Tin-powder ultrasonic atomization device and atomization process thereof

A technology of atomizing tin powder and ultrasonic wave, which is applied in the field of ultrasonic atomizing tin powder device and its atomization process, can solve the problems of secondary damage, oxide layer damage, oxygen content fluctuation, etc., and achieve high product precision and guarantee uniformity , the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

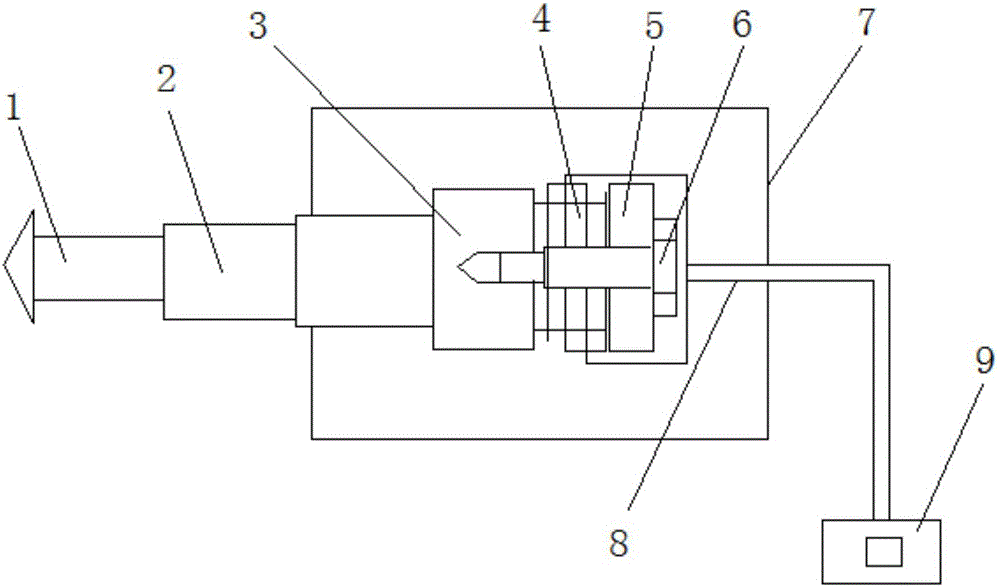

[0030] An ultrasonic atomization tin powder device, including a tool head 1, a horn 2 is provided on one side of the tool head 1, a cooling device 7 is provided on one side of the horn 2, and a cooling device 7 is located in the cooling device 7 One end of the rod 2 is provided with a transducer front cover 3, and one side of the transducer front cover 3 is provided with a transducer rear cover 5, and a press is provided between the transducer front cover 3 and the transducer rear cover 5. Electroceramic stack 4 , one side of the cooling device 7 is provided with an electrode lead 8 electrically connected to the piezoelectric ceramic stack 4 , and a signal generator 9 is provided at one end of the electrode lead 8 . One side of the transducer back cover 5 is provided with a prestressed bolt 6 threadedly connected to the transducer back cover 3 . The cross-sectional area of the transducer front cover 3 and the transducer rear cover 5 is the same.

[0031] The present inventi...

Embodiment 2

[0040] An ultrasonic atomization tin powder device, including a tool head 1, a horn 2 is provided on one side of the tool head 1, a cooling device 7 is provided on one side of the horn 2, and a cooling device 7 is located in the cooling device 7 One end of the rod 2 is provided with a transducer front cover 3, and one side of the transducer front cover 3 is provided with a transducer front cover 5, and a press is provided between the transducer front cover 3 and the transducer rear cover 5. Electroceramic stack 4 , one side of the cooling device 7 is provided with an electrode lead 8 electrically connected to the piezoelectric ceramic stack 4 , and a signal generator 9 is provided at one end of the electrode lead 8 . One side of the transducer back cover 5 is provided with a prestressed bolt 6 threadedly connected to the transducer back cover 3 . The cross-sectional area of the transducer front cover 3 and the transducer rear cover 5 is the same.

[0041] The present invent...

Embodiment 3

[0050] An ultrasonic atomization tin powder device, including a tool head 1, a horn 2 is provided on one side of the tool head 1, a cooling device 7 is provided on one side of the horn 2, and a cooling device 7 is located in the cooling device 7 One end of the rod 2 is provided with a transducer front cover 3, and one side of the transducer front cover 3 is provided with a transducer rear cover 5, and a press is provided between the transducer front cover 3 and the transducer rear cover 5. Electroceramic stack 4 , one side of the cooling device 7 is provided with an electrode lead 8 electrically connected to the piezoelectric ceramic stack 4 , and a signal generator 9 is provided at one end of the electrode lead 8 . One side of the transducer back cover 5 is provided with a prestressed bolt 6 threadedly connected to the transducer back cover 3 . The cross-sectional area of the transducer front cover 3 and the transducer rear cover 5 is the same.

[0051] The present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com