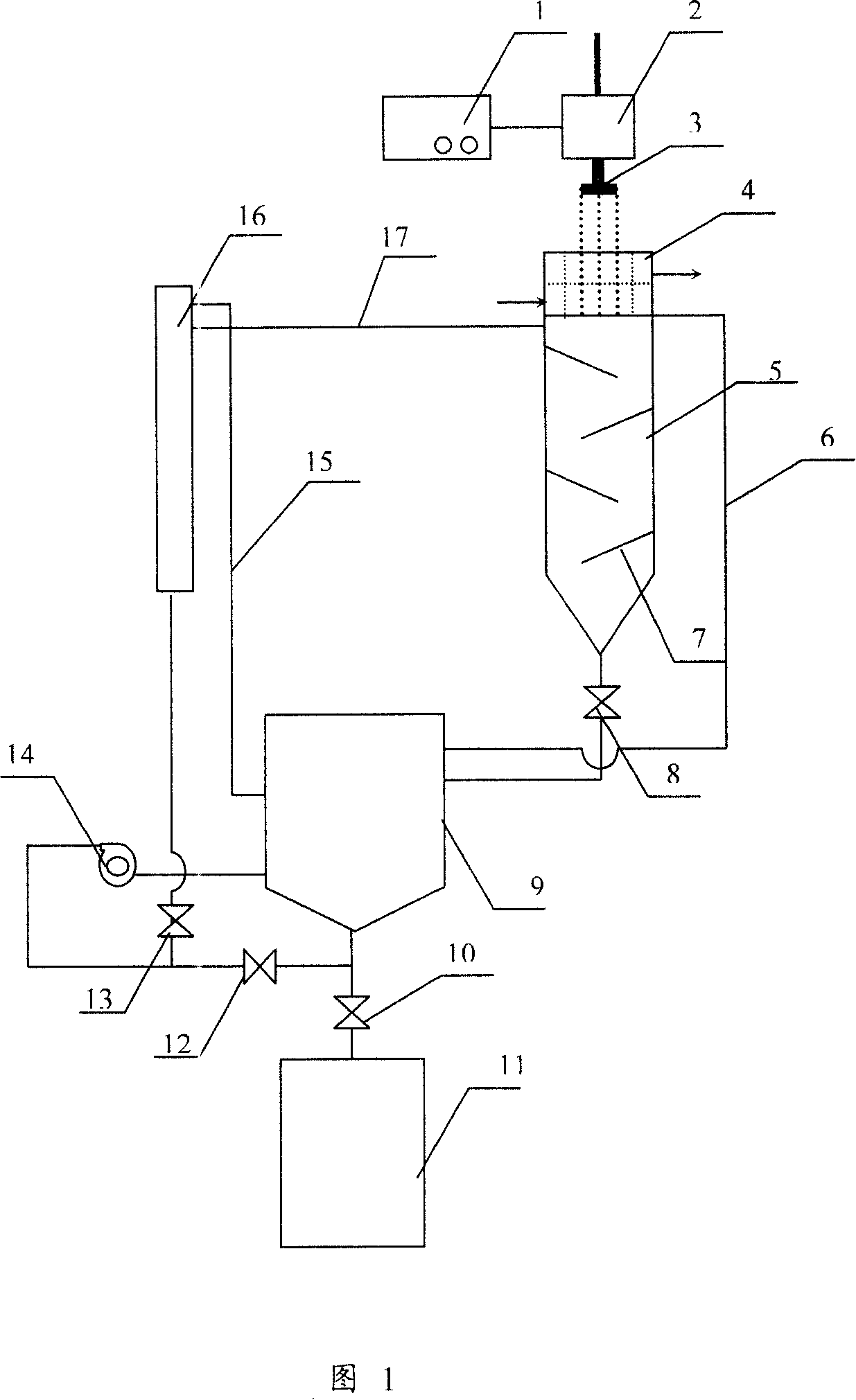

System for preparing gel bead

ActiveCN1843610AFull gelExtended stayNuclear energy generationGranulation by liquid drop formationEngineeringAmmonia

The invention relates to a system for preparing gel ball, belonging to the technique that preparing ceramic gel ball. Said system comprises two parts as vibration dispersion system and gel system. Wherein, the vibration dispersion system comprises a signal controller 1, a vibrator 2, and an ejector; the gel system comprises a ammonia distributing ring 4, a gel post 5, a liquid groove 9, a baffle post 16, and a ball storage pot 11. The liquid of gel via cycle pump 14 can be cycled between the gel post 5, the liquid groove 9, and the baffle post 16; the sol via the ammonia distributing ring 4 is gelled into gel ball in the gel post 5; and the gel ball will flow into liquid groove 9 with liquid. Said system can confirm full gelling on the sol ball and reduce the pressure between gel balls, to avoid the distribution of flowing medium liquid on the liquid level. And it has simple operation and the application for continuous operation.

Owner:TSINGHUA UNIV

Recovery processing method for waste Ti or Ti alloy powder in additive manufacturing

The invention relates to a recovery processing method for waste Ti or Ti alloy powder in additive manufacturing. Under inert gas shielding and an indoor temperature condition of 10-20 DEG C, the wasteTi or Ti alloy powder is processed by the steps that (1) sodium amalgam is added into the waste Ti or Ti alloy powder in additive manufacturing, so a mixed sizing agent is obtained; (2) the mixed sizing agent obtained at the step (1) is mixed, so the mixed sizing agent can reach a fluidized state; (3) an inert gas is fed into the mixed sizing agent in the fluidized state, shear friction is motivated to generate the Ti or Ti alloy powder and evaporation of sodium amalgam in the sizing agent is accelerated through convection effects between bubbles generated in the mixed sizing agent and the sizing agent, so solid Ti or Ti alloy powder is obtained through separation; and (4) the Ti or Ti alloy powder obtained at the step (3) is cleaned and dried, so the Ti or Ti alloy powder which can be reused in additive manufacturing is obtained.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

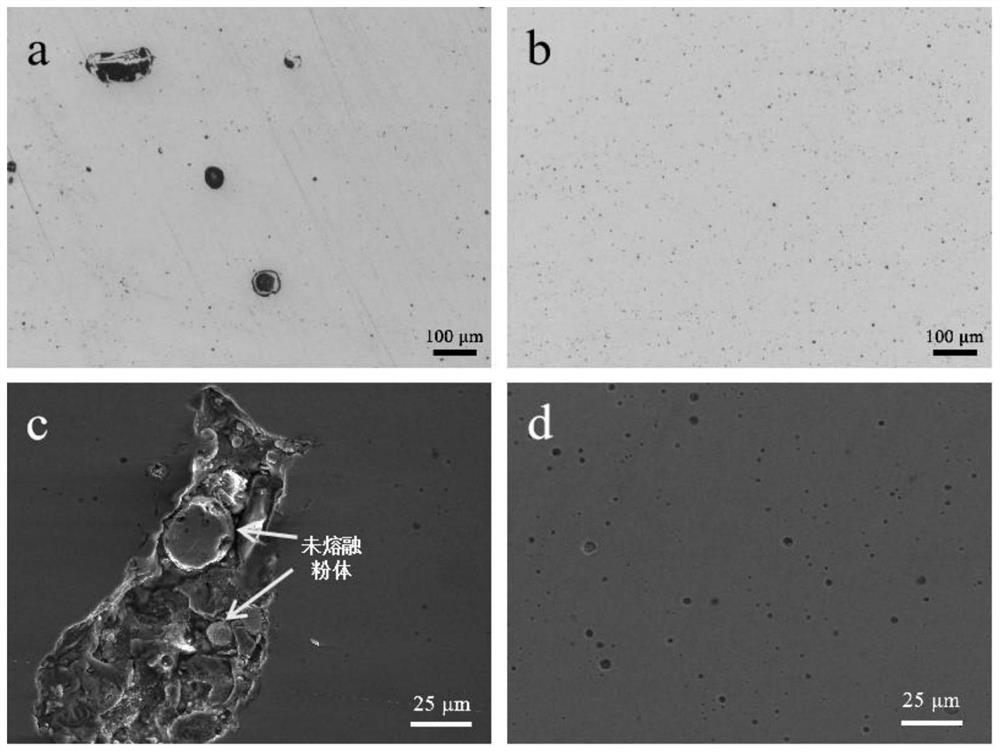

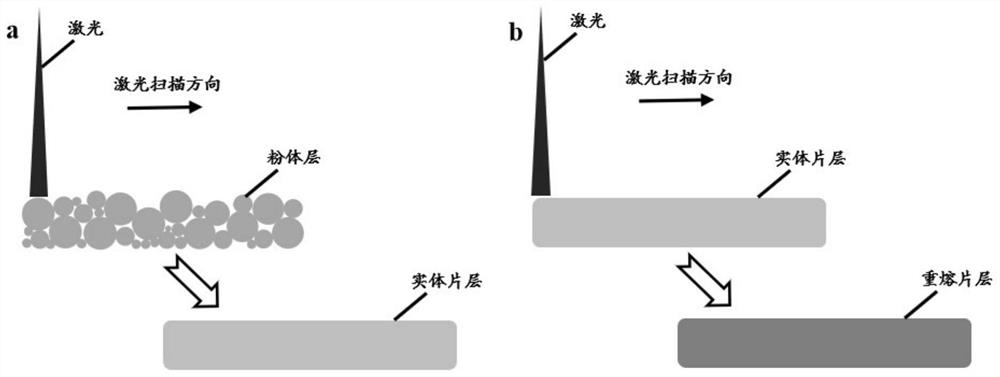

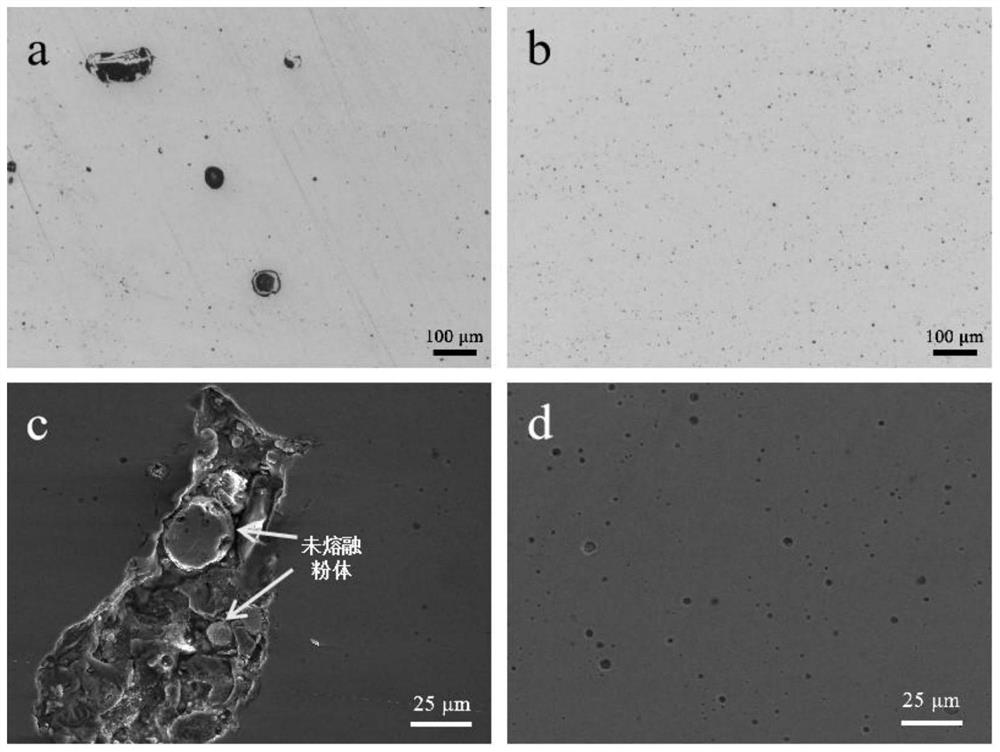

Laser additive manufacturing method of in-situ synthesized nano Al2O3 reinforced aluminum-based composite material

ActiveCN112176213AAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMg composite

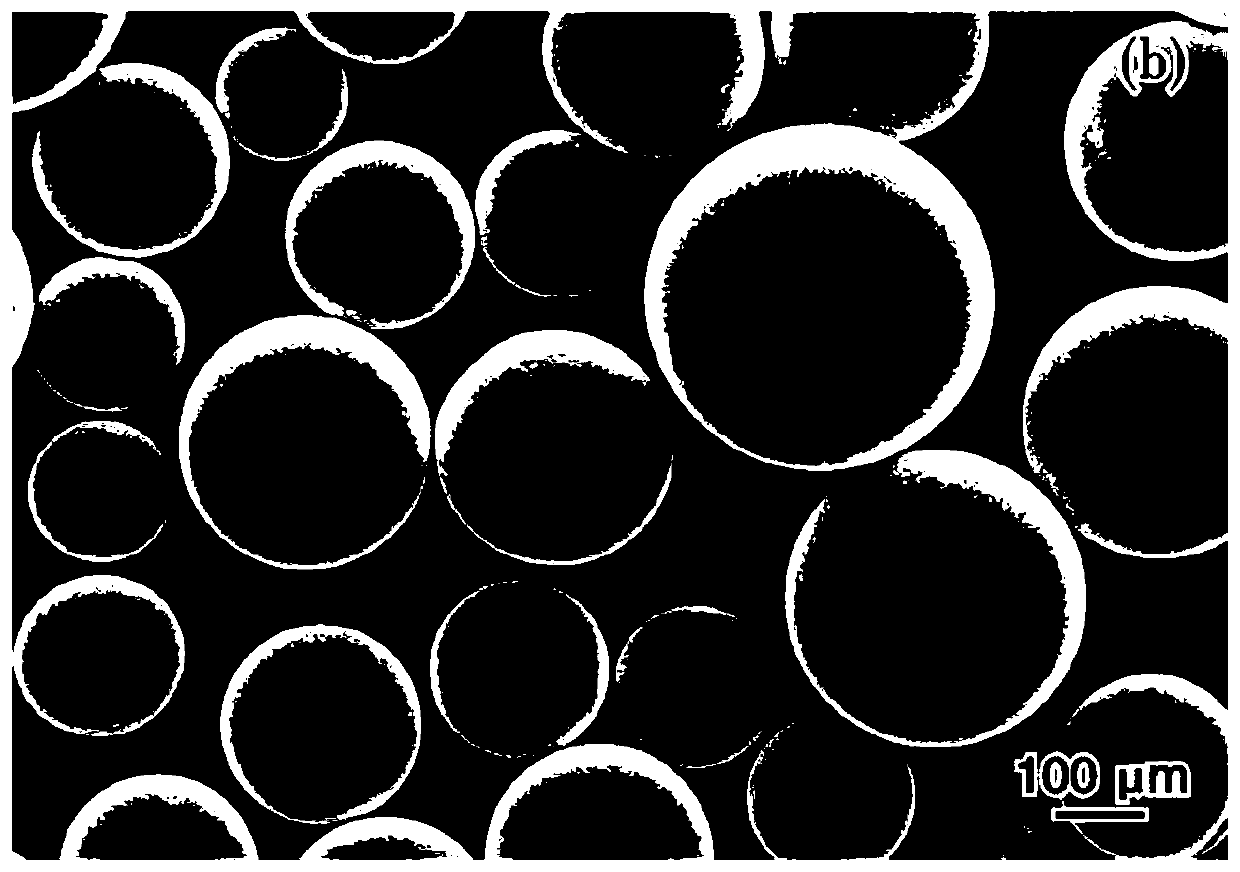

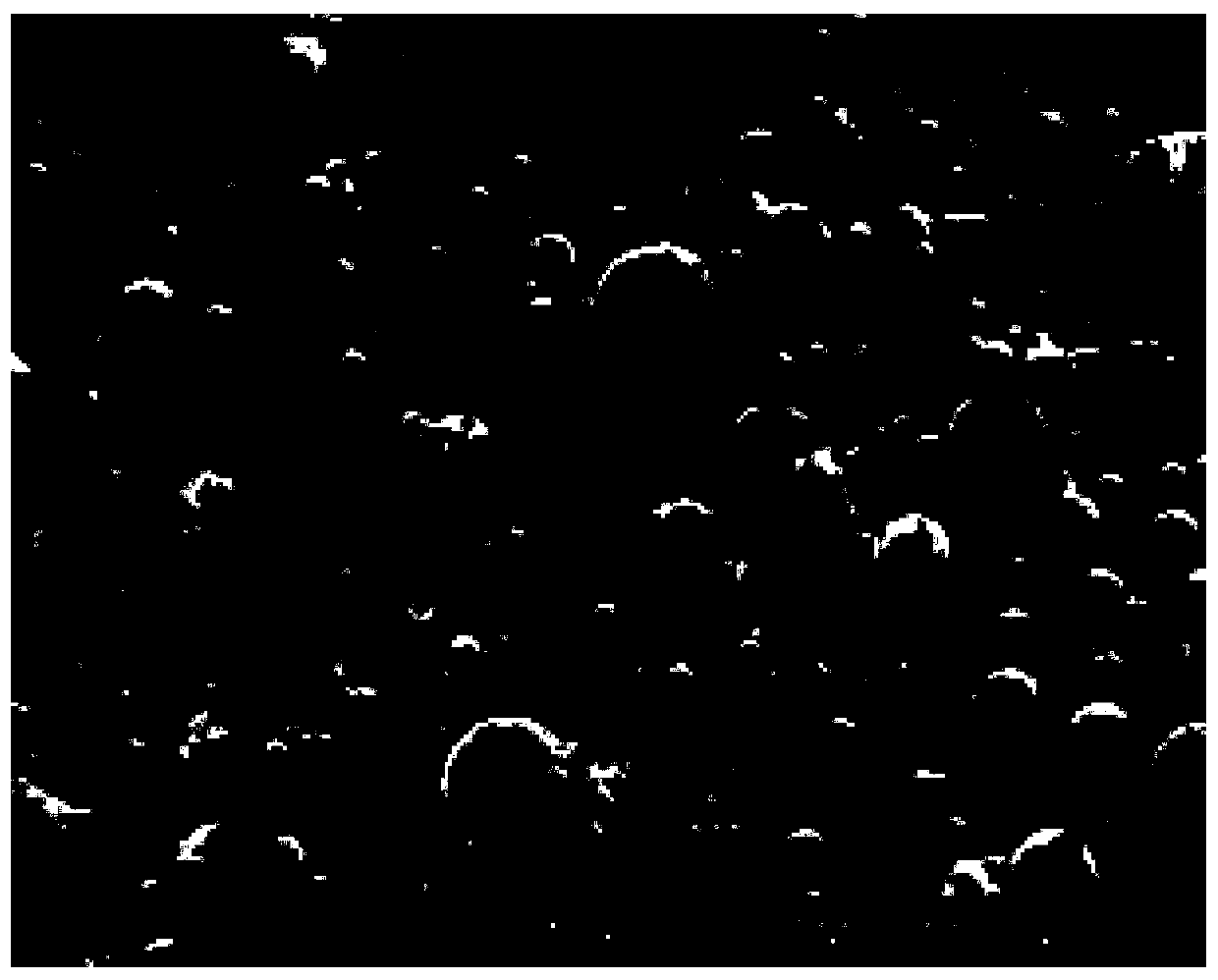

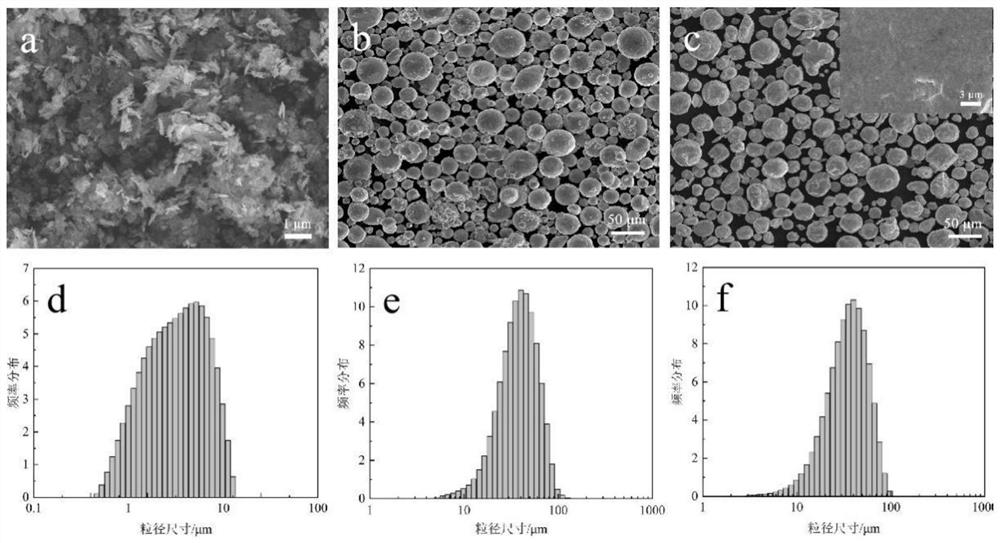

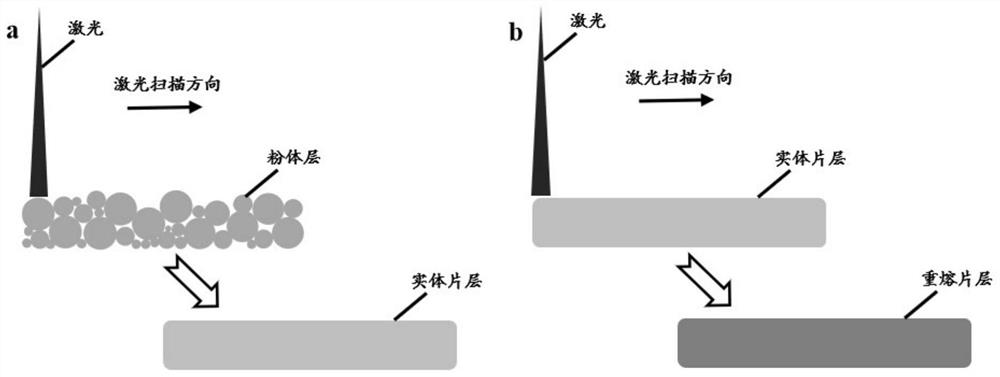

The invention discloses a laser additive manufacturing method of an in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. The method comprises the following steps of (1) mixingZnO ceramic powders and AlSi10Mg aluminum alloy powders, and carrying out ball milling to obtain ZnO / AlSi10Mg composite powders; (2) carrying out additive manufacturing forming on the composite powders by adopting a selective laser melting process to form a solid sheet layer; (3) carrying out laser scanning on the solid sheet layer again to form a remelting sheet layer; (4) repeating the steps (2)and (3), and finally forming to obtain the in-situ synthesized nano Al2O3 reinforced aluminum-based composite material. A laser is used for exciting Al and ZnO to generate aluminothermic reactions between the Al and ZnO to generate Al2O3 ceramic particles in situ, the overall process design of the method is improved, selective laser melting and laser remelting scanning are matched, the prepared aluminum-based composite material is high in density and fine in microstructure, the in-situ synthesized Al2O3 particles are nanoscale in size and are uniformly distributed, and the phase interfaces ofthe Al2O3 particles are well combined with an aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

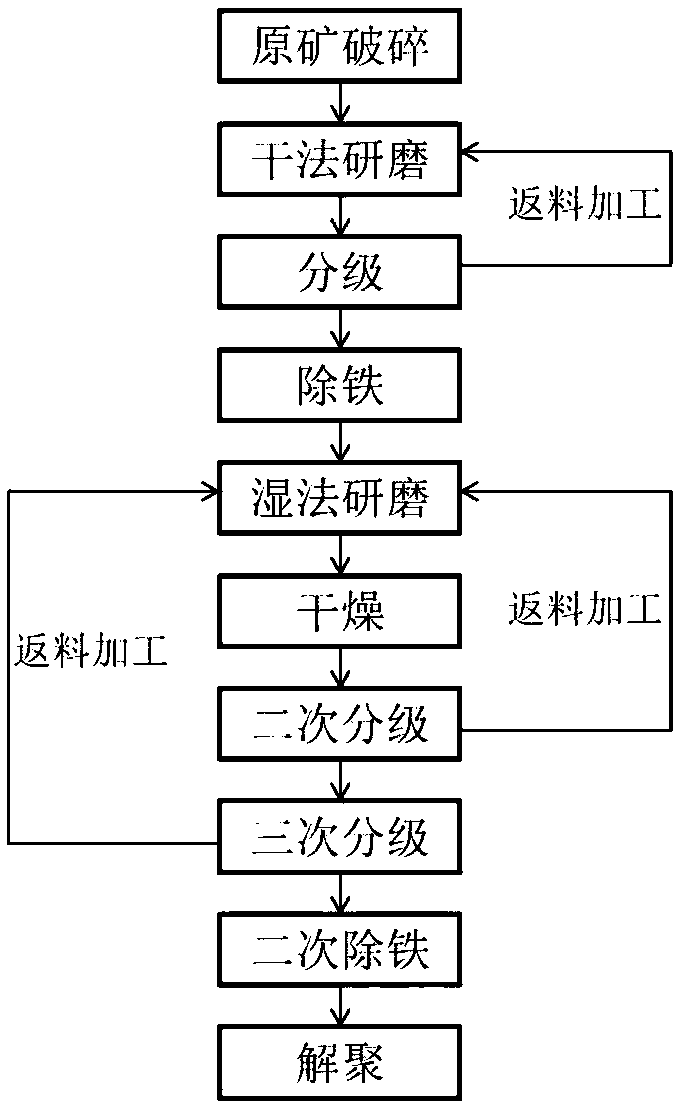

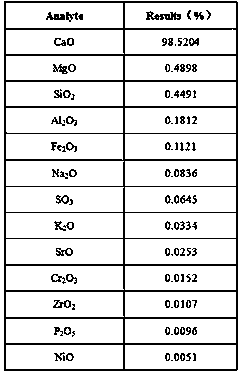

Ground calcium carbonate for rare earth separation and saponification and preparation method of ground calcium carbonate

InactiveCN108410213AEfficient separationGuaranteed high purityPigment physical treatmentDepolymerizationRare earth

The invention discloses ground calcium carbonate for rare earth separation and saponification and a preparation method of ground calcium carbonate. The ground calcium carbonate for rare earth separation and saponification is characterized in that the acid non-soluble substance content is smaller than or equal to 0.5%, the effective calcium content is larger than or equal to 98.5%, whiteness is larger than or equal to 95%, fineness range D97 is 2-20micron adjustable narrow particle size distribution, specific surface area is larger than or equal to 1.5m<2> / g, and an oil absorption value is smaller than or equal to 40mL / 100g. The parpearation method of the ground calcium carbonate includes raw ore crushing, dry grinding, grading, deironing, wet grinding, drying, secondary grading, tertiary grading, secondary deironing and depolymerization. The ground calcium carbonate for rare earth separation and saponification has advantages of high purity, low silicon, low ferro-aluminum, ultra-fineness, large specific surface area and narrow particle size distribution, the problem of exceeding of ammonia nitrogen ion and sodium ion contents in wastewater can be solved while occurrence of a thirdphase at an organic phase and aqueous phase interface is effectively inhibited, organic phase loss is reduced, production cost is saved, rare earth separation efficiency can be improved, and requirement of a novel rare earth extraction process can be well met.

Owner:SICHUAN SHIMIAN JUFENG POWDER

System for preparing gel bead

ActiveCN100371064CRelieve pressureReduce distortionNuclear energy generationGranulation by liquid drop formationEngineeringAmmonia

The invention relates to a system for preparing gel ball, belonging to the technique that preparing ceramic gel ball. Said system comprises two parts as vibration dispersion system and gel system. Wherein, the vibration dispersion system comprises a signal controller 1, a vibrator 2, and an ejector; the gel system comprises a ammonia distributing ring 4, a gel post 5, a liquid groove 9, a baffle post 16, and a ball storage pot 11. The liquid of gel via cycle pump 14 can be cycled between the gel post 5, the liquid groove 9, and the baffle post 16; the sol via the ammonia distributing ring 4 is gelled into gel ball in the gel post 5; and the gel ball will flow into liquid groove 9 with liquid. Said system can confirm full gelling on the sol ball and reduce the pressure between gel balls, to avoid the distribution of flowing medium liquid on the liquid level. And it has simple operation and the application for continuous operation.

Owner:TSINGHUA UNIV

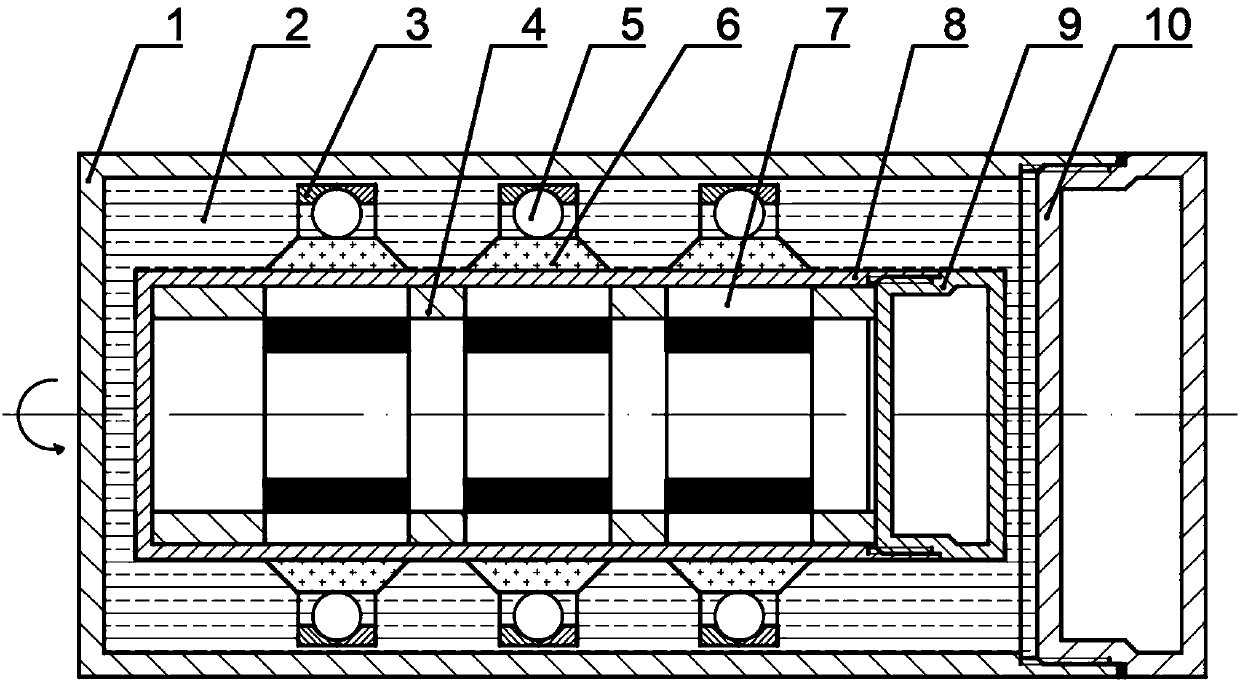

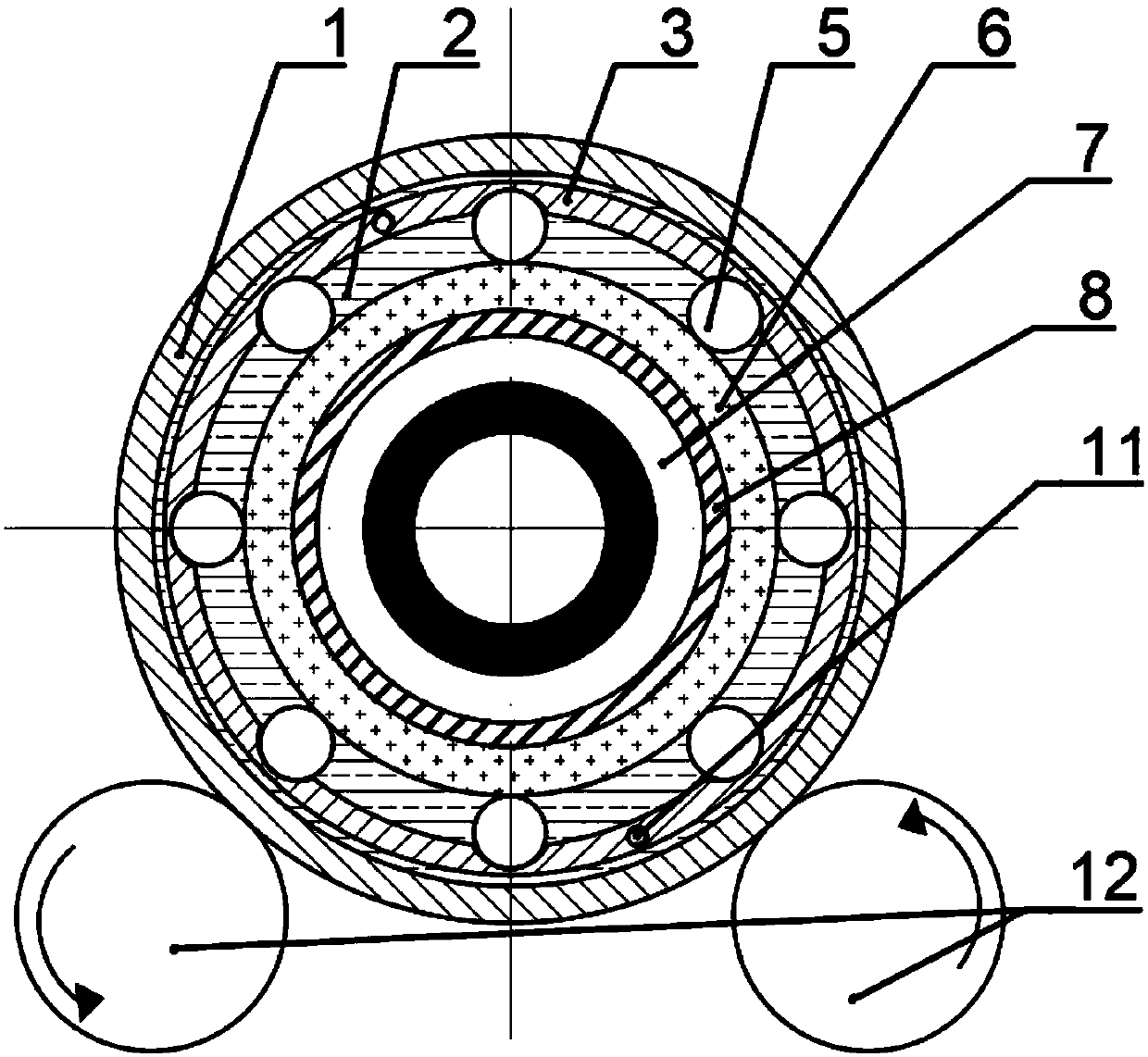

Rolling-bearing magneto-rheological polishing device for high-accuracy ceramic balls

ActiveCN107855834ASimple structureEasy clampingSpherical surface grinding machinesGrinding work supportsMagnetic currentMagneto rheological

The invention discloses a rolling-bearing magneto-rheological polishing device for high-accuracy ceramic balls. The rolling-bearing magneto-rheological polishing device comprises an inner-ring barrel(8), an outer-ring barrel (1) and a ceramic ball retainer (3) arranged between the inner-ring barrel and the outer-ring barrel (1), wherein a ceramic ball accommodating space (5) is formed in the ceramic ball retainer (3), a plurality of annular magnets (7) are arranged in the inner-ring barrel (8), location blocks (4) are arranged among the annular magnets (7), and the location blocks (4) are uniformly arranged in the inner-ring barrel (8); and the ceramic ball retainer (3) is connected with the inner-ring barrel (8) through a bolt, and concentrically arranged with the inner-ring barrel (8),and the space between the outer-ring barrel (1) and the inner-ring barrel (8) is filled with a magneto-rheological polishing liquid (2). In combination with magneto-rheological flexible polishing, thepolishing device disclosed by the invention is capable of efficiently obtaining high-quality smooth ceramic ball surfaces with both high dimension accuracy and shape accuracy.

Owner:GUANGDONG UNIV OF TECH

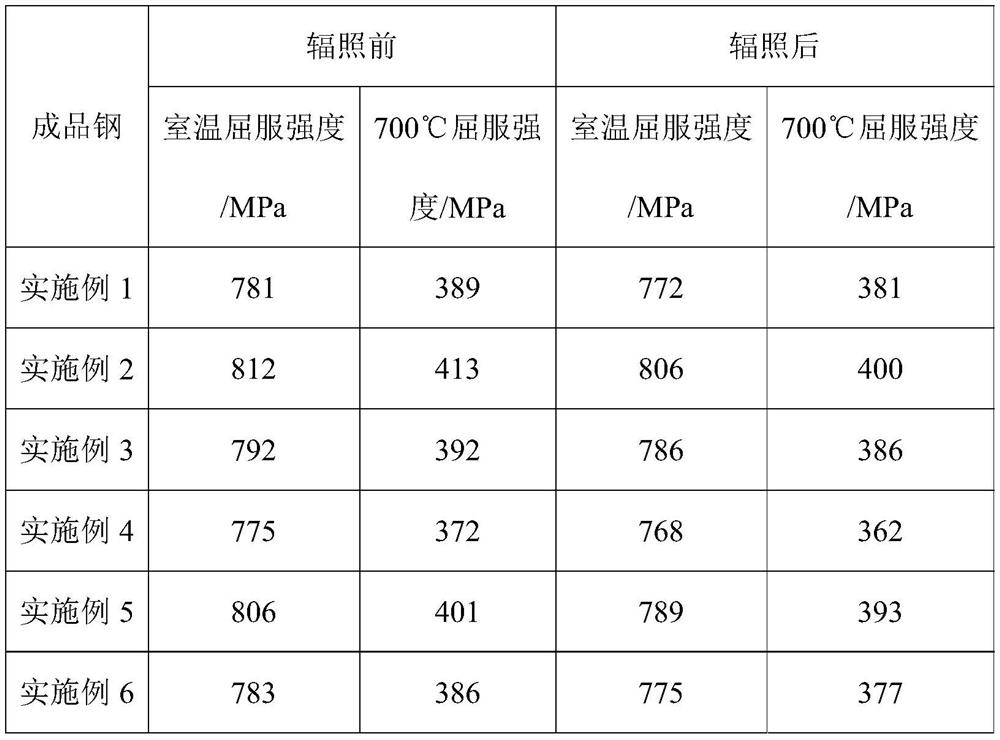

Nanoscale oxide reinforced low-activation steel composite material and preparation method thereof

ActiveCN113215470AImprove wettabilityEvenly distributedAdditive manufacturing apparatusSelective laser meltingUltimate tensile strength

The invention discloses a nanoscale oxide reinforced low-activation steel composite material and a preparation method thereof. The preparation method comprises the following steps that nanoscale Y2O3, nanoscale Al2O3 and nanoscale particles A are subjected to ball milling solid solution to obtain a solid solution A, and the nanoscale particles A are nanoscale TiO2 and / or nanoscale ZrO2; hollow erosion is carried out on the solid solution A by using a NaOH solution, and then washing and drying are carried out to obtain a solid solution B; the solid solution B and low-activation steel powder are subjected to ball milling and mixing, and a mixture C is obtained; the mixture C is formed by adopting a selective laser melting process to obtain a formed body; and stress relief annealing is carried out on the formed body. According to the nanoscale oxide reinforced low-activation steel composite material and the preparation method thereof provided by the invention, the complex rare earth oxide is firstly prepared, the structure of the complex rare earth oxide is adjusted to improve the wettability of the complex rare earth oxide and low-activation steel, the dosage and size of the complex rare earth oxide are optimized, the complex rare earth oxide is evenly distributed in a low-activation steel matrix through the laser melting technology, the strength of the low-activation steel is remarkably improved, and the preparation method has important significance for improving the safety of a fusion reactor.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

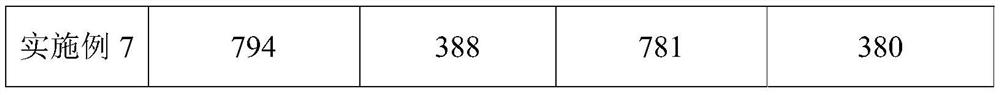

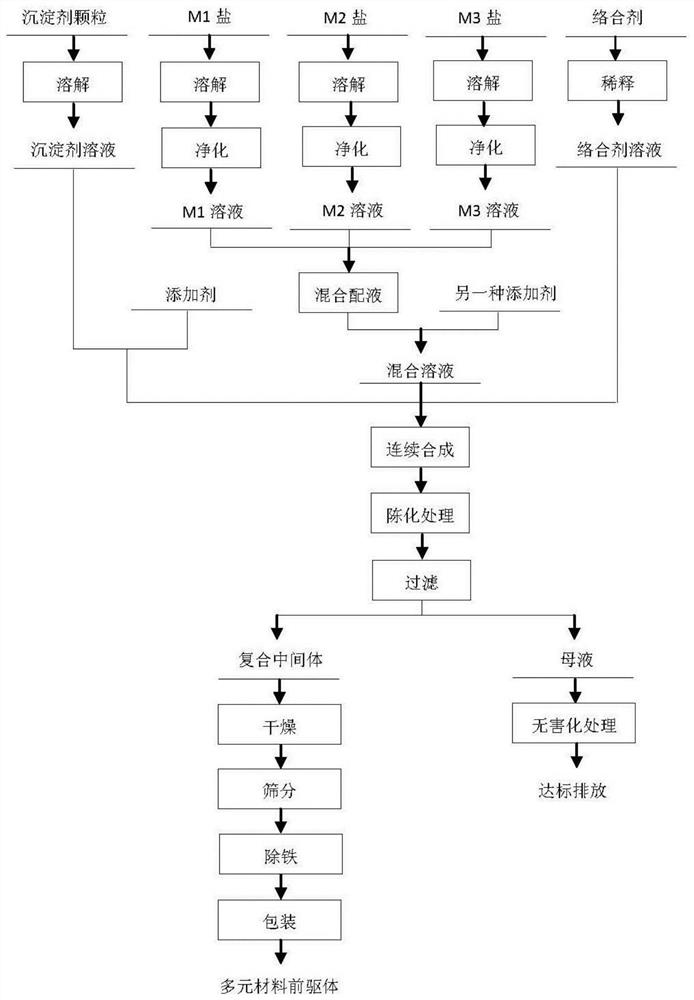

Synthesis of high-dispersion multi-element precursor

InactiveCN112357976AControl shapeBlock continuous growthCell electrodesSecondary cellsAqueous solutionAmmonia

The invention discloses a synthesis method of a high-dispersion multi-element precursor. The synthesis method comprises the following steps: a, preparing a mixed solution from metal salt and a negative additive or a positive additive by using deionized water; b, preparing a mixed solution from an alkaline precipitator and a negative additive or a positive additive by using deionized water, whereinthe additive used in the step is different from the additive used in the step A; c, adding the mixed solution obtained in the step A and the step B and an ammonia water solution into a reaction device for synthesis to obtain a reaction product; and d, sequentially filtering, washing and drying the reaction product. The method has the advantages that: 1) the purpose of controlling the reaction microenvironment is achieved through the action of two reverse additives, so that the morphology of primary particles and the size of secondary particles are effectively controlled; 2) the problem of poor sphericity of small-particle products is solved. 3) the particle morphology consistency of the blended product is improved. 4) the synthesized material is in narrow distribution, and the particle morphology consistency among different batches is high.

Owner:宜宾光原锂电材料有限公司

Refractory metal powder spheroidizing process

ActiveCN114192793AAvoid reunionGuaranteed decentralizationMaterial nanotechnologyTransportation and packagingPolyolHydrogen peroxide

The invention discloses a spheroidizing process for refractory metal powder, and relates to the technical field of metal processing. According to the method, hydrogen peroxide and polyhydric alcohol are used for pretreating the nanoscale refractory metal oxide, and then the pretreated refractory metal oxide is subjected to reduction and spheroidizing treatment through a plasma spheroidizing device, so that the nanoscale refractory metal spherical particles are obtained. According to the treatment process, refractory metal spherical particles with the diameter of 50-350 nm can be obtained, the sphericity degree is high, and the dispersity among the particles is high.

Owner:河北京东管业有限公司

A kind of preparation method of titanium-doped lithium iron phosphate cathode material

ActiveCN107611413BIncrease the kinetic energy of the reactionRapid responseCell electrodesSecondary cellsPhosphoric acidMaterials science

The invention discloses a preparation method of titanium-doped lithium iron phosphate positive electrode material. Lithium source compound, phosphorus source compound, iron source compound and metal titanium are used as raw materials, mixed uniformly, melted at high temperature in a furnace, and quenched in water. into granules, and then together with carbon source compounds, through grinding and dispersion, so that the particle size reaches the fineness index of D90≤0.2μm, and then spray-dried to make powder, and calcined in an atmosphere furnace at 600-800°C for 40-300 minutes, After cooling, the lithium iron phosphate positive electrode material is obtained; the uniformity of the lithium iron phosphate positive electrode material is improved by adopting a high-temperature melting method; metal titanium powder is introduced, and the Fe in the melt is melted at a high temperature. 3+ reduced to Fe 2+ , and make the generated Ti 4+ Doped into the lithium iron phosphate structure, the electronic conductivity of the lithium iron phosphate positive electrode material is improved by forming vacancies; the specific surface area is reduced by grinding, dispersing and carbon coating, and the tap density of the lithium iron phosphate positive electrode material is improved. Breaking and integrating not only maintains the original sphericity but also simplifies the process.

Owner:威远县大禾陶瓷原料有限公司

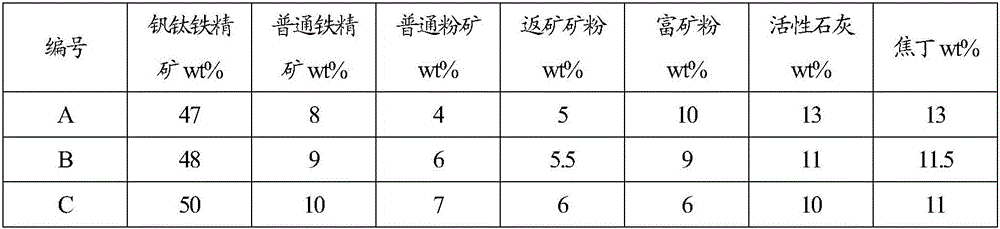

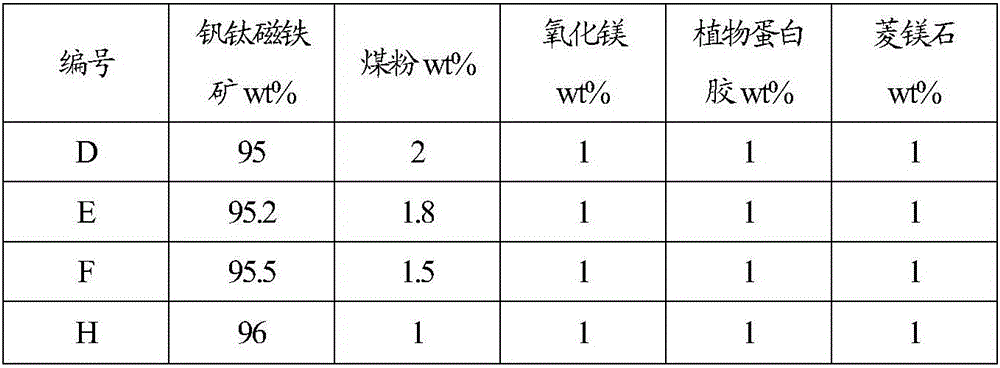

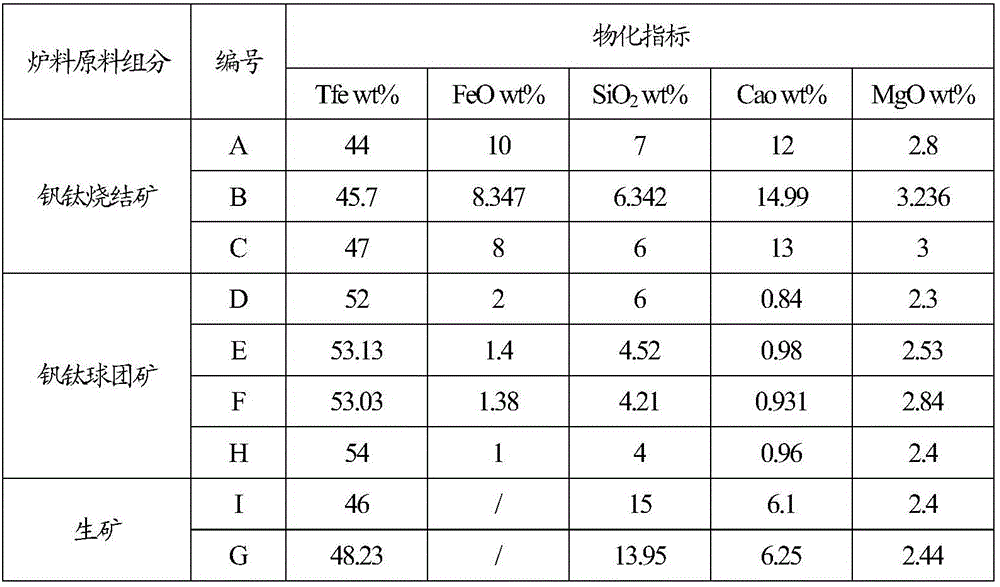

Vanadium-titanium magnetite blast furnace burden structure and blast furnace smelting method

The invention discloses a vanadium-titanium magnetite blast furnace burden structure. The furnace burden structure comprises mineral aggregates and coke nuts, and the mineral aggregates are composed of, by mass, 45-50% of vanadium-titanium sintered ore, 8-12% of vanadium-titanium sintered ore nuts, 34-40% of vanadium-titanium pellets, and 5-10 % of raw ore. The use ratio of vanadium-titanium magnetite is increased by optimizing the furnace burden structure, the vanadium-titanium magnetite resources are sufficiently utilized, and cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

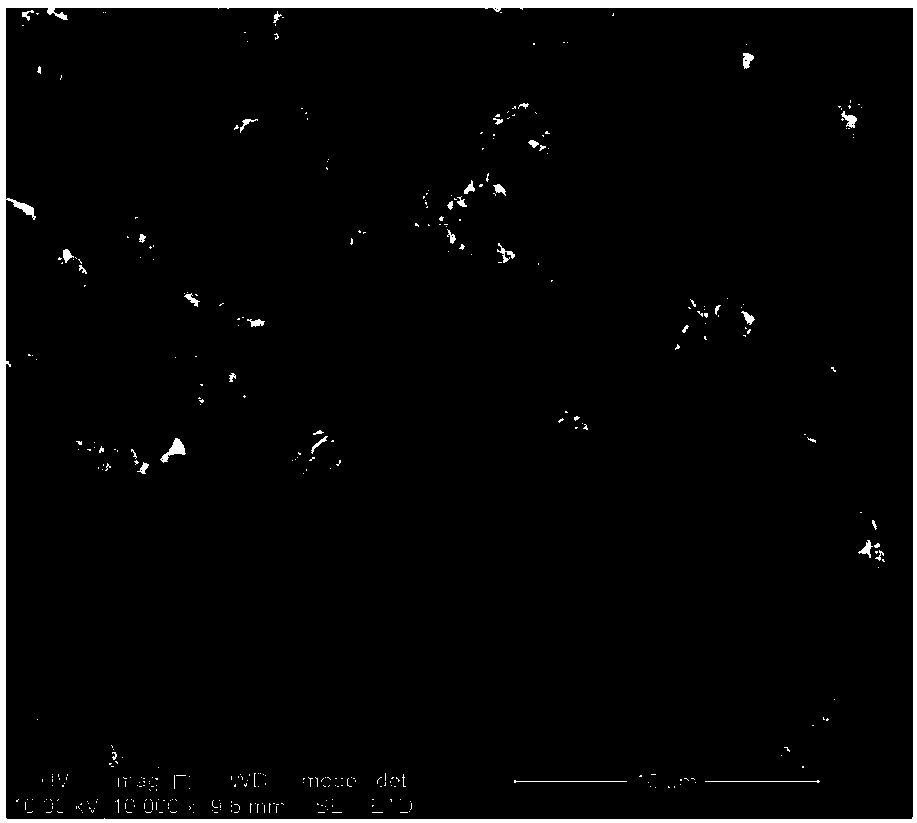

Copper-based composite powder of iron-based amorphous reinforced copper-based alloy formed by selective laser melting

ActiveCN112643022APrevent oxidationGuaranteed sphericityAdditive manufacturing apparatusThermal conductivityCopper matrix

The invention discloses copper-based composite powder of iron-based amorphous reinforced copper-based alloy formed by selective laser melting. The copper-based composite powder is characterized in that the iron-based amorphous reinforced copper-based alloy is prepared by using the copper-based composite powder with the particle size of 40-50 mu m as a forming material and adopting a selective laser melting method, wherein the copper-based composite powder is mainly composed of iron-based amorphous powder and copper alloy powder according to the mass ratio of 1: 9-1: 7. The copper-based composite powder has the advantages that in the selective laser melting forming process of the copper-based composite powder, liquid phase separation occurs, spherical amorphous iron particles are formed through self-assembly, and the amorphous iron particles are dispersed and distributed in a copper-rich matrix; and the iron-based amorphous reinforced copper-based alloy has excellent comprehensive properties such as high strength, high corrosion resistance, high wear resistance and high thermal conductivity.

Owner:JINAN UNIVERSITY

Preparation technology of spherical chromium oxide composite agglomerated powder, and product prepared by preparation process

ActiveCN111662578AImprove dispersion uniformityImprove uniformityCoatingsChromium oxides/hydratesSpray GranulationChemical composition

The invention discloses a preparation technology of spherical chromium oxide composite agglomerated powder, and a product prepared by the preparation process, and belongs to the technical field of composite powder materials. The preparation technology comprises the following steps: dissolving chromium nitrate in deionized water, adding SiO2 nano-powder and TiO2 nano-powder, dropwise adding ammoniawater to adjust the pH value of the solution to prepare a coated precursor with SiO2 nano-powder and TiO2 nano-powder as cores, filtering, and drying to obtain a solid product; and preparing the solid product into slurry by using deionized water, preparing spherical agglomerated powder by combining spray granulation with an atmosphere protection sintering process, and then carrying out particle size grading on the spherical agglomerated powder to prepare spherical chromium oxide composite agglomerated powder. The chromium oxide composite agglomerated powder with uniform chemical components and good sphericity, compactness, fluidity and the like can be prepared by adopting the preparation technology.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Method for baking industrial iron base catalyzer through Fischer-Tropsch synthesis from plasma phase

ActiveCN1260006CReduced wear indexGuaranteed sphericityHydrocarbon from carbon oxidesCatalyst activation/preparationResidenceSynthesis methods

A slurry phase Fischer-Tropsch synthesis industrial iron-based catalyst roasting method is to combine the continuous co-precipitation and spray drying method to prepare the industrial large-particle spherical iron-based catalyst with a thickness of 20-100 mm, which is tiled on the swirling airflow belt drying method. On the material conveyor belt of the dryer, adjust the inlet temperature of the heating section of the dryer to 200-300°C, and stay for 5-10 hours; After 4 to 8 hours, a catalyst that has been roasted and can be directly used for industrial slurry phase Fischer-Tropsch synthesis without sieving is obtained. The attrition index of the catalyst after calcination of the present invention is less than 0.5%. The invention has the advantages of continuous drying of large batches of materials, easy operation, less failure and less equipment investment.

Owner:SYNFUELS CHINA TECH CO LTD

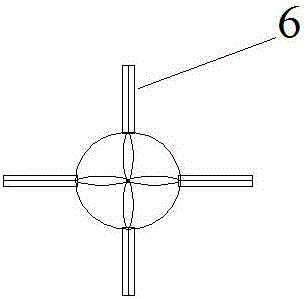

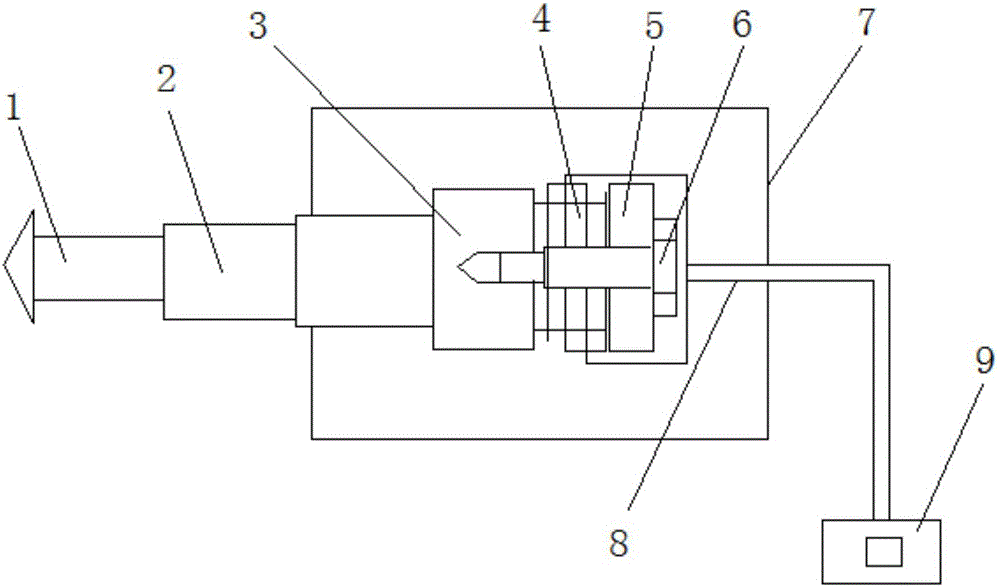

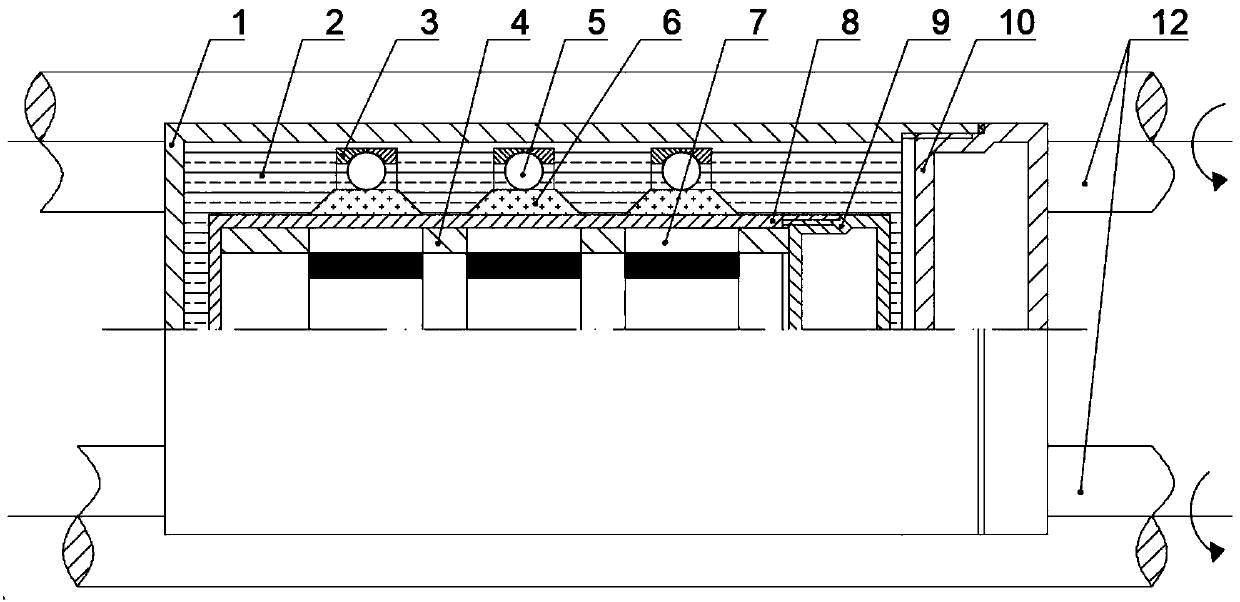

Liquid drop collision generation device

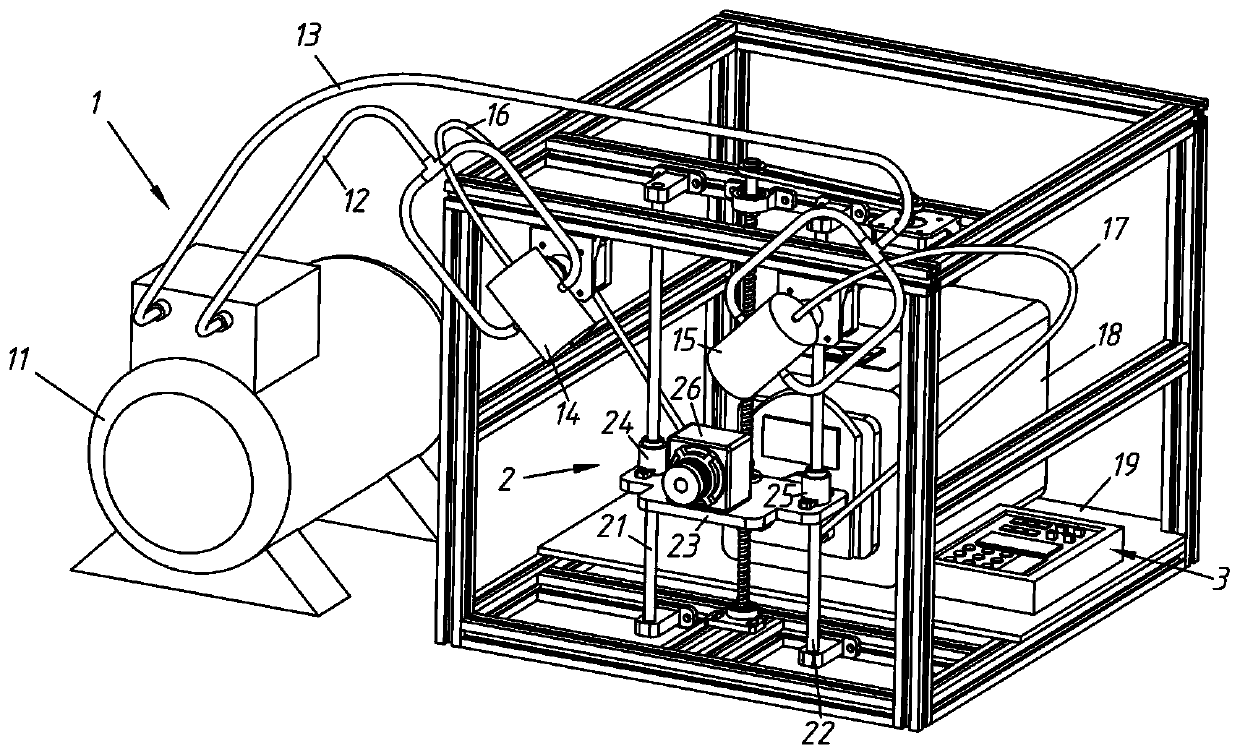

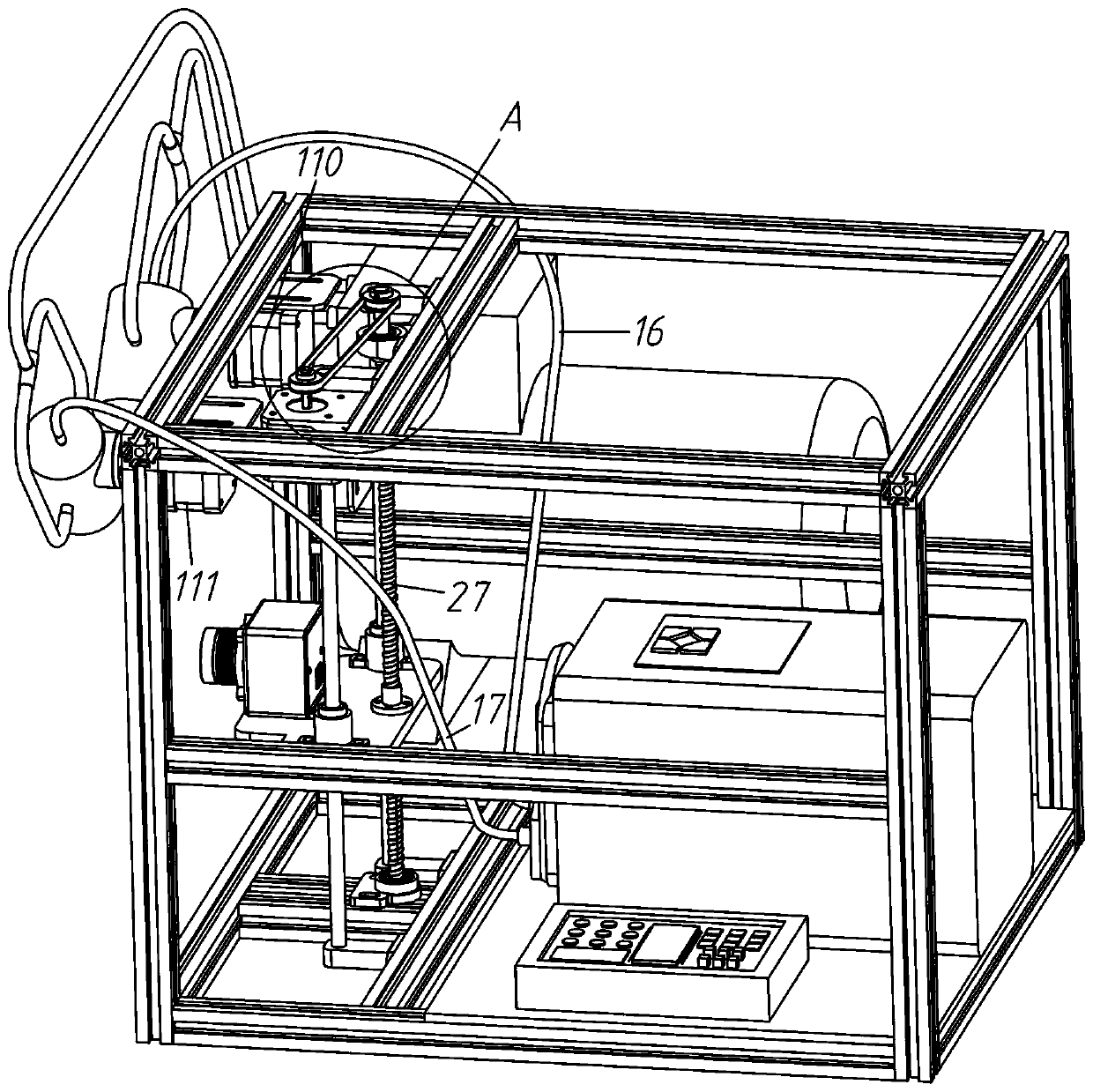

PendingCN110201812AReal-time control of collision angleGuaranteed sphericityLiquid spraying apparatusPeristaltic pumpMicrocontroller

The invention discloses a liquid drop collision generation device. The liquid drop collision generation device is mainly divided into a liquid drop generation module, a shooting module and a single chip; a flow type peristaltic pump is a liquid supply device of a first liquid drop generator and a second liquid drop generator and can control the grain size of the generated liquid drop; a gas pump is a gas supply device of the first liquid drop generator and the second liquid drop generator and can give the initial speed of the liquid drop; the single chip is connected with a first stepped motorand a second stepped motor and can control the collision angle of the first liquid drop generator and the second liquid drop generator; a high-speed video camera is fixed on an objective table; the objective table is connected with a first sliding guide rail and a second sliding guide rail through a first linear bearing and a second linear bearing; and the single chip is connected with a third stepped motor and controls the up-and-down motion of the video camera to shoot the collision process of the liquid drops. The liquid drop collision generation device can accurately control the grain size and the speed of the liquid drops, can control the collision angle of the liquid drops in real time, and is simple and easy to operate.

Owner:CHINA JILIANG UNIV

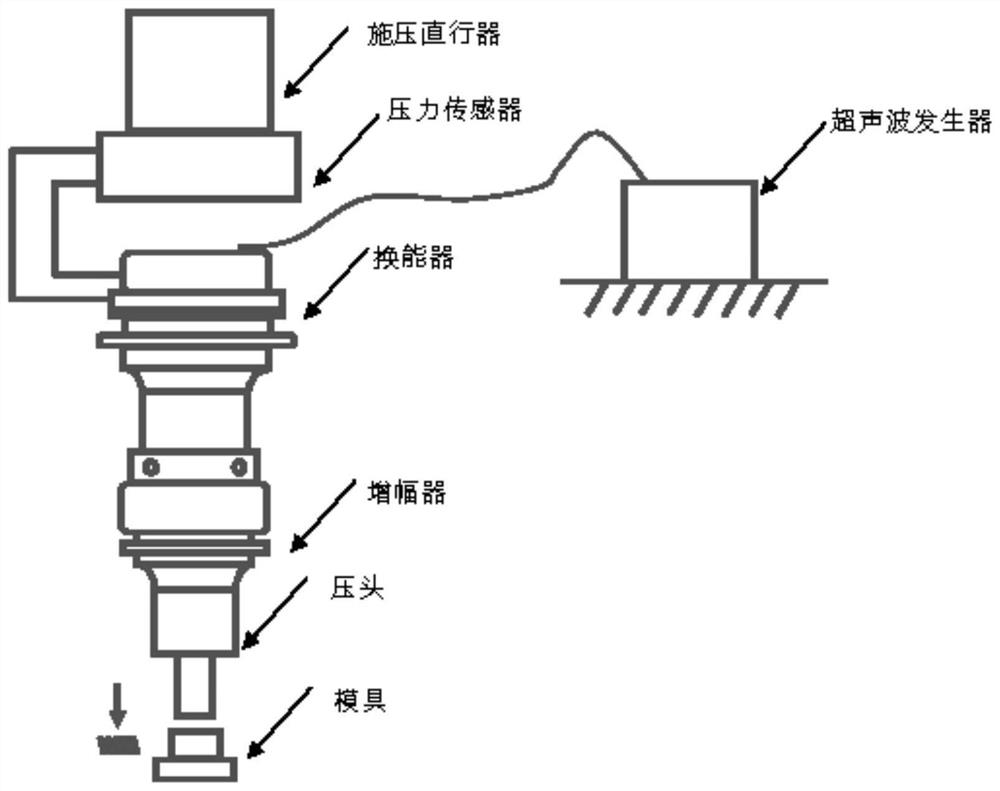

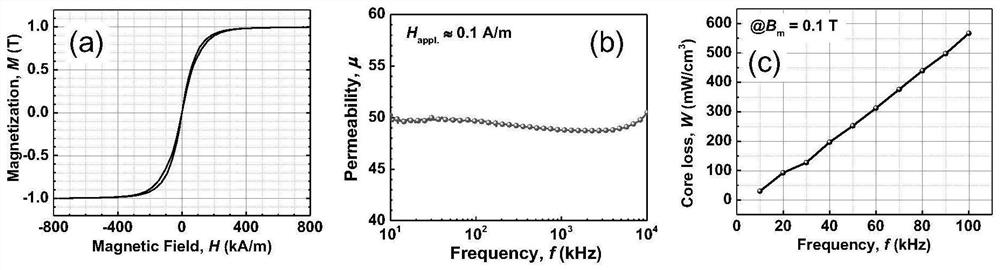

Ultrasonic-enhanced magnetic powder core compression molding method and compressed powder magnetic core

PendingCN113871179APromote sportsFacilitate rearrangementInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingInitial permeability

The invention discloses an ultrasonic-enhanced magnetic powder core compression molding method and a compressed powder magnetic core. The invention discloses an ultrasonic enhanced magnetic powder core compression molding method which comprises the following steps: placing soft magnetic powder (coated) in ultrasonic compression molding equipment, setting the ultrasonic frequency to be 15-60kHz and the vibration amplitude to be 70-90%, and simultaneously starting a pneumatic system to pressurize, wherein the pressure is 0.3-0.9 MPa, the compression time is 0.1-10s and the dwell time is 3-5s, and completing the compression molding of a magnetic powder core. The method / process has the advantages of being small in required pressure, short in completion time, high in powder forming density, simple and efficient. The invention further discloses the magnetic powder core prepared by the ultrasonic enhanced magnetic powder core compression molding method, the magnetic powder core has high saturation flux density, low iron loss and high initial magnetic conductivity, and the magnetic conductivity of the magnetic powder core shows good high-frequency stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Ytterbium/gadolinium/yttrium ternary co-doped zirconium oxide nanostructure agglomerated sphere and production method thereof

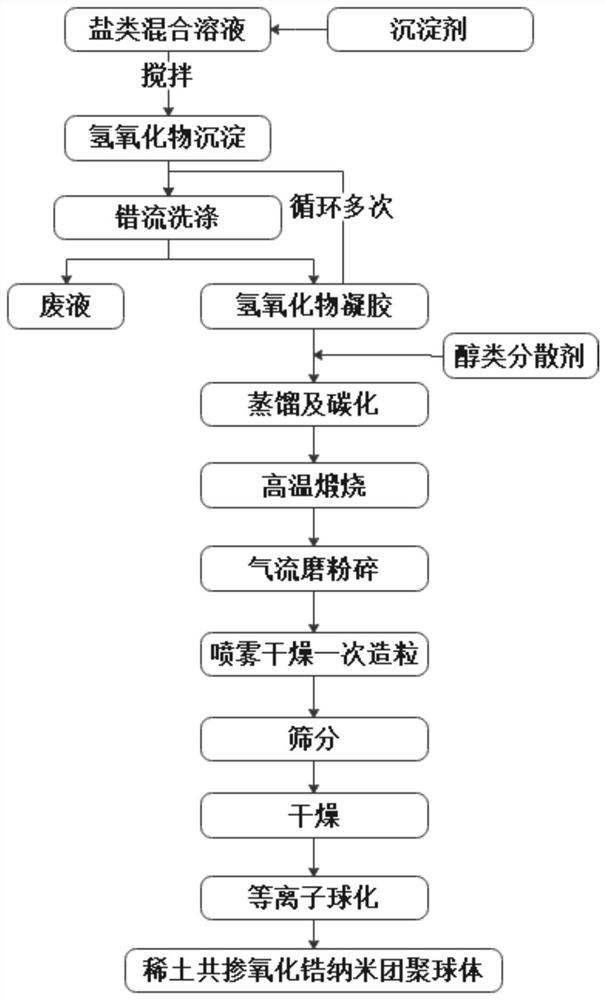

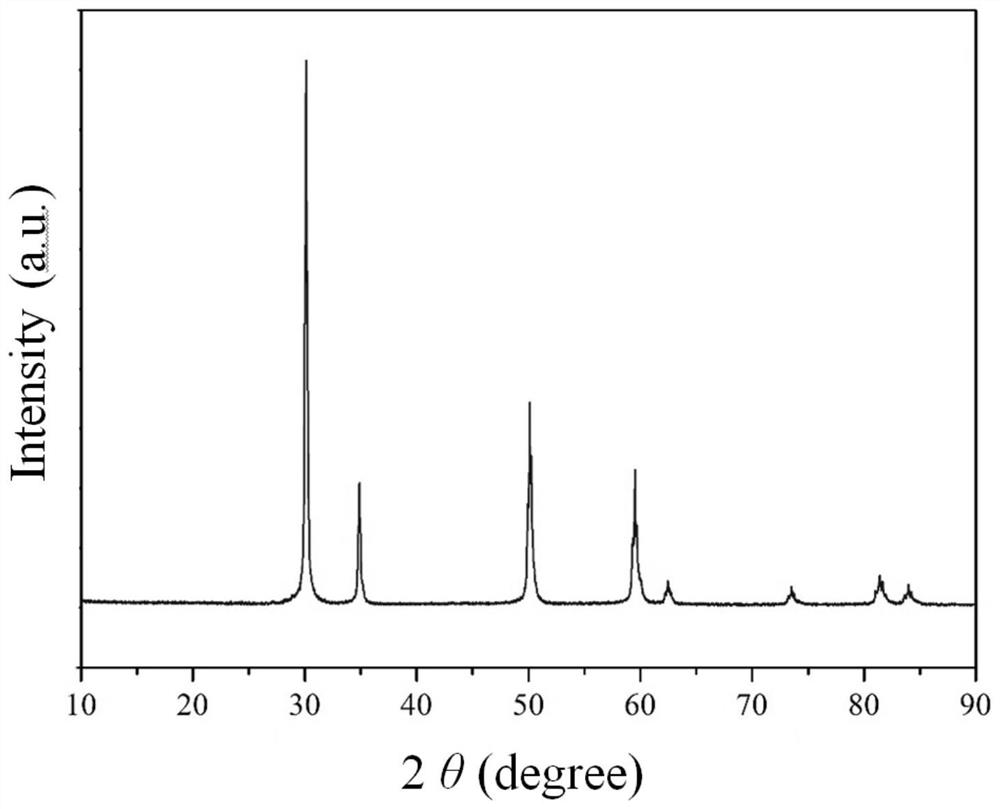

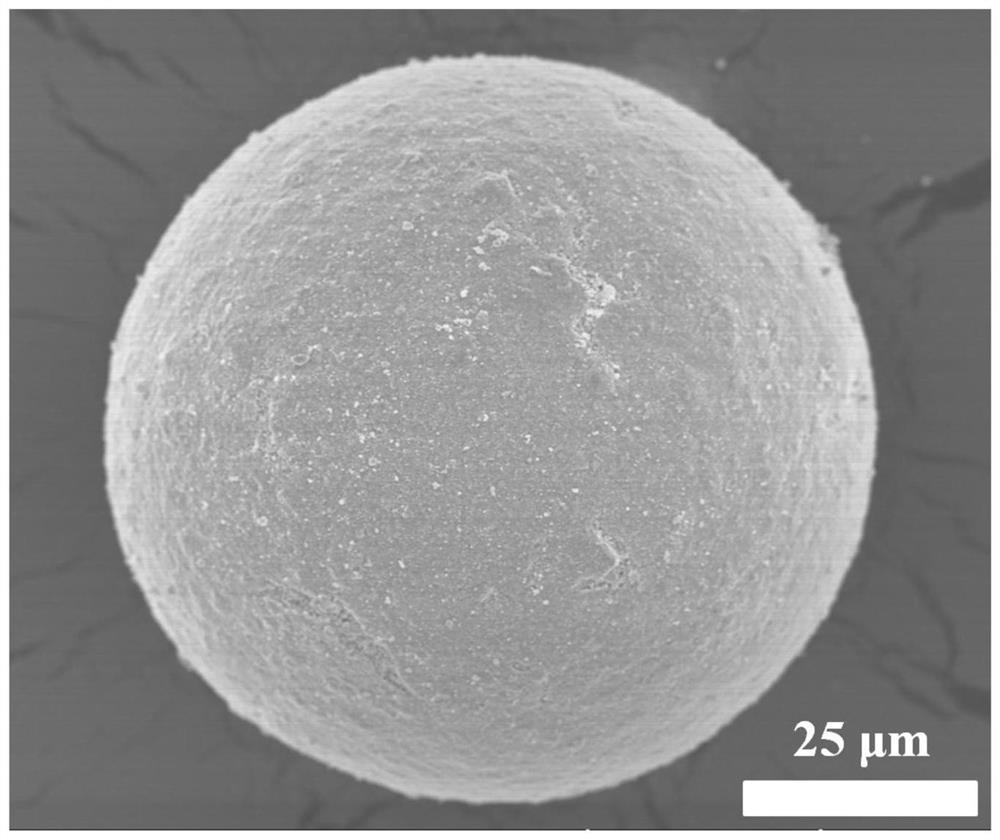

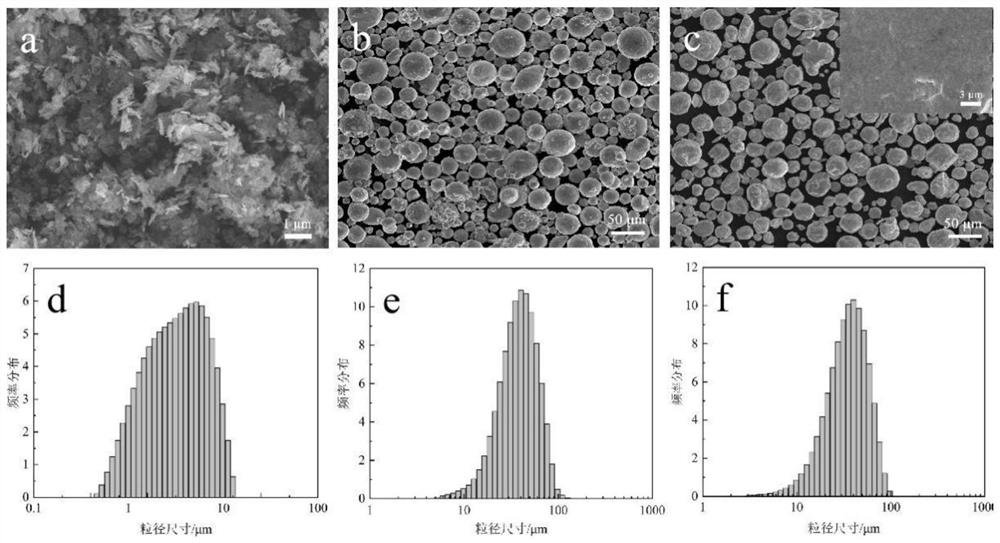

The invention discloses an ytterbium / gadolinium / yttrium ternary co-doped zirconium oxide nanostructure agglomerated sphere and a production method thereof. The preparation method comprises the following steps: uniformly stirring ytterbium salt, gadolinium salt, yttrium salt and zirconium oxychloride to obtain a mixed solution; gradually adding a precipitator into the mixed solution, and conducting standing and aging to obtain hydroxide colloid; performing cross flow washing; carrying out azeotropic distillation: conducting mixing with a dispersing agent, and carrying out distillation and carbonization treatment to obtain powder; performing high-temperature calcination to obtain tetragonal-phase nano powder; carrying out jet milling treatment on the tetragonal-phase nano powder; using the colloid to prepare micron-sized agglomerated spheres by adopting a spray drying technology; performing screening; removing moisture in the balls; and carrying out plasma secondary spheroidizing to obtain the sphere with the size range meeting the requirement. According to the preparation method, the powder with relatively good dispersity is obtained by combining a coprecipitation method with membrane separation, azeotropic distillation and jet milling crushing technologies, and the nano powder is made into nano-structure agglomerated balls, so that a foundation is laid for preparation of a high-performance nano ceramic thermal barrier coating.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

In situ self-generated nano al 2 o 3 Laser additive manufacturing method for reinforced aluminum matrix composites

ActiveCN112176213BAchieve alloyingImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyMg compositeHigh density

The invention discloses an in-situ self-generated nano-Al 2 o 3 A laser additive manufacturing method for strengthening an aluminum-based composite material, the method comprising the following steps: (1) mixing ZnO ceramic powder and AlSi10Mg aluminum alloy powder and ball milling to obtain a ZnO / AlSi10Mg composite powder; (2) preparing the composite powder The laser selective melting process is used for additive manufacturing forming to form a solid sheet; (3) The laser re-scans the solid sheet to form a remelted sheet; (4) Repeat steps (2) and (3) to finally form the original self-generated nano-Al 2 o 3 Reinforced aluminum matrix composites. In the present invention, laser is used to excite Al and ZnO to generate aluminum thermal reaction between them in situ. 2 o 3 Ceramic particles, and by improving the overall flow process design of the method, combining laser selective melting and laser remelting scanning, the aluminum matrix composite material obtained has high density, fine microstructure, and in-situ self-generated Al 2 o 3 The particle size is nanoscale, uniformly distributed, and its phase interface is well combined with the aluminum matrix.

Owner:HUAZHONG UNIV OF SCI & TECH +1

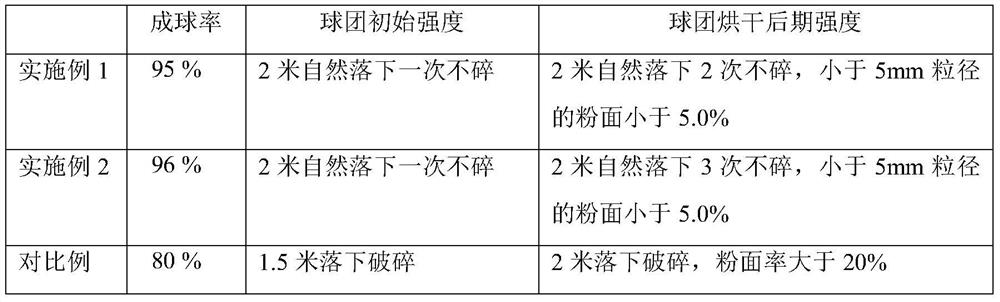

Special binder for corundum slag pellets and its preparation and use method

The invention belongs to the technical field of comprehensive utilization and processing of secondary resources, and relates to a special binder for corundum slag pellets and a preparation and use method thereof. The technical problem to be solved by the present invention is to provide a special binder for corundum slag pellets that can improve the pelletizing rate and strength of the pellets. The special binder is prepared from the following raw materials in weight ratio: 65-70% of plant starch, 4-5% of high molecular polyanion cellulose, 16-18% of plant dextrin and 10-12% of curing agent. The special binder for corundum slag pellets of the present invention has high viscosity, which can improve the viscosity of corundum slag materials, ensure the ball forming performance, initial strength and later drying strength, the ball forming rate can reach more than 95%, and the initial strength can reach 2 meters high. Drop once without breaking, and later drying strength reaches 2 meters high, drop 3 times naturally without breaking. The use of the binder of the invention significantly improves product quality, reduces the cost of the binder by 50 yuan / ton, and has broad application prospects.

Owner:PANZHIHUA GANGCHENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com