High speed centrifugal atomization device used for metal centrifugal atomization powder preparation

A centrifugal atomization and high-speed centrifugation technology, applied in the field of metal centrifugal atomization pulverizing devices, can solve the problems of short service life and low rotation speed of the centrifugal device, and achieve the effects of reducing production costs, reducing differences, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

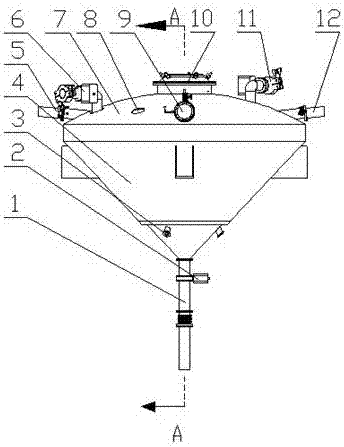

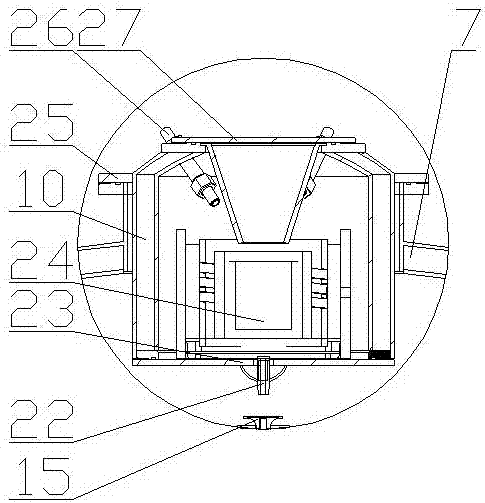

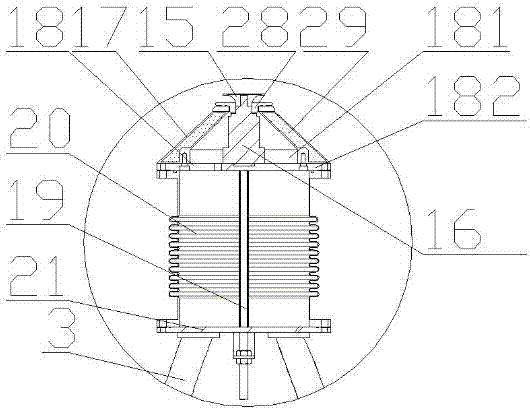

[0038] refer to Figure 1~5 : A high-speed centrifugal atomization device for metal centrifugal atomization powder making in this embodiment, comprising an atomization tank body, a rotating disk 15 and a gas-driven rotating shaft 16; the top center of the atomization tank body is provided with a metal smelting leak bag , the lower end of the side wall is provided with a gas delivery pipe 3 for delivering driving gas to the gas-driven rotating shaft 16, and the bottom is provided with a powder outlet pipe 1; the gas delivery pipe 3 is connected with a high-pressure gas source; the rotating disk 15 is located in the metal smelting Directly below the leak bag, the rotating disk 15 is connected to the top of the gas-driven rotating shaft 16, and is driven by the gas-driven rotating shaft 16 to rotate at a high speed; the maximum rotation of the gas-driven rotating shaft 16 is 80000r / min.

[0039] The air-driven rotating shaft 16 is an air main shaft, and the air main shaft uses co...

Embodiment 2

[0053] refer to Figure 6 , compared with Example 1, a kind of high-speed centrifugal atomization device for metal centrifugal atomization pulverization of the present embodiment has the following differences:

[0054] The high-speed centrifugal atomization device also includes a powder filter 30 in the shape of a truncated cone, and the powder filter 30 is fixed at the middle and lower end of the atomization tank through the gas delivery pipe 3 .

[0055] The working principle and usage method of a high-speed centrifugal atomization device for metal centrifugal atomization powder making in the present invention are as follows: the high-speed centrifugal atomization device melts metal raw materials into a solution through metal smelting leakage; The inert gas is sprayed inside the tank, and the gas blown out from the gas filling port 11 can cool the metal powder after centrifugal atomization, and is also conducive to the efficient dispersion of the metal powder on the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com